Professional Documents

Culture Documents

Dry Docking Procedure

Uploaded by

nattiemobsterCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dry Docking Procedure

Uploaded by

nattiemobsterCopyright:

Available Formats

FYP - Introduction

http://www.angelre.com/rnb/drydocking/intro.htm

undened

Introduction to Dry Docks

In this section we will touch on briey what we will be covering in our project: Introduction to Dry Docking Aim Scope Background Knowledge Types of Dry Docks Dry Dock Operations in Short Underwater work Owners Requirements and Docks Requirements

Introduction

Dry docking is a process whereby a ship is brought into a dock which is then emptied of sea water so that work can be performed on the exterior part of the ship below the waterline. Ships are also constructed on dry docks. To launch the new or repaired ship from the dry dock, the ship is either oated in place or slid from its berth. To prepare the dry dock, keel blocks are set into position at the bottom of the dock. Dock-based winches positioned at the forward end of the dock are usually used to pull and position the ship in the dock. It is important to nish the work to the submerged part of the ship when it is in the dry dock as soon as possible, to make way for other ships that need to be dry docked. Ships are usually sent for dry docking once in 3 years.

Aim

Our aim is to understand and implement the knowledge of dry-docking by explaining some of the various tasks in the operation itself. A website will be launched to provide information for DMR and COC students as a form of reference. We hope that in the future our project will be continued by other students.

Scope

As Dry Docking is a huge topic to cover, we will only be going into a few topics of it. These are: Procedures, Propeller work, Rudder work, Hull work and Safety measures. For procedures, we will discuss the docking and undocking sequence as well as then preparation for the dock. For the propeller work we will go into how the propeller is removed and how it is seated back. For the rudder work we will talk about how the rudder is removed. In the hull part we will talk about corrosion and how it can affect a ship. Then we will talk about ways how the ship is sand blasted and painted again in order to reduce resistance. Finally in the safety portion we will talk about general safety practices in a shipyard.

Background

1 of 3

1/7/14 5:45 PM

FYP - Introduction

http://www.angelre.com/rnb/drydocking/intro.htm

The dry dock is the repair or service yard for the ship. The whole ship is brought to dry land so that the submerged portions of the hull can be cleaned or inspected. This dry docking is done every 12 months to 24 months. There are some machinery and systems that cannot stop while the ship is in use, these are also serviced, repaired or replaced at the same time. Large ships are brought into a dock that consists of a large basin with a gate that can be closed watertight. After the ship is positioned over carefully arranged resting blocks (called keel-blocks), the water from the basin is pumped out. As the water level drops, the ship gradually rests on the blocks. Wooden wedges are then knocked in to take up any clearances between the hull of the ship and the resting blocks. For a routine dry-docking, the usual work to be done are: Hull cleaned of marine growth. Painting with anti-corrosive and anti-fouling paints. Sacricial anodes renewed. Hull inspection and repairs. Shipside gratings cleaned and repaired. All overboard and sea suction valves overhauled. Cleaning and surveying of tanks. Rudder, locking devices clearances examined. Propeller damage, nut looseness, blade polishing done. Tail shaft bearing wear down checked. Tail shaft removed and inspected. Coupling bolts and holes deformation. Anchor chain examined, cleaned and re-marked. All underwater stufng boxes repacked. For the ship's personnel, this is a busy time. Although shipyard workers will do most of the work, many of the repair and servicing work will be assigned to them. As with everybody working on the ship, this is a time to be extra careful on safety. Many people are working in the same place at the same time. In the engine room, rigging workers lift heavy materials using chain blocks, while other machinery workers dismantle foundation bolts for the engine below. Welders cut pipes while others removed oor plates so that they can crawl down to inspect the cofferdams. Cleaning is carried out on the boiler especially to the boiler tubes, and soot is removed. The engine room at this point is likely to be in a mess! For safety purposes, re hoses connected to shore hydrants are laid on deck and pressurized. Precautions are taken to avoid tools or other materials from falling from the sides of the ship. Safety helmets must be worn by all personal at all times in all parts of the ship during dry docking. Cables or hoses are positioned such that they do not obstruct excess to passageways. Fire extinguishers are made available near welding sites and are usually color coded for easy identication. In the case of cold climates, water in engines or pipes has to be drained away to prevent freezing. Some of the normal utilities may not be functional at the time of dry docking. Often, the seamen will have to use the shore shower and toilet facilities. If for any reason cooling seawater is not supplied to the air-conditioning system on board by hoses, then there will not be air-conditioning. But this rarely occurs. Sometimes repair work has to be done on the seawater piping. The boilers have to be dismantled, so there is no heating in the living quarters. Sometimes shipping companies arrange special accommodation for their crew on shore during dry-docking. But again, this is very rare. Dry-docking is not the normal routine work for the seafarer. In fact, this is the only time when the generators are not running.

Underwater Work

Underwater work is the most important work that is carried out when a ship is in a dry dock. It refers to the work that must be carried out on the ships hull which is normally submerged, or underwater. It is crucial that underwater work is carried out within the timeframe that the ship is in the dry dock for. Normal underwater works include: Sandblasting to remove all paint and rust. Inspection of the hull for repair requirements. There are a large number of through-the-hull openings to bring water into the ship and to remove liquids. All of these are covered with welded steel plates. These plates must be replaced. Most of the hull plating is riveted, not welded. After all these years, the rivets are susceptible to leaking. The

2 of 3

1/7/14 5:45 PM

FYP - Introduction

http://www.angelre.com/rnb/drydocking/intro.htm

areas containing the riveted seams must be coated with a special compound which covers the rivets. Since the hull at the waterline (where the air and water interact) receives the most corrosion, it must have a half inch thick steel plate welded to the hull from four feet above to four feet below the waterline. Once all the repair and maintenance work has been accomplished, the hull will be coated with a multiple-part epoxy coating to minimize corrosion. This also reduces friction between the ship and the seawater.

Owner's requirements

Basic requirements 1) Dock's plannings 2) Water supply 3) Air supply 4) Electric Power supply Other requirements depend on owner.

Dock's requirements

1) All engines must be stopped totally. 2) Electric Power must be switch off totally. 3) All valves must be closed totally. 4) Dry docking mark is needed if ship needs dry docking. 5) All machines' codes. 6) Clear job pass is needed if owner want to repair some machines himself.

Back to top All Rights Reserved Copyright 2004 www.angelre.com/rnb/drydocking/ E-mail Webmaster

3 of 3

1/7/14 5:45 PM

You might also like

- Preparation For Dry DockingDocument8 pagesPreparation For Dry DockingWin Min100% (8)

- Dry Dock 1Document33 pagesDry Dock 1saurabh1906No ratings yet

- Docking SurveyDocument173 pagesDocking SurveyJORGENo ratings yet

- Dry Docking NotesDocument16 pagesDry Docking NotesIshan Vyas100% (1)

- Part 8 DrydockDocument9 pagesPart 8 Drydockaungthein_san100% (1)

- Duties of Ship's Chief Officer When Entering Dock: Preparing The Ship For Dry DockingDocument12 pagesDuties of Ship's Chief Officer When Entering Dock: Preparing The Ship For Dry DockingMohan Krishnan100% (1)

- Preparing The Ship For Dry DockDocument4 pagesPreparing The Ship For Dry Dockdanilo laraNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Ship RepairDocument27 pagesShip RepairMuhammed Razeem100% (1)

- Dry Docking PDFDocument3 pagesDry Docking PDFDeepakNo ratings yet

- Commercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysFrom EverandCommercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysRating: 4.5 out of 5 stars4.5/5 (6)

- Dry Docking A ProjectDocument5 pagesDry Docking A ProjectPrasanth DS100% (1)

- Drydock GuidelineDocument13 pagesDrydock GuidelineRakeshRanjan100% (1)

- Dry DockingDocument32 pagesDry DockingShahbaz Ali100% (4)

- Dry-docking-All About To KnowDocument200 pagesDry-docking-All About To Knownitishforindia100% (3)

- Scope of Work (Dry Docking List)Document16 pagesScope of Work (Dry Docking List)boen jayme100% (2)

- Dry DockDocument10 pagesDry Dockskm1974100% (2)

- Specification For Dry DockDocument35 pagesSpecification For Dry Dockkdsenipah666767% (6)

- 1 Course Notes - Dry Docking and Planned MaintenanceDocument19 pages1 Course Notes - Dry Docking and Planned Maintenancedarrelsilva100% (2)

- DryDock CompleteDocument24 pagesDryDock Completeashry_tarek100% (2)

- Example of Drydock SpecificationDocument44 pagesExample of Drydock Specificationmetallourgos100% (6)

- Preparation For Dry DockingDocument4 pagesPreparation For Dry Dockingrajishrrr0% (1)

- Dry DockingDocument11 pagesDry DockingBhushan Pawaskar50% (2)

- Drydocking RepairDocument95 pagesDrydocking RepairAung Paing OoNo ratings yet

- MS - Ship Repair - 2006 7 GuideDocument42 pagesMS - Ship Repair - 2006 7 Guidenawkong50% (2)

- Draft Survey: Draft Reading and Precaution Measurement of Seawater Density Step by Step CalculationDocument16 pagesDraft Survey: Draft Reading and Precaution Measurement of Seawater Density Step by Step CalculationNyan Min Htet100% (2)

- Dry DockingDocument84 pagesDry DockingInder Mukhopadhyay100% (5)

- OPS 02 - Pre-Visit Checklist For SuperintendentsDocument6 pagesOPS 02 - Pre-Visit Checklist For SuperintendentsEmre AlgülNo ratings yet

- Dry Dock: MV Victorious Ace: Presentation by Shivendra Deck Cadet MolDocument53 pagesDry Dock: MV Victorious Ace: Presentation by Shivendra Deck Cadet Molshubh vermaNo ratings yet

- On Hire Survey and Off Hire SurveyDocument4 pagesOn Hire Survey and Off Hire SurveyOhh Min75% (4)

- Loc Survey ReportDocument26 pagesLoc Survey Reportluckystrike9008100% (1)

- Ship Repair Most Common VocabularyDocument20 pagesShip Repair Most Common VocabularyAnonymous IXswcnW100% (1)

- DryDocking Technical SpecificationsDocument11 pagesDryDocking Technical SpecificationsRem Larazi50% (2)

- SPT - Ship SurveyDocument10 pagesSPT - Ship SurveySyafiq Salim100% (1)

- 1.procedure of Sea TrialDocument51 pages1.procedure of Sea Trialvran77100% (6)

- Dry Docking OperationsDocument5 pagesDry Docking Operationshutsonianp100% (2)

- Marine Survey Practice - Surveyor Guide Notes For Anchors and Chains SurveyDocument5 pagesMarine Survey Practice - Surveyor Guide Notes For Anchors and Chains SurveywisnukerNo ratings yet

- On Off Hire SurveyDocument7 pagesOn Off Hire Surveyio75100% (2)

- NK Good Maintenance On Board Ships eDocument74 pagesNK Good Maintenance On Board Ships eArdyas Wisnu Baskoro100% (4)

- Survey DrydockDocument20 pagesSurvey DrydockHarshad Tallur100% (3)

- Dry-Dock Repair ListDocument6 pagesDry-Dock Repair ListAnwarul Islam100% (3)

- Standard P&i Condition SurveyDocument31 pagesStandard P&i Condition Surveyluchiappi100% (9)

- Diploma in Marine SurveyingDocument8 pagesDiploma in Marine Surveyingvipinchellakudam50% (2)

- Superintendent Visit Report Tytyan Karimata 02Document8 pagesSuperintendent Visit Report Tytyan Karimata 02alsitorNo ratings yet

- Sample DAILY PROGRESS REPORT For DRY DOC PDFDocument6 pagesSample DAILY PROGRESS REPORT For DRY DOC PDFRio Marine Petroleum ServicesNo ratings yet

- Bulk Carrier Condition Survey ReportDocument33 pagesBulk Carrier Condition Survey Reportalxgam100% (1)

- Dry Docking QuotationDocument4 pagesDry Docking Quotationboen jayme100% (1)

- Design For Easy Ship Repair and SurveyDocument11 pagesDesign For Easy Ship Repair and Surveyujjwal kumar vidyarthiNo ratings yet

- Port State Detentions Quick ReferenceDocument36 pagesPort State Detentions Quick Referencestamatis100% (2)

- Dry-Docking Shipmanagement Checklist Low PDFDocument2 pagesDry-Docking Shipmanagement Checklist Low PDFmatirpmasterNo ratings yet

- Condition Survey ReportDocument21 pagesCondition Survey Reportsara_gr93% (15)

- Major Works in Ship RepairDocument10 pagesMajor Works in Ship RepairKrisel AbandoNo ratings yet

- Bunker Calculation Excel SheetDocument1 pageBunker Calculation Excel SheetJay Narayan TiwariNo ratings yet

- Pilot Transfer Arrangements BrochureDocument5 pagesPilot Transfer Arrangements BrochureMats Karlsson100% (1)

- P&I Club - How To Prevent Tanker Cargo Shortage Claims PDFDocument12 pagesP&I Club - How To Prevent Tanker Cargo Shortage Claims PDFСимеон Айков100% (1)

- Annex 2 RESOLUTION MSC.308 (88) (Adopted On 3 December 2010) Adoption of Amendments To The International Convention For The Safety of Life at Sea, 1974, As AmendedDocument11 pagesAnnex 2 RESOLUTION MSC.308 (88) (Adopted On 3 December 2010) Adoption of Amendments To The International Convention For The Safety of Life at Sea, 1974, As AmendednattiemobsterNo ratings yet

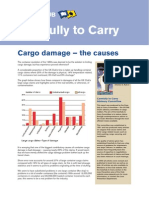

- Cargo DamageDocument2 pagesCargo DamagenattiemobsterNo ratings yet

- SOM Syllabus ICSDocument4 pagesSOM Syllabus ICSSailee KordeNo ratings yet

- PGPX BrochureDocument16 pagesPGPX Brochureankur_1231No ratings yet

- Liberia - Marine Advisory On PSC Inspection (No. 14-2012)Document10 pagesLiberia - Marine Advisory On PSC Inspection (No. 14-2012)nattiemobsterNo ratings yet

- Revised Time PDFDocument1 pageRevised Time PDFnattiemobsterNo ratings yet

- Chief Mates Cargo Work SyllabusDocument8 pagesChief Mates Cargo Work SyllabusnattiemobsterNo ratings yet

- Satanic RitualsDocument47 pagesSatanic RitualsBcrns Chua86% (7)

- Sample Menu Plan For Gestational Diabetes (North Indian Vegetarian) Calories - 1800 No of Carb Choices - 13Document2 pagesSample Menu Plan For Gestational Diabetes (North Indian Vegetarian) Calories - 1800 No of Carb Choices - 13priyankaswaminathanNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Cab. Reg. No. 197 - Port State ControlDocument31 pagesCab. Reg. No. 197 - Port State ControlnattiemobsterNo ratings yet

- Marpol Discharge Incl VIDocument4 pagesMarpol Discharge Incl VInattiemobsterNo ratings yet

- Chapt-17 Compass ErrorDocument4 pagesChapt-17 Compass ErrorShubham SinghNo ratings yet

- Ship Construction Syllabus MatesDocument3 pagesShip Construction Syllabus MatesnattiemobsterNo ratings yet

- Chief Mate Phase 1 Exam Paper Format - Cargo Handling and Stowage 19052011Document1 pageChief Mate Phase 1 Exam Paper Format - Cargo Handling and Stowage 19052011nattiemobsterNo ratings yet

- Dry Docking ProcedureDocument3 pagesDry Docking ProcedurenattiemobsterNo ratings yet

- FYP - Hull WorkDocument3 pagesFYP - Hull WorknattiemobsterNo ratings yet

- Masters ChecklistDocument6 pagesMasters ChecklisterandaarunaNo ratings yet

- ATPL Law 01Document18 pagesATPL Law 01Anuar SNo ratings yet

- KLQSMS-Y-G-02 Squat Calculation Sheet Appendix-C: Name of VesselDocument2 pagesKLQSMS-Y-G-02 Squat Calculation Sheet Appendix-C: Name of VesselSmart SethuNo ratings yet

- Tafe Report andDocument59 pagesTafe Report andsuryaa patilNo ratings yet

- Cycling Course DesignDocument68 pagesCycling Course Designplowe_1No ratings yet

- Tiguan VWDocument6 pagesTiguan VWMeor Amri100% (2)

- SJ6826/32 RT: Rough Terrain ScissorsDocument2 pagesSJ6826/32 RT: Rough Terrain ScissorsElias CamachoNo ratings yet

- Eta 02 03Document26 pagesEta 02 03Miyanda HimachilaNo ratings yet

- Chittagong Agent ListDocument11 pagesChittagong Agent ListMuhammad0% (2)

- Flying The Flag': Mapping IAL & Boac RoutesDocument7 pagesFlying The Flag': Mapping IAL & Boac RoutesDave FaganNo ratings yet

- 25 M Fast Supply Vessel Swe v1Document2 pages25 M Fast Supply Vessel Swe v1Sebastian RentschNo ratings yet

- Information On Pick Up Services & Hotel-Msts Johor (Pasir Gudang) (Wef 01.08.2015)Document5 pagesInformation On Pick Up Services & Hotel-Msts Johor (Pasir Gudang) (Wef 01.08.2015)bebulalaNo ratings yet

- 5470.43.530NR - 2013-07 - Coating PerformanceDocument22 pages5470.43.530NR - 2013-07 - Coating PerformanceMohamed Mostafa100% (1)

- ROCKWOOL - Technical Guidelines 2012 WebDocument108 pagesROCKWOOL - Technical Guidelines 2012 WebtoniferrazNo ratings yet

- Kiswire Steel Wire RopeDocument28 pagesKiswire Steel Wire RopeMulatua Sirait100% (3)

- Allison M6610&S6610 Series PDFDocument2 pagesAllison M6610&S6610 Series PDFluisedonossaNo ratings yet

- Mechanical Maintenance ManualDocument47 pagesMechanical Maintenance ManualAli Yimer Ali86% (7)

- PPP ModelDocument40 pagesPPP ModelMainak BhattacharjeeNo ratings yet

- Falklands V2.0 Order of BattleDocument25 pagesFalklands V2.0 Order of BattleArthur Barie100% (1)

- Gantrail Welded Base Fixing: SpecificationsDocument2 pagesGantrail Welded Base Fixing: SpecificationstobiasNo ratings yet

- TRANSLINK - Company Profile PDFDocument39 pagesTRANSLINK - Company Profile PDFKaran DaveNo ratings yet

- In The Small Design Office: ToolsDocument10 pagesIn The Small Design Office: ToolslapuNo ratings yet

- LOad On Bridge 2Document140 pagesLOad On Bridge 2shamsukarim2009No ratings yet

- SoR Chattis PH 2015 - Schedule of Rates - ChattisgarhDocument377 pagesSoR Chattis PH 2015 - Schedule of Rates - Chattisgarhnimm1962100% (1)

- 2023 JMSA Fuel Consumption in Seaway Considering The Dynamic Interaction Among Environment-Hull-Propeller-EngineDocument13 pages2023 JMSA Fuel Consumption in Seaway Considering The Dynamic Interaction Among Environment-Hull-Propeller-EngineFrank LiouNo ratings yet

- Quotation Bina Megah Indowood 30 HPDocument1 pageQuotation Bina Megah Indowood 30 HPKurniawan FebryNo ratings yet

- 8frba SeriesDocument2 pages8frba Seriesargo kuncahyoNo ratings yet

- Northwest African Air Forces-1943Document39 pagesNorthwest African Air Forces-1943cjnjr1No ratings yet

- Judging Ayodhya: Book ReviewsDocument79 pagesJudging Ayodhya: Book ReviewsUjjwal DixitNo ratings yet

- List of Life Jackets: No Location Cabin Manufactured Type Date Light Type DateDocument2 pagesList of Life Jackets: No Location Cabin Manufactured Type Date Light Type Datewawan iswadiNo ratings yet

- 747 FB 13-02Document2 pages747 FB 13-02JOEL VITOR PEREIRA DOS SANTOSNo ratings yet