Professional Documents

Culture Documents

MQP

Uploaded by

Aniket SankpalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MQP

Uploaded by

Aniket SankpalCopyright:

Available Formats

Project Number: CAB-MQP-0619 Reducing Free Play in an Automotive Steering System A Major Qualifying Project Report Submitted to the

Faculty of the Worcester Polytechnic Institute in partial fulfillment of the requirements for the Degree of Bachelor of Science in Mechanical Engineering by Matthew Fulmer

______________________________ Date: 4 / 30 / 2009

Keywords: 1. steering system 2. free play 3. automobile

Approved:

____________________________ Prof. Christopher A. Brown, Advisor

The objective is to design three methods for reducing free play in an automotive steering system. Existing mechanical steering systems are flawed because they attempt to use interference to make up for the gradual onset of free play. The current system combines an increase in steering torque and a reduction in free play in a giveand-take fashion. This project attempts to work around that problem by coming up with several design solutions that should reduce the risk of free play. One design involves a pinion that uses rollers instead of gear teeth, in order to decrease friction. Another design eliminates the mechanical gearbox and uses hydraulics to steer the vehicle. A third design is similar to the previous one, but instead employs an electromechanical servo to operate the system.

Table of Contents

Abstract Introduction Objective Rationale State-of-the-Art Approach Methods Roller Pinion Hydraulic Electromechanical Testing Optimization Discussion Conclusion Bibliography

2 4

19 24 27 29 30

Introduction The objective of this project is to design three methods for reducing free play in an automotive steering system. This objective is worth pursuing because the issue of steering system free play is a real problem in the modern automotive industry. It is near the top of the statistical list of most common steering failures. Strictly speaking, steering gear problems is the number one issue at 1.8 percent, and free play comes in second at 1.7 percent (Limpert 1982). If and when undue steering motion occurs, the drivability of the vehicle decreases. Whether driving on back roads or on the freeway, the performance of the vehicle is noticeably reduced. It can also throw the front end out of alignment, which is hard on the wheel bearings, tires, and suspension. In a worstcase scenario, reducing free play can even reduce the risk of sudden catastrophic failure of major steering components. By improving the design and reducing the free play, the driving experience is thus safer and more precise. The cause of free play which I focused on was the gearbox, consisting of the rack and the pinion. When the unit is assembled, the gears are installed tightly to prevent the early onset of free play. However, this interference tactic also increases the necessary steering torque, which is a disadvantage for the customer. Obviously, there is a level of give-and-take with this approach, because it eventually contributes to the exact problem that is being solved in the long run. This issue will be addressed later in this section. The current steering system for most vehicles is the rack and pinion, which uses a mechanical gearbox to steer the vehicle (Nice 2000). Axiomatic design has been used to form a design decomposition, to allow my later designs to meet the functional

requirements of this system. The other purpose of this decomposition is to show that there is a design flaw which results in parameter coupling, which I will soon discuss. The decomposition is shown below in Table 1. DP0: Rack and pinion system DP1: Increase interference DP2: Decrease interference

FR0: Transmit steering input X FR1: Regulate free play development X X O O O O O FR2: Control steering torque X X O O O O O FR3: Accept steering input O O X O O O O FR4: Transmit input to system O O O X O O O FR5: Convert input to linear motion O O O O X O O FR6: Transfer work to wheels O O O O O X O FR7: Steer front wheels O O O O O O X TABLE 1: Decomposition of a current steering device In summary, the rotary input to the steering wheel is transferred down the steering shaft, through several universal joints, and arrives at a pinion gear. The turning of the pinion pushes the rack gear left and right, which in turn manipulates a set of tie rods. The tie rods operate the steering knuckles, onto which the front wheels are mounted. With all of these design parameters in place, the wheels are successfully steered as a result of the drivers input (Nice 2001). To facilitate my design process, a rack and pinion steering system was created in SolidWorks. Specifically, it provided me with a foundation for additional designs. Some 5

DP6: Tie rods

Current Steering Device

DP7: Steering knuckles

DP5: Rack and pinion

DP4: Steering shaft

DP3: Input device

of the dimensions were reverse-engineered from an existing steering unit for real-life accuracy, such as the size of the housing, size of the rack, and distance between the rack teeth. From that information, I was also able to determine that the pinion gear had five teeth, simply by counting the number of rack teeth which were displaced during one revolution of the steering shaft. In addition, the displacement of the rack told me that I was dealing with a pinion gear that had a diameter of 0.725 inches including the teeth, and just 0.425 inches without the teeth. Figure 1 shows an image of the initial model, with a label for each of the design parameters from the decomposition in Table 1.

FIGURE 1: Current steering device This model, like all of my models, is an assembly of many separate components. By constructing the model in this manner, I was able to animate the assembly to see how it would behave as a real-life steering device. Also, in this and every instance of my solid models, the blue component represents the stationary frame of the vehicle, and the steering system moves relative to this component. In the following sections, several

images of my new designs will be shown. Note that some of these images will show a tighter view of the system than is shown in Figure 1. By creating a number of new steering system designs, I am attempting to decouple steering torque and free play. This problem is illustrated in Figure 2 and further described below.

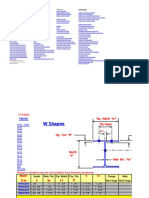

FIGURE 2: Coupling issue This diagram presents two possible scenarios for constructing a current steering device, both of which are flawed. Case one involves the installation of a tightly-built gearbox. This feature reduces the risk of an early onset of free play by toughening up the system right from the beginning. Once free play begins to appear, it will be stifled by the proximity of the gear teeth, which will minimize it as much as possible. However, this scenario results in a larger steering torque, which is a disadvantage for the customer. In addition, free play is likely to occur just as quickly, because the tightness of the gearbox increases the friction between the gears. This results in a steering system whose purpose is defeated because of the way it is designed. 7

Case two takes a different approach by designing the gearbox with less extreme interference. This decision also brings the steering torque back to a relatively normal level. But once again, free play is no less inevitable. By building a gearbox which may already contain some gaps, the onset of free play will occur just as quickly as with case one. My goal is to develop better methods for reducing free play which can decouple the aforementioned design parameters. My designs focus on this task by addressing the problems of interference and friction in the gearbox, which are the main causes of free play and excessive steering torque.

Methods To solve the problem before me, I designed three conceptual methods for reducing free play. The first design involved modifying several components of the existing system, without making any large-scale changes. The second and third designs stemmed from an assumption that the gearbox was the issue, and that it would make sense to install a different system for moving the linkage.

Roller Pinion Steering System The first design, instead of a conventional pinion gear, uses a new piece of hardware in its place. Dubbed the roller pinion, the device consists of six rollers which are installed on a Ferris wheel-style frame. To reduce friction, the rollers ride on the frame using a set of small cylindrical bearings. The frame mounts directly to the end of the steering shaft, and the solid shaft tunnel provides additional strength for the component. This sub-assembly of the steering system is shown on the next page in Figure 4. The conception of the roller pinion stemmed from the fact that rolling contact results in an almost complete elimination of friction (Esposito 1975). As the roller pinion is turned by an input from the driver, the rollers are inserted into the rack in the same manner that a round gear meshes with a straight gear. Accordingly, the rack is modified to have semi-circular notches in order to accommodate the rollers. An appropriate set of geometric parameters can be developed to allow the roller pinion to mesh with the rack without binding up. Also, to make use of the gear housing from the standard rack and pinion system, the roller pinion is designed to occupy the same

space as a conventional pinion gear. The layout of the system is shown below in Figure 3. Two of the design parameters are located outside of the boundaries of the image, but they are the same as those shown in Figure 1.

FIGURE 3: Roller pinion steering device

FIGURE 4: Roller pinion with rollers installed

10

A major shortcoming of the current steering system is that free play and steering torque are coupled in a give-and-take fashion. The roller pinion steering system decouples those features because of the way that the pinion is designed. This decoupling is represented in the axiomatic design decomposition for this system, shown below in Table 2. DP0: Rack and roller pinion system DP1: Friction reduction with rollers DP2: Adjust diameter of pinion

DP5: Rack and roller pinion

Roller Pinion Steering Device

FR0: Transmit steering input X FR1: Regulate free play development X O O O O O O FR2: Control steering torque O X O O O O O FR3: Accept steering input O O X O O O O FR4: Transmit input to system O O O X O O O FR5: Convert input to linear motion O O O O X O O FR6: Transfer work to wheels O O O O O X O FR7: Steer front wheels O O O O O O X TABLE 2: Decomposition of a roller pinion steering device The gearbox in this system does not need to be unusually tight, because contact friction between the gears is not an issue. It only needs to be tight enough to ensure that the roller pinion and the rack mesh properly. As a result, the steering torque is merely based on the size of the pinion. With a smaller pinion, the steering torque will

DP7: Steering knuckles

DP4: Steering shaft

DP3: Input device

DP6: Tie rods

11

decrease, and vice versa. Thus, the steering torque and free play parameters have successfully been decoupled with this new design.

Hydraulic Steering System The second steering system design takes a different approach to reducing the issue of free play. Instead of attempting to reduce the friction in the gearbox, the gears have been removed altogether. The steering wheel input from the driver is transmitted electronically to an onboard computer. The computer then converts the information into electrical signals which operate a pair of hydraulic pumps. In turn, the pumps drive a pair of hydraulic cylinders which move the rack left and right. From there, the vehicle is steered using the same tie rods and steering knuckles as the current steering system. This ensures that the dimensions of the linkage are the same, allowing this and the current steering system to have identical steering geometry. A solid model of the hydraulic steering device is shown below in Figure 5. As usual, all of the design parameters are labeled.

FIGURE 5: Hydraulic steering device

12

To assess the functionality of the hydraulic steering system, a new axiomatic design decomposition was constructed. Another purpose of the decomposition is to show that the coupling from Table 1 has been resolved by this new system. Elimination of the gearbox is one feature which allows this system to decouple steering torque control and free play development, as shown on the next page in Table 3. With gear contact friction being an issue in the current steering system, removing the gearbox effectively eliminates that problem. The other contributing feature of this system, the force-feedback steering wheel, will be discussed shortly. DP0: Hydraulic system DP1: Eliminate gearbox DP2: Adjustable force-feedback DP4: Drive-by-wire control unit

Hydraulic Steering Device

FR0: Transmit steering input X FR1: Regulate free play development X O O O O O O FR2: Control steering torque O X O O O O O FR3: Accept steering input O O X O O O O FR4: Transmit input to system O O O X O O O FR5: Convert input to linear motion O O O O X O O FR6: Transfer work to wheels O O O O O X O FR7: Steer front wheels O O O O O O X TABLE 3: Decomposition of a hydraulic steering device This design solution can be compared to a fly-by-wire aircraft, which uses hydraulics in order to move its control surfaces during flight. For added safety, this

DP7: Steering knuckles

DP6: Rack and tie rods

DP5: Hydraulic rams

DP3: Input device

13

steering system also exercises the aeronautical concept of redundancy. The presence of two pumps and two hydraulic cylinders allows the driver to maintain control if one side of the system malfunctions. If there is a problem, the system will isolate the damaged hardware and provide the driver with the ability to get home safely. Currently, there is a wide range of hydraulic devices on the market which could drive a steering system of this caliber. Not only are they adequately powerful, but also of the proper dimensions. The National Fluid Power Association manufactures a hydraulic cylinder, part number 62205K756, which can provide the necessary force at one hundred pounds per square inch of hydraulic pressure. With one cylinder pushing at 491 pounds and one pulling at 412 pounds, the combined total would be 903 pounds. This is twenty-eight pounds more than the minimum required steering force while the vehicle is at rest (see page 19). The steering force can easily be increased by boosting the hydraulic pressure of the system. The cylinders are also available in many stroke lengths, but we would use a stroke of six inches to fulfill our minimum requirement of 5.2 inches (McMaster-Carr 2009). The steering wheel would be equipped with a force-feedback feature to give the driver more confidence when operating the vehicle. Otherwise, the driver would have limited ability to judge the feel of the road when making steering corrections, primarily at highway speeds. This feedback feature would be electronic and fully adjustable, to allow the driver to modify the steering torque to suit his or her preferences. Forcefeedback is a feature common to gaming steering wheels, which means that the technology would be easy to adapt. This technology is another key feature which allows the hydraulic steering device to decouple the steering torque control and free

14

play development in Table 3. With no mechanical link between the steering wheel and linkage, there is no risk of having large steering torque. With this being the final link in the decoupling process, my hydraulic steering system succeeds in addressing the fundamental problem which is being faced. Of note, this steering device operates in a similar fashion to a number of patented systems. Quoting the abstract of one such system, the patented device has a hydraulic steering cylinder for displacement of the steerable wheels. It also features an electronic control and analysis device, which functions in the same manner as my drive-by-wire feature (Diekhans 1998). In another example, the steering system includes a hydraulic pump for generating hydraulic pressure, a hydraulic fluid reservoir, a hydraulic cylinder, and a control valve arrangement (Edson 2006).

Electromechanical Steering System The third steering system design takes a similar approach to the hydraulic system. By eliminating the gearbox and using other means to move the steering linkage, free play development and steering torque control are successfully decoupled. This steering system uses a gear-reduction motor to drive the steering linkage. As with the hydraulic setup, the steering wheel is linked to the rest of the system electronically. Inputs are converted into a source of power for the motor, which is connected to a transfer plate via an armature. The bearing between the armature and the transfer plate allows for rolling contact only, a method that has already been exercised by the roller pinion system. The transfer plate is directly mounted to the rack bar, which is pushed side to side and steers the vehicle. Though the preceding

15

description may seem complicated, the system itself is not, as shown in Figure 6 on the next page.

FIGURE 6: Electromechanical steering device This steering system is another design which decouples the steering torque from the gradual onset of free play. In similar fashion to the hydraulic steering system, the electromechanical system uses a drive-by-wire setup, removing the mechanical link between the steering wheel and linkage. This system also utilizes the same forcefeedback system as was described for the hydraulic system, to allow the driver to adjust the steering torque to his or her liking. In addition, the gearbox of old has been removed, and thus, gear interference is a non-existent parameter. With the gearbox gone, there is also no chance of gear contact friction which could gradually increase the free play of the system. With all of these new features in place, the electromechanical steering system succeeds in decoupling the steering torque from free play development. This is the exact issue which the design has been created in order to solve. The features which contribute to the success of this system are shown in the axiomatic design decomposition on the next page. Table 4 also shows that the

16

remainder of the steering system still meets the same requirements as those of the current steering device. DP0: Electromechanical system DP1: Eliminate gearbox DP2: Adjustable force-feedback

DP6: Plate, rack and tie rods

DP5: Gear reduction motor

DP4: Drive-by-wire system

Electromechanical Steering Device

FR0: Transmit steering input X FR1: Regulate free play development X O O O O O O FR2: Control steering torque O X O O O O O FR3: Accept steering input O O X O O O O FR4: Transmit input to system O O O X O O O FR5: Convert input to linear motion O O O O X O O FR6: Transfer work to wheels O O O O O X O FR7: Steer front wheels O O O O O O X TABLE 4: Decomposition of an electromechanical steering device As with the hydraulic steering system, there is a variety of equipment on the modern market which could drive a device such as this one. Almost any motor can be equipped with the necessary armature, so the only constraint is the torque of the motor. The distance between the motor shaft and the bearing on the transfer plate varies from two to four inches, so the maximum required torque is 3500 pounds per inch, which is a lot. While shopping around, I was able to locate a motor whose gearbox is rated for 2400 pounds per inch of torque. This amount is then augmented by a torque multiplier value, some of which were in the hundreds (MotorTech 2007). Though I was not able to

DP7: Steering knuckles

DP3: Input device

17

locate a specific motor for this system, I was able to recognize that there are gearmotors available which have the necessary torque rating for this device. Also, because many gear-motors are capable of spinning at a triple-digit number of revolutions per minute, steering quickness is not an issue. The driver will still be capable of reacting to danger as quickly as he or she would with a mechanical steering system. The next step of the project is to analyze certain components of the new steering systems, to see if they can stand up to the demands of vehicular control.

18

Testing The steering system designs in this project did not reach the construction stage. As a result, the analysis involved the use of finite element analysis on some of the key components. These components included the pinion from design one, the rack bar from design two, and the rack bar and transfer plate from design three. Appropriate materials were chosen for each part prior to analysis. To obtain an applied load value for finite element analysis, I measured the steering input force for a real automobile. A torque wrench was attached to the steering column of a Porsche 944, which uses a manual rack and pinion steering system similar to the one in the introduction. With the car at rest, the shaft was turned through one complete revolution, and the setting of the wrench was increased each time it clicked. This occurred up to a torque of twenty-one foot-pounds, after which the wrench did not click. This gave me an experimental force with which to test my solid models. With this force value in hand, it was a simple matter of calculating the torque at the pinion. When I reverse-engineered the physical steering device, I calculated that the inner radius of the pinion (without the teeth) was 0.213 inches, and the outer radius (with the teeth) was 0.363 inches. Therefore, the average distance from the center of the pinion to the face of any tooth is 0.288 inches. By doing a simple torque conversion, twenty-one foot pounds is the same as 875 pounds at 0.288 inches, or 437.5 pounds at each front steering knuckle. These are reasonable values, considering that the tires have to be twisted around while they are being pushed into the pavement by the weight of the car. In order to interpret the results of finite element analysis, an appropriate lower limit must be determined for the factor of safety. This number is a ratio of the breaking

19

strength of a material over the applied load. For example, if the load is exactly the same as the breaking strength, the factor of safety is one. If the load is half of the breaking strength, the factor of safety is two. Because of the sudden loads and load reversals taking place in a steering system, the factor of safety should be at least equal to two. Depending on the value for each of the analyzed components, they may or may not be considered as candidates for design optimization. First, I performed finite element analysis on the rack bars from the hydraulic and electromechanical steering systems. In both of these components, the two mounting points have to withstand a combined force of 875 pounds. So, 437.5 pounds was applied laterally to each location, and the components were restrained where the tie rods are installed at the ends. This configuration is shown in Figure 7 below. Both components were tested using AISI 1020 steel as the material, and the analyses were carried out.

FIGURE 7: Rack bar FEA setup The hydraulic rack bar passed with a minimum factor of safety of 8.26, making it many times stronger than necessary. The electromechanical rack bar also passed finite element analysis, with a minimum factor of safety of 3.11. On the basis of these values, 20

both of the components are good candidates for optimization, and that process is described in the next section. The electromechanical transfer plate was also tested using finite element analysis. The load and restraints were positioned as shown below in Figure 8, with the same color configuration as used in Figure 7.

FIGURE 8: Transfer plate FEA setup AISI 1020 was used as the material once again, but the result yielded a minimum factor of safety of just 1.94. This value is a bit lower than two, so a quick adjustment was made, changing the material to Alloy Steel. This metal is both lighter and stronger than AISI 1020, so it should benefit the component in both of those ways. The result was a new minimum factor of safety of 3.42, which is an acceptable result. This component, like the rack bars, will be optimized in the next section. Finally, the roller pinion was subjected to finite element analysis. Because of the diminutive size of this component, Alloy Steel was chosen as a strong starting material. The load and restraint locations are shown in Figure 9 on the next page, once again using the same color configuration as Figure 7. Note that the restraints occur on both ends of the pinion, and not just the end which is visible. They also continue through the central tunnel inside of the component, because this is the location of the steering shaft in the full assembly.

21

Figure 9: Roller pinion FEA setup Unfortunately, the roller pinion did not pass finite element analysis. Even with Alloy Steel as the material, the minimum factor of safety was just 0.08 which is unacceptably low. The weak areas of the component are shown below in Figure 10.

FIGURE 10: Roller pinion with FOS < 2 indicated in red 22

As you can see, the downfall of this component is that the spokes, as well as the end plates, are too thin. In order for this design to cope with 875 pounds of force, it will have to be optimized. Otherwise, it will break as soon as the driver attempts to steer the vehicle. This finite element failure is an excellent justification for optimization. The only difference is that unlike the other three parts, this one will have to be strengthened rather than weakened.

23

Optimization For each of the four critical components which were analyzed using finite element analysis, the minimum factor of safety was determined. For three of these components, this value came out higher than needed. This result meant that the components were much stronger than necessary, and could be made lighter and cheaper without sacrificing their functionality. This is accomplished through a process called optimization. The two rack bars had excellent minimum factors of safety. The rack from the hydraulic steering system had an outstanding minimum value of 8.26, and the one from the electromechanical steering system had a minimum value of 3.11. The reason why one of these parts had a higher factor of safety is that the mounting points for the hydraulic rams are more substantial than the mounting brackets for the transfer plate. As a result, I decided to optimize both racks in a way that would not affect those areas. Because these components are almost identical, they can be optimized in many of the same ways. I decided to hollow out both of them, leaving the outer shells and mounting points the same. I removed a three-quarter inch diameter cylinder from the inner center of the hydraulic rack, and a half-inch diameter cylinder from the electromechanical rack. This brought the hydraulic bars factor of safety to 5.92 and the electromechanical bars factor of safety to 2.67. Because the former of these values was still high, I changed the material to AISI 304, which lowered the minimum factor of safety to 3.48. This value is much closer to the desired value of two, and therefore more practical for a steering system setup. In terms of weight savings, both components started at around 5.7 pounds, and were lightened to 2.8 pounds and 4.4

24

pounds, respectively. Thus, these optimizations had the benefit of reducing both weight and volume of material in both of their respective steering systems. The transfer plate from the electromechanical device was also considered for optimization. With a factor of safety of 3.42, the component is capable of having its frame reduced without compromising the safety of the component. The extent of the reduction is shown below in Figure 11.

FIGURE 11: Transfer plate optimization On the original transfer plate, the perpendicular distance between the cutouts and the long edges was one half of an inch. On the optimized version of the model this distance was halved, to one quarter of an inch. The rounding fillets inside the cutouts are strengthening features of the plate, and thus were kept in the design. The final minimum factor of safety came out at 2.39, which is far closer to the intended value of two. Also of note, the starting weight of the plate was 1.8 pounds, and the weight after optimization was just 1.3 pounds using the same. The roller pinion was the last component to be scheduled for optimization. Unfortunately, the 0.08 factor of safety did not bode well for the eventual success of the device, and those doubts were soon justified. Because of the specific function of the roller pinion, the only areas that could be modified were the end plates and the central tube. Even when the thickness of those areas was doubled, the design failed the finite element analysis once again. With a final factor of safety of just 0.12, this component 25

will require more extensive optimization. The most likely scenario would involve an upscaling of the roller pinion, possibly to twice its original size. To test this theory, I doubled the dimensions of the roller pinion, and performed the finite element analysis again. Using the same Alloy Steel material, I determined a new minimum factor of safety of 0.51. This may still be low, but it is a surprising result. Having increased the dimensions by a factor of two, I managed to increase the factor of safety by a multiple of four. If this trend holds true, the component will only have to be doubled in size one more time to meet the design requirements. In the end, three of my four critical components passed finite element analysis and were successfully optimized. The fourth component will need more work, but conceptually speaking, it is a definitely a design idea that is worth pursuing.

26

Discussion At the beginning of this project, an objective was established. That objective has clearly been met with the three new steering system designs which I have presented. All of them still succeed in performing the duty of a current steering device, while also addressing the fundamental problem of coupling between steering torque and free play development. The hydraulic and electromechanical steering systems certainly managed to decouple these problems, but they also presented another safety-related difficulty. If there is ever a power failure in the vehicle, the motor and hydraulic pumps will shut down, resulting in a total loss of steering control. This shortfall requires that some type of redundant safety mechanism be integrated into the vehicles electrical system. Once that mechanism is in place, the vehicle will operate safely. This consideration is also a good example of why the current steering system, despite its shortcomings, is the most reliable of the bunch. If the car quits, the steering continues to work. The roller pinion steering system, of course, carries on that tradition by using a mechanical steering shaft. However, it also presents a unique challenge with its tiny pinion. Because this component did not pass FEA, it needs to be strengthened in order to work without breaking. This is no simple task, since the minimum factor of safety was only 0.08 which is more than ten times less than unity. A number of different metals were tested, but the results stayed the same. In the end, the best and most reliable way to improve the strength of the roller pinion is to make it bigger. If the entire steering system is scaled up by a multiplicative factor, the factor of safety will surely increase. However, this will also increase the torque required to steer the vehicle, which in turn

27

can be remedied by increasing the length of the steering knuckles. This was one of the situations which I encountered over and over again in the design process - whenever one problem was solved, another coupled issue presents itself. This design process was efficient in its use of foundation components. Though each design had unique features, all of the steering systems were based on the same basic frame. All of the linkages used the same geometry, and the rack housings were identical except for the eventual deletion of the gearbox. This consistency shows that such devices are easily able to be integrated into existing steering systems without sacrificing extra space. The only exception is the hydraulic system, which will take up more space because of its remotely-located pumps. They could also be quite heavy, but that is a problem which will be addressed by someone who undertakes the task of building such a device.

28

Conclusion Based on the results of my project, I can claim that it is possible to design methods for reducing free play in an automotive steering system. These designs are capable of decoupling the problematic link between steering torque and free play which exists in current steering systems. The designs can also be made to meet certain functional and structural requirements, meaning that they have real-world potential outside of a computer simulation.

29

Bibliography

Diekhans, Norbert. Electrohydraulic Steering System. CLAAS KGaA, assignee. Patent 6,067,782. 30 Jan 1998. USPTO. 21 Apr 2009 <http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&d= PALL&p=1&u=%2Fnetahtml%2FPTO%2Fsrchnum.htm&r=1&f=G&l=50&s1=606 7782.PN.&OS=PN/6067782&RS=PN/6067782> Edson, Joey D, et al. Electrically Acutated, Hydraulic Power Steering System. Fluid Routing Solutions, Inc, assignee. Patent 7,487,856. 30 Aug 2006. USPTO. 27 Apr 2009 < http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO2&Sect2= HITOFF&p=1&u=%2Fnetahtml%2FPTO%2Fsearch-bool.html&r=5&f=G&l=50 &co1=AND&d=PTXT&s1=%22rack+pinion+steering%22&OS=%22rack+pinion+s teering%22&RS=%22rack+pinion+steering%22> Esposito, Anthony. Machine Design. Columbus, OH: Charles E. Merrill Publishing Company, 1975. Limpert, Rudolf. Vehicle System Components: Design and Safety. New York, NY: John Wiley & Sons, 1982. McMaster-Carr. 2009. McMaster-Carr Supply Company. 27 Apr 2009. <http://www.mcmaster.com/#62205k756/=1n9x1o> MotorTech. 2007. Motor Technology, Inc. 27 Apr 2009. <http://www.motortech.com/ dcgearmotorHILG2_GI.htm> Nice, Karim. "How Car Steering Works." 31 May 2001. HowStuffWorks.com. <http://auto.howstuffworks.com/steering.htm> 19 Nov 2008. Nice, Karim. "How Gears Work." 16 Nov 2000. HowStuffWorks.com. <http://science.howstuffworks.com/gear.htm> 1 Dec 2008.

30

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Autonomous Dump Trucks System For Transporting and Positioning Heavy-Duty Materials in Heavy ConsDocument8 pagesAutonomous Dump Trucks System For Transporting and Positioning Heavy-Duty Materials in Heavy Cons2692rimmi5902No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Inspect & Service Braking SystemsDocument42 pagesInspect & Service Braking SystemsAnonymous VWlCr439No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Revised Syllabi of B.techDocument31 pagesRevised Syllabi of B.techAniket SankpalNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 08 Chapter 3Document23 pages08 Chapter 3Sahaya GrinspanNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Intelligent Control of Automotive Braking SystemDocument5 pagesIntelligent Control of Automotive Braking Systemashifashraf5No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ImpDocument214 pagesImpAniket SankpalNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- How To Open Nfo FilesDocument1 pageHow To Open Nfo FilesChiara DavidNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Xfmea DfmeaDocument9 pagesXfmea DfmeamaxlentiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Catalogo Maz Man Dump Truck Chassis 6x2Document2 pagesCatalogo Maz Man Dump Truck Chassis 6x2Aniket SankpalNo ratings yet

- IGC13 Final Rule BookDocument31 pagesIGC13 Final Rule Bookvk100No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Lowest Wholesale Prices on Stock Zinc and Steel Pillow Block BearingsDocument37 pagesLowest Wholesale Prices on Stock Zinc and Steel Pillow Block BearingsAniket SankpalNo ratings yet

- Braking Systems: Railway Technology Today 7Document0 pagesBraking Systems: Railway Technology Today 7Mohan Kumar SNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SKF Concentra Ball Bearing Units: True Concentric Locking, For Fast and Reliable MountingDocument28 pagesSKF Concentra Ball Bearing Units: True Concentric Locking, For Fast and Reliable MountingAniket SankpalNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Numericals For StudentsDocument45 pagesNumericals For StudentsAniket SankpalNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- FDR - Jasper Racing Trailing ArmDocument50 pagesFDR - Jasper Racing Trailing ArmAkshay TilekarNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Automobile Engg Lab VISemDocument39 pagesAutomobile Engg Lab VISemBibhuti BhusanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Braking SystemDocument96 pagesBraking SystemApril Showers100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- An Introduction To Brake SystemsDocument52 pagesAn Introduction To Brake SystemsrocknrollamarNo ratings yet

- New Microsoft Office PowerPoint PresentationDocument1 pageNew Microsoft Office PowerPoint PresentationAniket SankpalNo ratings yet

- X FamilyDocument23 pagesX FamilyAniket SankpalNo ratings yet

- Rolls-Royce Silver Cloud Workshop Manual Chapter on Braking SystemsDocument35 pagesRolls-Royce Silver Cloud Workshop Manual Chapter on Braking SystemsAniket SankpalNo ratings yet

- Ese ECMS2010 0054Document5 pagesEse ECMS2010 0054Aniket SankpalNo ratings yet

- AAM Applications Chassis Suspension 5 Brake SystemDocument12 pagesAAM Applications Chassis Suspension 5 Brake SystemAniket SankpalNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 800 wp008 - en PDocument8 pages800 wp008 - en PAniket SankpalNo ratings yet

- New Text DocumentDocument2 pagesNew Text DocumentAniket SankpalNo ratings yet

- New Text DocumentDocument2 pagesNew Text DocumentAniket SankpalNo ratings yet

- Testing The Bluetooth With 8051Document10 pagesTesting The Bluetooth With 8051Aniket SankpalNo ratings yet

- MQ303ADocument2 pagesMQ303APVPPPNo ratings yet

- DCC2011 BLUETOOTHinMicrocontroller W2FSDocument8 pagesDCC2011 BLUETOOTHinMicrocontroller W2FSAniket SankpalNo ratings yet

- To Find The Inverse Z Transform Of: %X (Z) Z/ (3z2-4z+1)Document3 pagesTo Find The Inverse Z Transform Of: %X (Z) Z/ (3z2-4z+1)Aniket SankpalNo ratings yet

- Understanding The Complexities of Designing Diaphragms in Buildings For EarthquakesDocument21 pagesUnderstanding The Complexities of Designing Diaphragms in Buildings For Earthquakesjunhe898No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Catalogo Repuestos YBR125DX 2008 ColombiaDocument58 pagesCatalogo Repuestos YBR125DX 2008 ColombiaadrielairaldoNo ratings yet

- 2019 - Uniflair Room Cooling BrochureDocument92 pages2019 - Uniflair Room Cooling BrochureJeff100% (2)

- Fluid and Fluid PropertiesDocument42 pagesFluid and Fluid PropertiesCIPETIPT Tool RoomNo ratings yet

- Volvo 242 244 245 Owners Manual 1976Document105 pagesVolvo 242 244 245 Owners Manual 1976Leif AndersonNo ratings yet

- OEM Viscosity Compensated Flowmeter Model VKA Specs & DetailsDocument2 pagesOEM Viscosity Compensated Flowmeter Model VKA Specs & Details王敏No ratings yet

- NVU Vertical Up-Blast Range BrochureDocument5 pagesNVU Vertical Up-Blast Range BrochurekirmaniNo ratings yet

- Sobek Endurance ToolsDocument14 pagesSobek Endurance ToolsAhmet KöseleciNo ratings yet

- OSHA safety standards and engineering reference sheetsDocument452 pagesOSHA safety standards and engineering reference sheetsobaniceNo ratings yet

- Hvac NotesDocument9 pagesHvac NotesMegha SinghNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Modal Analysis Example ExcelDocument1 pageModal Analysis Example Excelkaranbir123No ratings yet

- Catalogo SupcoDocument137 pagesCatalogo SupcoArmando Flores MatiasNo ratings yet

- Hyperbolic ShellsDocument42 pagesHyperbolic ShellshythamNo ratings yet

- 2018 1 X Y HamadaDocument28 pages2018 1 X Y HamadaGaurav Kumar ThakurNo ratings yet

- Properties of Natural Gas and Condensate SystemsDocument80 pagesProperties of Natural Gas and Condensate SystemsHashem HashemNo ratings yet

- Seahawk Cement Unit 2300 BHP AC Electric: Available OptionsDocument2 pagesSeahawk Cement Unit 2300 BHP AC Electric: Available Optionsbruce lianNo ratings yet

- Section 5 - Relief SystemsDocument22 pagesSection 5 - Relief Systemslulis171No ratings yet

- TTU Fittings Ttu Industrial Corp., LTD.: Manufacturer'S CertificateDocument1 pageTTU Fittings Ttu Industrial Corp., LTD.: Manufacturer'S CertificateMohamed RaafatNo ratings yet

- Welding DefectsDocument4 pagesWelding DefectsSD Recruiters100% (1)

- Suction-Specific Speed:: Questions and Answers About Pumping's Least Understood MeasureDocument5 pagesSuction-Specific Speed:: Questions and Answers About Pumping's Least Understood MeasureLuis Joel Ramos RamosNo ratings yet

- Pressure Testing ChecklistDocument3 pagesPressure Testing Checklistjerin100% (3)

- Diesel engine efficiency and power calculationsDocument11 pagesDiesel engine efficiency and power calculationsMarc Graham Nacua100% (1)

- Module 2Document59 pagesModule 2PSkotsNo ratings yet

- TSBDocument3 pagesTSBnoe dela vegaNo ratings yet

- FANUC Laser C1000-C6000 Operator's ManualDocument166 pagesFANUC Laser C1000-C6000 Operator's ManualTec PachucaNo ratings yet

- 7 - In. Posiset Thru-Tubing Plug (2 / - In. Od) : Description FeaturesDocument1 page7 - In. Posiset Thru-Tubing Plug (2 / - In. Od) : Description Featureshamed1725No ratings yet

- Thern Ta2 Air Winch PressDocument2 pagesThern Ta2 Air Winch PressKiat LimNo ratings yet

- Abrasive Wear Mechanisms PDFDocument9 pagesAbrasive Wear Mechanisms PDFRBZNo ratings yet

- Mastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressFrom EverandMastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressRating: 5 out of 5 stars5/5 (1)