Professional Documents

Culture Documents

Maintenance Task List

Uploaded by

iedmondCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Task List

Uploaded by

iedmondCopyright:

Available Formats

2011MaintenanceEventTaskList PUMPTASKLIST 1. Turn the pump HOA switch to the OFF position. 2.

Turn the pump circuit breaker the OFF position. 3. Lock out of pump circuit breaker by Safety Supervisor. Lock out tag to be signed and dated by Safety Supervisor. Use the red lock, the multi-lock hasp (optional) and the lock-out tag to lock out the pump breaker. 4. Turn pump HOA switch to the HAND position to verify the pump will not reenergize. 5. Verbalize Pump locked out. 6. Place pump HOA switch to the OFF position. 7. Place any other locks on pump circuit breaker as needed. 8. Unlatch the hook on the hoist from the parked position and extend the boom to the desired hole location (if hoist has not already been used for the mixer). 9. Reaching from the side of the platform attach the hook to the clevis on the pump. 10. Remove the pump from the slide rail using the hoist set the pump to the service floor pad work area with the pump in a vertical position. 11. Drain oil from the seal housing. Remove socket head drain plug (10 mm hex bit). Position funnel under drain plug and place other end in the drain pan and

12. 13.

14. 15.

lean the pump towards the drain pan to facilitate draining the oil. Hold at no more than a 45 for the entire drain time. Verbalize 10 second count (one-one thousand, two one-thousand etc). Replace nylon washer on oil drain plug (if red is removed, replace with white (natural) color coded washer and vice versa). Remove the pump volute Remove the pump volute by removing six (6) hex head bolts and lock washers (19 mm socket/wrench) and, using the hoist for the lift, pull the motor with the impeller attached out of the volute. If the volute sticks to the motor housing, use rubber mallet on the volute to release unit (6 or less above the mat). Lower the motor, seal housing and impeller on to the floor pad work area using the hoist. Lay the motor, seal housing and impeller on to its side with hoist still attached to expose the impeller bolt.

ts020211

Page1

PUMPTASKLISTCONT 16. Remove the impeller. Restrain impeller from turning for next step (leather work gloves must be worn by this team member). Remove impeller bolt, special lock washers and bushing (17 mm socket and 6 extension). Remove double shrouded impeller using the two (2) gray pry bars supplied. 17. Remove the motor from the seal housing. Remove three (3) socket head bolts and washers (8 mm hex bit). Lift the motor out of the seal housing with the hoist. Place the motor on the floor pad and lay it on its side. 18. Remove the plastic simulated EBS cartridge seal by hand and set on the table of the work area where the stainless steel EBS seal is to be rebuilt. 19. Rebuild the stainless steel EBS cartridge seal on the seal rebuild table. Remove the three (3) drive pins. Separate the cartridge halves and remove seal faces. Install new faces (if red is removed, replace with silver (natural) color coded faces and vice versa). Press cartridge halves together by hand and insert the three (3) drive pins. Verbalize Seal rebuilt. Return the plastic simulated EBS cartridge seal back to the pump to be reinstalled. 20. Reinstall the plastic simulated EBS cartridge seal. Place seal on shaft o-ring end first. Use the aluminum seal installation tool and rubber mallet to seat o-ring into top of motor housing with 2-3 sharp blows. 21. Reinstall seal housing. Use the hoist to lift the motor. Align seal housing so that the drain plug faces the platform edge closest to the pump when installed. Lower motor onto seal housing and replace bolts and washers. Tighten bolts to 25 ft-lbs with the torque wrench.

ts020211

Page2

PUMPTASKLISTCONT 22. Replace impeller. Lay the motor and seal housing on its side on the work area. Install the impeller with impeller bolt, lock washer, and bushing. Tighten impeller bolt to 30 ft-lbs (41 Nm) with the torque wrench. 23. Simulate refilling the seal housing with 0.7 liters of oil. Verbalize 8 oil dispenser pump strokes. 24. Install drain plug in seal housing. Tighten to 10 ft-lbs using the 3/8 torque wrench. 25. Replace volute. Use hoist to lift the motor with seal housing and impeller attached and lower into volute. Install six (6) double washers and six (6) hex head bolts. Tighten volute bolts in a cross pattern to 30 ft-lbs (41 Nm) with the torque wrench. 26. Using hoist, reinstall pump on to rail system. 27. Remove locks and tag. Remove all locks except the red lock. Remove Safety Supervisors red lock last. Remove the multi-lock hasp if used. 28. Turn pump circuit breaker to the ON position. Verbalize Pump breaker on. 29. Depress the pump moisture reset button. Verbalize Moisture probe reset. 30. Move the pump HOA switch to the AUTO position. Verbalize Pump in auto.

ts020211

Page3

MIXERTASKLIST 1. Turn the mixer HOA switch to the OFF position. 2. Turn the mixer circuit breaker the OFF position. 3. Lock out of mixer circuit breaker by Safety Supervisor. Lock out tag to be signed and dated by Safety Supervisor. Use the red lock, the multi-lock hasp (if needed or desired) and the lockout tag to lock out the mixer breaker. 4. Turn mixer HOA switch to the HAND position to verify the mixer will not reenergize. 5. Verbalize Mixer locked out. 6. Place mixer HOA switch to the OFF position. 7. Place any other locks on mixer circuit breaker as needed. 8. Unlatch the hook on the hoist from the parked position and extend the boom to the desired hole location (if hoist has not already been used for the pump). 9. Reaching from the side of the platform attach the hoist hook to the clevis on the mixer. 10. Remove the mixer from the slide rail using the hoist, rotate the unit 90 degrees and reinstall on the rail. 11. Place oil drain pan on floor under the pre-chamber and gearbox drain plugs. 12. Drain oil from pre-chamber. Remove socket head drain plug (when facing propeller, left side, front plug, 10 mm hex bit). Verbalize 10 second count (one-one thousand, two one-thousand etc). 13. Verbalize Oil is contaminated. 14. Replace nylon washer on pre-chamber oil drain plug (if red removed, replace with white (natural) color coded washer and vice versa). 15. Drain oil from gearbox (when facing propeller, left side, back plug). Remove socket head drain plug (10 mm hex bit). Verbalize 10 second count (one-one thousand, two one-thousand etc). 16. Verbalize Oil is clean. 17. Replace nylon washer on gearbox oil drain plug (if red is removed, replace with white (natural) color coded washer and vice versa). 18. Reinstall the pre-chamber and the gearbox drain plugs. Torque each drain plug to 10 ft-lbs using the 3/8 torque wrench. 19. Remove the propeller nose cone. Insert screwdriver into hole in nose cone. Turn to right to loosen (reverse threads). ts020211 Page4

MIXERTASKLISTCONT 20. Remove the propeller. Remove propeller bolt and flat washer (6 mm hex bit). Slide propeller off the splined shaft. 21. Remove the mechanical seal. Remove the steel mechanical seal cover by hand or with the aid of the rubber mallet. Remove the mobile portion of the mechanical seal by hand or with the cotter pin puller. Remove the stationary portion of the mechanical seal by hand or with the

22.

23.

24.

25.

26.

cotter pin puller (stationary face shall be drilled in two places, 180 degrees apart, so that the cotter pin puller may be used to assist removal). Install new mechanical seal (if red is removed, replace with silver (natural) color coded seal and vice versa). Push the new stationary face down the shaft with your hands (o-ring side of the seal should be facing the mixer). Push the new mobile face and tension spring down the shaft with your hands. Install the steel mechanical seal cover by hand. Replace the propeller. Slide propeller back on to the splined shaft. Thread propeller bolt with flat washer in the end of the shaft. Tighten to 10 ft-lbs with 3/8 torque wrench. Replace the propeller nose cone and tighten with hand to snug fit. Refill the gearbox with oil. Remove the gearbox fill plug (rear oil fill hole - top of mixer). Replace the two nylon washers (if red removed, replace with white (natural) color coded washer and vice versa). Fill the gearbox with 0.5 liters of oil, verbalize 5 pump strokes. Refill the pre-chamber with oil. Remove the pre-chamber fill plug (front oil fill hole, top of mixer). Replace the nylon washer (if red color coded washer is removed, replace with white (natural) or vice versa). Fill the pre-chamber with 1.2 liters of oil, verbalize 14 pump strokes. Using hoist, reinstall mixer back to original orientation.

ts020211

Page5

MIXERTASKLISTCONT 27. Remove locks and tags. Remove all locks except the red lock. Remove Safety Supervisors red lock last. Remove the multi-lock hasp if used. 28. Turn mixer circuit breaker to the ON position. Verbalize Mixer breaker on. 29. Depress the mixer moisture reset button. Verbalize Moisture probe reset. 30. Move the mixer HOA switch to the AUTO position. Verbalize Mixer in auto.

FINALTASKS 1. Complete question sheet for the pump (questions taken from 4 page study guide). 2. Return tools and supplies to their original position. 3. Return hoist to its starting position.

ts020211

Page6

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Introduction To Ethernet IPDocument43 pagesIntroduction To Ethernet IPiedmondNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- DL205 Power Requirements and DimensionsDocument2 pagesDL205 Power Requirements and DimensionsiedmondNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Industrial Internet of Things (IIoT) Impact On The Oil & Gas Industry Value ChainDocument16 pagesIndustrial Internet of Things (IIoT) Impact On The Oil & Gas Industry Value ChainiedmondNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- DL205 Power Requirements and DimensionsDocument2 pagesDL205 Power Requirements and DimensionsiedmondNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- OPC Data Manager ManualDocument50 pagesOPC Data Manager ManualiedmondNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Easy9 - EZ9ET24L Consumer Unit Specification SheetDocument1 pageEasy9 - EZ9ET24L Consumer Unit Specification SheetiedmondNo ratings yet

- Pt100sensoren eDocument4 pagesPt100sensoren eMuhammadRaihanNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Pt100sensoren eDocument4 pagesPt100sensoren eMuhammadRaihanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Business Traveller Africa BT105-July-2016Document68 pagesBusiness Traveller Africa BT105-July-2016iedmondNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- W03160en - Seat Leakage DetectionDocument4 pagesW03160en - Seat Leakage DetectioniedmondNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

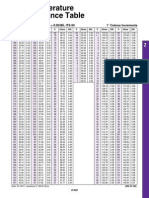

- For European Curve, Alpha 0.00385, ITS-90 1° Celsius IncrementsDocument3 pagesFor European Curve, Alpha 0.00385, ITS-90 1° Celsius IncrementsMary HarrisonNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Halogen FreeDocument8 pagesHalogen FreeMarko IvanečkiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Basic Process Control Systems Used For Safety Instrumented FunctionsDocument14 pagesBasic Process Control Systems Used For Safety Instrumented FunctionsLuc SchramNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Modular Greenhouse KitDocument2 pagesModular Greenhouse KitiedmondNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Migdcs Pp008 en eDocument4 pagesMigdcs Pp008 en eiedmondNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Echochange-Gateway Doku v10 e PDFDocument32 pagesEchochange-Gateway Doku v10 e PDFiedmondNo ratings yet

- Logix Hot Backup SolutionsDocument2 pagesLogix Hot Backup SolutionsiedmondNo ratings yet

- Basic Process Control Systems Used For Safety Instrumented FunctionsDocument14 pagesBasic Process Control Systems Used For Safety Instrumented FunctionsLuc SchramNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- HART Communication Made EasyDocument2 pagesHART Communication Made EasyiedmondNo ratings yet

- Modulair GreenhouseDocument4 pagesModulair GreenhouseiedmondNo ratings yet

- Modulair GreenhouseDocument4 pagesModulair GreenhouseiedmondNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- American Wire Gauge Conversion ChartDocument2 pagesAmerican Wire Gauge Conversion ChartiedmondNo ratings yet

- FactoryTalk View ME and PanelView PlusDocument2 pagesFactoryTalk View ME and PanelView PlusiedmondNo ratings yet

- The Internet of Things: Opportunities & ChallengesDocument17 pagesThe Internet of Things: Opportunities & ChallengesiedmondNo ratings yet

- 1756 Um523 - en PDocument186 pages1756 Um523 - en PMohamed ShebaNo ratings yet

- Conditions Min Typ Max Unit: +1 / 508 295 0771 Usa: +49 / 7731 8399 0 EuropeDocument1 pageConditions Min Typ Max Unit: +1 / 508 295 0771 Usa: +49 / 7731 8399 0 EuropeiedmondNo ratings yet

- Connecting To Allen-BradleyDocument16 pagesConnecting To Allen-Bradleycjutp86No ratings yet

- Courseware Sample by Lab-VoltDocument24 pagesCourseware Sample by Lab-VoltiedmondNo ratings yet

- PLC 4Document24 pagesPLC 4iedmondNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Dasar Dasar PLCDocument65 pagesDasar Dasar PLCAgie FernandezNo ratings yet

- Fleet ManagementDocument8 pagesFleet ManagementDiana LorenaNo ratings yet

- Dedi Kristiawan: Personal DetailDocument5 pagesDedi Kristiawan: Personal DetaildedyNo ratings yet

- Verilog Interview Questions & AnswersDocument6 pagesVerilog Interview Questions & AnswersKrishna Saroja SankaNo ratings yet

- Electricity Scavenger HuntDocument1 pageElectricity Scavenger HuntksonicoNo ratings yet

- Vista 128BPT Program ManualDocument72 pagesVista 128BPT Program ManualyalmanzaNo ratings yet

- Hybrid or Standard?: Why The Urge To "Go Green"Document20 pagesHybrid or Standard?: Why The Urge To "Go Green"Tyler McPhersonNo ratings yet

- Husky Air Assignment 5 and 6Document15 pagesHusky Air Assignment 5 and 6varunkalra6No ratings yet

- Hoisting Systems ExplainedDocument21 pagesHoisting Systems Explainedsparda94No ratings yet

- Environmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96Document22 pagesEnvironmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96scribdledeeNo ratings yet

- Sectional Results: Sofistik 2020Document28 pagesSectional Results: Sofistik 2020ec05226No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Air Conditioning Fact SheetDocument6 pagesAir Conditioning Fact SheetrjchpNo ratings yet

- Part # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalDocument1 pagePart # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalmnvijaybabuNo ratings yet

- Whatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Document6 pagesWhatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Kuningan NesiaNo ratings yet

- RT 50Document2 pagesRT 50valentin prouteauNo ratings yet

- Axle, Front - Differential and Carrier - Jee0123251Document3 pagesAxle, Front - Differential and Carrier - Jee0123251Husi NihaNo ratings yet

- Wabco Air Suspension Compressor RepairDocument3 pagesWabco Air Suspension Compressor RepairgarcolNo ratings yet

- Structural Analysis of Beams Using Moment Distribution MethodDocument15 pagesStructural Analysis of Beams Using Moment Distribution MethodneetuNo ratings yet

- YaskawaDocument375 pagesYaskawaCristian IozsaNo ratings yet

- Electric Electronics BrochureDocument8 pagesElectric Electronics BrochurejolualNo ratings yet

- Formulation - Beton - Dreux - Gorisse Good - Fr.enDocument9 pagesFormulation - Beton - Dreux - Gorisse Good - Fr.enRabnawaz ImamNo ratings yet

- MEITRACK MVT100 User Guide V2.4Document19 pagesMEITRACK MVT100 User Guide V2.4MeitrackNo ratings yet

- Thermostats and Dial Thermometers PDFDocument252 pagesThermostats and Dial Thermometers PDFAsep MustopaNo ratings yet

- Zimbabwe Engineer ITDG Small Scale Production of Fired Clay BricksDocument8 pagesZimbabwe Engineer ITDG Small Scale Production of Fired Clay BricksdkataleNo ratings yet

- Fisher Poistioner CatalogueDocument12 pagesFisher Poistioner CatalogueUsama IqbalNo ratings yet

- Introduction To Manufacturing Engineering: Lecturer: Ass - Prof.Dr. Nguyen Tien DuongDocument14 pagesIntroduction To Manufacturing Engineering: Lecturer: Ass - Prof.Dr. Nguyen Tien DuongTOAN Du100% (1)

- Quick Union Reference Tables: Pressure Control EquipmentDocument1 pageQuick Union Reference Tables: Pressure Control EquipmentMiguel FNo ratings yet

- Optimal Design & Operation of RO Systems 3-Day SeminarDocument10 pagesOptimal Design & Operation of RO Systems 3-Day SeminarasankandessNo ratings yet

- Ricoh 2090Document832 pagesRicoh 2090cosmin176100% (1)

- c600 17lookinsideDocument6 pagesc600 17lookinsideИван МинчевNo ratings yet

- E380b PDFDocument12 pagesE380b PDFanaNo ratings yet

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)