Professional Documents

Culture Documents

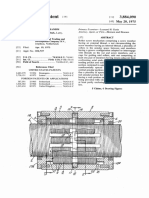

Sept. S, 1931. 1,822,027: J. Hartness

Uploaded by

Vinoth KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sept. S, 1931. 1,822,027: J. Hartness

Uploaded by

Vinoth KumarCopyright:

Available Formats

Sept. s, 1931.

J. HARTNEss

CAM coNTRoLLED THREAD GAUGE-

1,822,027

"

"Fied March 2.

1929

@y19 Mil#

1

/4

1. @iff

02225.

Patented Sept. 8', QS

1,822,027'

UNITED STATES PATENT OFFICE

' JAMES HARTNESS, OF SPRINGFIELD, VERMONT

CAM-CONTROLLED THREAD GAUGE

Application mea March 2, 1929. seran No. 343,990.

gauge members being capable of relative -the gaging thread, there will be apparent rotational gaging motion, the angles of such relative movement of the gaging threads, rotation when the members are' in engage the rate of such movement per turn of the 10 ment with a master thread being compared members depending on the 'difference in with the angles of rotation permissible when pitch between the gaging thread and the con the members are in engagement with a screw necting thread. Thus, if this diiference is to be tested. The embodiments of the pres considerable the slack between the gaging

This invention relates to a gauge for test- movement of the gaging members when the ing screw threads for error in pitch diameter members are rotated, as the bodily axial and lead. A gauge embodying the present movement of the members will exactly offset invention may comprise essentially two Vthe apparent relative movement of the 5 threaded members for engagement with a gaging threads. lf the pitch of the connect screw thread to be tested, the threaded ing thread is less or greater than the pitch of

55

15 a pair of ring-shaped members, each having the gauge members are mounted is quickly

ent invention hereinafter described consist of threads and the threadof a screw on which

these gauge members be rotated while `held able relative rotation of the members is against axial movement, the gaging thread necessary to take up the sameamount of V20 will have an apparent axial movement, the slack or looseness. Since the amount of such direction depending on the direction ofrota slack to be taken up is, in the absence of lead

an interior thread to receive an exteriorly taken up when the members are rotated, threaded screw to be tested. lf either of whereas if the"v difference is small, consider

tion and on whether it is a right hand or a error and malformation of the thread, a left hand thread. This apparent axial prog measure of the flank thickness of the screw> ress of the thread due to rotation of a mem to be tested, the relative rotation of the

25 ber may be modified by bodily axial move ment of the member so as to increase, dimin ish or reverse the apparent motion of the thread. If two such gauge members are

gauge members when in engagement with `the

screw is also a measure of the flank thick

ness. The sensitivity of the gauge may thus

be determined by the choice of a connecting held against axial movement and -are rotated thread which diifers in pitch from the relatively to each other, their respective gaging thread by little or much according as threads will have an apparent travel axially greater or less sensitivity is desired. According to the present invention, the in opposite directions. This relative appar ent travel of the threads of the gaging mem , gauge members may be connected in such bers may be modified by controlled relative a way that the difference between their rel axial movement of the members as they ative axial motion and the apparent rela

rotate. W'hen the gaging` members are in tive motion of their threads need -not be engagementwith a screw and their bodily constant, but can be varied as by the use movmcnt is controlled, the mutual approach of cams. Thus for example a gauge of this

85

ing and separating motions of the gaging type may be screwed on to a screw threaded

threads cause these threads to bring up member to be tested, then the two gauge

the screw and thus limit the extents of rela the present invention, the axial movement of tive rotation of 'the two'members. The rela the members during such relative rotation tive bodily movement of the members may, may be so controlled that at first there is a

4. O

against the opposite flanks of the threadsof members relatively rotated. According to

for example, be controlled by mutual thread quick take-up of most of the slack or loose- y ed engagement, as shown and described in ness between the threads of the gauge mem

my co-pending application Serial No. 192, bers and the thread of"the screw, then the 236, filed May 18, 1927. It the connecting rate of take-up may be much slower so thatv

50

thread hasv a pitch equal to that of the gag thegauge may be'made very sensitive.V . ing thread there will be no relative apparent through the zones of tolerance without re '100

1,822,027 l

quirine excessive rotation of the gauge mem~ bers from the open position to the zones. For a complete disclosure of the inven tion, reference is had to the description

bodily movement of the disks 20 and 22, I

may form a plurality of slots 26 extending

through the flange 2l. The walls of these

slots are adapted to act as cam surfaces to

10

15 ure l.

either screw thIreadedinto. the holes or. Figure @shows cam slots similar to .those be driven thereinto `so as to: be securely held.y in Figure 5b`utofmodified configuration.. The -threadslwithinthe apertures 23 and.2iJcf 85` Figure Tis a ,front elemtionV of 'a modified forni of'gauge embodying theinvention. are, preferably somewhatshort, as indica-ted`

25

gaging member illustratedfin Figure 3.

gaging member of the gauge shown in Fig flange 2l, the pins 27 being thereafter in their respective slots 26 and 80 FiguieY is aplane cleveloprrnentrof the sertedthrough invv radial holes previously. formed cam slots in the~peripherali portion _of the secured. in the. edge _of-the dsk.22. The pins 27 may.

or equivalent cam followers, which may be Figure l is a front elevation of a< gauge secured ,tothe peripheryhvof the disk 22. The of the ringy type embodying theinvention-n pins ,2:7 besides` acting -as: cam ifo'llowers are Figure 2 is an edge elevation ofthe same. also convenient handles for operating the Figure 3 is a perspective view of'one of" gauge. ' the gaging members of-ithefgaugeillustrated.' Inaassemblingfaigauge such as that illus in Figure l. in Figure l, thedisk 22 may be in Figure 4 is a perspective vie-:wof a-~second trated sertedinto^therecess surrounded by the

thereof which follows, and to the drawings, guide a corresponding number of pins 27, .(0 of which,

the flange 21 being,preferably.elongated` cor respondingly.4 It is preferred to regulate. Figure 13 showsvin elevation a gauge~of` the-#distance between the mutually remote. 100> the plug` type embodying the presentinven

*igure l1; '

tion. '

the gagingmembers of Vthegaugeshown. in. thepoints of-engagement of themembers 2O 95p Figure 9. and .22 with ,the thread .to be tested maybe. Figure 12 is a plane> development'offthe regulatedzby the. thickness oflthe disk 22, eripheral portion of "the -member Y shown ,inl

outerfaces ofthe members 20 and 22 so that

portion thereof. Inthis -way thethreadedy Figure 9 -is a front' elevationof another engagement offthe gaginginembers 20. and 9o. modified 'form ofthe invention. 22 ona screwto. be tested is at spaced points.A Figure l0~is a'section-on theline l0--10,l The extent~ of engagement` of each gagingf membeix is preferably. equivalent to one> or> Figure ll'is an edge elevation of`one. of: two .turns of thread. The distance between

Figurev 8 is a section-Von the line 8`-81 of " ingrbored-,outso as toshorten the> threaded. F igure 7l '

in1 _Figure 2, a portion of the aperture 24 bef

Figurellis a section on theline lef-let to .the _length of threaded >engagement which .

Figure l5 'is an end elevation of fthe Gauge ,

.

this.,distance willbe> approximately equal:

theK screwrto> be. tested will >have inactual

sho-wn 1n Figure 513.

_,

50

similarly apertured as at 24, theseapertures threaded engagement thereoffwere to be con'

55

trally apertured asat 23 'and the disk' 22`is ina-:screw ofthesamesiZe if the working

have a form somewhat similar to that illusf an inch, itis preferred to construct thel trated in Figures l'to el; As shownfthis: _of gauge so> that the distance `of-overall engage-> comprises a pair of'gaging members lin the mentofthe gauge with th'escrew to be test 11e form of 'perforated'disks One of these; edwillhe,approximately an inch..> This fea-. disks 20 is provided with' an axial flange 2l tureis. of Vspecial importance where a lead which forms therewith'a recess adaptedto. error'is 'liable to be present-in the screw-to receive the other disk 22.' The disk 22i'isv be> tested.> A". lead~` error which would be. preferably fitted within the flange 21'so as serious in thecaseof athreaded engagement. 115 to rotate freely therein. The dis'k 20r`is een oflan inch orso.' might notvbe objectionable.

A' gauge embodying the invention-may threaded`holes in .castings for the. distance.

service._ lf, . for~ example, it is desired to 105 test threadsof bolts which areto. extend intoA

60

65

25. In order to controlthe relative axial; bers are fr'ee _totravel bodilytoward Voraway. 13G.,`

and .24, such dust vbeing collected vinthe slotsV ofthe members. , If, however, thetwo mem

any dust or other foreign matter which> may threads >takes up the slackof the loose litbe- 125 happen to be on. the flanks `.ofthe thread 'to' tween the gagin-gmembers and the screw to be tested will be cleaned 'off as the screw to be tested,.the-_ amount .of such- slack being be tested is screwed into the apertures 23 indicated '_byV theL amount v>of relative rotation t

Thegaging action of -thegaging. lmembers 12o to be gaged 'when the gauge is~in its open" arises from- th'efapparent frelativeaxial travel position, that is.when the- gagingthreads~ of theinternal'threads ofthe members when lie in a commonV helix. Each thread iis pref-f the members areA relatively rotated. This erably transversely slotted-as at 25 so thatv approachingor separating movement of the

engagement )with the largest tolerable thread

being internally threaded for loose fitting siderablyV less than an inch..

1,822,027 ~

from each other, such bodily motion may> marks on the other gaging member. As entirely offset the apparent approaching and shown, the index 29 is located on the outer

separating motion of their threads so that face of the disk 22, this index cooperating the slack between the threads of the gauge with suitable markings on the rim of the members and the thread of the screw to be flange 21. One such mark may indicate the tested is not taken up at all. By so control open position for the index 29 when the i

members 22 are in such a position ling the relative bodily movement of the Igauge gaging members along the axis, the appar that their interior threads lie in a common ent approaching and separating movement helix. Thus when the index 29 is opposite

10

,of their threads can be regulated so as to the open mark, the gauge is ready to re be relatively large or small for any given ceivea screw to be tested. It is preferable angle of relative rotation of the members. that when the gauge is in this position the The slots 26 may thus each be cut on a helix, pins 27 are approximately at the mid points the pitch of the helix being different from of the slots 26. The employment of gaging members 15, the pitch of the internal threads oi the

the apparent approaching and separating and at axially spaced points assists the oper

20

member. Iffthe helix of the slots is in the having threads which engage a screw to be same direction as the helix of the threads tested over relatively short lengths of thread

80

movement of the threads when the members ator in distinguishing error of lead from

are relatively rotated will be decreased, thus error of flank thickness. Lead error in a increasing 'the sensitivity of the gauge. By screw thread amounts to a virtual crowding making the slots 26 with a pitch nearly together or axial stretching out of the turns equal to that of the threads oi the members, of the thread. . The most conspicuous result

85

'

90

25

the gauge may be constructed with as high of lead error on a gauge of >the type illus a degree of sensitivity as desired. For prac trated is an inequality ofreadings as the tical purposes, however, it is not desirable gaging members are relatively rotated first

ordinarily to have a gauge so sensitive that in one direction and then in the other. If an unduly large angle ot relative rotation the gaging threads are so made as to-engage

of the members is required to take up the the thread under test over short lengths oi' slack between the threads of the gauge and thread and at spaced points, the spacing be

a screw of correct flank thickness. In order

tween the points of engagement magniiies

95

35

to take up. quickly the larger part of the any lead error present by the number of slack and then >to have the gauge more sensi thread turns between the points of engage tive in taking up the remainder of the slack, ment. By reason of the short lengths of en cam slots 28, such for example as are illus gagement, the shortening of the angle of trated in Figure 6, may be provided. These throw of the gauge in one direction is ap slots. as shown, comprise a central portion proximately balanced by the increase of the which may be in a plane perpendicular to angle of throw oi' the members in the oppo the axis of the gauge. Vhile the pins 27 site direction from the open position. ride in this portion of the slots, the disks Thus the mean of the two angles of throw

20 and 22 are heldagainst any relative axial will give approximately the angle to which

bodily movement so that upon relative rota

the members would turn if the screw under

tion the slack between the gauge threads and test had no lead error. Hence this mean

45

those of the screw to be tested is taken up angle is an approximate measure ofV the - . comparatively rapidly. The remainder of flank thickness oi the thread. While it may lili the slack take-up is more gradual owing to usually not be desired to ascertain' the

50

the helical shape of the end portions of each of the slots 28, there being a bodily relative advance between the gaging members when the pins 27 enter the end portions of the slots 28. If desired, the central portion of the slots 28 may be pitched slightly in the direction opposite to the pitch of the end

amount of lead error of a screw in terms ot '

any particular unit, it is important to know

whether the lead error is sui'licient, in com# bination with whatever error of pitch diam eter there may be present, to render the

screw unfit for the service for which it is

which Zones the index 29 must fall if the screw under test is to be accepted. Thus if the pitch diameter is correct or nearly so,

a certain amount of leeway remains for lead '

H5

. intended. `For this purpose I may indicate portions, this resulting in a still more rapid Zones of tolerance on the gauge, within

55

_initial take-up of the slack between the threads. By varying the conguration of the slots 28, different types of relative ad vancing and separating motions between the threads of the gaging members may be ob

tained. In order to -facilitate the observation oi slackness between the threads of the gaging members and the screw to be tested, I may provide an index 29 on one of the gaging

error.

Conversely, if there is little or no

60

lead error present, the pitch diameter may vary within prescribed limits. In some

screws there may be error both in pitch

diameter and in lead, neither error being sufcient in itself to make the screw objec

65

members 'to cooperate with suitable scale tionable, but both together being suilicient to

41

1,822,027'.

30

40

the actual >stresses which .are placed upon ~ end of' a suitable spindle 47 having a

This `information' isof particular impor~ gauge of the plug type embodying the presin=1 whichthere is relatively little margin may comprise a pair of external threads 120i" between its maximum holding strength and l5, 46, the thread 4_5 being mounted at the ~

tance where the screw is destined for a use entlnvention. As therein shown, this gauge

be continuous, but may be inthe' form of' ent, a scale calibrated in terms of percentage radial Vprojections extending 'inwardly from l of standard liank thickness will give at once the flange, and of :suliicient size' to 'support an'A accurate idea as to actual holding a set-screw 39. By shapin'gvthe cam sur strength ofthe screw compared/to that of faces of thecanr fl() as desired,` the action a perfect screw, since the holding strength of the gauge may be modified inthe same is closely related to the flank thickness there manneras the action ofthe gauges herein ofwhere the contour of the thread is fairly before described. regular' and the lead error is negligible. In Figures 13, irland l5 is illustrated a

should have. If there `is no lead error pres

lylground to dimensions on the border lines pushed toward or fromthe-latter, the rate 10053 of tolerance. of such motion at any moment beingde-` In placeA of or in'addition vto the teler~` tei-mined by the pitch ofthe' segments of ance VZones indicated on the gauge, there the flange e0. In order to permitthe' as~' may be-.scale markings to indicate the flank sembling of gauge ofthe formv shown, thickness of the thread tested, either in the flange 3Tthe of the disk 36 is preferably fractions of some unit as an inch or in per made separate therefrom and is secured" centagesof'ther standard flank- thicknesses thereto kas by a suitable`v number: of Vscrews which >a 'perfect-screw of the type measured The lip 3801i the flange 37 neednot

of a portion of a helix; Against each of ance limits may be found by calculation or these segments opposed abutments such - as they` may be located empirically by the use set-screws'f 'bear-so Athat as the diskA is" of master threads which have been accurate rotated with respect to thedisk 36,l it is

is formed on or screwedto 'the-periphery" location, these zonesbeing on either side of of the disk 35 and'exten'ds radially thereAV the open mark. The markings _for suoli from. is indicated in Figures lll. and-12v Zonesfof tolerance depend upon the `class of the flange Ll() is composed'of a number of->` lit~desired aswell as the characteristics of segments, each 'of which maybe in ithei formH structure vof theI - gauge itself. These toler

screw under test, , in the absence of lead being adapted to engage-respectively- cam error.` Zones oftolerance mav be indicated surfaces on the sides ofa flanges()A which on the rimof theflange 2l or. other suitable

Ther latterI is provided with an axial iangev which has an intufrned YlipBS.~ Through est> Zero mark'is an' indication of how fa' this inturned 'lip a number offsetfsc-rews39 from- standard is the flank thickness of the are passed, the' inner ends ofthese- set- screws

is subsequently testedin the gauge, the an guiar .distance .of the index 29 from the near

tween"> their. threads-and the thread of a described. This gauge may"compriseal disk standard plugigaugef. .Vhen a screw thread 35 whichcooperates Withfa second'disl'.;

- forming f the camV surfaces ~ in .theffl'ange 31, A lated. howevenlthey _are formed by slots 33'1cutf 70 In order tti-determine the extents ~of`rela-1 into periphery of 'therdisk-'Sf Suitable tive' rotation the gaging members should pins the 3~l>may~ be- projected Lth-r'oughthe `rini have when'inr Contact with a perfect thread:` 31 to enter. the respectivefslots.33~a1idto to. be: tested, a: master plug gauge may be' act as cani followers=againstithesidesoff screwed into the gauge andthe gaging mem the cam slots.- Thefaction :of the -ga-ugefmay-Av bers relatively rotated in both directions as be determined as in the 1)1'evious1`carse'b_y= farzas-they will go until the slack between suitably shaping'th'eslots33'." The Operai the threads istaken up each time. Suitable tionof this gauge isidenticalwith that of Zero marks may "be made on the rim of the the gauge showny iii-1F igure l.l flange'Ql opposite the index> 29 when the Figure 9 shows affurther- modified form` gangefmembers have been krotated in oppo of invention, this gauge operatingon sitezdirectionsfse asto take up the slack be 'the the saine principle- as the ones hereinbefore

l and 8; In this ~form aidiskiO' cienciesare detachable: by the gauge herein inFigures7 is nested'in avrecessformed by an' axial;describedsothatino unfit'screw escapes re flange 3l ofva seconddiskl32.'` Insteadofi jection if*` the r gauge ' is properly 1nanipu-.

renderv the screwdeli'cient. All such deli

of airv craft, it is desirable to use screw

it; Thus, for: example, in the construction knurled linger pieceY 4&8 secured at the fur

threaded members of'minimum .weight con sistent with required holding power so that itis-.essential to determine how close each threaded .element comes to the holding pow

_ er`of-aperfectelement ofthe same type.y

ther end. This spindle Yisrotatively fittedv

within a sleeve 49, which carries the thread

i6 atene end thereof. On its opposite end. a flange 50 may be'provided, this- flange having a lseries-ofslots 5l therethrough, the

sides of which constitutev cam surfaces A .modified form ~of-` gauge is illustrated-^ against which lmove cam followers such'asY

i 1,822,027

pins 52, projecting from an enlarged por cam follower carried by the other said disk. 4. A screw thread gauge comprising a tion 53 of the finger piece 4S, the portion 53 being preferably of disk form and fitted pair of relatively rotatable disks having

10

for rotation within the flange 50. On the threaded bores the threads of which are ca end face of theflange 50 I may provide pable of lying in a common helix and of suitable scale marks and/or Zone-indicating a size to receive with a loose fit the maxi marks, as well as a mark to indicate the mum tolerable screw to be tested, means for open position of the gauge wherein the holding said disks against relative radial threads 45 and 46 lie in a common helix. movement, and means for causing controlled To cooperate with the marks on the flange relative axial movement of said disks when 50 I may provide a suitable index 54 on relatively rotated, said latter means includ

the enlarged portion 53 of the finger piece ing a plurality of cams on one said disk 48. When the finger piece 48 is rotated and spaced about the bore thereof, and a

relatively to the flange 50, the thread 45 cooperating cam follower for each said cams also rotates relatively-to the thread 46. The carried by the other said disk.

slots 5l are preferably formed so as to cause

SO

5. A screw thread gauge comprising a

bodily axial movement of the thread 45 rel

pair of relatively rotatable disks having

to modify the apparent relative axial move pable of lying in a common helix, an axial ment of the threads caused by the rotation, flange on one of said disks forming there

ative to the thread 46 in such a manner as threaded bores the threads of which are ca

' being observed. If the index 54 falls out pair of relatively rotatable disks having side the zone of tolerance on either side, bores threaded to receive with a loose fit a

as hereinbefore described in connection with with a recess to receive the other said disk the slots v26 and pins 27. In using a gauge and to maintain the bores of the disks co of this type, the members are turned to the axial, said other diskhaving a series of cam open position whereupon the gauge grooves cut radially into the periphery 90 threads 45, 46 are screwed into engagement thereof, and a series of cam followers pro with a thread to be tested. The members jecting inwardly from said flange, each said are then relatively rotated in one direction, cam follower being in cooperative engage then the other, the amount of rotation pos ment with one of said grooves. 6. A screw thread gauge comprising a , sible in each case from the open position

95

the tested piece may be rejected.

I claim:

screw to be tested having the maximum

, 1. A screw thread gauge comprising a from the rim of one of said disks and form pair of relatively rotatable members hav ing a recess to receive the other said disk 100

tolerable pitch diameter, a flange extending

ing gaging threads capable of lying in a and cooperating elements on said fiange and common helix, and means connecting said other disk respectively for causing relative members, said means including a cam of axial movement of the disks when relatively varying pitch and a cam follower for caus rotated, said cooperating elements includ

ing relative axial movement of said mem bers when they are relatively rotated.

2. A screw thread gauge comprising a

ing a cam slot and a cam follower project

40

105

ing into said slot.

7. A screw thread gauge comprising a

110

pair of relatively rotatable members hav pair of relatively rotatable disks having ing gaging threads capable of lying in a threaded bores therethrough, the threads of

45

common helix and of receiving with a loose which are capable of lying in a common fit the maximum tolerable screw thread to helix and of receiving with a loose fit a be tested, and means connecting said gauge screw to be tested having the maximum tol

members and causing varying relative axial erable pitch diameter, a flange extending

movement of said gauge members whenA rela

from the periphery of one of said disks and

115

tively rotated, said means including a cam forming a recess to receive the other disk of varying pitch on one of said members and and to maintain the assembled disks coaxial, a cam follower on the other gauge member said other disk having a series of slots in

and in operative engagement with said cam. the periphery thereof making a varying

3. A screw thread gauge comprising a

angle with the plane of the disk, and pins extending inwardly from said flange into pair of relatively rotatable disks having

120

threaded bores the threads of which are ca

said slots to cause relative axial movement

signature. ~

l t JAMES HARTNESS.

pable of lying in a common helix and of a of said disks when relatively rotated. In testimony whereof I have affixed my size to receive with a loose fit the maximum

Vtolerable screw to be tested, means on said

60

disks for holding said disks against relative

radial movement, and means for causing controlled relative axial movement of said

125

disks when relatively rotated, said latter

65

means including a cam of varying pitch carried by one said disk and a cooperating

130

You might also like

- W. F. Draper & C. F. - Ruper.: Let-Dff Mechanism For Looms.Document6 pagesW. F. Draper & C. F. - Ruper.: Let-Dff Mechanism For Looms.DavictorNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- SSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899Document7 pagesSSntanv Engine.,: No. 630,648. - Pamnfed Aug.-A, - 899monem2014100% (1)

- United States Patent (19) : Primary Examiner-Samuel ScottDocument7 pagesUnited States Patent (19) : Primary Examiner-Samuel ScottRockerss RockerssNo ratings yet

- A. E. Jones: Filed March 20, 1924 2 Sheets-SheetDocument5 pagesA. E. Jones: Filed March 20, 1924 2 Sheets-SheetRinnoNo ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- US Patent 3884090Document5 pagesUS Patent 3884090sthollanderNo ratings yet

- Thompson Proto US1425810Document4 pagesThompson Proto US1425810apoorva singhNo ratings yet

- E.I. ZS: Else ADocument5 pagesE.I. ZS: Else ABelay ShibruNo ratings yet

- Galvanometer Coil and Method of Making Same: A. D. RichardsonDocument5 pagesGalvanometer Coil and Method of Making Same: A. D. Richardsonmohamed hemdanNo ratings yet

- US1685447Document5 pagesUS1685447Redirecting DecoyNo ratings yet

- Us2018240 PDFDocument4 pagesUs2018240 PDFPolygrapack SA DE CVNo ratings yet

- The Influence of Granular Vortex Motion On The Volumetric PerformanceDocument12 pagesThe Influence of Granular Vortex Motion On The Volumetric PerformancelarosemaximeNo ratings yet

- 1895 - Us570025Document5 pages1895 - Us570025Enrico Bruce GioloNo ratings yet

- US768413 Tattoo GunDocument4 pagesUS768413 Tattoo GunEl GrandeNo ratings yet

- Electricidad Diseño ElectricoDocument6 pagesElectricidad Diseño ElectricoemernelsonmanNo ratings yet

- Rifle Mauser Automatic 1907Document4 pagesRifle Mauser Automatic 1907cll1968No ratings yet

- Design of Single Plate Shear ConnectionsDocument12 pagesDesign of Single Plate Shear Connectionssecanet10No ratings yet

- Patented Dec. I7, I90".: ' WH NesseszDocument3 pagesPatented Dec. I7, I90".: ' WH NesseszPayal MinochaNo ratings yet

- Cloth Tow Target Low Drag Sleeve (1944)Document4 pagesCloth Tow Target Low Drag Sleeve (1944)CAP History LibraryNo ratings yet

- Switchlayoutssho 00 TorrrichDocument214 pagesSwitchlayoutssho 00 TorrrichPascal CustonNo ratings yet

- No. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed GearingDocument4 pagesNo. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed Gearingbelchior alvaroNo ratings yet

- US1423587 Yarn Retriever For Braiding or Similar Machines PDFDocument8 pagesUS1423587 Yarn Retriever For Braiding or Similar Machines PDFParikshit Paul100% (1)

- ?. 22/22. Sering-?zc?ize.: XY2 ZA230 Pa?enie? 322/2 /346Document6 pages?. 22/22. Sering-?zc?ize.: XY2 ZA230 Pa?enie? 322/2 /346Missy MaynardNo ratings yet

- Tow Target Release Mechanism (1927)Document5 pagesTow Target Release Mechanism (1927)CAP History LibraryNo ratings yet

- April 28, 1970 K. Kohl 3,508,419: Filed June 25, 1968Document3 pagesApril 28, 1970 K. Kohl 3,508,419: Filed June 25, 1968Sher Hai HamNo ratings yet

- MVMK Mm. .: File?d Jan. 29, 1944Document4 pagesMVMK Mm. .: File?d Jan. 29, 1944Syed Umair RizviNo ratings yet

- Stephenson Versus Walschaert Vlave GearDocument16 pagesStephenson Versus Walschaert Vlave Gearmaes.daan1No ratings yet

- BY WWW/a : April 12, 1960v A. Witte - 2,932,081Document3 pagesBY WWW/a : April 12, 1960v A. Witte - 2,932,081PrasadNo ratings yet

- Variable Lay LengthsDocument8 pagesVariable Lay LengthsNajaf HussainNo ratings yet

- June 17, 1941-A. U. Huggenberger: Filed March 14, 1959Document3 pagesJune 17, 1941-A. U. Huggenberger: Filed March 14, 1959Ar JunNo ratings yet

- How To Design With Precision BallscrewsDocument10 pagesHow To Design With Precision BallscrewsRichard CapewellNo ratings yet

- Worn Gearing - Ralph e Flanders Book No. 1Document49 pagesWorn Gearing - Ralph e Flanders Book No. 1Rocio Mtz100% (1)

- A Rit Scher, No. 556,643. Patented Mar. LT, l896.: de Tachable Link For, Drive ChainsDocument2 pagesA Rit Scher, No. 556,643. Patented Mar. LT, l896.: de Tachable Link For, Drive ChainsAnonymous OYGu9L6No ratings yet

- Rail Transporting MachineDocument7 pagesRail Transporting MachineAkashNo ratings yet

- US1170811Document4 pagesUS1170811George AcostaNo ratings yet

- Us 2120533asfafafDocument5 pagesUs 2120533asfafafankitsarvaiyaNo ratings yet

- Sept. 11, 1951 B. B. Scott 2,567,735: His AttorneyDocument3 pagesSept. 11, 1951 B. B. Scott 2,567,735: His AttorneyTri PujiyantoNo ratings yet

- Elements For E-Plane Split-Block Waveguide CircuitsDocument9 pagesElements For E-Plane Split-Block Waveguide CircuitsstrubbelsNo ratings yet

- Pistol Nickl Us1427966Document11 pagesPistol Nickl Us1427966cll1968No ratings yet

- Chapter - 15 Electrical Measuring InstrumentsDocument11 pagesChapter - 15 Electrical Measuring Instrumentsusama113No ratings yet

- (Patente 1) US1489458Document3 pages(Patente 1) US1489458diegoNo ratings yet

- Us2996100 PDFDocument8 pagesUs2996100 PDFerzrzretgertfertgeNo ratings yet

- Sam W Hoke Torch PatentDocument5 pagesSam W Hoke Torch PatentRichard.nlNo ratings yet

- Us1172719 PDFDocument3 pagesUs1172719 PDFsebastian escobarNo ratings yet

- Screw - Design of Screws, Fasteners and PowerDocument39 pagesScrew - Design of Screws, Fasteners and PowerAljen MojeNo ratings yet

- Filed July 30, 1923: Pedal of Erator For Flush ValvesDocument3 pagesFiled July 30, 1923: Pedal of Erator For Flush ValvesmarlondijiNo ratings yet

- MFPWLG @4595.: R. S. ConleyDocument3 pagesMFPWLG @4595.: R. S. Conleymaiale123No ratings yet

- Us1434007 PDFDocument5 pagesUs1434007 PDFsebastian escobarNo ratings yet

- Torsion of Crankshafts: Imoshenko Hiladelphia ADocument15 pagesTorsion of Crankshafts: Imoshenko Hiladelphia ALahiru Prabhatha AmarasenaNo ratings yet

- Distortion Inside A Piston BoreDocument38 pagesDistortion Inside A Piston BoreMike DeSpenzaNo ratings yet

- US1835018Document4 pagesUS1835018mohamed farmaanNo ratings yet

- Improved Yarn Traversing Mechanism For A Filter Winder: Dr. Milind KoranneDocument6 pagesImproved Yarn Traversing Mechanism For A Filter Winder: Dr. Milind KoranneShobhit JaiswalNo ratings yet

- Patented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Document3 pagesPatented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Oscar DorantesNo ratings yet

- In The Workshop: Duplex "Document6 pagesIn The Workshop: Duplex "johnboy183No ratings yet

- Wire Rope Splice and Method of Making The SameDocument3 pagesWire Rope Splice and Method of Making The SameFiqri AnraNo ratings yet

- Apl'il 7, 1959 W. Settele ' v2,880,518Document4 pagesApl'il 7, 1959 W. Settele ' v2,880,518राजकुमार यादवNo ratings yet

- Three Phase Stator Windings: Types of A-C WindingsDocument10 pagesThree Phase Stator Windings: Types of A-C Windingsvaraprasad93No ratings yet

- TestingDocument1 pageTestingVinoth KumarNo ratings yet

- Introduction To CATIA V5: Release 16 (A Hands-On Tutorial Approach)Document33 pagesIntroduction To CATIA V5: Release 16 (A Hands-On Tutorial Approach)Vinoth KumarNo ratings yet

- University of Texas at Arlington: Monday Tuesday Wednesday Thursday FridayDocument11 pagesUniversity of Texas at Arlington: Monday Tuesday Wednesday Thursday FridayVinoth KumarNo ratings yet

- Tcs Employment Application FormDocument6 pagesTcs Employment Application FormVinoth KumarNo ratings yet

- 01 06 02Document21 pages01 06 02Vinoth KumarNo ratings yet

- MechDocument2 pagesMechVinoth KumarNo ratings yet

- Pipe Inspection Robot PDFDocument7 pagesPipe Inspection Robot PDFKarthi KeyanNo ratings yet

- Fuel Pumps: Operation, Diagnosis, & RepairDocument3 pagesFuel Pumps: Operation, Diagnosis, & RepairVinoth KumarNo ratings yet

- Fabrication Quality Control 2-20-08Document4 pagesFabrication Quality Control 2-20-08Vinoth KumarNo ratings yet

- Instructions To CandiatesDocument32 pagesInstructions To CandiatesVinoth KumarNo ratings yet

- D155ADocument491 pagesD155AMehdi Daneshvariyan75% (4)

- Marking On Bolts & Nuts and Washers As Per Standard Energya Po No 5745Document1 pageMarking On Bolts & Nuts and Washers As Per Standard Energya Po No 5745chander sharmaNo ratings yet

- ShopNotes Issue 93Document53 pagesShopNotes Issue 93Enginerdouglas100% (11)

- MODULE 11 Unified Screw Thread ValuesDocument5 pagesMODULE 11 Unified Screw Thread ValuesJCNo ratings yet

- Detail of Sleeve: NotesDocument1 pageDetail of Sleeve: Notesطه حلمىNo ratings yet

- B20D Parts Manual Section 6 ElectricalDocument38 pagesB20D Parts Manual Section 6 ElectricalerickbothaNo ratings yet

- Pegasus EX 3200-5200 Parts ListDocument120 pagesPegasus EX 3200-5200 Parts ListJanos KornfeldNo ratings yet

- Ecosyn Plast ENDocument8 pagesEcosyn Plast ENGogo GogevNo ratings yet

- August 2021 Parts - 2021 - 08 - 25 - 0906AMDocument791 pagesAugust 2021 Parts - 2021 - 08 - 25 - 0906AMRicardo LaraNo ratings yet

- Thread Size Comparison ChartDocument1 pageThread Size Comparison ChartMuharrem BeyogluNo ratings yet

- ES9-54 Fastener Installation and Torque Value Rev JDocument35 pagesES9-54 Fastener Installation and Torque Value Rev Jganesh100% (1)

- Controls - Operators Compartment (Yn03m00091f1 - f3)Document3 pagesControls - Operators Compartment (Yn03m00091f1 - f3)carlosNo ratings yet

- ISO Metric Screw Thread - WikipediaDocument6 pagesISO Metric Screw Thread - WikipediaWalrus Honey BadgerNo ratings yet

- Iso General Purpose Metric ScrewthreadsDocument1 pageIso General Purpose Metric ScrewthreadsAyman MousaNo ratings yet

- Bearings For Screw DrivesDocument10 pagesBearings For Screw DrivesTravis DavisNo ratings yet

- BS en 20898-7-1995 (Iso 898-7) (1999)Document13 pagesBS en 20898-7-1995 (Iso 898-7) (1999)Олег СоловьевNo ratings yet

- Din 76-1Document5 pagesDin 76-1Emmanuel100% (1)

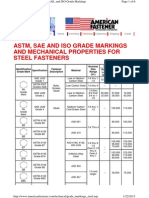

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- MRO Stop Industrial Fastener CatalogDocument53 pagesMRO Stop Industrial Fastener CatalogMROstop.comNo ratings yet

- Maryland Metrics Thread Data ChartsDocument3 pagesMaryland Metrics Thread Data Chartsnovkovic1984No ratings yet

- CH 8: Screws, Fasteners, and The Design of Non-Permanent JointsDocument15 pagesCH 8: Screws, Fasteners, and The Design of Non-Permanent JointsBhuwaneshwar DahalNo ratings yet

- Machine Screws: Dimensions and Other DataDocument1 pageMachine Screws: Dimensions and Other DataSteven PentonNo ratings yet

- Ref. SiloDocument8 pagesRef. Siloahmed aboyosefNo ratings yet

- Trascabo 621 GDocument2 pagesTrascabo 621 GJusaNadaNo ratings yet

- Model No. SJ401 SCROLL SAWDocument5 pagesModel No. SJ401 SCROLL SAWClassical LiteratureNo ratings yet

- NL Superbolt Standard-Range-Brochure 70186ENDocument28 pagesNL Superbolt Standard-Range-Brochure 70186ENalvia3No ratings yet

- JKUISDFDocument21 pagesJKUISDFShahed HusaainNo ratings yet

- UNIT 4 Power ScrewsDocument4 pagesUNIT 4 Power Screwsrahul dNo ratings yet

- Screw Dimensions According To DIN StandardsDocument1 pageScrew Dimensions According To DIN StandardsAhmee MahmoudNo ratings yet

- DuplexDocument226 pagesDuplexÁrgyó András-BotondNo ratings yet