Professional Documents

Culture Documents

Tesla Turbomachinery, 1991

Uploaded by

timmyjim333Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tesla Turbomachinery, 1991

Uploaded by

timmyjim333Copyright:

Available Formats

Proc. IJ International Aikola 1esla Symposium (Sept.

23-25, 1991)

Tesla Turbomachinery

Warren Rice

Prof. Emiritus, Dept. of Mechanical & Space Engineering,

Arizona State University

Summary

The Tesla-type turbomachinery is distinguished by the Iact that the rotor is composed oI Ilat

parallel corotating disks, spaced along a shaIt. A throughIlow oI Iluid between the disks

results in momentum exchange between the Iluid and the disks and hence shaIt torque and

power. Tesla designed, built and tested such machines but was not able to achieve industrial

applications oI them.

In the subsequent years, many investigations have been carried out to determine the

perIormance and eIIiciency oI this type oI turbomachinery. These have been both analytical

and experimental. Most oI the investigations have had a certain limited application as the

objective, with regard to size and speed as well as the nature oI the operating Iluid. However,

some oI the investigations have tried to establish the generalized perIormance oI Tesla-type

turbomachines. In general, it has been Iound that the eIIiciency oI the rotor can be very high,

at least equal to that achieved by conventional rotors. But it has proved very diIIicult to

achieve eIIicient nozzles in the case oI turbines. For pumps and compressors, eIIicient

diIIusion aIter the rotor has proven diIIicult to achieve. As a result, only modest machine

eIIiciencies have been demonstrated. Principally Ior these reasons the Tesla-type

turbomachinery has had little utilization. There is, however, a widespread belieI that it will

Iind applications in the Iuture, at least in situations in which conventional turbomachinery is

not adequate. This includes the use with very viscous Iluids, Iluids containing abrasive

particles, and two-phase Iluids.

The Ilow in the rotor may be either laminar or turbulent, with certain advantages and

disadvantages in each oI the regimes. It is necessary to careIully distinguish which type oI

Ilow is considered in reports by the various investigators.

Herein, the principles oI the Tesla-type turbomachinery are reviewed and the problems with

nozzles and diIIusers (which limit the machine eIIiciency) are discussed. The analytical

methods that have been Iound useIul in modeling and calculating the Ilow in the rotor are

reviewed and the experimental results obtained by some investigators are described. An

extensive list oI ReIerences is presented and summaries are made oI the main results and

conclusions that have been reported.

Introduction

Tesla is most widely recognized Ior his outstanding achievements in the Iields oI generation,

transmission and utilization oI electrical power. However, he was also the inventor oI a

unique type oI turbomachinery that can be applied as liquid pumps, liquid or vapor or gas

turbines, and gas compressors (1). The Tesla turbine was widely recognized in the semi-

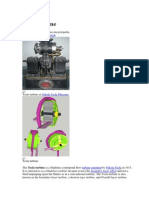

technical press at the time oI the invention (2-7). The Tesla turbomachinery is distinguished

by the Iact that the rotor is composed oI Ilat parallel corotating disks spaced along a shaIt. A

throughIlow oI Iluid between the disks results in momentum exchange between the Iluid and

the disks and hence shaIt torque and power. Tesla designed, built and tested such machines

but was not able to achieve signiIicant industrial application oI them. Figures 1 and 2 are

schematic diagrams oI a Tesla-type pump and turbine.

As a turbine, the multiple-disk rotor is contained in a housing provided with nozzles to supply

high-speed Iluid approximately tangential to the rotor. The Iluid Ilows spirally inward and

Iinally exhausts Irom the rotor through holes or slots in the disks near the shaIt. As a pump or

compressor, Iluid enters the rotor through holes near the shaIt, Ilows spirally outward, and

exhausts Irom the rotor into a diIIuser such as a volute scroll. ShaIt power is delivered by the

turbine and shaIt power must be supplied to the pump or compressor. The perIormance and

eIIiciency oI the rotor oI such machines is dependent on the combination oI shaIt speed, disk

inner and outer diameters, the spacing between the disks and the Iluid properties and Ilow

rate. The perIormance oI the overall turbine is strongly dependent also on the eIIiciency oI the

nozzles and the nozzle-rotor interaction. The perIormance oI the pump is also strongly

dependent on the interaction oI the Iluid leaving the rotor with that in the volute and on the

eIIiciency oI diIIusion in the volute. In general, Ilow in the rotor may be laminar or turbulent

or mixed.

There was little activity concerning the Tesla turbomachinery until a revival oI interest began

in the 1950s (8-17). Research was widespread aIter that, particularly in the area oI analytical

modeling oI the Ilow in the space between two disks in a rotor, and continues at present.

ReIerences (18-79) are representative. Many attempts have been made to commercialize

Tesla-type turbomachinery, especially as pumps, but no widespread applications are apparent.

While rotor eIIiciencies can be very high in this type oI turbomachine, there are inherent

losses in the Iluid Ilows entering and exiting the rotor. As a turbine, the nozzles are

necessarily long and ineIIicient. As a pump or compressor, the diIIuser or volute must handle

Ilow with a very small entering angle which causes the volute to be very ineIIicient. For these

and other reasons actual Tesla turbomachines have eIIiciencies much less than might be

expected Irom consideration oI the Ilow in the rotor. There is little or no literature devoted to

the Ilows that cause the main losses in Tesla-type turbomachinery. The Tesla-type

turbomachinery is variously reIerred to in the literature as multiple-disk or Iriction or shear-

Iorce (or, nonsensically, boundary layer) turbomachinery.

Multiple-Disk Rotors Having Laminar Flow ~

A way oI analytically modeling the Ilow in a multiple disk rotor known as bulk-parameter

analysis, was used by early investigators (7, 9-11, 16, 17, 21, 24, 49). It is usable Ior both

laminar and turbulent Ilow. In this method oI analysis, the Irictional interaction between the

Iluid and the disks is represented in terms oI an empirical Iluid Iriction Iactor. This results in

ordinary diIIerential equations which, together with simple boundary and entrance conditions,

constitute a problem easily solved using computer-implemented step-wise calculations. The

method is limited in useIulness by the inadequacy oI the Iriction Iactor concept.

In the case oI laminar Ilow, much better analytical modeling can be achieved. Partial

diIIerential equations can be established rather simply together with appropriate boundary and

inlet conditions. Because the Ilow path is long compared with the disk spacing, order-oI-

magnitude arguments can be made to simpliIy the equations somewhat and reduce them to

pseudo-parabolic Iorm. The problem can then be solved by any one oI several available

means.

Some investigators have used truncated series substitution methodology to make solutions

(23, 25, 29, 32) but the method has accuracy limitations. A much more widely used method is

to solve the problem using computer-implemented Iinite diIIerence methods; reIerences (19)

and (33) are typical examples. Integral methods have also been used, mainly to shorten the

computer execution time required Ior solution (38). Most oI the literature has considered the

Iluid to be incompressible although some investigators have calculated compressible Ilows

(48, 53, 65, 71).

Wu (78) in 1986, made detailed comparisons oI results Irom all oI the available literature. It

was Iound that when the results oI investigations using similar solution means were compared

there was close agreement, within accuracy limitations. It was also concluded that the Iinite

diIIerence solutions all obtained good accuracy and produced essentially the same results and

such solutions are recommended to be used.

It is also clear Irom the literature that the calculated results Ior laminar Ilows between

corotating disks are in excellent agreement with experimental results Ior such Ilows (35, 44).

While Iuture eIIorts may lead to increased eIIiciency or shorter computer execution time,

present published methodology and results are suIIicient Ior use in the design oI laminar Ilow

multiple disk rotors Ior pumps, compressors, and turbines. Some generalized inIormation Ior

such rotors has been presented. (45, 46)

The results oI a solution oI a Ilow consist oI detailed knowledge oI the distribution oI the

velocity and pressure throughout the Ilow between the disks. From this, the relationship

between the mass Ilow and the pressure change Irom inlet to exit become known and allow

determination oI design Iacts such as the number oI disks required Ior an application oI

interest. The solutions are parameterized using the Iollowing or equivalent parameters: Ior

outward Ilows (pumps), Reynold`s number, Ilow rate number and radius ratio; Ior inward

Ilows (turbines) the additional parameter ( vo/omega ro : average disk-disk radial component

oI velocity, at outer radius oI disk / angular velocity oI pair oI disks x outer radius oI disk ) is

required. The results can be arranged to provide values oI dimensionless torque,

dimensionless pressure, dimensionless power, rotor eIIiciency, etc.

With proper use oI the analytical results, the rotor eIIiciency using laminar Ilow can be very

high, even above 95. However, in order to attain high rotor eIIiciency, the Ilowrate number

must be made small which means high rotor eIIiciency is achieved at the expense oI using a

large number oI disks and hence a physically large rotor. For each value oI Ilow rate number

there is an optimum value oI Reynolds number Ior maximum eIIiciency. With common

Iluids, the required disk spacing is dismally small causing laminar Ilow to tend to be large and

heavy Ior a prescribed throughIlow rate.

Extensive investigations have been made oI Tesla-type liquid pumps using laminar-Ilow

rotors (64). It was Iound that overall pump eIIiciency was low even when rotor eIIiciency was

high because oI the losses occurring at the rotor entrance and exit earlier mentioned.

Criteria for the Occurrence of Laminar and of Turbulent Flow in Multiple-Disk Rotors

~

It is established that a wide range oI types (or regimes) oI Ilow can occur between corotating

disks including wholly laminar Ilow, laminar Ilow with regions oI recirculation, wholly

turbulent Ilow, and turbulent Ilow proceeding through "reverse transition" or "relamination"

to laminar Ilow. There is experimental evidence concerning these Ilows (26, 27, 31, 35, 42,

44) and the hydrodynamic stability oI laminar Ilows between corotating disks has been

investigated (31, 66). Wu (78) considering all available experimental and analytical evidence,

concluded that the visco-geometric number alpha proposed by Nendl (42, 55) most adequately

characterizes the Ilow regime, where alpha uh2/vr. While the data oI the various

investigators are somewhat contradictory, a reliable guide appears to be that Ilow is laminar

Ior alpha 10, in transition Ior 10 alpha 20 and turbulent Ior alpha ~ 20. Various

investigators introduce rather pragmatic and diIIering deIinitions oI "laminar" and "turbulent"

which Iurther complicates the matter. It is desirable that it be explored Iurther both

experimentally and by additional hydrodynamic stability analysis.

Multiple-Disk Rotors Having Turbulent Flow ~

The bulk-parameter (Iriction Iactor) type oI analysis oI Ilow in a multiple-disk type oI rotor

was reIerenced in the Ioregoing discussion oI laminar Ilows. It has been used extensively to

calculate turbulent Ilows but with mostly unknown degrees oI adequacy. The transition

criteria presented is not applicable Ior bulk-parameter use and the hydraulic diameter concept

is required and the assumption must be made that pipeIlow Irictional correlations are valid Ior

Ilows between corotating disks. Nevertheless, such analyses has been the only analytical

prediction method available until relatively recently and methods now becoming available are

not yet well-established. Wu (78) gives an extended comparison oI the results oI various bulk-

parameter methods oI analysis with several sources oI experimental data Ior turbulent Ilows

between corotating disks.

Momentum integral equation methods have been and continue to be used to calculate the

subject turbulent Ilows (26, 34, 36). In these methods, ordinary diIIerential equations

describing the Ilow are written based on assumed distribution Iorms Ior the velocity and on

empirical expressions Ior the stresses in the Ilow. Some oI these rely on experience and/or

specialized experimental results and are Iound not to be universal. Within careIully noted

bounds however these methods can be very successIully used by an experienced investigator

and have yielded strong insights into and design inIormation Ior the turbulent Ilows oI

interest.

In principal, the set oI partial diIIerential equations applicable Ior turbulent Ilow can be

written, provided with appropriate boundary and entrance conditions, and then solved in some

manner using computer-implemented calculations. In practice, there are several aspects oI the

process that cannot be executed with conIidence that the calculated results will agree with

reality. Principally among these is that a model or mechanism describing the turbulent

transport oI linear momentum must be prescribed. Furthermore, the partial diIIerential

equations are much more complicated Ior turbulent than Ior laminar Ilow. In the entrance

region, the equations must be solved in elliptical Iorm beIore changing over to simpliIied

pseudo-parabolic equations to continue the calculations.

Truman (73) carried out calculations Ior turbulent Ilow between corotating disks using eddy-

viscosity/mixing-length turbulence (stress) modeling, and using a Iinite-diIIerence method Ior

solving the partial diIIerential equations. Wu (78) used a slightly modiIied version oI the

computer-implemented calculations provided by Truman, to compare calculated results with

experimental data Ior turbulent Ilow due to Bakke (26) and Kohler (34). In general, agreement

was good but with some qualiIications and reservations discussed in detail by Wu (78). It was

noted that at high rotor angular speeds the calculations indicated recirculation in the turbulent

Ilow that could not be detailed since the pseudo-parabolic equations are not applicable Ior

recirculating Ilows.

Truman, et al.(76) have also calculated similar Ilows using an anisotropic two-equation

turbulence model. More analytical study and much more experimental investigation oI the

turbulent Ilow between corotating disks is needed to establish the most applicable methods Ior

calculating the Ilows with conIidence and Ior the results to be useIul in the design oI

turbomechanics. Wu (78) has outlined an experimental apparatus and procedure that might

provide the next needed insights Ior progress in this area.

Actual Tesla-Type Turbomachinery ~

Many individuals and groups attempting to commercialize Tesla-type turbomachines have

designed, constructed and operated them. Pumps have received the most interest but

compressors and turbines have also been built and operated. While much useIul test data has

no doubt been recorded, very little has been published or otherwise made known because oI

the perceived need Ior keeping inIormation proprietary. Thus, this large body oI inIormation

is not available to most investigators.

Most Tesla-type turbines and pumps have been designed using intuition and simple

calculations or empirical experience and rules-oI-thumb. This has almost always led to the use

oI large spaces between the disks corresponding to turbulent Ilow between the disks.

The published inIormation concerning actual Tesla-type pumps includes reIerences (17, 18,

20, 21, 28, 34, 37, 47, 49, 50, 54, 59, 64, 67). All oI the inIormation presented shows lower

eIIiciency than was desired. In general, the pumps designed with little prior calculated rotor

design inIormation showed eIIiciencies below 40. Adequate calculated rotor design

inIormation resulted in higher eIIiciency but still in the range oI 40 to 60. All things

considered, it seems probable that Tesla-type pumps oI reasonable size, operating with

common Iluids, will not exceed an eIIiciency oI 65 at best, with careIul attention to

volute/rotor matching. Many Tesla-type pumps intended to be commercially competitive have

not been provided with a volute or any other type oI diIIuser.

A number oI Tesla-type turbines have been constructed Ior use with steam, gas and water.

Very Iew data have been published concerning them. The published inIormation includes

reIerences (2-6, 8-11, 13, 16, 24, 51, 63). As with pumps, the turbine eIIiciencies have been

low and the machine sizes large per unit oI power delivered. All oI the turbines reported

probably operated with turbulent Ilow in the rotor.

Most recent pumps and turbines oI the Tesla-type have used rotors composed oI disks with a

central hole rather than the spoke construction used by Tesla. The disks are carried on

throughbolts extending Irom a thicker masterdisk Iastened to the shaIt; thus the rotor is

overhung. Although most machines have used thick disks, there seems to be little reason to do

so since the disks have only small Iorces acting on them and are not required to be perIectly

Ilat.

Many design questions remain unanswered at this time. Whether the disks should be rough or

smooth, Ior best perIormance, is controversial as is the question concerning appropriate rotor-

to-housing seals. There are some ideas concerning ways to improve volute or nozzle

perIormance that remain undemonstrated. An early idea oI improving perIormance oI rotors

by composing them oI nested cones rather than Ilat disks has been shown to produce no

perIormance advantages and to introduce structural handicaps (20, 79).

Conclusion ~

Tesla-type turbomachinery probably cannot prove competitive in an application in which

more conventional machines have adequate eIIiciency and perIormance. Thus, they cannot be

expected to displace conventional water pumps or conventional water turbines or gas turbines.

Tesla-type turbomachinery should be considered in applications in which conventional

machines are inadequate. This includes applications Ior small shaIt power, or the use oI very

viscous Iluids or oI non-Newtonian Iluids. There is some reason to believe that multiple-disk

turbomachines can operate with abrasive two-phase Ilow mixtures with less erosion oI

material Irom the rotor. For that reason they should be Iurther investigated Ior applications to

produce power Irom geothermal steam and particle-laden industrial gas Ilows. There may also

be unique applications possible using ceramic disks. There is considerable evidence that

multiple disk turbomachinery can be quieter in operation than is conventional machinery and

that the noise is more nearly "white" without a prevailing sound signature. Multiple-disk

pumps are well-known to resist cavitation (20, 49). It is the only type oI turbomachinery that

can be easily constructed in a relatively primitive machine shop.

References ~

Vojin Popovic, Radoslav Horvat and Nikola Nikolic: "Nikola Tesla, 1856-1943, Lectures,

Patents, Articels", Nikola Tesla Museum, Belgrade, Yugoslavia, 1956.

References

You might also like

- Manual Naval de Proteccion CatodicaDocument248 pagesManual Naval de Proteccion CatodicaFabricio Mayta BenitezNo ratings yet

- Bob-Stern Roseville NCSLI 1410Document23 pagesBob-Stern Roseville NCSLI 1410makara5966No ratings yet

- C10550231 PDFDocument1 pageC10550231 PDFsudhindra_tiwariNo ratings yet

- Clevis Bolts Material 3Document5 pagesClevis Bolts Material 3Andres_Pastor1987No ratings yet

- (1994 Tesla Symposium at Colorado Springs) K.L. Corum, J.F. Corum - Nikola Tesla, Lightning Observations, and Stationary Waves (1994)Document72 pages(1994 Tesla Symposium at Colorado Springs) K.L. Corum, J.F. Corum - Nikola Tesla, Lightning Observations, and Stationary Waves (1994)gospodarmunjaNo ratings yet

- Escoa Fintube Corporation, An Oklahoma Corporation v. Tranter, Inc., A Michigan Corporation, 631 F.2d 682, 10th Cir. (1980)Document22 pagesEscoa Fintube Corporation, An Oklahoma Corporation v. Tranter, Inc., A Michigan Corporation, 631 F.2d 682, 10th Cir. (1980)Scribd Government DocsNo ratings yet

- Shock Trial Simulation For Naval Ships PDFDocument14 pagesShock Trial Simulation For Naval Ships PDFFernando Raúl LADINONo ratings yet

- 3.1 MC-2317-01 - FA3102 Rev - 2Document372 pages3.1 MC-2317-01 - FA3102 Rev - 2IME SOLUTIONSNo ratings yet

- 057521Document20 pages057521M.Senthil VelavanNo ratings yet

- Audible Noise ReductionDocument4 pagesAudible Noise ReductionGaurav SharmaNo ratings yet

- Api 610Document11 pagesApi 610prakasharmyNo ratings yet

- How To Install Thermal Desktop 4.8Document3 pagesHow To Install Thermal Desktop 4.8Johann RodriguezNo ratings yet

- Shock and Vibration Bulletin Part 5 Covers Pyrotechnic Shock and Fragility TestingDocument181 pagesShock and Vibration Bulletin Part 5 Covers Pyrotechnic Shock and Fragility Testinganselm_wierciochNo ratings yet

- As 2382-1981 Surface Roughness Comparison SpecimensDocument7 pagesAs 2382-1981 Surface Roughness Comparison SpecimensSAI Global - APACNo ratings yet

- Anclajes Red HeadDocument8 pagesAnclajes Red HeadLeonardo AvilaNo ratings yet

- Microstructure and Properties of ThermalDocument12 pagesMicrostructure and Properties of ThermalEmre Bali100% (1)

- A2 Form Indian BankDocument2 pagesA2 Form Indian BankVoletiram Babu100% (2)

- Tesla TurbineDocument15 pagesTesla TurbineJY GDNo ratings yet

- Guha Smiley IMechE PartA 2010 Tesla TurbineDocument18 pagesGuha Smiley IMechE PartA 2010 Tesla Turbineemir__dNo ratings yet

- Design and Off-Design Analysis of A Tesla Turbine Utilizing CO2 As Working FluidDocument6 pagesDesign and Off-Design Analysis of A Tesla Turbine Utilizing CO2 As Working Fluidbillthegunm0% (1)

- D Eng 21 0023 AeDocument13 pagesD Eng 21 0023 Aesaumya irugalbandaraNo ratings yet

- Holmes SciDACDocument13 pagesHolmes SciDACDaniel MoraNo ratings yet

- Design and Computational Analysis of 1 KW TeslaDocument5 pagesDesign and Computational Analysis of 1 KW Teslaemir_delic2810No ratings yet

- Study OF Operation OF Tesla Turbine: International Journal of Advance Research in Engineering, Science & TechnologyDocument5 pagesStudy OF Operation OF Tesla Turbine: International Journal of Advance Research in Engineering, Science & Technologyreventhk465No ratings yet

- AJK2015 TeslaPumpPaper FinalDocument7 pagesAJK2015 TeslaPumpPaper FinalErick TorregrosaNo ratings yet

- IJIRT157883_PAPERDocument10 pagesIJIRT157883_PAPERMilan ĐurićNo ratings yet

- Comparison of Methods ForDocument13 pagesComparison of Methods ForClaudio NovaesNo ratings yet

- Fractal Impeller Amol KulkarniDocument10 pagesFractal Impeller Amol KulkarniTej ChoksiNo ratings yet

- Tesla Turbine2Document8 pagesTesla Turbine2Tahir DemirNo ratings yet

- Investigation of Mixed Flow Turbine Under Inlet Pulsating FlowDocument12 pagesInvestigation of Mixed Flow Turbine Under Inlet Pulsating Flowkallurkar23No ratings yet

- General Disclaimer One or More of The Following Statements May Affect This DocumentDocument14 pagesGeneral Disclaimer One or More of The Following Statements May Affect This DocumentUmair MunirNo ratings yet

- The Design of A Test Rig and Study of The Performance and Efficiency of A Tesla Disc TurbineDocument15 pagesThe Design of A Test Rig and Study of The Performance and Efficiency of A Tesla Disc Turbinearturo ortegaNo ratings yet

- 1 s2.0 S1631072112000290 MainDocument12 pages1 s2.0 S1631072112000290 MainLilou MGKNo ratings yet

- Interaction of Turbomachinery ComponentsDocument7 pagesInteraction of Turbomachinery ComponentsPedro LeyvaNo ratings yet

- Energy: Olivier Dumont, Antoine Parthoens, R Emi Dickes, Vincent LemortDocument9 pagesEnergy: Olivier Dumont, Antoine Parthoens, R Emi Dickes, Vincent LemortCHELIN_2305No ratings yet

- StatorDocument6 pagesStatorVishal SalveNo ratings yet

- Flow Simulations of An Axial Transonic Compressor Stage: January 2009Document14 pagesFlow Simulations of An Axial Transonic Compressor Stage: January 2009Adel AyoubNo ratings yet

- Characteristics of Batch Rotor-Stator Mixer Performance Elucidated by Shaft Torque and Angle Resolved Piv MeasurementsDocument20 pagesCharacteristics of Batch Rotor-Stator Mixer Performance Elucidated by Shaft Torque and Angle Resolved Piv MeasurementsMohamed MaherNo ratings yet

- Turbomachinery ThesisDocument5 pagesTurbomachinery Thesiswcldtexff100% (2)

- Rotordynamics 2: Problems in Turbo MachineryDocument6 pagesRotordynamics 2: Problems in Turbo MachineryJessica SandersNo ratings yet

- Numerical and Experimental Analysis of Transient Flow in Roots BlowerDocument13 pagesNumerical and Experimental Analysis of Transient Flow in Roots BlowerSynbedNo ratings yet

- Explore the bladeless Tesla turbineDocument11 pagesExplore the bladeless Tesla turbineLucy TyasNo ratings yet

- Glass 110421Document5 pagesGlass 110421Julian MartineliNo ratings yet

- Tidal TurbineDocument10 pagesTidal TurbineAdson Santos Silva Jr.No ratings yet

- Basics of Rotor and Structural VibrationDocument23 pagesBasics of Rotor and Structural VibrationdiegovalenzuelaNo ratings yet

- Design Methodology for Micro Gas TurbinesDocument18 pagesDesign Methodology for Micro Gas TurbinesMelvin LeongNo ratings yet

- Performance of A Small-Scale Organic Rankine Cycle System Using A Regenerative Flow Turbine: A Simulation AnalysisDocument10 pagesPerformance of A Small-Scale Organic Rankine Cycle System Using A Regenerative Flow Turbine: A Simulation Analysissundaram.thangaraj sundaram.thangarajNo ratings yet

- Wemco flotation cell design criteria and scale-up developmentsDocument18 pagesWemco flotation cell design criteria and scale-up developmentsfornelas75% (4)

- $MP 008 22 PDFDocument12 pages$MP 008 22 PDFmoustafaNo ratings yet

- Fransson Jocker Bolcs Ott Igti490 98Document11 pagesFransson Jocker Bolcs Ott Igti490 98HomeNo ratings yet

- A Theory of Tesla Disc Turbines: Sayantan Sengupta and Abhijit GuhaDocument14 pagesA Theory of Tesla Disc Turbines: Sayantan Sengupta and Abhijit GuhahatemNo ratings yet

- Design, Construction and Simulation of Tesla Turbine: Keywords - Physical Model, CFD Simulation, RadialDocument9 pagesDesign, Construction and Simulation of Tesla Turbine: Keywords - Physical Model, CFD Simulation, RadialhatemNo ratings yet

- (International Centre For Mechanical Sciences 297) Neville F. Rieger (Eds.) - Rotordynamics 2 - Problems in Turbomachinery-Springer-Verlag Wien (1988) PDFDocument579 pages(International Centre For Mechanical Sciences 297) Neville F. Rieger (Eds.) - Rotordynamics 2 - Problems in Turbomachinery-Springer-Verlag Wien (1988) PDFDendyAdantaNo ratings yet

- TLP Global Motion Performance Analysis ProceduresDocument8 pagesTLP Global Motion Performance Analysis ProceduresTee Shi FengNo ratings yet

- Nergy and Nvironment: A Numerical Investigation of Flow Profile and Performance of A Low Cost Crossflow TurbineDocument22 pagesNergy and Nvironment: A Numerical Investigation of Flow Profile and Performance of A Low Cost Crossflow TurbineAnonymous h3huS5DlNo ratings yet

- Design Analysis of Tesla Micro-Turbine Operating On A Low-Boiling MediumDocument6 pagesDesign Analysis of Tesla Micro-Turbine Operating On A Low-Boiling MediumHaidar RahmanNo ratings yet

- Cross-Flow Turbine Design For Variable Operating Conditions: SciencedirectDocument10 pagesCross-Flow Turbine Design For Variable Operating Conditions: SciencedirectvcockscribdNo ratings yet

- CHAPTER 2 & 3 - Archimedes Screw TurbineDocument16 pagesCHAPTER 2 & 3 - Archimedes Screw TurbineDear Kim100% (1)

- Computational Fluid Flow AnalysisDocument6 pagesComputational Fluid Flow AnalysisRiddhesh PatelNo ratings yet

- Babadjanian - Elegie PDFDocument5 pagesBabadjanian - Elegie PDFrobertofpNo ratings yet

- Moussorgsky Rachmaninoff HopakDocument4 pagesMoussorgsky Rachmaninoff Hopaktimmyjim333No ratings yet

- Schubert-Tausig Marche Militaire Sheet MusicDocument12 pagesSchubert-Tausig Marche Militaire Sheet Musicnubluize100% (1)

- NASA TM-108852: Parametric Study On Laminar Flow For Finite Wings at Supersonic SpeedsDocument108 pagesNASA TM-108852: Parametric Study On Laminar Flow For Finite Wings at Supersonic Speedstimmyjim333No ratings yet

- (Ebook) - Martial Arts - The History and Philosophy of Wing Chun Kung FuDocument12 pages(Ebook) - Martial Arts - The History and Philosophy of Wing Chun Kung Fuallexandru2671% (7)

- Advanced Supersonic Cruise Aircraft TechnologyDocument19 pagesAdvanced Supersonic Cruise Aircraft Technologytimmyjim333No ratings yet

- National Advisory Committee for Aeronautics Report 1135Document73 pagesNational Advisory Committee for Aeronautics Report 1135dakservice1No ratings yet

- Effect of Winglets On Induced Drag of Ideal Wing ShapesDocument30 pagesEffect of Winglets On Induced Drag of Ideal Wing Shapestimmyjim333100% (1)

- Simons - Model Aircraft Aerodynamics PDFDocument331 pagesSimons - Model Aircraft Aerodynamics PDFPedro Bello Saenko88% (8)

- Naca Report 921Document56 pagesNaca Report 921Michael OlsenNo ratings yet

- 2006-9 IAC, Advent of Clean Nuclear Fusion, BussardDocument30 pages2006-9 IAC, Advent of Clean Nuclear Fusion, Bussardtimmyjim333No ratings yet

- Tesla turbine design principlesDocument6 pagesTesla turbine design principlesemir100% (1)

- Head Boy and Girl Final Application FormDocument5 pagesHead Boy and Girl Final Application FormboobooNo ratings yet

- Advanced Pranic Healing Pranic CrystalDocument6 pagesAdvanced Pranic Healing Pranic CrystalbombeiromaxNo ratings yet

- Ngos & Risk: Managing Uncertainty in Local-International PartnershipsDocument52 pagesNgos & Risk: Managing Uncertainty in Local-International PartnershipsNiihih Heyem LamtehNo ratings yet

- Module 5Document41 pagesModule 5Ysabel TolentinoNo ratings yet

- JEE(Main) 2023 Answer Key ChallengeDocument9 pagesJEE(Main) 2023 Answer Key ChallengeCHAKRI BABLUNo ratings yet

- Prototype Unmanned Aerial Sprayer For Plant Protection in Agricultural and Horticultural CropsDocument14 pagesPrototype Unmanned Aerial Sprayer For Plant Protection in Agricultural and Horticultural CropsTacke NguyenNo ratings yet

- De HSG 60Document8 pagesDe HSG 60Phạm Trần Tiến KhánhNo ratings yet

- Topic: References: Materials: Value Focus: Lesson Plan in Health 6Document7 pagesTopic: References: Materials: Value Focus: Lesson Plan in Health 6Kathleen Rose ReyesNo ratings yet

- Virtual Reality in Tourism: A State-Of-The-Art ReviewDocument39 pagesVirtual Reality in Tourism: A State-Of-The-Art ReviewMegi VisiNo ratings yet

- FDocument23 pagesFNurbaiti NasutionNo ratings yet

- Why NAM remains relevant todayDocument2 pagesWhy NAM remains relevant todaySourabh PawarNo ratings yet

- Molecular Technique For Gender Identification: A Boon in Forensic OdontologyDocument12 pagesMolecular Technique For Gender Identification: A Boon in Forensic OdontologyBOHR International Journal of Current research in Dentistry (BIJCRID)No ratings yet

- Software Quality Assurance: Department of Computer Science Ncba&E EccDocument16 pagesSoftware Quality Assurance: Department of Computer Science Ncba&E EccAqib AsadNo ratings yet

- Econ 222 W2012 Assignment 3 Answers PostedDocument9 pagesEcon 222 W2012 Assignment 3 Answers PostedakNo ratings yet

- Low-Cost DIY Vane Anemometer Based On LabVIEW InteDocument5 pagesLow-Cost DIY Vane Anemometer Based On LabVIEW Inteb7412369No ratings yet

- Test Bank For Risk Management and Insurance 12th Edition James S TrieschmannDocument24 pagesTest Bank For Risk Management and Insurance 12th Edition James S TrieschmannGeorgeWangeprm100% (41)

- Comparative effect of phosphatic fertilizers on tobacco yield and qualityDocument27 pagesComparative effect of phosphatic fertilizers on tobacco yield and qualityAizaz AliNo ratings yet

- Planetary Longings - Mary Louise PrattDocument353 pagesPlanetary Longings - Mary Louise PrattjuliocattaiNo ratings yet

- Deffi Ayu Puspito Sari, PH.DDocument8 pagesDeffi Ayu Puspito Sari, PH.DYogiNo ratings yet

- CHEN 4460 - Process Synthesis, Simulation and OptimizationDocument40 pagesCHEN 4460 - Process Synthesis, Simulation and Optimizationmppatilmayur1679No ratings yet

- Two Approaches To Historical Study: The Metaphysical (Including 'Postmodernism') and The HistoricalDocument32 pagesTwo Approaches To Historical Study: The Metaphysical (Including 'Postmodernism') and The HistoricalDavid HotstoneNo ratings yet

- Arabic SyntaxDocument26 pagesArabic SyntaxagahNo ratings yet

- Atmosphere Lesson PlanDocument7 pagesAtmosphere Lesson PlanJasmine DanaNo ratings yet

- Marimekko's Approach to Sustainability and Global OperationsDocument3 pagesMarimekko's Approach to Sustainability and Global OperationsHannah Van GeeresteinNo ratings yet

- Calamansi-Aloe Vera-Malunggay Organicantibacterial Hand SanitizerDocument7 pagesCalamansi-Aloe Vera-Malunggay Organicantibacterial Hand SanitizerELIZABETH MABIDA100% (2)

- Morphotectonic and Satellite Imagery Analysis For Identifying Quaternary Fault at Southern Part of Cianjur-Garut Region, West Java, IndonesiaDocument10 pagesMorphotectonic and Satellite Imagery Analysis For Identifying Quaternary Fault at Southern Part of Cianjur-Garut Region, West Java, IndonesiaDian Ayu Lestari Alifa PutriNo ratings yet

- 04 ET EXCERPTS Field Guide To Human Centered DesignDocument49 pages04 ET EXCERPTS Field Guide To Human Centered DesignMahesh ReddyNo ratings yet

- Bsce Quarantine Reviewer Diagnostic Exams PDFDocument27 pagesBsce Quarantine Reviewer Diagnostic Exams PDFLaurence CervoNo ratings yet

- Fractured Fairytale Unit-Year 7 Leah 2012Document12 pagesFractured Fairytale Unit-Year 7 Leah 2012api-111350055No ratings yet

- Perceptual Mapping with Multidimensional ScalingDocument70 pagesPerceptual Mapping with Multidimensional Scalingpankaja_16No ratings yet