Professional Documents

Culture Documents

Flat Slab Design Example

Uploaded by

Kong SooYitOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flat Slab Design Example

Uploaded by

Kong SooYitCopyright:

Available Formats

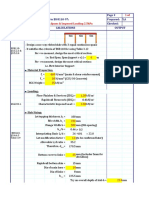

Project :

Woman & Child Hospital, Kuala Lumpur

SLAB DESIGN (FLAT SLAB)

PRC

Design by :

Date:

Location/slab mark: Typical panel

18/11/13

Key in the RED field

(Refer to Clause 3.7, BS 8007)

ly = 8.00 m

lx = 8.00 m

Thickness of Slab, h

200 mm

Self Weight,

4.8 kN/m2

Superimposed dead loads

6.05 kN/m2

2

Dead Load, DL

= 10.85 kN/m

Live Load, LL

n = 1.4DL + 1.6LL

UDL, w

Drop panel size

35 N/mm2

Reinforcement, fy

460 N/mm2

Effective depth, d (middle strip)

3 kN/m2

As min = bh/100

= 19.99 kN/m2 (from slab)

= 19.99 kN/m

(x-dir)= 2700 (y-dir)

Concrete, fcu

2700 mm

Concrete cover

Rebars size used

0.13%

=

=

= 159 mm

260 mm2

25 mm clear

16 mm

The average drop panel load per bay

0.68 kN/m2

Drop panel thickness, hdrop =

Column head, ho

=

Column head, hc

=

450 mm

800 mm

0 mm

Effective depth, d (support)

Effective span, L

8.00 mm

As min = bh/100

Width of column strip, b

Width of middle strip, bm

=

=

2700 mm

5300 mm

Propotion to span

Propotion to span

0.13%

409 mm

585 mm2

= 0.675

= 1.325

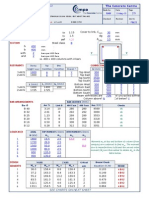

A) Design loads and moment

Total dead load, Gk

= 11.53 kN/m2

Total live load, Qk

Design ultimate laod, n

= 20.95 kN/m2

3.00 kN/m2

Total design load per bay, F

The moments are calculated using coefficient from Table 3.19, BS 8110

The moments distribution into panels of flat slab as per Table 3.20

Near center of 1st span, M1span = +0.083xFxL

1st Interior Support, M1supp

= -0.063xFxL

Center of Interior Span, Mspan = +0.071xFxL

Interior Support, Msupp

= -0.055xFxL

=

=

=

=

890.2

675.7

761.5

589.9

= 1340.6 kN

Moment distribution

Column Strip

Middle Strip

55% 359.4 kNm

45% 530.8 kNm

75% 451.8 kNm

25% 223.8 kNm

55% 307.4 kNm

45% 454.0 kNm

75% 394.5 kNm

25% 195.4 kNm

kNm

kNm

kNm

kNm

M1sup = - 675.7 kNm

Msup = - 589.9 kNm

Mspan= +

M1span= +

761.5 kNm

890.2 kNm

Moment Envelop (kNm)

Mspan= +

761.5 kNm

B) Column Strip Design

Negitive Moments:1st Interior Support

M1supp

= 451.8 kNm

k

z

As

Interior Support

Msupp

= 394.5 kNm

2

= M / bd fcu

= 0.0286

= [ 0.5 + (0.25 - k/0.9)1/2] d

= 0.967 d

>

0.95 d

= 0.95 x 409

= 388.6 mm

= m x / 0.87 fy z

=

2906 mm

As

=

1076 mm /m

2/3 of the bars are placed in the center half of column strip

As

= 1937 mm2

= 1435 mm2/m

As req

Provide

As prov

=

T

1435 mm2/m

16 @

125 mm c/c within 1/2 strip

1608 mm2/m

> As req ==> OK !

Remining bars required

As

=

969 mm2

As req

Provide

As prov

=

T

717 mm2/m

16 @

= 717.5 mm2/m

250 mm c/c within 1/2 strip

> As req ==> OK !

= 804.2 mm /m

2

= M / bd fcu

= 0.0250

= [ 0.5 + (0.25 - k/0.9)1/2] d

= 0.971 d

>

0.95 d

= 0.95 x 409

= 388.6 mm

= m x / 0.87 fy z

=

2537 mm2

= 939.6 mm2/m

2/3 of the bars are placed in the center half of column strip

As

= 1691 mm2

= 1253 mm2/m

As req

Provide

As prov

=

T

1253 mm2/m

16 @

150 mm c/c within 1/2 strip

1340 mm2/m

> As req ==> OK !

Remining bars required

As

=

846 mm2

As req

=

626 mm2/m

T

16 @

Provide

As prov

=

804 mm2/m

= 626.4 mm2/m

250 mm c/c within 1/2 strip

> As req ==> OK !

Positive Moments:Center of 1st span

M1span

= 359.4 kNm

k

z

As

2

= M / bd fcu

= 0.1504

=

=

=

=

[ 0.5 + (0.25 - k/0.9)1/2] d

0.788 d

<

0.95 d

0.788 x 159

125.3 mm

= m x / 0.87 fy z

=

As req

Provide

As prov

Center of interior span

Mspan

= 307.4 kNm

=

T

=

7169 mm

As

=

2655 mm /m

2655 mm /m

20 @

2

3142 mm /m

100 mm c/c

> As req ==> OK !

As req

Provide

As prov

2

= M / bd fcu

= 0.1287

= [ 0.5 + (0.25 - k/0.9)1/2] d

= 0.827 d

<

0.95 d

= 0.83 x 159

= 131.5 mm

= m x / 0.87 fy z

=

5841 mm2

=

T

2163 mm /m

20 @

2

2513 mm /m

2163 mm2/m

125 mm c/c

> As req ==> OK !

C) Middle Strip Design

Negitive Moments:1st Interior Support

M1sup

= 223.8 kNm

k

z

As

2

= M / bd fcu

= 0.0477

=

=

=

=

[ 0.5 + (0.25 - k/0.9)1/2] d

0.944 d

<

0.95 d

0.944 x 159

150.1 mm

= m x / 0.87 fy z

=

As req

Provide

As prov

Interior Support

Msup

= 195.4 kNm

=

T

=

3727 mm

As

2

= 703.1 mm /m

703 mm /m

12 @

150 mm c/c

> As req ==> OK !

754 mm /m

As req

Provide

As prov

2

= M / bd fcu

= 0.0417

= [ 0.5 + (0.25 - k/0.9)1/2] d

= 0.951 d

>

0.95 d

= 0.95 x 159

= 151.1 mm

= m x / 0.87 fy z

=

3232 mm2

=

T

610 mm /m

12 @

= 609.9 mm2/m

175 mm c/c

> As req ==> OK !

646 mm /m

Positive Moments:1st Span

M1sup

k

z

As

2

= M / bd fcu

= 0.1132

=

=

=

=

[ 0.5 + (0.25 - k/0.9)1/2] d

0.852 d

<

0.95 d

0.852 x 159

135.5 mm

= m x / 0.87 fy z

=

As req

Provide

As prov

Interior Span

Msup

= 454.0 kNm

= 530.8 kNm

=

T

=

9784 mm

As

=

1846 mm /m

1846 mm /m

20 @

2

2094 mm /m

150 mm c/c

> As req ==> OK !

As req

Provide

As prov

2

= M / bd fcu

= 0.0968

=

=

=

=

[ 0.5 + (0.25 - k/0.9)1/2] d

0.877 d

<

0.95 d

0.877 x 159

139.5 mm

= m x / 0.87 fy z

=

8132 mm2

=

T

1534 mm /m

20 @

2

1571 mm /m

1534 mm2/m

200 mm c/c

> As req ==> OK !

(D) Deflection Check (base on basic ratio in Table 3.10, BS8110)

(calculations are made using total moment at mid-span and the average of the column and middle strip tension steels)

Near center of 1st span

Near center of 1st span, M1span = +0.083xFxL

M / bd

= 890.2 kNm

4.40

Total rebars provided, Asreq aveg

=(

2655

1846 )/2

2

2251 mm /m

Total rebars provided, Asprov aveg

=(

3142

2094 )/2

2

2618 mm /m

fs = (5/8) x fy x (As / As prov)

247 N/mm2

2

Modification = 0.55 + (477 - fs) / [120 (0.9 + mx/bd )]

= 0.91

<

2.00

= 0.91

=

Allowable l/d = 0.91 x 26 = 23.69

Actual

l/d = 8000 / 159 = 50.31

==> Deflection check, FAIL !!!

Near center of interior span

Center of Interior Span, Mspan = +0.071xFxL

M / bd

= 761.5 kNm

3.76

Total rebars required, Asreq

=(

2163

1534 )/2

2

1849 mm /m

Total rebars provided, Asprov

=(

2513

1571 )/2

2

2042 mm /m

fs = (5/8) x fy x (As / As prov)

260 N/mm2

2

Modification = 0.55 + (477 - fs) / [120 (0.9 + mx/bd )]

= 0.94

<

2.00

= 0.94

=

Allowable l/d = 0.94 x 26 = 24.36

Actual

l/d = 8000 / 159 = 50.31

(E) Shear Check

==> Deflection check, FAIL !!!

(base on basic ratio in Clause 3.7.6, BS8110)

Internal Columns

Punching shear check

Shear, V

= 1.15xnx(Lx x Ly - ho2)

=

2

= 1.166 N/mm

Vmax

2

< 0.8xfcu1/2 =

4.733 N/mm

==> Punching shear check, OK !

1526 kN

Shear check @ 1.5d from column face

= 0.435 N/mm2

perimeter, u =(2 x 1.5 x d) + ho)x4

Shear stress, v

= 8108 mm

shear plane, ls =(2 x 1.5 x d) + ho) =

Top reinforcement provided =

100As/bd

= 0.328

Shear, V

2.027 m

1340 mm2/m

= 1.15xnx(Lx x Ly - ls )

vc = 0.79x(100As/bd))1/3(400/d)1/4(fcu/25)1/3/1.25

vc

1443 kN

= 0.485 N/mm2

==> 1.5d shear check, OK !

You might also like

- Deflection Check (Beams BS 8110)Document2 pagesDeflection Check (Beams BS 8110)dhanya1995No ratings yet

- C1 Design of Column With Biaxial Bending: B MZ MyDocument2 pagesC1 Design of Column With Biaxial Bending: B MZ Myabdul kareeNo ratings yet

- Vertical reinforcement (Walls: BS 8110) guidelinesDocument4 pagesVertical reinforcement (Walls: BS 8110) guidelinesdhanya1995100% (1)

- RC Column Design BS8110Document5 pagesRC Column Design BS8110dantevariasNo ratings yet

- Design of Cantilever BeamDocument110 pagesDesign of Cantilever BeamCONSTHURAG2012100% (3)

- Design of composite slabDocument7 pagesDesign of composite slabjonathanbido100% (4)

- Basement Wall DesignDocument19 pagesBasement Wall DesignwaikenNo ratings yet

- Reinforced Concrete Flat Slab Design GuideDocument93 pagesReinforced Concrete Flat Slab Design GuideTan100% (1)

- Cantilever Slab DesignDocument18 pagesCantilever Slab DesignSarah Huff67% (9)

- One-Way Ribbed Slab Design As Per BS8110Document5 pagesOne-Way Ribbed Slab Design As Per BS8110yusuf abdinasir100% (5)

- Design Shear Resistance (Beams - BS 8110)Document2 pagesDesign Shear Resistance (Beams - BS 8110)Lavanyan SatchithananthanNo ratings yet

- Flat SlabDocument108 pagesFlat SlabArnel Dodong100% (2)

- Flat Slab DesignDocument2 pagesFlat Slab DesignJinWon Kim100% (1)

- BS8110 RC Beam DesignDocument1 pageBS8110 RC Beam DesignPcEng100% (1)

- TCC33 Flat Slabs (A&D)Document47 pagesTCC33 Flat Slabs (A&D)Nazar Shafiq100% (1)

- Flat Slab ExcelDocument6 pagesFlat Slab Excelasad_naqvi67% (3)

- Design Shear Resistance (Beams EC2)Document2 pagesDesign Shear Resistance (Beams EC2)dhanya1995No ratings yet

- Design For Torsion (Beams BS 8110)Document3 pagesDesign For Torsion (Beams BS 8110)dhanya1995100% (1)

- Guide For SpreadsheetsDocument82 pagesGuide For SpreadsheetsIsabelle Wong100% (1)

- Flat SlabDocument2 pagesFlat SlabIrshad FarrukhNo ratings yet

- Design of SumpDocument7 pagesDesign of SumpRASSAL KARIMNo ratings yet

- Composite SlabDocument13 pagesComposite Slabkosithuag50% (2)

- Design of Continuous Beam and Slab Footing Using BS 8110-1:1997Document8 pagesDesign of Continuous Beam and Slab Footing Using BS 8110-1:1997Ubani Obinna Ranks80% (5)

- Design of ColumnDocument6 pagesDesign of ColumnShivsagar YadavNo ratings yet

- TCC32 Ribbed Slabs (A & D)Document56 pagesTCC32 Ribbed Slabs (A & D)hala_azhari100% (2)

- RCC61 Basement WallDocument15 pagesRCC61 Basement WallMUTHUKKUMARAMNo ratings yet

- Examples Design Reinforced Concrete Buildings Bs8110 PDFDocument2 pagesExamples Design Reinforced Concrete Buildings Bs8110 PDFDanielle59% (17)

- Designing reinforced concrete shear walls according to Eurocode 2Document22 pagesDesigning reinforced concrete shear walls according to Eurocode 2Yemi Eshetu MeeNo ratings yet

- RC Beam Design (Cantilever)Document7 pagesRC Beam Design (Cantilever)api-1975359867% (3)

- Reinforced Concrete Design BS 8110Document15 pagesReinforced Concrete Design BS 8110Kutty Mansoor75% (4)

- RCC RAFT FOUNDATION DESIGNDocument33 pagesRCC RAFT FOUNDATION DESIGNUma Mahesh100% (1)

- Microsoft Word - Design and Detailing of Flat SlabDocument22 pagesMicrosoft Word - Design and Detailing of Flat Slabanjana susan john100% (1)

- Slab Design To BS 8110Document11 pagesSlab Design To BS 8110Samuel Antobam100% (2)

- Flat Slab ExcelDocument50 pagesFlat Slab ExcelJEFFY JACOB100% (1)

- Shear wall design parametersDocument6 pagesShear wall design parametersSreehari Ashok100% (1)

- Design For RC Flat SlabsDocument70 pagesDesign For RC Flat SlabsAil Aafaaq100% (3)

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFRegan Tandukar44% (9)

- Beam Design To BS 8110Document14 pagesBeam Design To BS 8110Gihan Chathuranga60% (5)

- Slab Designer As Per IS 456-2000Document7 pagesSlab Designer As Per IS 456-2000mofizahmed64% (11)

- Graded Examples in Reinforced Concrete Design DiasDocument118 pagesGraded Examples in Reinforced Concrete Design DiasAmgad Talal92% (13)

- Strip Footing DesignDocument4 pagesStrip Footing Designkm_ananth100% (1)

- Design and Detailing of Flat Slab.Document22 pagesDesign and Detailing of Flat Slab.DarsHan MoHanNo ratings yet

- Staircase ExcelDocument5 pagesStaircase ExcelvishnuNo ratings yet

- Rectangular Column Design SpreadsheetDocument1 pageRectangular Column Design SpreadsheetBikram92No ratings yet

- Detailing To BS 8110Document88 pagesDetailing To BS 8110Sudhakar KrishnamurthyNo ratings yet

- Wall Design 01Document20 pagesWall Design 01cloud652167% (3)

- Design of combined footing and strap beamDocument4 pagesDesign of combined footing and strap beamSakar ShresthaNo ratings yet

- TCC53 Column DesignDocument18 pagesTCC53 Column DesignVasileios Manginas100% (3)

- RCC Staircase Design in ExcelDocument3 pagesRCC Staircase Design in ExcelDebarshi Sahoo100% (1)

- Design of Two-Way Slab and BeamsDocument36 pagesDesign of Two-Way Slab and Beamsveenabalu20No ratings yet

- Auditorium Building DesignDocument28 pagesAuditorium Building DesignChandra Sekar100% (1)

- Structural Report On 400 KLD STPDocument16 pagesStructural Report On 400 KLD STPVipin SinghalNo ratings yet

- Slab DesignDocument28 pagesSlab DesignUlasi IfeanyiNo ratings yet

- 4b-Flexural Analysis of Reinforced Concrete T-Section BeamsDocument14 pages4b-Flexural Analysis of Reinforced Concrete T-Section Beamsßlack ßoodyNo ratings yet

- Design of Rectangular Water TankDocument242 pagesDesign of Rectangular Water Tankmumarbsc7244No ratings yet

- Design of BeamDocument9 pagesDesign of BeamdrajkumarceNo ratings yet

- Design of Rectangular Water Tank with L/B Ratio Greater than 2Document5 pagesDesign of Rectangular Water Tank with L/B Ratio Greater than 2Hareesh RameshNo ratings yet

- Proposed Residential House Design and Structural PlansDocument16 pagesProposed Residential House Design and Structural Plansjeromefamadico90% (20)

- FinalDocument42 pagesFinalVishnu Kumar0% (1)

- Final Post OffDocument49 pagesFinal Post Offnalayathan123No ratings yet

- Midas - Wind Calculation To BS6399Document6 pagesMidas - Wind Calculation To BS6399Kong SooYitNo ratings yet

- Construction JointsDocument4 pagesConstruction Jointshansnito67% (3)

- Infra DesignDocument65 pagesInfra DesignKong SooYit100% (3)

- Design reinforced concrete slabs using finite element analysisDocument2 pagesDesign reinforced concrete slabs using finite element analysisKong SooYitNo ratings yet

- 2017 Malaysian Tax Booklet PDFDocument105 pages2017 Malaysian Tax Booklet PDFJohn TiNo ratings yet

- IWK Buffer ZoneDocument1 pageIWK Buffer ZoneKong SooYitNo ratings yet

- Determine compressive strength of coal measure rock using point load testDocument10 pagesDetermine compressive strength of coal measure rock using point load testScott Downs0% (1)

- Koi Selecting and Judging Standards by Dr. Arthur LembkeDocument18 pagesKoi Selecting and Judging Standards by Dr. Arthur LembkeKong SooYitNo ratings yet

- Span To Depth Various CodesDocument5 pagesSpan To Depth Various CodesKong SooYitNo ratings yet

- STEEL CONFERENCE EXPANSION JOINTSDocument4 pagesSTEEL CONFERENCE EXPANSION JOINTSCharles Orebola OresanwoNo ratings yet

- STEEL CONFERENCE EXPANSION JOINTSDocument4 pagesSTEEL CONFERENCE EXPANSION JOINTSCharles Orebola OresanwoNo ratings yet

- Form CIDB IBS Score M1 Rev 2010Document7 pagesForm CIDB IBS Score M1 Rev 2010amirriyyahNo ratings yet

- Design of ESCP FacilitiesDocument30 pagesDesign of ESCP FacilitiesMohd Salmi YusoffNo ratings yet

- Real Money Maker - A Guide To Passive IncomeDocument17 pagesReal Money Maker - A Guide To Passive IncomeKong SooYitNo ratings yet

- Guidelines On GBI Facilitators' Scope of Work & Fees V1.0 PDFDocument2 pagesGuidelines On GBI Facilitators' Scope of Work & Fees V1.0 PDFKong SooYitNo ratings yet

- The Use of Modules: M 100 MM Basic ModuleDocument6 pagesThe Use of Modules: M 100 MM Basic ModuleKong SooYitNo ratings yet

- Span To Depth Various CodesDocument5 pagesSpan To Depth Various CodesKong SooYitNo ratings yet

- M16940Document47 pagesM16940Kong SooYitNo ratings yet

- M16940Document47 pagesM16940Kong SooYitNo ratings yet

- Blue Eyes: Human-Operator Monitoring SystemDocument20 pagesBlue Eyes: Human-Operator Monitoring SystemVidya KumarNo ratings yet

- Expt 8a-Study and Analysis of Hidden Terminal Problem in WLAN Using NetsimDocument5 pagesExpt 8a-Study and Analysis of Hidden Terminal Problem in WLAN Using NetsimKritika VermaNo ratings yet

- SF DumpDocument22 pagesSF Dumpjhastin alejosNo ratings yet

- Prototyping of Heart Rate and SpO - 2 Measurement Using MAX30100Document11 pagesPrototyping of Heart Rate and SpO - 2 Measurement Using MAX30100Rich LeeNo ratings yet

- Install Java on Ubuntu with AptDocument19 pagesInstall Java on Ubuntu with AptNavneet HoodaNo ratings yet

- Cs8591 - CN Unit 5Document53 pagesCs8591 - CN Unit 5Vidhya RajNo ratings yet

- LA SpecificationDocument3 pagesLA SpecificationVino VinoNo ratings yet

- SEKSYEN RADIATOR 4B11 Mitsubishi Motors Service ManualDocument5 pagesSEKSYEN RADIATOR 4B11 Mitsubishi Motors Service ManualAz Zahra AzmanNo ratings yet

- Rear Axle: SectionDocument17 pagesRear Axle: SectionLíder DieselNo ratings yet

- C-Splash 2 SpecificationsDocument7 pagesC-Splash 2 SpecificationsGiovanna ChaniNo ratings yet

- Three Thumb Rules To Be Followed Are As Follows:: RCC ColumnsDocument2 pagesThree Thumb Rules To Be Followed Are As Follows:: RCC ColumnsAnuranga SahampathNo ratings yet

- Rexroth PSX 6Xxx.630 Timer and I/O Level: Technical InformationDocument131 pagesRexroth PSX 6Xxx.630 Timer and I/O Level: Technical InformationMiguel ReyesNo ratings yet

- Chapter 2 Entrepreneurial Ideas, Creativity & InnovationDocument57 pagesChapter 2 Entrepreneurial Ideas, Creativity & Innovationhanissaibrahim7002No ratings yet

- Company-Profile GemstoneDocument1 pageCompany-Profile Gemstoneanan diNo ratings yet

- KAC-8102D/8152D KAC-9102D/9152D: Service ManualDocument18 pagesKAC-8102D/8152D KAC-9102D/9152D: Service ManualGabrielConsentidoNo ratings yet

- Alloy Wheel Repair Centre 2Document16 pagesAlloy Wheel Repair Centre 2Rahul MhaskeNo ratings yet

- AEP StudyGuide MediaPlanning PDF Inline DownloadDocument68 pagesAEP StudyGuide MediaPlanning PDF Inline DownloadRayan Mirza100% (1)

- Ujian Tengah Semester Genap TA 2020/2021 Fakultas Ekonomi dan SosialDocument4 pagesUjian Tengah Semester Genap TA 2020/2021 Fakultas Ekonomi dan SosialAchmad VidyNo ratings yet

- Section Roll No Full Name Mobile No Option Q. No 1Document12 pagesSection Roll No Full Name Mobile No Option Q. No 1Gazala KhanNo ratings yet

- Aiml Virtual InternshipDocument21 pagesAiml Virtual InternshipPainampuram JuhithaNo ratings yet

- Complete System Administrator ChecklistDocument8 pagesComplete System Administrator Checklistيعىسسفشى نهلثىغه64% (14)

- Necessary Documents For Passport or E-Passport ApplicationDocument1 pageNecessary Documents For Passport or E-Passport ApplicationMizanul HoqueNo ratings yet

- Boss GT-8 Service NotesDocument31 pagesBoss GT-8 Service NotesFernando Gómez50% (4)

- LSPS ReporteDocument5 pagesLSPS ReporteCarlosNo ratings yet

- Course 1 Anchor Instalation inDocument39 pagesCourse 1 Anchor Instalation inViktorMarkuletsNo ratings yet

- Undercarriage Inspection Report: Audit Check EX2500-5 S/N 502Document4 pagesUndercarriage Inspection Report: Audit Check EX2500-5 S/N 502ferryokfyanNo ratings yet

- V94.2 Beggenum Experience & Improve Concept For Syngas Application PDFDocument24 pagesV94.2 Beggenum Experience & Improve Concept For Syngas Application PDFEliyanto E BudiartoNo ratings yet

- Design and Code Review Checklist: InstructorsDocument38 pagesDesign and Code Review Checklist: InstructorsSakthivel PNo ratings yet

- The European Business Review - July August 2023Document98 pagesThe European Business Review - July August 2023bambiemily tanNo ratings yet

- Section Course OutlineDocument3 pagesSection Course OutlineAftab AhmadNo ratings yet