Professional Documents

Culture Documents

Alternator Rebuild On A 2007 Honda Accord 4CYL

Uploaded by

JohnC_NHOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alternator Rebuild On A 2007 Honda Accord 4CYL

Uploaded by

JohnC_NHCopyright:

Available Formats

RebuildingtheAlternatorfora2007HondaAccord4CYL Disclaimer: I have benefited greatly from others who have taken the time to post auto repair

r videos/tutorialsonline.Totryandreturnthefavor,Ihavedocumentedafewofmyrecentrepairs.Itryto perform the work conscientiously in accordance with the Honda service manual, but I am not a professional technician by any stretch so please use this material at your own risk. I do hope this informationmightbenefitotherswhoarepreparingtodothisjob. Honda20074CYLAlternator(Denso)

This alternator does not have any semiconductor components in it (no voltage regulator and not even any rectifier diodes). The only parts that are subject to wear are the brushes and the front and rear sealed bearings (I suppose eventually the slip rings on the rotor could wear out but this probably isnt very likely). The OEM brushes and bearings are available for purchase online. On my vehicle with ~240k miles, the brushes had worn down to approximately 1/3 of their original length. If you only need to replace the brushes, that is a very easy job. If you need to replace the front bearing, that is also quite straightforward. However, if the rear bearing is bad, the job is significantly more difficult because removingtherearbearingisachallenge.InthiswriteupIshowthetechniqueIusedtoreplaceallthree.

#1Removethepulleylocknutusingastrapwrenchandbreakerbaroranimpactwrench.(Ifyouare onlyreplacingthebrushesthenthisstepisnotnecessary).Itisastandardthread(CCWtoloosen).

#2Removethe4nutsholdingtheendcoverinplace.Therearetwonutsonthewiresupportbracket (onetoholdthebracketandanotherunderneathtoholdthecover).

WireSupport Bracket

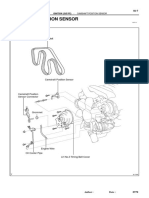

#3Removethetwoscrewsholdingthebrushholderassemblyinplace.

BrushHolder Assembly

#4RemovetheBrushHolderAssembly.

Brush Holder Assembly

SlipRings

#5Removethefourboltsholdingthealternatorcasingtogether.(Ifyouareonlyreplacingthebrushes thenthisstepisnotnecessary)

#6Useaplastichammertodriveoffthefrontcoverofthealternatorbyhammeringalternatelyon eachside.

#7Andpulloffthefrontcover.

#8Ifthefrontbearingneedstobereplaced,removethefourscrewsonthebearingretainer.

#9Toexposethefrontbearing:

Front Bearing

#10Todriveoutthefrontbearingyouwillneedareceivertosupportthefrontcover.Iusedapipe lengthfromaballjointremoverkit.

New Front Bearing

Receiver Cup

#11Andyouwillneedsomethingtoforcethebearingoutwith.Iusedasocketwhichfitinsidethehole inthefrontcovertopressdownonthebearingasshownbelow.

#12Idroveoutthebearingwitha20tonpress.However,itcameoutveryeasilyandIbelieveyou couldalsodriveoutthebearingwithahammerinstead.

#13Hereiswhatitlookslikewiththefrontbearingremoved.Icleanedupthebearingseatwitha scotchbritepadinpreparationforinstallingthenewfrontbearing.

#14Toinstallthenewbearingyouwillneedsomethingthathasthesamediameterasthebearing becausewhenyoupressthenewbearingin,youwillwanttoonlypushontheouterracesoasnotto damagethebearing.Iusedalargesocketasshownbelow.

Socket

Bearing

#15Andpressthenewbearingintoplace.Again,thispressedinquiteeasilyandIsuspectthata hammerwouldaccomplishthejobjustfineaswell.

#16Withthenewfrontbearinginstalled,replacethebearingretainerandfastenitinwithitsfour screws.

Bearing Retainer

#17IF Fyouneedtoreplacetherear r bearing,thenyouwilll havetoremo ovetherotor r.Youneedto obe verycarefultonotda amagetheslip pringsorthe eirplastichold der!Donoth hammerorpr ressontheen ndof therotor rshaftdirectl ly.Instead,use u apointedpunch p topus honlyonthe edimpleinthe eendofthes shaft (redarro ow)whichwi illallowyouto t putpressur redirectlyon therotorsha aftandnotth heplasticslipring assembly. a

#18Iusedapunchandhydraulicpresstopushouttherotor.ItcameoutquiteeasilyandIsuspecta hammerwouldhaveworkedfinetoaccomplishthetask.(Iknowitlooksalittleprecarious!Fortunately notmuchpressurewasneeded!).Besuretocatchtherotorasitdropsoutofthebottom!Ifitlandson theflooritwilllikelybedamaged!

#19Bytheway,whenpressingouttherotor,supportthehousingofthealternatorasshownbythered arrows(donotsupportitbythefieldcoilswhichcouldgetdamaged).

FieldCoils

#20Therearbearingcameoutattachedtotherotor.Noticethatthereisaspacerwasherbetweenthe bearingandtherearhousing.Itisallbendy(dontworry,youdidntmashitup,itissupposedtobethis way!).

Rear Bearing Spacer Washer

#21Useascrewdrivertoremovetheflangewasherbyevenlypryingallaroundit.

#22Nowherestherealkicker!Howdoyougetthatrearbearingofftherotorshaft?Theproblemis thattheflangefromtherotorcomesoutbeyondtheendofthebearingandtheremaininggapistoo smalltogetmostpullersinto.

Flange Rear Bearing

Rotor Shaft

#23Icouldntfigureoutacleverwaytodothis(Idlovetohearifyouhaveanyothertechniques!),soI endedupusingablindbearingpuller.Ibeganbyremovingthebearingsealusingapick.

#24Theblindbearingpullerhasaroundedendwithtwoshavedoffsides.Itisinsertedintothe bearingandthenrotated90degrees.Oncerotateditislockedinplacebetweentheinnerandouter bearingracesanditcanbeusedtoextractthebearing.

#25Thebearingcanthenbepulledoffbytighteningthepullerboltsshownbytheredarrows(and occasionallylengtheningthestationaryarmstogetmorereach).

#26Andhereiswhatitlookslikewiththerearbearingremovedfromtheshaft.

#27Topressthenewrearbearingontotherotorshaft,findasocketthatfitsonlyontheinnerraceof thebearingasshownbelow.Makesuretheinsideofthesocketislargeenoughthatitfitsfreelyoverthe rotorshaft(andsliprings).

#28Andpressthenewbearingontotherotorshaft.

Socket Bearing

Rotor

#29Dontforgettoreinstalltheflangewasher!

#30Cleanouttherearbearingseatwithsomescotchbriteandinsertthebendyspacerwasherinto thebearingseatbeforeinstallingtherotor.

Bendy Spacer Washer

#31Inserttherotorintotherearalternatorcasing(handpressurewasallIneeded).

#32Reinstallthealternatorfrontcover.

#33Insertthefourboltsthatholdthealternatorcasingtogetherandtightenthemdownalternating betweenthemsothatthecoveristighteneddownuniformly.

#34Ifyouarereinstallingtheoriginalbrushes,pressdownonthespringloadedbrusheswithyour fingerwhileinsertinganunfoldedpapercliporwirethroughtheholeinthebackofthebrushholder assembly.Thiswillkeepthebrushesretractedandallowyoutoputthebrushassemblybackinplace (onceinplacethepaperclipwillbepulledouttoallowthebrushestopushoutandcontactthesliprings ontherotor).

1.Push brushes down withyour finger 3.The frontof thepaper clip shouldgo through thishole.

2.Inserta paperclip through thishole tokeep brushes retracted.

#35Positionthebrushholderassemblyinplace,andfastenitdownwiththetwoscrews.

#36Oncethebrushassemblyisfasteneddown,pulloutthepapercliptoallowthebrushestoexpand outwardandcontactthesliprings.(Ifyouareinstallinganewbrushassemblyitwillcomewithametal retainingpinholdingthebrushesretractedasshown).

#37Installthebackcoverandfastendownthenuts.Dontforgettoreattachthewiremounting bracket.

#38Installthepulleyandtightendownthepulleylocknutto81ftlb.Turnthepulleybyhandfora whileuntiltherotorspinsfreelywithoutnoise(pertheHondaservicemanualitseemsthatittakesa bitofturningtherotortogetittopositioncorrectly,perhapsasthespacerwasherexpandstocorrectly positiontherotorfromfronttoback?)

Problemsyoumayencounter: As you can probably tell, removing the rear bearing is not easy and likely requires some kind of specialized tool (blind bearing puller or puller with very fine arms). However, if you only have to replace thebrushesand/orfrontbearing,thejobisquitestraightforwardandyoumightbeabletosaveyourself some money by repairing your alternator rather than purchasing a rebuilt unit. I suspect also that it is probably more common for the front bearing to go bad then the back given that the front bearing has mostoftheloadingoftheserpentinebelttensiononit. Hopethiswashelpful! JohnC.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Brake Drum Micrometer: Operating Instructions and Parts IdentificationDocument4 pagesBrake Drum Micrometer: Operating Instructions and Parts IdentificationoldtrukluvrNo ratings yet

- Compressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveDocument3 pagesCompressed Air Test 16 S 221, 16 S 181, 8 S 181: 13.3 5/2-Way ValveThylaneNo ratings yet

- Camshaft Position Sensor: ComponentsDocument13 pagesCamshaft Position Sensor: ComponentsNathan GabbottNo ratings yet

- Da10 Air Cooled Engine (Appn Code D3.2007 & D3Document26 pagesDa10 Air Cooled Engine (Appn Code D3.2007 & D3Sandeep NikhilNo ratings yet

- Stylus Pro 5500Document21 pagesStylus Pro 5500gesssmNo ratings yet

- SP3200-84 Flaking Mill - Parts BookDocument63 pagesSP3200-84 Flaking Mill - Parts BookVinicius Morais PedraNo ratings yet

- Broasca JD 6410Document2 pagesBroasca JD 6410Fer EmilNo ratings yet

- Helicopter Transmission MCQDocument143 pagesHelicopter Transmission MCQUjata IsraelNo ratings yet

- AL4 TransmissionDocument59 pagesAL4 Transmissionericsolver97% (62)

- New Holland WE190, WE210, WE210 Industrial, WE230, WE230 Industrial Wheeled Excavator Service Repair ManualDocument21 pagesNew Holland WE190, WE210, WE210 Industrial, WE230, WE230 Industrial Wheeled Excavator Service Repair ManualggjjjjotonesNo ratings yet

- Design of An Efficient Gear Driven Bicyc PDFDocument10 pagesDesign of An Efficient Gear Driven Bicyc PDFFranklin Delano JuniorNo ratings yet

- 491-Md-310 Inspection Report: 1. Head SprocketDocument4 pages491-Md-310 Inspection Report: 1. Head SprocketsantoshNo ratings yet

- WARN CE M8274-50 WINCH REPLACEMENT PARTS LISTDocument2 pagesWARN CE M8274-50 WINCH REPLACEMENT PARTS LISTORLANDO CASTILLONo ratings yet

- Catálogo de Peças: 6145J TractorDocument760 pagesCatálogo de Peças: 6145J TractorHeloany LimaNo ratings yet

- V Series Vickers 4520v Standard Double Pump Parts DataDocument4 pagesV Series Vickers 4520v Standard Double Pump Parts DataNick OchoaNo ratings yet

- Hino Motors Sales Indonesia service quoteDocument2 pagesHino Motors Sales Indonesia service quoteJujuNo ratings yet

- CR20-14 Service Part ListDocument4 pagesCR20-14 Service Part Listmjivani645No ratings yet

- Eaton Power Take Off Ratios and SpecsDocument2 pagesEaton Power Take Off Ratios and SpecsJose Leandro Neves FerreiraNo ratings yet

- Replacement Parts For 3m Elite Random Orbital Sander 28496 PartsDocument3 pagesReplacement Parts For 3m Elite Random Orbital Sander 28496 Partsskyler summersNo ratings yet

- Compufire20100 Hd-1m Dual FireDocument4 pagesCompufire20100 Hd-1m Dual Fire12dan11No ratings yet

- Seastar Helm InstallationDocument22 pagesSeastar Helm InstallationcombaheeNo ratings yet

- Three Phase Motor Data and Gear Motor Selection TablesDocument35 pagesThree Phase Motor Data and Gear Motor Selection TablesBanele CaluzaNo ratings yet

- Final ReportDocument28 pagesFinal Reportapi-534506556No ratings yet

- Havells ConsumerCables2020Document6 pagesHavells ConsumerCables2020juga2013No ratings yet

- AM AT (A4CFx)Document20 pagesAM AT (A4CFx)Edin raul Yalle rafaelNo ratings yet

- Loctite Industrial Gearbox Service ManualDocument13 pagesLoctite Industrial Gearbox Service ManualDumitrescuNo ratings yet

- Transmission CatalogDocument100 pagesTransmission CatalogNguyễn Đức HuyNo ratings yet

- K15/21/25 Gasoline Engine: Service Manual # 99789-75100Document64 pagesK15/21/25 Gasoline Engine: Service Manual # 99789-75100NelsonSanguinoMorosNo ratings yet

- At-90 Pedal SNDocument41 pagesAt-90 Pedal SNgragalNo ratings yet

- Parts Catalogue Elegan 250absDocument113 pagesParts Catalogue Elegan 250absHairulIzhamIshakNo ratings yet