Professional Documents

Culture Documents

Nicholson

Uploaded by

Imhotep72Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nicholson

Uploaded by

Imhotep72Copyright:

Available Formats

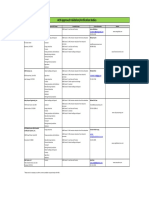

Pottery Making in Upper Egypt: An Ethnoarchaeological Study Author(s): Paul Nicholson and Helen Patterson Source: World Archaeology,

Vol. 17, No. 2, Ethnoarchaeology (Oct., 1985), pp. 222-239 Published by: Taylor & Francis, Ltd. Stable URL: http://www.jstor.org/stable/124512 Accessed: 05/11/2010 15:45

Your use of the JSTOR archive indicates your acceptance of JSTOR's Terms and Conditions of Use, available at http://www.jstor.org/page/info/about/policies/terms.jsp. JSTOR's Terms and Conditions of Use provides, in part, that unless you have obtained prior permission, you may not download an entire issue of a journal or multiple copies of articles, and you may use content in the JSTOR archive only for your personal, non-commercial use. Please contact the publisher regarding any further use of this work. Publisher contact information may be obtained at http://www.jstor.org/action/showPublisher?publisherCode=taylorfrancis. Each copy of any part of a JSTOR transmission must contain the same copyright notice that appears on the screen or printed page of such transmission. JSTOR is a not-for-profit service that helps scholars, researchers, and students discover, use, and build upon a wide range of content in a trusted digital archive. We use information technology and tools to increase productivity and facilitate new forms of scholarship. For more information about JSTOR, please contact support@jstor.org.

Taylor & Francis, Ltd. is collaborating with JSTOR to digitize, preserve and extend access to World Archaeology.

http://www.jstor.org

Pottery making in Upper Egypt:an ethnoarchaeological study

Paul Nicholson and Helen Patterson

Introduction expediThis paper deals with the work of the 'BallasPottery Project', an ethnoarchaeological tion to the potting village of Deir el-Gharbi,UpperEgypt. The villageis situated some 628 kin, south of Cairo, and about 40 km, north of Luxor by road or river,and is on the west bank of the Nile (Figs. 1 and 2). The site was visited briefly by one of us (P.T.N.) in 1983, while working for the British Mission at Tell el-Amarna(Middle Egypt) and the expedition, which undertook fieldworkin April 1984, was a result of that visit. The industry produces only one type of vessel, which is named after the nearby village of Ballds (hence the expedition name), an amphoralike jar used primarily for carryingwater. These jars (pl. Baldlis) are made from a fme marl clay, extracted from the nearby hills of the western desert, which has a white surface when fired. This clay source appearsto have been similarto those proknown since antiquity and Pharaonicand Roman vessels, often of formns duced today, were almost certainly made there. A programmeof researchcurrentlyunderway should throw new light on this question. Although the village of Ballas lies some 5 kms away, the modern village of Deir el-Gharbiencompasses the remains of the ancient Palace site of Ballas,which was excavated by Reisnerin the middle of this century, and there is evidence of earlier occupation from the area at the Amratian and Gerzean(or NaqadaI and II c. 40003000 B.C.) cemetery at Ballds (Petrie and Quibell, 1895). It is even possible that the marl fabrics which began to appearin Gerzeantimes were of a Ballas/Deirel-Gharbiclay (Trigger, 1983, 33). The long established location of the site, along with the relatively simple technology employed by the potters,weremajorfactorsin our choice of the villageas a study area.In addition, although there have been severalethnographicstudies of potteries, (Balfet, 1966; Whitehouse, 1977; Gosden, 1982), these have tended to concentrate on smalleror simplerindustriesthan that described here. We felt that a study of the Ballas industry could offer a valuableinsight into a mode of pottery productionwhich Peacock has defined as 'a ruralnucleated industry' (Peacock, 1982, 9 and 42-3), comprisingindividual workshops grouped together 'to form a work has isolated more or less tightly clusteredindustrialcomplex'. Peacock using ethnographic rangeof high quality, the main features of such industries,which producea fairly standardized usually more specialized wares and rely heavily on the professional dealer for distribution. These characteristicsare clearly seen in the Ballds industry. However, although Peacock's World Archaeology Volume1 7No. 2 Ethnoarchaeology ? R.K.P. 1985 0043-8243/85/1702-222 $1.50/1

Pottery makingin UpperEgypt 223

N Alexandri

gi

\<

100

kms

Cairo

7

\0

50 MIS

\ <'~~~~~~~ Irrigated

SAUDI

/

~~~~ARABIIA

Minya E3El-

EGYPT

Oena Luxor

Red Sea

Aswan

SUDAN

Figure 1 Map of Egypt showing key towns and cities.

2Okns.

-___

I'

potteries at Deir el-Gharbi.

224

Paul Nicholson and Helen Patterson

analysis of production modes is very useful, he fails to discussin any depth how stich cindustries be in might reflected the archaeological record. Thus our main aimswere to recordthe industryin detail, preferablywith a full photographic record, and to examine its archaeologicalcorrelates (Binford, 1983). Besides an inl;erestin ceramic technology we wante.dto investigatesome of the social and economic aspects of the industry, and for this we were fortunate enough to be assisted on two occasions by Mr. Paul Blank of the University of Austin, Texas, who acted as interpreter.Throughour interpreter, as well as through informantsat a nearby school, we learnedthat the industrywas at a turning point, and was declining rapidly, for reasons which we will examine below. In view of this, we paid even greaterattention to its recording,not least because the industry has some quite unusualfacets.

In what follows the production process is described in chronological ord-r, anid the archae-

ological correlatesof each stage are discussed.

Mining One of the more unusual features of the industry at Deir el-Gharbiis thu ronethod of clay extraction, this takes the form of adit mining. The mines enter the hillsides at some little distance (about 40 minutes on foot) from the village, and are situated on the fringes of the western lesert. The mine entrances are marked by piles of rubble and occasion ly also by large piles of clay blocks awaiting transport to the village. The narrowentrance leads into a wide cavern partly filled with spoil and rubble, producinga tunnel'like effect. This branches out, each branchleadingoff into one or more huge galleries. It had been hoped that it might be possible to survey one of the galleries,but this proved impossible and it can only be stressedthat they are extremely largeiFrom collapsedexamples it seems that at the very least a small house could be fitted into some of them. The mines are of 'pit props' being employed anywhere.They rely purely on entirely unsupported, no formn the strength of the hard marl clay, for this reason mining is impossible during the winter months (December to mid March)taking place for only nine months of the year, for far of damp causing collapse. It is not unheard of for unexpected collapses to be fatal. The mines are also unlit except by candles, oil or gas lanternsand even these are few in number.This was one of the main obstaclesto any kind of surveying. Tim4 minersthemselvestold us that they had long ('for thousandsof years')been a prof ssion separate from that of the potters. Each group of miners snupplied specific potters bit did not belong to any particularworkshop, nor did they come from the same families as the potters. The miners had a distinct accent, difficult for even our fluent interpreterto follow, and were of a lower statuxs than the potters. The tools they use are very basic;an iron spike for use as a wedge, a steel mallet, and a pickaxe. The method of working is not so much to follow seams of clay, -for the hills are Iargely

of clay, but to avoid areasof lime includedamongthe deposits. A workingface is worked from top to bottom in step fashion, as in some stone quarries,by breakingoff sizeableblocks. Tfbhe blocks a.reloaded on to donkeys, which can be brought into the mine, or camelsfor transpor tation. Alternatively,the blocks are taken, by donkey, to the mine entranceand piled outside, where they are later collected by a tractor and trailer. This representsone of the few modern

Pottery makingin UpperEgypt

225

inroadsinto this otherwise,fairly traditionalindustry.The tractoris either owned, or borrowed, by only one group of miners and although it takes largerloads than do the animalsit cannot enter the mines, which is inconvenient. To the archaeologist,the mine itself would be obvious, given that it did not completely collapse, but traces of the miners would be far less evident. Each group of miners have what few tools they possess kept in undergroundcamps, along with spare lamps, fuel, and teamaking accessories.The camps might be detected by traces of the fires, used by some groups in food preparationratherthan a stove, and by scatters of food debris. It is unlikely that any tools would remain to be found at the camps. Also, because there are in total so few tools in the mines, and the area covered by mining is so large, the chances of recoverywould again be slim; except for chance finds of lost items, much would depend on how frequent collapses had been over former floor levels. The positions of lamps or candlescan sometimesbe seen by patches of sooting on the sides of the gallerynear the work face. There are no penningfacilities for the donkeys, which serve as a kind of 'pit porny',they are simply hobbled and taken back to the village when not in use. Their only traces are the inevitable dung and small heaps of foliage broughtin as fodder and later discarded. the miners received for their labours. It was extremely difficult to find out how mnuch However, it appearsthat for enough clay to make 1,000 medium sized Balalis, they received about fifty EgyptianPounds(EL 50).

Clay preparation Once at the village, the clay blocks are piled up around the workshop till required.There are aboutfifteen workshopsat Deir el-Gharbi and, althoughindependentlyowned they are clustered in groups of three to five aroundtheir respectiveclay puddlingpits and wells, with the kilns lying off to one side (Plate 1). Pairsof workshopsbuilt with one common wall, often with a window linking the two independent units, are quite usual. Each workshop has a work force comprisinga potter and three assistants,all male. The potter remainsat his wheel throughout the working day, while the three assistantscarry out a variety of tasks. Occasionallysome of the male children are seen to help. Although the women work in the fields, it is unheardof for a woman to be involvedin the potting industry,the work was too hard for them we were told. Before use, the large blocks of clay are reduced, by hammering,into smallerroughly fist sized lumps. They are then put into a stone lined soakingpit to be softened. The pits are about 50 cms deep and 2.5-3 m in diameter, and are connected by channels to a well. Despite its hard, rock-like appearance,the clay softens quite readily in water. When sufficiently soaked, the clay is trampled for 3 hours by two water buffalo and an assistant from the workshop (Plate 2). The 3 hour period consists of two 1?/2 hour sessions, the water buffalo being hired from the agriculturalists for this purpose. Any large pieces of lime which come to the notice of the assistantare removedat this stage. It is common to find one well being sharedby two workshops,and it is often unclearwhich features of the workshop yard belong to which workshop. This partly reflects the cooperation between groups of workers which exists except when there is good, brisk, business when competition is more marked. A plan of a workshop and its associated features is given in Figure3.

226

PaulNicholson and Helen Patterson

1 ~~~~~~~~~Kiln

I~ ~~ I'

Drying

Room

Workshop

-TT

r-

i-

;Clay

9Jla

Pit~~l

'F~

Scale L __

Weli Workshop ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ l

Figure 3 Plan of workshops and associated features.

For the archaeologist there would be little difficulty in recognizing that some form of industrial activity took place in these yard areas, even though the clay piles would probably have been removed. The pits and their associated well channels would be sufficient indication. However, determining that this had been a pottery workshop might be more difficult. The workshops are clustered on the edge of the settlement bordering on the desert. Potteries often have such locations (Peacock, 1982, 38) but so do other antisocial or unpleasant activities, such as tanneries. These latter also use pits. The density of broken sherds would be of no help, as very few are to be found in this area, certainly no more than in a domestic context. The surest way of determining the use of such yards would be by excavating the associated workshop, but even these are not unequivocal. If of course, there could be total excavation the kilns would be the obvious clue, but these are located even beyond the workshop and would be outside the range of all but the largest, or the problem orientated excavation, especially in times of limited finance.

Indoor clay preparation, and Stage I of vessel forming Once thoroughly trampled, clay is taken in armfuls, into the workshop (see Fig. 4 for plan of workshop), where it is spread in a roughly circular, low mound on the cobbled floor. During

Pottery makingin UpperEgypt

227

the aftemoon of each day this clay is trampled for about three hours and any remaininglime particlesremoved. Tramplingis an exhaustingjob, even for two skilled assistants.Thereis a set pattern in which the clay is turned and trampleduntil it is deemed sufficiently well prepared. At this point it is heaped up againstthe wall of the workshopwhereit adjoinsthe dryingroom; any surplusis placed againstthe wall near the entrance.The clay is usually coveredwith damp sack cloth to preventit from becoming too hard to work, especially importantwhen it is left overnight. The process of vessel forming begins in the afternoon, when the first part of each vessel is made. It should be recalledthat while all other operationsare continuing,in this case trampling, the potter and one assistantare busy producingthe vessels. The industryis very well organized and, despite its primitivenature,efficient. In the first stage, the assistantremovesfrom the pile of preparedclay a slab about 5 to 10 cm thick and the length of his arm.This he cuts from the face of the pile using his fingers,the clay being fairly soft. He takes the slab to the bench where he beginsto fold and kneadit ('wedge' it), much as describedby Birks (1975, 13-14). This is done on the work bench (mastaba) on a speciallybuilt sloping ramp.Ultimately,it is rolled on this into a tall cone (Plate 3). The ramp is dusted with chaff or ash to preventthe clay sticking.The cone is then slammedsmartly down on the flat surfacenext to the potter, in orderto compact it. The assistantskilfullyjudges if the cone is too tall, and if so nips off the surplusfrom the top, throwingit back onto the trampling floor. Whilstthe assistanthas been doing this, the potter has been making the previousvessel top which he now throws to the assistantwho carriesit into the drying room, located behind the potter. The potter sits the cone in the bucket-shapedwheel-headand increasesits speed by kicking the fly wheel more vigorously. He then begins to open up the cone and shape it into the shoulders, neck and rim of a vessel (Plate 4). The operation takes only two to three minutes, and during this time the next cone has been prepared.The bottom of the prepared vessel upper remains a solid lump of clay, untouched where it has been sitting in the wheelhead. In the dryingroom it stands on this lump. Vessels remainin the long drying room (Plate 5) until the potter has completed about 30. At this point, one of the assistants leaves the tramplingfloor and accompaniedby, in the case studied, an apprenticewho was still at school, takes an armful of preparedclay and a jar of water into the dryingroom. Here they wet the clay thoroughlyand the senior assistantpulls the handles while the young apprentice applies them with considerableskill and rapidity. It is of interest that the potter plays no part in the process,so that studies of handle form and especially their method of fixing could give spurious results.Were one to look for evidence of workshop continuity it would not be found in this case, as the assistant who applied the handleswas likely to go into anotherprofessionwhen he completed his schooling. At the end of the afternoon, at about 5 p.m., the vessels in the drying room, now mostly complete with handles, are covered with sorghumstems to insulate them from the frost. This becomes less necessary later in the season and is probably abandoned.The clay piles are left coveredwith damp cloth to keep them workable.

Vessel forming,Stage II At 5 a.m. the next morningwork is resumed.The potter spendingthe whole day at his wheel,

one of the groups of

j.

ii

(

at Deir el2 " gg wworkshops Gharbi. In the foreground are the piles of the unrefined clay, wells and soaking pits, the which around workshops are grouped. Beyond these can be seen the kilns, denoted by mounds of slag and wasters, and piles of vessels ready for trans2 Water buffaloes ~~~~~~Plate

clay. In the foreground one of the assistants is putting unrefined lumps of clay into a pit, ready *.for soaking.

trampling the soaked

nc

Plate 3 A potter making the upper part of a Ballas vessel. Meanwhile, his assistant is kneading the clay on the sloping surface into the cone from which the potter will form the next vessel top. Plate 4 A potter forming the upper part of a Ballas jar. Note the kickwheel and bucket shaped wheel head. Facing the potter are of the fixed features of the workshop ~~~~some bench; the sloping surface, and two bowls for dust and slurry. Plate 5 The top parts of the vessels laid out to dry in the drying room. Handles have yet to b-e applied on those on the left'. Note the bales of sorghum stems to the right of the assistants, ready for laying over the vessels in the evening to prevent cracking in the cool night air.

"

-Px.

6 A potter completing the bottom ~~~~Plate part of a Ballds jar. Note the cord placed around the widest point of the vessel. The next vessel top is already waiting to be inverted on to the wheel head; the lump of clay on which it stands will be drawn up to form the base of the vessel.

-.0~~

Pottery makingin UpperEgypt

229

while the assistantsundertake a variety of jobs. The morning'swork is, almost literally, the inverse of the previous afternoon's work. The assistant now takes the vessel tops out of the drying room and inverts them on the wheel-head. The wheel-headis bucket-shapedand has slits to receive the handles.Also, there is often a centralplug of clay to keep the vessel centred. The upper part is now sufficiently dry to withstand being inverted, but the largelump of clay at its base (now uppermost)can still be workedwith a minimumof damping. The potter proceeds to open this lump of clay as though he were drawingup a tall, slightly flaring vessel. However, once he reaches the point of maximum circumferencehe begins to close the orifice. He then slows his wheel and taking a length of cord passes it around this widest point. Normal speed is then resumed and the dome-shapedbase of the vessel drawn upward. The hole in the apex of the dome, left by the potter's finger, is then plugged with clay. This is either done as a sharpaction, and the base quickly but efficiently smoothed off, or with a flurry to leave a spiral pattern runningup to and over the plug. The now completed vessel is then removed from the wheel and taken outside, by the assistant,to dry. While the potter completeshis vessel the assistanthas alreadybroughtin the next top (Plate 6). From an archaeologist'sview point, the workshop itself would leave few indications of its original function, in the archaeologicalrecord. The cobbled floor of the workshop looks very much like that found in cattle, or other animalsheds. The impressionthat these are animal sheds is reinforcedby the void left by the removalof the potter's wheel. On the abandonment of a workshop, the wheel is amongst the first things to be removed. It leaves a mangershaped void in the mastabainside which one often finds traces of wind-blownor humanly deposited vegetation. It might be objected that doors of a width designed for humans would at once indicate to the excavator that this could not possibly be a building for the use of animals. Unfortuntely, this is not so. In fact, the primaryuse of a workshop, once abandoned,is as a cattle shed, and animalsas large as water buffalo pass through the narrow doorwaywith little difficulty (Plate 7). As shade for the animalspart of the roof is often left on these buildings, though less commonly on the drying room which is more rarelyused for animals.Naturally, fodder is brought in for the animals,and its remains,along with the inevitable dung, are the most obvious features of these workshops once they have been abandoned and allowed to fall into disrepair.Sherds of pottery are not to be found in most workshops, except in very low numbers,probably slightly less than in domestic contexts. Unfortunately,we were unable to examine, or find, any recently abandonedhouses. However, certain features specific to its potting function are still visible in an abandoned workshop. On the mastaba, in mud or mud brick, the remains of the sloping ramp for clay wedging, two bowls for dust and slurry, and a flat surface on which to stand completed cones or the upper part of the vessel, are still in evidence. Other potential clues, are the position of the trampling floor, which is always to the potter's left, and that of the drying room usually situated behind the potter (Fig. 4). The use of 'wasters'(misfirings)in the constructionof the workshops is ambiguous, since they also occur in houses and other buildingsin a wide area aroundthe potteries. The drying rooms are virtuallyimpossibleto identify, except in connection with the workshop, and if only a drying room were located in a trench, it would probablybe interpretedas an animal shed. The only strikingfeature is a hollow path runningdown the centre, on either side of which the pots once stood. However,it seems likely that such a featuremay be found in other structures.

230Q Paul Vicholson and Helen Patterson

Key

a b pot basin sloping I 1F

<

contailing

water slurry

surface

Scale

0 1.5 3m.

-d

sick-wheel

e(

Mastaba pf

she 7 g l 2 @>w heeead

otter's seat

_ -----

basin

containing

ash

d_

WORKSHO

DRYING

ROOWI

Fig'ure 4 Plan and section of a typical potter's workshop.

Finally, some workshops are completely dug out to leave a rectangular void, these could

only be identified in terms of size, based on analogy with positively identified structures.

Firikg

-ihevessels are fully formed and have left the workshop they are invertedon the ground in an area adjacentto the kilns. Here they dry in the sun and areeventually stood the fight way 'tp. During drying, the cord put on for support, comes off and is removed for re-use. Its imprest featureof the vessel. One wondersif corded beakerswere sito3t1 however, remaiis as a permaneen made ifn a similar way, the cord being removed before firing (Van der Leeuw, 1974). When is mad' for firing. Firstly fuel, in the about 00-700 vessels aro thoroughly dried, preparation form of sorghum purchased from the agriculturalists, is brought to the kilns. The bales of sorghum are stacked out in the deser, where many hundreds can be seen. They are transported, usually two at a time, by camel. About 70 bales are required for each firing.

Once

The kilns are of the updraughttype and are capable of holding approximately500 to 700

vessels at each firing. They are built of mud brick which fires in situ (Plate 8). It can be seen frornFiglre 5 that the kiln has no tunnel leadingto the fire, merely a stoke hole. The vexsels are stacked in the iln inverted, so that they rest on their rims and those nearest tthe wail slant so as to touch the sides. The vessels are densely packed. Each layer of pots is sepairatad from the next by a sherd inserted between it and the vessel above. The kln is stackd

to the top, the uppermostlayer of vessels havingtheir baseslevel with the top of the kiln wall. So vell-packedare the vessels that an assistantis able to squai.on them while he coversthem with a layer of broken sherds.This layer of sherdsis the only coveringfor the kiln, except for occasional sprinkdings of chaff during f iirig. It serves as a further reminder that even quite

Pottery makingin UpperEgypt

231

large, permanentkilns do not require a fixed dome structure.This is something all too clear from much experimentalwork (e.g. Bryant, 1971), where domes have proved impractical.A covering of sherds naturally suggestsitself in an area where there is a dense concentrationof brokenvessels,it is not so obvious on a 'virgin' experimentalkiln site. We intended to record the temperatureof a kiln duringfiring, and eventuallywere allowed to do so. However,because of difficulties in movingequipment,and becausethis was intended as a trial study, we had only one thermocouple,of the platinum-rhodium type. We were unable to insert this through the wall of the kiln, particularlysince the kilns arebuilt into mounds of ash and sherds, so it was inserted through the kiln top. Firing usually begins at about 5 a.m. and continues for about 31/2to 4 hours, on this occasion, until 8.40 a.m. The thermocouple, though designed to withstand temperaturesin excess of 10000C, failed after 31/2 hours having recordedonly 8600C. Nonetheless, the rate of climb of the graph(Fig. 6), indicateda temperature in the order of 1000?C at peak, that is after 3 hours 40 minutes as no 'soak time' seems to be allowed. Subsequent re-firing experiments kindly undertaken under the auspices of Dr. P. F. Messer, Sheffield University, Department of Ceramics, Glasses, and Polymers, of 10000C, and 11000Cin the case of an over-firedsherd. indicateda firingtemperature During firing, the bales of sorghum are fed in, allowed to bum, then raked to produce maximum heat. Periodically,a jet of flame will shoot through the kiln top and at such times an assistant douses the top with chaff. The densest smoke occurs duringthe feeding of the fire, whereasthe peak flame, or ratherheat intensity, occurs duringraking,and it is at this time that chaff and straw are thrown on to the kiln top, especially where flame bursts through. The potters claimed that they 'just knew' when the temperaturewas correct, though we suspect that they were able to judge by a combination of flame colour and time, certainly the flame colour variedeven to the untrainedeye. After a firing,the potters returnto the workshop and begin productionof the next batch of vessels. The kiln is left for two days to cool throughly. After two days, the kiln is unloaded and the vessels stacked on their sides, awaitingdistribution. It is usual to find that 5 to 10%of any firing are wasters. The most common firing fault is lime spalling,caused by the expansion of lime particlesnot removedduringtrampling. Some of these spalls are minor, and the vessel can be sold, whereas others burn right through and a void is left where the limnecracked out. These are unsaleable. Also useless, except as buildingmaterial, are those vessels which have bloated through over-firing in the kiln, or those which have grossly under-fired,the latter being more rare. Ideally, and in any future study, 'Buller'sRings'would have been used to determinewhere over and under-firing most commonly occurs in kilns. There is considerablecolour variationin any given firing. Along with the usual white buff vessels are some pink and some dark olive green vessels. These latter often have a lustrous glossy surfacewhere excess vitrificationhas occurred, and though over-firedare saleable. The white surface is the result of the migrationof salts, present in the clay, to the vessel surface(Matson, 1974, 136-7). In terms of archaeologicaltraces it is to be expected that the kilns would be the most easily identified feature, and this is largely true. However, every few years, between five and ten, the kilns are demolishedand re-builtor even re-sited.As the industrydeclines so do the number of kilns, and this has resultedin a seriesof bowl-shapedvoids left in the moulds of ash or sherds where the kilns once stood (Plate 9). No trace of the superstructureremains in such cases. However,the kilns are the only area of the production site on which great densitiesof broken pottery are to be found, and 'slag'that is vitrified material.We observed,out of interest, kilns

W N~

..4.M.

MMVM.Plate

7 A disusedworkshop now servesas

an animal shed. Note the gap in the bench where the wheel once stood, and the large amount of fodder strewn over the floor and the workshop bench.

Plate 8 A kiln. Note the two long iron rods,

which can just be seen to the left of the stokehole, used for raking the fuel during a firing.

Plate 9 Site of kiln which has been dug

out. Very little, if anything, remains of the actual kiln.structure.

Plate 10 The first stage in the decay of a Plate 11 Fired vessels in partially unloaded

kiln. Note the way the vessels are stacked, and the roundish patch on the base of each vessel where the sherds of pottery were placed to separate one layer from the next. disused kiln, the collapse of the kiln wall above ground level. The second stage is the collapse of the centre of the gridded mud brick kiln floor.

Pottery makingin Upper.Egypt 233 in variousstagesof decay. It seems that the upperwall is first to collapse(Plate 10), takingwith it the centre of the gridded floor of the firing chamber.This is then followed by parts of the arch above the stoke hole, and ultimately other areasof brickwork.It appearshowever, that kilns are usually repairedor removed before they collapse entirely. Rather perversely,their only secondaryuse seems to be as latrines,and this is unlikely to complicate any archaeological interpretation.No indication of the vast areasused for fuel storagewould be found. These lie at a little distancefrom the villageand from the workshops,presumablybeyond sparkdistance, out in the desert. Occasionallythere are traces of rows of small stones around the bales, but these are sporadicand ephemeraland could even have been made by local children.

Distributionand marketing Baedeker(1902, 231) states of Ballds,that 'jarssome of considerablesize, lie on the banks(of the Nile) awaiting shipment'. This is one of the few aspects of pottery manufacturewhich seems to have changed. It appearsthat the major distributionis now by lorry, we were told resulted in fewer breakages.Apart from those people that this was quicker, and surprisingly, in the vicinity who buy vessels directly from the potters for their own consumption,buyers of the Ballas jars seem to range from the small scale trader who hires a lorry for the day and collects one lorry load of vessels which he then distributesaroundhis home area by donkey, to the large-scalemiddleman, by far the largest purchaser,who collects severallorry loads of vessels, sometimes having first called at Qena to purchaseother types of pottery such as the water cooling zirs, which he then sells to the large markets, mainly in the Delta area. These vessels are distributedthroughout Egypt, from Cairoto Aswan, and until the arrivalof plastics and piped water, were the universalwater carryingvessels. They are to be seen for sale at many ruraland urbanmarketsalongsidelocal pottery. Some middlemen and individualbuyers prefer the work of a particularpotter, who may make especially heavy or light vessels. Also there is some preference as to colour, milk or honey are sometimes kept in the underfiredvessels ratherthan the correctly fired white ones. Decoration is also of some interest in this context. The potters apply decoration either in slack moments to break the monotony, or when it has been requested by a particulardealer. It consists generallyof a horizontal band of combed or wavy lines, such decorated vessels are much less common than plainvessels. It is notoriously difficult to obtain the prices paid for these vessels. One fact does emerge however, it is the middlemanand/or retailerwho makes most of the profit. We were told that the potters receive about EL 400 for 1000 jars of medium size, and that whereas five years ago each jar would have sold for 5 piastres(about 5p), they would now be 75 to 100 piastres each. These figures should be treated with caution however, and are best regardedas orders of magnitude.

The vessels The vessels themselvesare of considerableinterest and have some lessons to teach us as archaeologists. The first thing to notice on the vesselsis that most of those with white surfaceshave a

234

PaulNicholson and Helen Patterson

pink patch on the base (Plate 1 1). This is the result of placing a sherd between each layer of

vessels in the kiln. The same mark is commonly observed on vessels of a similarfabric found duringexcavations of the ancient palace of Ballas and has been noted on the pottery from the current excavations at Tell el-Amarna.Secondly, we have already spoken of the potential dangers of placing too great an emphasison handle typologies. In this context, we examined standpoint. some of the other featuresof the jars from an archaeologist's

Key

Scale

1 m.

a

combustioke <: firing

chabe r cham,ber

Figure 5 Section through a kiln.

The vessels are produced in three sizes; large, medium and small, large being the least common and medium by far the most frequent, how would the archaeologistcorrectly arriveat this conclusion?To this end we measuredthe diametersof the rimsof a seriesof vessels;twenty for each potter studied on the small and medium, and ten on the large(which rarelyoccurred in piles of more than ten). We found from this that althoughthe mean diametervaried,in each case the range of diameters for the large and small categories imcludedmany of the vessels which actually belonged to the medium category, in fact by far the most common. It is highly likely that this would result in only two categoriesbeing postulated. However,measurements of the circumferenceat the widest point of the vessel again showed that the means would be different, but, more significantly, there was no overlap in the range of diameters obtained. Three relatively clear groups emerged. These data are summarizedin Figure 7. As has been noted the point of maximum circumferenceis easily ascertainedby the string line, and so is measurablefrom sherds.We do not suggestthat this featureis applicableto all other situations, but we would suggest that those dealingwith vessels of this type, such as globular amphorae, to see if size classesbecome clearer. variables other than rimdiameters mightconsidermeasuring We also wished to determinehow individualpotters differentiatedtheir work from that of their colleagues, given that all produce similar vessels. Following on from work begun by Peter Lacovara(Lacovara,pers. comm.), we questioned the potters on this matter (cf. Hill, 1978), and especially on whether the rim was a significant feature. They said that such a category was too narrow, and implied that they could distinguishthe pots of different workshops on the basis of the overall appearanceof the vessel, as one potter said 'pots are like people, each alike yet different from others'. However, we drew the profiles of the rims of vessels produced by four differentpotters (Fig. 8), and they were clearly shown to be different. Despite the potters' statement, it seems that in a sherd collection they would only be able to

Pottery makingin UpperEgypt

23 5

1000

900

*

thermocouple broke

800

700

600

500

400

300

200

100 50 Temperature in C 0

5.20 5.30

I 6.oo

6.30

_ 7.oo

I_T___

7.30

8.oo

8.30

8.40

Time a.m.

Figure 6 Graph showing the temperature recorded during a kiln firing. differentiate their work by rim formn,and there is no doubt that variation here is characteris-tic. Another feature which we noted on our return, but not at the time, is that the vessels ap ,eC.r to exhibit a particular kind of fracture at the point where the top and bottom parts of the vessel meet, that is the point from which the base was drawn up on the second day of producon Greek tion. Such fractures are known from other types of vessel and are even illustra -K->I1 painted vases (Noble, 1966: 11 and Fig. 252). We did not ascertain how frequerf.;-`hic breaks were. Lastly, because the vessels are thrown in two parts, one inverted and the other not, the turning lines on the vessels run in two different directions. We must be wary of irnterpreting this as indicative of different workshops, one with a wheel rotating anti-clockwise and one clockwise, if there is only a limited sample of pottery to work on.

The potters and industrial decline It has frequently been noted that potting is a low status occupation, but since most st.udies have

236

Paul Nicholson and Helen Patterson

concentratedon smallindustrieswe decided to question the potters and other membersof their society about their social standing.The potters told us that they dislikedtheir work, that it was hard and unrewarding, and one potter stressedthat he hoped his childrenwould not follow his trade. They work twelve hours each day for nine months of the year, duringthe remainingtime they attend to repairsand do other odd jobs. We were told by them that they had no access to land and so could not take up agriculture,a life which they said they would prefer.The local school teachers confirmed the low status of the potters, especially in relation to clericaljobs, currently seen as the most readily attained status position. According to the teachers, the potters were paid more than the clerical workersthough despite this lower status in practice,

we believe, they also earned less. The potters we met were without exception, illiterate but the

better educated children hoped to leave the industry, and since the draw of Saudi Arabian money is strongit is likely that many may find work there.

t

12 ~~~10

14

rim diam. (cm.)

m

es

a( 7603

76

max. circ

0 (cm )

90

1011

0,

rim diam. (cm.)

m

76

80

90

iOO

ho

120

max. circ. (cm.) Key I

m large medium

small mean measurement

Figure 7 Graphshowing the groupingsof Ballasvessels obtained on the basis of (a) measurements of the rim diametersof the vessels, (b) measurementsof the maxrnum circumference of the vessels. In addition, it must be said, that the industry at Deir ekGharbihas suffered a dramatic decline over the last few years. There are two main reasons for this, firstly, the decline in

Pottery makingin UpperEgypt

237

demand; the increasing number of households with piped water and refrigerators,and the increasein metal and plastic containersis greatly reducingthe need for specializedvessels such as the Ballasjar. Secondly, the decline in the labourforce, as mentioned above, the young men no longer wish to work in the pottery industries,preferringto head for Saudi Arabia,where large sums of money can easily be made. It was this decline which led us to ensure that a detailed photographic record was obtained, it remains for others to document more fully the socio-economic aspects of the society. It might be thought that the introductionof modern equipment might help the industry. Although the potters are aware of this technology, they refuse to use it; an electric wheel, accordingto them, did not allow the potter enough control over the tuming of the vessels, a regulatedkiln would not work, 'all the pots would break'. The potters' conservativeattitude and determinationto adhere to traditionaltechniques is a third and possibly the final factor in the decline of the industry. It should be mentioned that given the erratic nature of the local power supply, their misgivingswould, perhapsprove to be well-founded.

rim shapesof the vesselsof four different potters. Figure8 The characteristic

Conclusion In conclusion it must be said that despite the largesize of the industry,its distinctiveproducts and their wide distribution, itg traces are more problematic, and would be difficult for the archaeologistto interpret with certainty were he not to excavate the whole complex. The low

238

PaulNicholsonandHelenPatterson

density of pot sherds in all areas but the kilns is also of interest, as is the fact that reused wasters are not confined to the workshopbut are found over many miles. Fortunatelyhowever, some of the features of the workbench (mastaba)are sufficiently durableto allow the correct identificationof the workshop,providedthat the bench itself remains. We hope that this study, though a pilot project for us, has provideda useful and detailed body of data from which others might profit, or which may at least generateideas. Certainly our own knowledge of pottery production has been greatly enhanced, as has our knowledge of field techniques. We would emphasizeto other workers the need to take more than one set of readings during kiln firings, somethingwe shall attempt in any future work. We hope also that we have provideda lastingrecordof an industryon the point of changeor decline, perhaps the end of an industrywhich spansfrom the days of the Pharaonicempireto our own.

Acknowledgmnents We wish to thank the following bodies for their encouragementand fimancialsupport: The Society, SigmaXi - the Scientific Society of Antiquariesof London, The Royal Geographical Research Association, The University of Sheffield Expeditions Fund and the Petrie Watson ExhibitionsCommittee. We also wish to thank our supervisorsat Sheffield University,Dr RichardHodges and Dr John Collis for their help and advice. Much assistance in Egypt was provided by Mr Barry Kemp, Ms PamelaRose, Professor Lanny Bell, and Mr Paul Blank to whose fluency in Arabic we are most grateful. Practicalhelp and hospitality were providedin 1983, and furtheradvice and Ms JanineBourriaualso provideduseful references. in 1984 by Peter Lacovara, we are deeply grateful. To these and to the potters of Deir el-Gharbi 28.ii. 1985 Dept. of Archaeologyand Prehistory Sheffield University

References Baedeker, K. 1902. Egypt. Leipsic: Baedeker. Balfet, H. 1966. Ethnographical observations in North Africa and archaeological interpretation. In Ceramics and Man (ed. F. R. Matson). London: Methuen, 161-77. Binford, L. R. 1983. In Pursuit of the Past. London: Thames & Hudson. Birks, T. 1975. Outline Guide to Pottery. Poole: Blandford Press. Bryant, G. F. 1971. An experimental firing of a replica medieval kiln at Barton-on-Humber, Lincs. Journal of the Northampton Museums and Art Gallery 9: 77-89. Gosden, C. H. 1982. The recognition and interpretation of the exchange of pottery in the Baringo district, Kenya: some preliminary results. Archaeological Review from Cambridge 1 (2): 13-29. Hill, J. N. 1978. Individuals and their artifacts: an experimental study in archaeology. American Antiquity 43: 245-57.

Pottery making in Upper Egypt

239

Matson, F. R. 1974. Technological studies of Egyptian pottery - modern and ancient. In Recent Advances in Science and Technology of Materials: Second Cairo Solid State Conference, 1983 (ed. A. Bishay). London, 129-39. Noble, J. V. 1966. The Techniques of Attic Painted Pottery. London: Faber & Faber. Peacock, D. P. S. 1982. Pottery in the Roman World. Harlow: Longmans. Petrie, W. M. F. and Quibell, J. E. 1895. Naqada and Ballas. Quaritch: London. Trigger, B. G. 1983. The Rise of Egyptian Civilization. In Ancient Egypt: A Social History (eds B. G. Trigger, B. J. Kemp, D. O'Connor and A. B. Lloyd). London: Cambridge University Press, 1-70. van der Leeuw, S. E. 1974. Neolithic beakers from the Netherlands: the potters' point of view. In Glockenbecher Symposium (eds. J. N. Lanting and J. D. van der Waals). Oberried, 81-139. Whitehouse, D. 1977. Kangan: una fabbrica tradizionale di ceramiche nell'Iran meridionale. In X Convegno Internazionale della Ceramica, 41-64.

Abstract Nicholson, Paul and Patterson,Helen Pottery makingin UpperEgypt: an ethnoarchaeological study

Despite the enormous importance of pottery to the archaeologist, detailed ethnoarchaeological studies of pottery production are rare, and tend to concentrate on the most primitive forms of pottery production. The study of the potteries and clay mines at Deir el-Gharbi, Upper Egypt was undertaken with this in mind. The potteries are of a type defined by David Peacock as a 'rural nucleated pottery industry', they produce large amphora-like vessels which are distributed throughout Egypt. The study revealed much about the technology of clay extraction and pottery production, as well as something of their organization. More significantly, it shed some new light on how such industries might or might not be reflected in the archaeological record. A study of the vessels themselves revealed several points of interest for the study of wheelturned ceramic assemblages generally.

You might also like

- The Town of Selle (Zaru) in The 'Amarnah Tablets PDFDocument4 pagesThe Town of Selle (Zaru) in The 'Amarnah Tablets PDFsuzyNo ratings yet

- Okon - Archaeological Reflections On Ancient Reiligion and Society - Esj 8 (2012)Document11 pagesOkon - Archaeological Reflections On Ancient Reiligion and Society - Esj 8 (2012)Imhotep72No ratings yet

- Quack - Review of Gs TawfikDocument4 pagesQuack - Review of Gs TawfikImhotep72No ratings yet

- Giveon, The Impact of Egypt On Canaan, 1978Document195 pagesGiveon, The Impact of Egypt On Canaan, 1978Imhotep72No ratings yet

- Salim - Cultural Indentity and Self-Presentation in Ancient Egyptian Fictional NarrativesDocument221 pagesSalim - Cultural Indentity and Self-Presentation in Ancient Egyptian Fictional NarrativesImhotep72No ratings yet

- Borghouts - The Evil Eye of Apopis - JEA 59 (1973)Document39 pagesBorghouts - The Evil Eye of Apopis - JEA 59 (1973)Imhotep7250% (2)

- Blackman - The Fellahin of Upper EgyptDocument348 pagesBlackman - The Fellahin of Upper EgyptImhotep72100% (6)

- Redmount - Major and Trace Element Analysis of Modern Egyptian Pottery - JAS 23 (1996)Document22 pagesRedmount - Major and Trace Element Analysis of Modern Egyptian Pottery - JAS 23 (1996)Imhotep72No ratings yet

- Magic and Ritual in The Ancient World 2002 PDFDocument489 pagesMagic and Ritual in The Ancient World 2002 PDFKatamba Rogers100% (2)

- Bmfa53 1955 68Document2 pagesBmfa53 1955 68Imhotep72No ratings yet

- Eaton-Krauss Jea 94 2008Document10 pagesEaton-Krauss Jea 94 2008Imhotep72No ratings yet

- Gardiner, A New Letter To The Dead (Jea 15)Document6 pagesGardiner, A New Letter To The Dead (Jea 15)Imhotep72No ratings yet

- Dance (Review Quack) JNES 129 (2009)Document3 pagesDance (Review Quack) JNES 129 (2009)Imhotep72No ratings yet

- Bmfa56 1958 63Document2 pagesBmfa56 1958 63Imhotep72No ratings yet

- Goldwasser Classifiers Fs PolotskyDocument24 pagesGoldwasser Classifiers Fs PolotskyImhotep72No ratings yet

- Fs. BrovarskiDocument40 pagesFs. BrovarskiImhotep72No ratings yet

- Praga 2007Document14 pagesPraga 2007Imhotep72No ratings yet

- Bmfa37 1939 117to118Document3 pagesBmfa37 1939 117to118Imhotep72No ratings yet

- Duistermaat Et Al - The Potters of Fustat - LJPS - 25 - 2009Document26 pagesDuistermaat Et Al - The Potters of Fustat - LJPS - 25 - 2009Imhotep72No ratings yet

- L. Gestermann, Pgardiner II, Proceedings of Egyptologists Congress 2000Document8 pagesL. Gestermann, Pgardiner II, Proceedings of Egyptologists Congress 2000Imhotep72No ratings yet

- Segal - The Myth-Ritualist Theory of Religion - JSSR 19 (1980)Document14 pagesSegal - The Myth-Ritualist Theory of Religion - JSSR 19 (1980)Imhotep72No ratings yet

- Staal - The Sound of Religion I - Numen 33 (1986)Document33 pagesStaal - The Sound of Religion I - Numen 33 (1986)Imhotep72No ratings yet

- Moreno Garcia - L'Organisation Sociale de L'agriculture - JESHO 44 (2001)Document41 pagesMoreno Garcia - L'Organisation Sociale de L'agriculture - JESHO 44 (2001)Imhotep72No ratings yet

- Moreno Garcia - A New Old Kingdom Inscription From Giza JEA 93 (2007)Document21 pagesMoreno Garcia - A New Old Kingdom Inscription From Giza JEA 93 (2007)Imhotep72No ratings yet

- Gabolde - Under A Deep Blue Starry SkyDocument24 pagesGabolde - Under A Deep Blue Starry SkyImhotep72No ratings yet

- Spaull - Review of James HekanakhtDocument4 pagesSpaull - Review of James HekanakhtImhotep72No ratings yet

- Dijk, Van - The Death of MeketatenDocument11 pagesDijk, Van - The Death of MeketatenImhotep72No ratings yet

- Richard Fazzini, Two Semi-Erased Kushite Cartouches in The Precinct of Mut at South Karnak PDFDocument15 pagesRichard Fazzini, Two Semi-Erased Kushite Cartouches in The Precinct of Mut at South Karnak PDFMostafa Mahmoud EllabanNo ratings yet

- Gabolde - Under A Deep Blue Starry SkyDocument24 pagesGabolde - Under A Deep Blue Starry SkyImhotep72No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Guide For Transmission Line Subsidence PDFDocument17 pagesGuide For Transmission Line Subsidence PDFjoydeep_d3232No ratings yet

- Grasberg Block Cave Mine Cave Planning and UndercutDocument12 pagesGrasberg Block Cave Mine Cave Planning and Undercutalvaroaac4No ratings yet

- First 5 ChaptersDocument21 pagesFirst 5 ChaptersalfaazmcsNo ratings yet

- Stirred-Tank Bioleaching of Copper and Cobalt From Mine Tailings in ChileDocument9 pagesStirred-Tank Bioleaching of Copper and Cobalt From Mine Tailings in ChilePatricckkNo ratings yet

- MSHA 2012 Mine Rescue Contest RulesDocument138 pagesMSHA 2012 Mine Rescue Contest Rulesbigfist171No ratings yet

- Orica SHOTPlus™ FlyerDocument2 pagesOrica SHOTPlus™ Flyerlladopi100% (1)

- Company Profile of Pama PersadaDocument2 pagesCompany Profile of Pama PersadairsyadjamaludinNo ratings yet

- ICB ClassificationDocument8 pagesICB Classificationchandra shekharNo ratings yet

- Sukinda India HexavalentDocument12 pagesSukinda India HexavalentmilindsangrealNo ratings yet

- Case Study BrazilDocument2 pagesCase Study BrazilTIERA salesNo ratings yet

- 5to Intento 100 PitsDocument1,401 pages5to Intento 100 PitsZato Collado LealNo ratings yet

- For nbc2Document1 pageFor nbc2irene100% (2)

- Rescue Robot ReportDocument3 pagesRescue Robot ReportÖmer ÖzkanNo ratings yet

- Barrick 2017 Operations and Technical Update 2Document219 pagesBarrick 2017 Operations and Technical Update 2Rudy Dwi PrasetyoNo ratings yet

- Cement Industry Internship ReportDocument43 pagesCement Industry Internship ReportHaritha V H89% (9)

- Leo Presentation and ComparisonDocument55 pagesLeo Presentation and ComparisonVineetSharmaNo ratings yet

- Study Investor PresentationDocument49 pagesStudy Investor PresentationZaenal BahriNo ratings yet

- Final Examination: Your Answer On The Space Provided For. (40 Points)Document5 pagesFinal Examination: Your Answer On The Space Provided For. (40 Points)Wichel AnnNo ratings yet

- MD6420C Features and BenefitsDocument46 pagesMD6420C Features and Benefitsnikbeam100% (3)

- Taganito Mining Vs CIRDocument1 pageTaganito Mining Vs CIRPatrick RamosNo ratings yet

- Rock Geochemistry in Mineral Exploration by G.J.S. Govett (Eds.) PDFDocument444 pagesRock Geochemistry in Mineral Exploration by G.J.S. Govett (Eds.) PDFcarlosNo ratings yet

- Acr Approved Validation Verification Bodies 20190327Document1 pageAcr Approved Validation Verification Bodies 20190327Enoch SimpsonNo ratings yet

- How To Calculate The Potential Value of A Mining ProjectDocument3 pagesHow To Calculate The Potential Value of A Mining ProjectHusnain MurtazaNo ratings yet

- Mining CasesDocument116 pagesMining CasesKrstn QbdNo ratings yet

- Rib Pillar Design in Open Stope Mining: June 1989Document7 pagesRib Pillar Design in Open Stope Mining: June 1989trinitrocainaNo ratings yet

- Main ProjectDocument85 pagesMain ProjectMani Prasanth0% (1)

- Master-Drilling-Interim-Results-Report 05aug14Document24 pagesMaster-Drilling-Interim-Results-Report 05aug14api-272329104No ratings yet

- SEML PresentationDocument47 pagesSEML PresentationalparathiNo ratings yet