Professional Documents

Culture Documents

Acdb FQP

Uploaded by

Anonymous vcadX45TD7Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acdb FQP

Uploaded by

Anonymous vcadX45TD7Copyright:

Available Formats

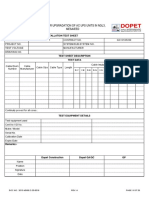

DOC NO : FQP/ELCTRICAL/ACDB/17

Standard Field Quality Plan For ACDB PANEL

APD Name Signature

SDM Name Signature

SKT Name Signature

0 Revision Date

Prepared By

Reviewed By

Approved By

DOC NO : FQP/ELCTRICAL/ACDB/17

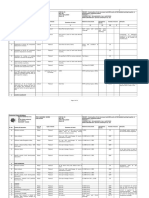

AREVA T & D (India) Limited Name of document :- FQP FOR ACDB PANEL WORKS Name of Client:Name of project:Name of Sub-contractor:Issued on : Rev : 0 Reference no:FQP/ELECTRICAL/ACDB/17

Standard Field Quality Plan for ACDB Panel.

S.NO.

1 1.1

CHARACTERISTICS/ITEM

INSTRUMENT

TYPE OF CHECK

QUANTUM/ FREQUENCY OF CHECK

REF. DOC. & ACCEPTANCE STANDARD

FORMAT OF RECORDS

REMARKS

RECEIPT AND STORAGE RECEIPT OF MATERIALS Check for Manufacturer's name as per Purchase Order, 1.11 Name Plate details / Details as per the test certificates / Delivery Challan. Check supply of accessories / Loose supply items (if 1.12 any)

Visual Visual

100% 100%

Delivery Challan & Packing List Packing List / BOQ

SIR/ACDB /01 SIR/ACDB /01 If Yes, Report immediately to Project Manager

1.13 Visual examination for damage.

Visual

100%

No Damages

SIR/ACDB /01

1.2

STORAGE OF MATERIALS Ensure that the material is stored on raised wooden platform to avoid direct contact with ground / Moisture Ensure that the material is stored in systematic manner rating wise for easy removal Ensure that different accessories / loose supply material Visual Visual

1.21 1.22

100% 100%

Instruction Mannaul Standard engg. Practice do

SIR/ACDB /01 SIR/ACDB /01

1.23 are stored separately section and size wise labelled and

tagged for easy identification

Visual

100%

do

SIR/ACDB /01

1.24

Ensure that all hardware are tagged & kept separately in racks size-wise for easy identification

Visual

100%

do

SIR/ACDB /01

SIR-Site inspection report, STR - Site Test Report, Mfr TC-Manufacture test certificate . This document shall be read in conjunction with Client's tech. spec., BOQ, Page 2 of 9 drawing s any other relevant document.

AREVA T & D (India) Limited Name of document :- FQP FOR ACDB PANEL WORKS Name of Client:Name of project:Name of Sub-contractor:Issued on : Rev : 0 Reference no:FQP/ELECTRICAL/ACDB/17

Standard Field Quality Plan for ACDB Panel.

S.NO. 2 2.01 2.02 2.03 2.04 2.05 2.06 2.07 2.08

3 3.1 3.2 3.3 3.4 3.5

CHARACTERISTICS/ITEM PRE INSTALLATION Check name plate details of the ACDB Panel with drawing / BOQ Check size & type of hardware / accessories required as per the drawing / BOQ Ensure that no physical damage to ACDB Panel body /insulator etc. is observed. Ensure that avialbility of proper foundation and floor. Check the lay out drawing with panel drawing for access to the location and clearences from the wall for panel. Check Matching of floor / hole on ACDB Panel, and mounting foundation. Ensure availability of necessary tools &, tackles, crane & sling for lifting of ACDB Panel etc. Ensure that room ventilation and area lighting available.

INSTRUMENT

TYPE OF CHECK

QUANTUM/ FREQUENCY OF CHECK 100% do do do

REF. DOC. & ACCEPTANCE STANDARD Drawing / BOQ do

FORMAT OF RECORDS

REMARKS

Visual Visual Visual Visual

SIR/ACDB/02 SIR/ACDB/02 SIR/ACDB/02 SIR/ACDB/02

Visual Visual Visual

do do do

Erection Drawings

SIR/ACDB/02 SIR/ACDB/02 SIR/ACDB/02

INSTALLATION

Check Rating Plate details Check Verticality of equipment on support structure & Leveling Check the Earth bus connection at two different point Check the clearences between phases and phase to earth Check the temporary blocking of movable parts are removed including relay.

Visual Visual Visual Visual Visual

100% do do do do

GA Drawing

SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03

do do do

Manufacturer instruction manual

SIR-Site inspection report, STR - Site Test Report, Mfr TC-Manufacture test certificate . This document shall be read in conjunction with Client's tech. spec., BOQ, Page 3 of 9 drawing s any other relevant document.

AREVA T & D (India) Limited Name of document :- FQP FOR ACDB PANEL WORKS Name of Client:Name of project:Name of Sub-contractor:Issued on : Rev : 0 Reference no:FQP/ELECTRICAL/ACDB/17

Standard Field Quality Plan for ACDB Panel.

S.NO.

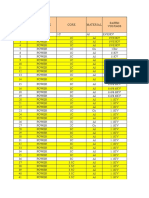

3.6 3.7 3.8 3.9 3.10 3.11 3.12 3.13 3.14 3.15 3.16 3.17 3.18 3.19 3.20 3.21 3.22 3.23

CHARACTERISTICS/ITEM

Check the tightness of bus bar joints terminal joints at breaker fixed pads in switchgear panels. Check the inter panel bus bar alignment is OK in switchgear panel. Check all bus bar supprot insulator and bus bar insulation in the panel. Clean the bus bar duct thoroughly and ensure that all component of bus duct are installed as per approved drawing. Check all wiring of circuit breaker and its fixed chasis are as per drawing Check all limit switches,auxiliary switches,micro switches are mounted and aligned properly. Ensure that power and control cables are terminated with proper ferruling Ensure correct sizes of cable are used and properly tagged. Check for proper ratings of fuses. Check healthiness of fuses, links, MCBS, Switches, indication lamps, push buttons, space heater & illumination circuit. Check the CT and PT circuits are as per drawing. Check the wires are dressed & routed properly. Check cables are supported properly Check the healthiness of AC & DC supply Check the metering circuit Check the polarity of ammeter, voltmeter etc. Check space heater for continuity Check indicating lamps rating and their circuits and ensure their colours are in order

INSTRUMENT

TYPE OF CHECK Visual Visual Visual Visual

QUANTUM/ FREQUENCY OF CHECK do do do do

REF. DOC. & ACCEPTANCE STANDARD

_ _ Schematic drawing. Manufacturer instruction manual Schematic drawing.

FORMAT OF RECORDS SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03

REMARKS

SIR/ACDB/03

do Visual Visual Visual Visual Visual Visual Visual Measurment Measurment Measurment Measurment Visual do do do do do do do do do do do do do do do do do do do do do do do do SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03

Multimeter Multimeter Multimeter Multimeter

SIR-Site inspection report, STR - Site Test Report, Mfr TC-Manufacture test certificate . This document shall be read in conjunction with Client's tech. spec., BOQ, Page 4 of 9 drawing s any other relevant document.

AREVA T & D (India) Limited Name of document :- FQP FOR ACDB PANEL WORKS Name of Client:Name of project:Name of Sub-contractor:Issued on : Rev : 0 Reference no:FQP/ELECTRICAL/ACDB/17

Standard Field Quality Plan for ACDB Panel.

S.NO.

3.24 3.25 3.26 3.27 3.28 3.29 3.30 3.31 3.32 3.33 3.34 3.35 3.36 3.37

CHARACTERISTICS/ITEM

Check door alignment Check door lock facility Check panel to panel bolting for tightness Check cleanliness of the board. Check function of all switch fuse units Check rating of all fuses Checked for broken gIass, switch handle, lamp cover elc. Check the completeness of supply Ensure Glanding of external cables Ensure blanking of unused cable entry holes Ensure proper sealing and locking arrangement of panel door Ensure removal of top and side blanking plates, if applicable Provide danger board ,rubber mat ,etc,at required location. Check the auto changeover if any.

INSTRUMENT

TYPE OF CHECK Visual Visual Visual Visual Visual Visual Visual Visual Visual Visual Visual Visual Visual

QUANTUM/ FREQUENCY OF CHECK do do do do do do do do do do do do do

REF. DOC. & ACCEPTANCE STANDARD do do do do do do do Drawing / BOQ

GA Drawing

FORMAT OF RECORDS SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03 SIR/ACDB/03

REMARKS

do do do do

Schematic drawing.

4 4.1 4.2 4.3 4.2 4.4 IR Value test

TESTING

Megger Test Kit Test Kit Test Kit Test Kit

Measurment Measurment Measurment Measurment Measurment

100% do do do do

Test Report Test Report Test Report Test Report Test Report

STR/ACDB/01 STR/ACDB/01 STR/ACDB/01 STR/ACDB/01 STR/ACDB/01

Bus Bar contact resistance test. Commissioning check Protection relays and schemes test.

Carry out all tests as per Client Specification or AREVA'S standard test format.

SIR-Site inspection report, STR - Site Test Report, Mfr TC-Manufacture test certificate . This document shall be read in conjunction with Client's tech. spec., BOQ, Page 5 of 9 drawing s any other relevant document.

AREVA T & D India Limited STANDARD SITE INSPECTION RECORD OF ACDB WORKS RECEIPT AND STORAGE INSPECTION GENERAL INFORMATION Project Name: Project Ref Customer PO Ref MDCC NO: LR NO. TRUCK NO INVOICE NO NO OF PAKAGES. RECEIPT 1 1.1.1 Receiving Inspection All items are received with respect to following delivery challans: Delivery challan nos. 1.1.2 Documents Instruction Manual Test Certificate Applicable instructions. 1.2 Visual Examination Shortages and damages checked w.r.t packing list. Shortages and damages. Material verification report no. 1.3 Proper storage All items are stored properly. Specific instruction from manufacturer on the wooden packing crates/instruction manual regarding storage (Outdoor/lndoor/Semicovered) of any individual item to be followed strictly. Remarks: Yes/No. Received/Not received Received/Not received Form No. SIR/ACDB /01 FQP ref. No. FQP/ELECTRICAL/ACDB/17 Equipment SI. No. Rating Voltage Level Make: Location/Bay Sh. 1 Total Sh. 1

REMARK

Performed by Agency Name Date

Verified by Agency Name Date

Accepted by Agency Name Date

AREVA T & D India Limited STANDARD SITE INSPECTION RECORD OF ACDB WORKS Form No. SIR/ACDB /04 TESTING GENERAL INFORMATION Project Name: Project Ref Customer PO Ref FQP ref. No. FQP/ELECTRICAL/ACDB/17 Equipment SI. No. FQP ref. No. Rating Voltage Level Make: Location/Bay 4.1 GENERAL INSPECTION Ensured all devices and fittings are mounted and not physically damaged. Verified Mimic on ACDB panels as per the station layout, if any. Checked earthing of ACDB panel earth bus. 4.2 CIRCUIT DIAGRAM TEST Panel wiring checked as per wiring diagram using a multimeter or continuity tester including alarm system . Verified interpanel wirings and bus wire interconnections (where applicable) as per wiring diagrams and schematics. Checked rating of fuses and also checked soundness of fuses and links. 4.4 AUXILIARY POWER SUPPLY TEST Applied rated AC supply voltages at the incoming supply terminals in the panel and switched on the supply ON/OFF switches withstood. 4.5 OPERATIONAL TEST OF FITTINGS ON THE PANEL Checked for operation of Interior Illumination lamp, Space heaters, Thermostat,socket outlet supply, switches etc. in the panel. 4.6 FINAL DOCUMENT REVIEW Inspection record of Installation & equipment testing checked for completeness & approval. 4.7 Carry out all tests as per Client Specification or AREVA'S standard test format. Remarks: Sh. 1 Total Sh. 1

Performed by Agency Name Date

Verified by Agency Name Date

Accepted by Agency Name Date

AREVA T & D India Limited STANDARD SITE INSPECTION RECORD OF ACDB WORKS

Form No. SIR/ACDB /01 PRE-INSTALLATION / INSTALLATION VERIFICATION GENERAL INFORMATION Project Name: Project Ref Customer PO Ref FQP ref. No. FQP/ELECTRICAL/ACDB/17 Equipment SI. No. Rating Voltage Level Make: Location/Bay 2 2.1 2.2 2.3 2.4 2.5 2.6 PRE-INSTALLATION CHECKS Checked availability of GA drawings and supplier's instruction manual / Test Procedure. Checked availability of materials as per B0Q / and drawings. Checked equipment foundaiton is properly levelled as per foundation civil drawing and channel, bolts etc.are installed as per drawing. Checked name plate details of the ACDB Panel with drawing / BOQ Checked size & type of hardware / accessories required as per the drawing / BOQ Ensured that no physical damage to ACDB Panel body /insulator etc. is observed.

Sh. 1 Total Sh. 1

2.7 Ensured that room ventilation and area lighting is available. Remarks:

Performed by Agency Name Date

Verified by Agency Name Date

Accepted by Agency Name Date

AREVA T & D India Limited STANDARD SITE INSPECTION RECORD OF ACDB WORKS Form No. SIR/ACDB /01 FQP ref. No. FQP/ELECTRICAL/ACDB/17 Equipment SI. No. Rating Voltage Level Make: Location/Bay Sh. 1 Total Sh. 1

PRE-INSTALLATION / INSTALLATION VERIFICATION GENERAL INFORMATION Project Name: Project Ref Customer PO Ref 3 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 3.10 3.11 3.12 3.13 3.14 3.15 3.16 3.17 3.18

INSTALLATION CHECKS

Checked Rating Plate details Checked verticality, alignment and leveling of support structure, fixing and tightening of foundation fasteners and sequence of erected panel. Ensured connection of earthbus of all panels through coupling links and connection to station earth. Checked and replace broken glass, switch handle,lamp cover etc. if any. Checked compeleteness of supply.

Checked the clearences between phases and phase to earth Checked the temporary blocking of movable parts are removed including relay. Checked the tightness of bus bar joints terminal joints at breaker fixed pads in switchgear panels. Checked the inter panel bus bar alignment is OK in switchgear panel. Checked all bus bar supprot insulator and bus bar insulation in the panel. Clean the bus bar duct thoroughly and ensure that all component of bus duct are installed as per approved drawing. Checked all wiring of circuit breaker and its fixed chasis are as per drawing Checked all limit switches,auxiliary switches,micro switches are mounted and aligned properly.

Checked glanding of all external cables entering the panel. Checked blanking of all unused cable entry holes after completion of cabling as per cable schedule. Checked for proper sealing and locking arrangement of panel doors. Checked that top and side blanking plates have been removed, if applicable. Ensured correct sizes of cable are used and properly tagged.

Checked the polarity of shunt, ammeter, voltmeter etc. 3.19 3.20 Checked availability of all catalogues / Equipment manual Remarks:

Performed by Agency Name Date

Verified by Agency Name Date

Accepted by Agency Name Date

You might also like

- Switch Yard ErectionDocument274 pagesSwitch Yard Erectionkishorebodhale86% (29)

- Final Work Instructions - Electrical ErectionDocument116 pagesFinal Work Instructions - Electrical ErectionBuggy App100% (2)

- Lvac Switch Gear SpecsDocument18 pagesLvac Switch Gear Specsljklksdfsjkjjsdf9974No ratings yet

- Upgrade AC UPS Units in QatarDocument1 pageUpgrade AC UPS Units in QatarmeeNo ratings yet

- FQPDocument9 pagesFQPtushar647No ratings yet

- Ipc Co 00 Itp 005 - Rev.0 Electrical Earthing WorksDocument9 pagesIpc Co 00 Itp 005 - Rev.0 Electrical Earthing WorksTony PhungNo ratings yet

- Lighting Philosphy NTPCDocument8 pagesLighting Philosphy NTPCHarpreet SinghNo ratings yet

- Appendix-I Field Quality Plan For Transmission LinesDocument20 pagesAppendix-I Field Quality Plan For Transmission LinesKapil Mishra100% (1)

- Electrical LV Panel Form ClassificationDocument2 pagesElectrical LV Panel Form Classificationjlcheefei9258No ratings yet

- 400 KV Switchyard Testing ScheduleDocument2 pages400 KV Switchyard Testing ScheduleBedabyas_dehury100% (2)

- TBEA ENERGY PROPOSED VENDOR LISTDocument4 pagesTBEA ENERGY PROPOSED VENDOR LISTAnonymous vcadX45TD7No ratings yet

- FQP GeneralDocument21 pagesFQP GeneralgaladrialNo ratings yet

- Installation, Testing and Jointing of LT and HT Power Cables Up To 33 KVDocument7 pagesInstallation, Testing and Jointing of LT and HT Power Cables Up To 33 KVanjum araNo ratings yet

- Commissioning LT SwitchgearDocument13 pagesCommissioning LT Switchgearvikivarma147100% (1)

- 33 KV VCB Panel Crompton Greaves CGL CG Power SolutionsDocument16 pages33 KV VCB Panel Crompton Greaves CGL CG Power SolutionsRAKESH CHANDRA PATRANo ratings yet

- 132 KVDocument32 pages132 KVWan Zamani Wan AbdullahNo ratings yet

- Electrical SubstationsDocument137 pagesElectrical SubstationsKuntal SatpathiNo ratings yet

- QAP ASSURANCE PLANDocument4 pagesQAP ASSURANCE PLANsasikumarNo ratings yet

- CVT Site Test Report: Capacitive Voltage TransformerDocument7 pagesCVT Site Test Report: Capacitive Voltage TransformerkamarajkanNo ratings yet

- Global Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelDocument10 pagesGlobal Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelTHULASI RAMNo ratings yet

- BOQ For 66KV AIS EquipmentDocument14 pagesBOQ For 66KV AIS EquipmentAhmed Said GhonimyNo ratings yet

- Standard Inspection and Test Plan ITP No: 904 Emergency Diesel GeneratorDocument5 pagesStandard Inspection and Test Plan ITP No: 904 Emergency Diesel GeneratorZaid RNo ratings yet

- Inspection Procedure For Unit Transformer PDFDocument13 pagesInspection Procedure For Unit Transformer PDFsingha980% (1)

- LV Panel ChecklistDocument1 pageLV Panel ChecklistvaradharajanNo ratings yet

- Before Dispatch Before Dispatch On The Day of Receipt at The Earliest After Receipt. Design, Engineering Standard DocumentsDocument24 pagesBefore Dispatch Before Dispatch On The Day of Receipt at The Earliest After Receipt. Design, Engineering Standard Documentsnarinder100% (1)

- COMMNG-ELEC-043 HT Motor PrecommissioningDocument6 pagesCOMMNG-ELEC-043 HT Motor PrecommissioningsantoshkumarNo ratings yet

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Document4 pagesFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 pagesFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005No ratings yet

- Electrical Erection ChecklistDocument59 pagesElectrical Erection ChecklistMohan Babu100% (2)

- Electrical Pre-Commissioning ProtocolsDocument85 pagesElectrical Pre-Commissioning ProtocolsAlok NayakNo ratings yet

- 06.fqp-Cabling and Earthing MDocument20 pages06.fqp-Cabling and Earthing Msamwel kariukiNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestDocument24 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestabderrahmaneNo ratings yet

- Request For Inspection (Rfi) : OperationDocument3 pagesRequest For Inspection (Rfi) : OperationMohd Jamal Mohd MoktarNo ratings yet

- QAP - LT Panel PDFDocument8 pagesQAP - LT Panel PDFAkshay Ajay100% (2)

- Emax ACBDocument280 pagesEmax ACBFreddy SuhartonoNo ratings yet

- Ref FQP ErectionDocument12 pagesRef FQP ErectionSaurabh HimkarNo ratings yet

- Erection BOQ SaranDocument339 pagesErection BOQ SaranBudoy SmithNo ratings yet

- Checklist For Erection of USSDocument3 pagesChecklist For Erection of USSsasikumarNo ratings yet

- Copper For BusbarsDocument104 pagesCopper For BusbarsKhaled Salahul Den100% (1)

- SOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSDocument159 pagesSOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSVikas SinghNo ratings yet

- Item description and quality checks for 11kV VCB panelDocument5 pagesItem description and quality checks for 11kV VCB panelARUNKUMARANNANBHEDANo ratings yet

- Waaree Energies LTD Post-Commissioning Checklist For 3kwroof Top ProjectDocument8 pagesWaaree Energies LTD Post-Commissioning Checklist For 3kwroof Top ProjectvvrrdyNo ratings yet

- Grounding Works ITP Inspection PlanDocument2 pagesGrounding Works ITP Inspection PlanElisco Pher SalmasanNo ratings yet

- PM Installation Method of The M&E WorksDocument27 pagesPM Installation Method of The M&E WorksXozanNo ratings yet

- 2 ++Switchyard+erection+for+400kVDocument56 pages2 ++Switchyard+erection+for+400kVracing.phreakNo ratings yet

- EARTHING - Wp-ODocument11 pagesEARTHING - Wp-OTarun GodiyalNo ratings yet

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- FQP CONDUITING, WIRING and LIGHTING FIXTURESDocument1 pageFQP CONDUITING, WIRING and LIGHTING FIXTURESPramod Kumar YadavNo ratings yet

- Ac Panel Test ReportDocument14 pagesAc Panel Test ReportUtku Can KılıçNo ratings yet

- SEC-EOA Site Test ReportDocument9 pagesSEC-EOA Site Test ReportmaheshknmNo ratings yet

- Current Transformer Testing SWP: 1. Purpose and ScopeDocument9 pagesCurrent Transformer Testing SWP: 1. Purpose and ScopeDEADMANNo ratings yet

- Project Quality Assurance Volume-IIIDocument11 pagesProject Quality Assurance Volume-IIISantosh KumarNo ratings yet

- 5 Clamps Connectors 220 400kv SsDocument12 pages5 Clamps Connectors 220 400kv SsJaswanth SaiNo ratings yet

- Tender No: 1/2011 - Amran Project: SubstationDocument5 pagesTender No: 1/2011 - Amran Project: SubstationMais AlyanNo ratings yet

- 16950s01 HV Testing ProceduresDocument1 page16950s01 HV Testing ProceduresVICTOR JOSE VILORIANo ratings yet

- Pre-Commissioning Formats for TransformerDocument19 pagesPre-Commissioning Formats for TransformerBalaji DevathaNo ratings yet

- Enclosed Bus Bar Electric DistributionDocument6 pagesEnclosed Bus Bar Electric DistributionRaul Cacchione100% (1)

- SF6 Insulated Metal-Enclosed Switchgear Installation and Maintenance GuideDocument18 pagesSF6 Insulated Metal-Enclosed Switchgear Installation and Maintenance GuideGANIM100% (1)

- JKR Specification For Low VoltageDocument55 pagesJKR Specification For Low VoltageSiddiq Rahim100% (1)

- IMS 448-EQCL - Transformer Installation Checklist Rev01Document1 pageIMS 448-EQCL - Transformer Installation Checklist Rev01zhangjieNo ratings yet

- ITP Work DownDocument5 pagesITP Work DownMuralimohan Pandian100% (1)

- Check List For Testing: Equipment Needed To Be TestedDocument2 pagesCheck List For Testing: Equipment Needed To Be TestedKarthik EvilordNo ratings yet

- Switch Yard REVISEDocument28 pagesSwitch Yard REVISEPratheek ReddyNo ratings yet

- Kammadanam-Check List For 33or11KV SubstationsDocument12 pagesKammadanam-Check List For 33or11KV SubstationsHarsha SagarNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Method Statement For Testing & Commissioning of Central Battery SystemDocument6 pagesMethod Statement For Testing & Commissioning of Central Battery SystemBabuNo ratings yet

- 8 Field Quality PlanDocument18 pages8 Field Quality PlanRamaKrishna ANo ratings yet

- Description: Test Procedure For ACDB Distribution Panel Index Ref: ACDB 1Document3 pagesDescription: Test Procedure For ACDB Distribution Panel Index Ref: ACDB 1Islam El-kadyNo ratings yet

- Appendix-2 (POWER PANEL Test Report)Document2 pagesAppendix-2 (POWER PANEL Test Report)hafed baccoucheNo ratings yet

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- 02 13 Section LightingSystemRev05Document33 pages02 13 Section LightingSystemRev05Sanj PandeyNo ratings yet

- Commissioning Checks for LV Load Panel at King Abdul-Aziz AirportDocument3 pagesCommissioning Checks for LV Load Panel at King Abdul-Aziz Airporteswaran005No ratings yet

- ACE Pilot User GuideDocument109 pagesACE Pilot User GuideEnrique Tejada FarfanNo ratings yet

- 1400 Kva DG SetDocument1 page1400 Kva DG SetAnonymous vcadX45TD7No ratings yet

- Energy Reading March-17 CompareativeDocument64 pagesEnergy Reading March-17 CompareativeAnonymous vcadX45TD7No ratings yet

- OHL DRG - Annexure CDocument8 pagesOHL DRG - Annexure CAnonymous vcadX45TD7No ratings yet

- 33 KV Multifunc Meter - 33KV SBDocument2 pages33 KV Multifunc Meter - 33KV SBAnonymous vcadX45TD7No ratings yet

- ChecklistDocument13 pagesChecklistAnonymous vcadX45TD7No ratings yet

- Transformer Efficiency and Regulation CalculationDocument1 pageTransformer Efficiency and Regulation CalculationAnonymous vcadX45TD7No ratings yet

- 000411034202Document1 page000411034202Anonymous vcadX45TD7No ratings yet

- Shift SH Engr MAYDocument1 pageShift SH Engr MAYAnonymous vcadX45TD7No ratings yet

- Checklist IslandingDocument2 pagesChecklist IslandingAnonymous vcadX45TD7No ratings yet

- To Whom So Ever It May ConcernDocument2 pagesTo Whom So Ever It May ConcernAnonymous vcadX45TD7No ratings yet

- Turbine Performance Curves Midrex Stage 1 & 2Document15 pagesTurbine Performance Curves Midrex Stage 1 & 2Anonymous vcadX45TD7No ratings yet

- Adhar LinkDocument1 pageAdhar LinkAnonymous vcadX45TD7No ratings yet

- SMS SLDDocument1 pageSMS SLDAnonymous vcadX45TD7No ratings yet

- Checklist IslandingDocument2 pagesChecklist IslandingAnonymous vcadX45TD7No ratings yet

- Digital Motor Protection Relays: Electronic Protection Type Up To 60A With Micro Controller Unit & Digital Display PartDocument13 pagesDigital Motor Protection Relays: Electronic Protection Type Up To 60A With Micro Controller Unit & Digital Display PartAnagha Deb100% (1)

- Satya Exp - CertificateDocument1 pageSatya Exp - CertificateAnonymous vcadX45TD7No ratings yet

- Commissioning Certificate 4561001627Document1 pageCommissioning Certificate 4561001627Anonymous vcadX45TD7No ratings yet

- Balance Items of TowerDocument2 pagesBalance Items of TowerAnonymous vcadX45TD7No ratings yet

- Circuit Breaker BomDocument4 pagesCircuit Breaker BomAnonymous vcadX45TD7No ratings yet

- Elbo ApplicationDocument2 pagesElbo ApplicationAnonymous vcadX45TD7No ratings yet

- Switchyard - Cable YardDocument11 pagesSwitchyard - Cable YardAnonymous vcadX45TD7No ratings yet

- Tasklists MDS 11-1-16Document20 pagesTasklists MDS 11-1-16Anonymous vcadX45TD7No ratings yet

- Improving Island Detection with Enhanced Vector Shift RelayingDocument4 pagesImproving Island Detection with Enhanced Vector Shift RelayingPablo ArancibiaNo ratings yet

- TR#3Document12 pagesTR#3Anonymous vcadX45TD7No ratings yet

- 2 RPM Sources and Sinks MNMDocument29 pages2 RPM Sources and Sinks MNMRohit VyasNo ratings yet

- Sub Station Design EngineerDocument3 pagesSub Station Design EngineerAnonymous vcadX45TD7No ratings yet

- Ge Shunt ReleaseDocument4 pagesGe Shunt ReleaseAnonymous vcadX45TD7No ratings yet

- SDSADocument32 pagesSDSAfreeware freeNo ratings yet

- Busbar Trunking Systems Technical OverviewDocument8 pagesBusbar Trunking Systems Technical Overviews525497No ratings yet

- Busway 2012 CatalogDocument156 pagesBusway 2012 CatalogCarlos LunaNo ratings yet

- Catalogo Blindobarra Siemens PDFDocument52 pagesCatalogo Blindobarra Siemens PDFSebastian MartinezNo ratings yet

- Euroload Changeover Switch Technical SpecificationsDocument10 pagesEuroload Changeover Switch Technical SpecificationsSUBHONo ratings yet

- Busbar Calculation: Design RulesDocument8 pagesBusbar Calculation: Design Rulesavishai04No ratings yet

- Project Report Latest - BinDocument48 pagesProject Report Latest - Binselva rajaNo ratings yet

- Cable & Busbar - LegrandDocument2 pagesCable & Busbar - LegrandAshish MulikNo ratings yet

- PIX-36 Operation MANUAL PDFDocument32 pagesPIX-36 Operation MANUAL PDFpatel chandramaniNo ratings yet

- 4 GHA Presentation Englisch SE Nov2011Document49 pages4 GHA Presentation Englisch SE Nov2011ahmed aliNo ratings yet

- Back Feeding ProcedureDocument4 pagesBack Feeding ProcedureranowijayaNo ratings yet

- Abb UniairDocument11 pagesAbb UniairVanessa HoustonNo ratings yet

- Bu1 PDFDocument31 pagesBu1 PDFGilberto MejíaNo ratings yet

- Fuzhou Tianyu Electric Co., LTD.: KYN31-12 Armored Metal-Enclosed Switch CabinetDocument26 pagesFuzhou Tianyu Electric Co., LTD.: KYN31-12 Armored Metal-Enclosed Switch CabinetRusman LumbantoruanNo ratings yet

- GBM-GBC ManualDocument26 pagesGBM-GBC ManualKittiphan LungkeeNo ratings yet

- HPB IEC Copper PDFDocument13 pagesHPB IEC Copper PDFkulaseraNo ratings yet

- Abb 1677859211Document43 pagesAbb 1677859211Mohamed ElsayedNo ratings yet

- Al-Balqa Applied University Faculty of Engineering TechnologyDocument79 pagesAl-Balqa Applied University Faculty of Engineering TechnologyMohammedSaadaniHassaniNo ratings yet

- Compact Bus Duct System GuideDocument15 pagesCompact Bus Duct System GuidemahmoudNo ratings yet

- Application of Busbars in High Power Spacecrafts: February 2014Document7 pagesApplication of Busbars in High Power Spacecrafts: February 2014MANGAL KUMAR MOHAPATRANo ratings yet