Professional Documents

Culture Documents

Carbon

Uploaded by

peralta78Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbon

Uploaded by

peralta78Copyright:

Available Formats

TECHNOLOGY STORIES

2013

FELT CARBON FIBER

Once limited to aerospace and motor sports, carbon ber is now the material of choice for high-performance bicycles. Lighter than aluminum, stronger than steel, and with Felts manufacturing techniques, carbon ber bicycles offer an unmatched combination of ride compliance, stiffness, strength, and efciency. With its incredibly high strength-to-weight ratio and malleability, carbon ber is second to none for building the worlds best bicycles.

WHAT IS CARBON FIBER Carbon ber, in its raw form, is a conjoining of thin, strong bers. These bers come in a variety of grades based on overall strength and stiffness. The higher the modulus, the stiffer and lighter it is. However, this doesnt mean that the best bikes are completely constructed from high modulus carbon ber. On the contrary, the key to building bikes is to mix and match modulus, nding the ideal characteristic balance stiffness, strength, weight and cost.

CaRBON FIBER

TECHNOLOGY STORIES

2013

UNDERSTANDING UNIDIRECTIONAL CARBON FIBER To help visualize this, think of a wine glass. If you drop it on a hard oor it shatters because its so thin, stiff, and brittle. Now think of a plastic cup. You can drop it and nothing happens because of its exible properties. Carbon follows similar rules. As you increase the modulus, the stiffer and more fragile the bers become. And if you go in the other direction, the bers are not as stiff, but more compliant and durable. FROM FIBERS TO FRAME Imagine youve been transported to the Felt factory oor and are looking over the lay-up schedule for a new F1 road frame. Listed on the piece of paper before you are various instructional entries, each representing an individual piece of carbon ber. Key metrics include dimensions, modulus, ber orientation, resin content, and ber areal weight. Together, this information provides the road

STIFF

Unidirectional Carbon Fiber: Has a high stiffness to weight ratio, but is exible as a single ply and easily penetrated. Maintaining this critical balance is the ongoing goal of Felts team of skilled designers and engineers. Building frames that are simply lighter or stiffer is not enough. Each bike must deliver the unique ride quality that only Felt can deliver.

Unidirectional bers are very stiff vertically (Y Axis)

Unidirectional bers are moderately stiff when bent laterally (Z Axis)

Unidirectional bers are not stiff when resin is bent laterally (Y Axis)

STIFFER

Uni. Carbon Fiber layered: Has a high stiffness to weight ratio, is stiffer & stronger when layered in different orientations.

Unidirectional carbon ber responds to stress in very distinct manners. See examples above for an idea.

There is no such thing as a bicycle frame constructed completely from high modulus carbon ber, at least not one that would be safe to ride. It would likely break apart the rst time you hit a big enough pot-hole. High modulus carbon ber can be tricky to work with and there must be balance between stiffness, weight, strength, and durability.

STIFFEST

Many Uni. Carbon Fibers layered: Has an ultra high stiffness to weight ratio, is stiff & strong and protected by a carbon ber weave adding impact protection.

TECHNOLOGY STORIES

2013

map that leads to a nished frame. Now imagine hundreds of these entries, each one slightly different from the next. Quickly you begin to understand the complexity of this equation. Many people think all carbon bicycle construction is the same. Though, when you consider all the parameters involved, you realize what a complicated process it really is. Every bike manufacturer can tweak ply orientations, tweak material, and use different resins to hold everything together. But if you dont put in the time during the design phase to truly understand structural relationships, youre just creating generic bikes. Thats not what we do at Felt.

Every frame design behaves differently, and every frame size requires a unique lay-up. The blending of these materials can vary greatly. For example, stiffer ber plies are typically used in areas requiring maximum performance, such as the bottom bracket and down tube. Higher-strength ber is best for areas more susceptible to impact. The same attention is applied to changes in frame size. As tube diameters and intersections change, so will ply orientation and material specications. These determinations take months, even years to nalize considering all the variations. FEA analysis indicates areas of high stress

The beginnings of a Nine frame One of many pages that compose a layup schedule TENSILE STRENGTH v MODULUS

TENSILE STRENGTH ksi 1050

When we were in the development phase of the F1, we went through ve different lay-up schedules. explains Jim Felt. Even though wed hit the basic testing numbers we were looking for, it still didnt ride quite the way we wanted it to. So we kept going back and tweaking the plies until it had that electric feel. We could have stopped, but thats not how we operate. Its that attention to detail that sets us apart. Our goals are not just about hitting certain numbers or tolerances or weights. Our goal is to build great riding bikes. Every time. Once the ideal blend of materials and ply orientation is determined, the lay-up schedule is nalized, outlining every detail of the construction process. Finally all specied plies of carbon ber are ready to be assembled by hand to create a Felt frame.

750

350 30 60 MODULUS msi 90

Performing an in-house torsional stiffness test

Instead, through extensive Computer Aided Design (CAD), Finite Element Analysis (FEA), and prototype testing by Felts professional riders, we are able to ascertain which ber types to use. The goal is to precisely position each piece on the frame to take maximum advantage of its specic properties. In some areas, Felt uses intermediate modulus material, because it offers the ideal balance between stiffness and strength. In other areas we opt for high modulus material to take advantage of its high stiffness. Most of the time, these different materials are layered with each other to get the results were after.

Tests are simulated before actual frames are tested

TECHNOLOGY STORIES

2013

GOING THE EXTRA MILE Some carbon manufacturers use old-fashioned tube-and-lug construction similar to steel lugged frames, where tubes are inserted into lugs at the intersections and everything is glued together. While facilitating mass production, the problem with this technique is it requires overlapping of material, and yields a frame that is overbuilt, heavy and lacking that critical responsive feel. Rather than choose the easiest production methods, Felt employs its own unique manufacturing methods to create frames that meet the highest quality ride standards.

Like MMC, the DMC process starts with sheets of unidirectional ber. These sheets can be made from bers with different levels of modulus, depending on the intended use of the bike. Some bikes are geared toward competitive racers who require minimal weight and maximum stiffness above all else. Others are for riders seeking maximum performance and durability, and are willing to sacrice a few grams. Because the DMC process splits the frame into more specic pieces, we are able to use the most appropriate molding process for the section being made. For example, the bottom bracket area and chainstays are molded as one piece. This eliminates any seams in the chainstays, allowing maximum renement to the ber placement in this critical-to-performance area. This is a much more time-consuming construction method, however you get better renement of material and everything stays nice and thin. This enhances ride quality because any time tubes can be kept thin they absorb vibration better and give the frame life. INSIDEOUT In both MMC and DMC manufacturing Felt uses it own proprietary internal molding process called InsideOut. By placing polyurethane inserts inside the frame during the lay-up process, then applying a precise amount of pressure and heat, a frames interior walls can then be formed without any excess resin or material. Once the frame is removed from its mold, so are the internal PU inserts leaving a smooth, highly rened surface nish inside and out. FELT CARBON FIBER GRADES

Modular Monocoque Construction (MMC) is the process used for the majority of Felts carbon bikes. This advanced manufacturing technique allows Felt to mold complete major sections of a frameset, and then join them together. Having larger one-piece sections gives designers the ability to reduce excess material and optimize each section for specic engineering demands. Dynamic Monocoque Construction (DMC) is the process where smaller individual sections of the frameset are molded separately, then joined via a proprietary co-molding process. This allows each frame section to be further optimized for its intended purpose while keeping maximum ride quality and performance as a priority.

A DA frameset in pieces before assembly

The Nine frame in various stages of completion.

There is an adage in the bike building business that says the best frame material is only the best if its used correctly. Its like two cooks in a kitchen. Each has access to the same ingredients, but only one knows how to blend the ingredients the best way. The same is true with carbon ber. Most bike manufacturers have access to a variety of carbon ber types, and they can all orient those bers however they see t. But truly understanding how to meld these variables is what separates good bikes from great bikes. Thats why Felt currently uses three distinct carbon ber grades.

TECHNOLOGY STORIES

2013

UHC PERFORMANCE If you want to know why Felts UHC (Ultra Hybrid Carbon) Performance carbon ber is the ideal material for making performance bicycles, simply consider the facts:

CARBON FIBER FRAME CONSTRUCTION MOLDS Multiple silicone and exible polyeurethane internal molds are assembled and used as an armature. Think of it as a temporary surface used to lie the pieces of carbon ber on.

This proprietary blend combines uni-directional structural ber and a protective 3k weave, making it stronger than 3/2.5 titanium, stiffer than 6061 aluminum, and less than a quarter the density of steel. These factors combine to allow for the formation of all manner of tube shapes with near innite fatigue life.

LAYUP Precisely following the layup schedule, the frame maker lays and wraps multiple pieces of unidirectional carbon ber onto and around the molds. The size and orientaion of each piece plays a monumental role in the frames ride quality (feel).

The materials used in Felts performance-level carbon ber bikes are as good, if not better than many other manufacturers top-end models. Felt achieves this via a design process where technological development is constantly being built upon and shared across various bike lines. That means much of the same technology used on Felts top-tier F1 frameset is incorporated into all carbon F-Series models. And because of this ongoing commitment to continually evolve, Felt can offer a level of performance that far exceeds other similarly priced bikes. UHC Performance frames deliver unmatched durability and the signature Felt feel thats known throughout the cycling world. UHC ADVANCED UHC Advanced is Felts lightweight, stiff, and durable carbon ber blend. The higher modulus material in UHC Advanced has an increased ber-to-resin ratio, which allows Felt engineers to design frames with thin-walled tubing, meaning frames constructed with this material are on average about 20% lighter than their UHC Performance counterparts. This is all done without sacricing strength or stiffness. The result is the ideal blend of value and performance for competitive riders or racers.

CARBON FIBER WEAVE Once all the unidirecional carbon ber has been laid, the entire frame is wrapped in a 1K or 3K weave adding impact protection.

FINISH Once the carbon ber has all been laid, its time to remove the exible silicone inserts, but leaving internal PU molds during curing process. The piece is then placed into large pressurized molds and heated at a very specic time and temperature to allow the resin to cure.

TECHNOLOGY STORIES

2013

Most Upper-Level Competetors Carbon Fiber Frames

+

Unidirectional carbon fiber (intermediate modulus)

+

Resin (binds plies of carbon fiber)

=

More resin* *Resin, though used as a bonding agent, adds weight and too much of it deadens the frame robbing the bike of ride quality the carbon fiber provided.

(All purpose performance carbon fiber)

MODERATE WEIGHT

Felts UHC Performance Carbon Fiber

+

Unidirectional carbon fiber (intermediate modulus)

+

Carbon fiber weave outermost ply (adds impact protection)

=

Resin (prepregnated) (binds plies of carbon fiber)

(All purpose performance carbon fiber)

LIGHT WEIGHT

Felts UHC Advanced Carbon Fiber

+

Unidirectional carbon fiber (intermediate modulus)

+

3 K carbon fiber weave outermost ply (adds impact protection)

=

Resin (prepregnated) (binds plies of carbon fiber)

Additional plies of High Modulus carbon fiber (adds stiffness and is lighter)

(Higher carbon fiber to resin ratio)

LIGHTER WEIGHT

Felts UHC Ultimate + Nano Carbon Fiber

+

Unidirectional carbon fiber (intermediate modulus)

+

Additional plies of Ultra High Modulus carbon fiber (adds stiffness and is lighter) 1 K carbon fiber weave outermost ply (adds toughness)

+

(Even less resin) (binds and strengthens plies of carbon fiber)

=

Nano Particles (binds and strengthens plies of carbon fiber to compensate for resin reduction)

Additional plies of High Modulus carbon fiber (adds stiffness and is lighter)

ULTRA-LIGHT WEIGHT

(Highly-refined light weight carbon fiber)

TECHNOLOGY STORIES

2013

Like any high performance material, UHC Advanced presents some engineering challenges. The increased ber stiffness and reduced weight can also be more brittle than the UHC Performance blends. Our engineers are innately aware of the relationship between tube shape and performance, and strive to limit the number of small radii at tube intersections. This not only prevents the bers from fracturing during construction, but also assures that the end product is as light, stiff, and strong as it can possibly be. UHC ULTIMATE+NANO Felts UHC Ultimate+Nano blend is the ultimate carbon frame building material. The process starts with a quartet of uni-directional carbon bers: 1) intermediate, 2) high modulus 3) ultra high modulus, and 4) 1K weave, which all work together in perfect unison to provide the ideal blend of stiffness, strength, impact resistance and compliance.

During the frame design process, engineers make specic lay-up decisions based on the forces put into varying areas of the frame, interspersing stiff bers and durable bers as needed. But, the real secret to the UHC Ultimate+Nano blend is the proprietary Nano resin matrix. Most carbon bicycle frames use a standard epoxy resin to bind together individual bers. Felts Nano blend requires less resin, resulting in an overall frame weight reduction. Since Nano resins microscopic particles are elongated instead of round, the bond between resin and ber is tougher due to the increase in surface area the Nano particles have with the carbon ber. This increase in surface area translates to toughness, which means its possible to use more high modulus material without losing strength. It is literally a molecular change that yields impressive real world results.

This is what Felt is all about. Spending more time for even just a 2-3% gain. says Jim Felt. We are not worried about making as many bikes as possible. We are focused on all the extra details that go into making the perfect bike.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

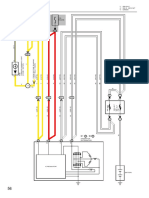

- Charging: 1: 22R-E A/T 2: 3VZ-E, 22R-E M/T 3: CanadaDocument2 pagesCharging: 1: 22R-E A/T 2: 3VZ-E, 22R-E M/T 3: Canadaperalta78No ratings yet

- VW Passat b8 Communication EngDocument66 pagesVW Passat b8 Communication EngDima Afanasiev100% (1)

- Cylinder Head Research InvestigationDocument5 pagesCylinder Head Research Investigationperalta78No ratings yet

- dl24m ManualDocument47 pagesdl24m Manualperalta78No ratings yet

- Charging: 1: 22R-E A/T 2: 3VZ-E, 22R-E M/T 3: CanadaDocument2 pagesCharging: 1: 22R-E A/T 2: 3VZ-E, 22R-E M/T 3: Canadaperalta78No ratings yet

- Look Out For These Unwanted Substances in Your CosmeticsDocument3 pagesLook Out For These Unwanted Substances in Your Cosmeticsperalta78No ratings yet

- Forex Price Action Scalping - Bob VolmanDocument3 pagesForex Price Action Scalping - Bob Volmandanadamsfx50% (10)

- How Dealers Conduct Foreign Exchange Operations: All About..Document10 pagesHow Dealers Conduct Foreign Exchange Operations: All About..WickedadonisNo ratings yet

- TFF 10W-30 CF-4: DescriptionDocument2 pagesTFF 10W-30 CF-4: Descriptionperalta78No ratings yet

- OBFX Users ManualDocument18 pagesOBFX Users ManualNo Name100% (1)

- Piccione Manipulating Market 2016Document12 pagesPiccione Manipulating Market 2016peralta78No ratings yet

- Biodiesel TotalDocument4 pagesBiodiesel Totalperalta78No ratings yet

- How Dealers Conduct Foreign Exchange Operations: All About..Document10 pagesHow Dealers Conduct Foreign Exchange Operations: All About..WickedadonisNo ratings yet

- 1404 3274 PDFDocument17 pages1404 3274 PDFnld64No ratings yet

- Tec Champ Alcar13Document1 pageTec Champ Alcar13peralta78No ratings yet

- OBFX Users ManualDocument18 pagesOBFX Users ManualNo Name100% (1)

- Trade Journal V2Document48 pagesTrade Journal V2MaxNo ratings yet

- 2star - Aida .Guidelines.2009 0Document5 pages2star - Aida .Guidelines.2009 0peralta78No ratings yet

- How To Learn More About Pointing Dogs:: OrganizationsDocument1 pageHow To Learn More About Pointing Dogs:: Organizationsperalta78No ratings yet

- How To Learn More About Pointing Dogs:: OrganizationsDocument1 pageHow To Learn More About Pointing Dogs:: Organizationsperalta78No ratings yet

- S 05 NMDL 2 DsDocument8 pagesS 05 NMDL 2 Dsperalta78No ratings yet

- Bomba Toc Toc ManualDocument26 pagesBomba Toc Toc Manualperalta78No ratings yet

- 1X11 Itmb-280-1-6/16-6000-304/304-H: CMB Edited For Quotation 0Document1 page1X11 Itmb-280-1-6/16-6000-304/304-H: CMB Edited For Quotation 0peralta78No ratings yet

- Two Stroke Tuning GuideDocument171 pagesTwo Stroke Tuning Guideavista123100% (1)

- PCX Training ManualDocument88 pagesPCX Training Manualperalta78No ratings yet

- FrictionDocument8 pagesFrictionperalta78No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ChemTeam - Combustion Analysis - Problems 1 - 10Document12 pagesChemTeam - Combustion Analysis - Problems 1 - 10David KabuyaniNo ratings yet

- Foaming Capacity of Soaps (Ameen Rasool)Document18 pagesFoaming Capacity of Soaps (Ameen Rasool)Ameen RasoolNo ratings yet

- Phosphorus: Ceniza, John Raymund D. Physics 314 B MWF/TTH 11:00-12:00/3:30-5:00Document13 pagesPhosphorus: Ceniza, John Raymund D. Physics 314 B MWF/TTH 11:00-12:00/3:30-5:00Ezra Hilary CenizaNo ratings yet

- ARKI ALE Structural NotesDocument5 pagesARKI ALE Structural Notesiloilocity100% (1)

- 324-Chapter 1 Rock Bit Interactions PDFDocument42 pages324-Chapter 1 Rock Bit Interactions PDFBilge KaanNo ratings yet

- Gear Box-Flender Rro3710421Document23 pagesGear Box-Flender Rro3710421Shihab JamaanNo ratings yet

- En 13811Document12 pagesEn 13811Dule JovanovicNo ratings yet

- Elastomer Types VtaDocument24 pagesElastomer Types VtaCamilo MorenoNo ratings yet

- Triboelectric NanogeneratorsDocument537 pagesTriboelectric NanogeneratorsAviraj Limaye100% (1)

- Additive Sunset YellowDocument2 pagesAdditive Sunset YellowMohammad RofikNo ratings yet

- Introduction To Polyurethane!: Chemistry and Structure-Property RelationshipsDocument31 pagesIntroduction To Polyurethane!: Chemistry and Structure-Property RelationshipsMohammed ShaabanNo ratings yet

- Automig 70S-61Document1 pageAutomig 70S-61tarun kaushalNo ratings yet

- Zinc Sulfate 35 Maxi Granular Spec Sheet CCIDocument1 pageZinc Sulfate 35 Maxi Granular Spec Sheet CCIricko4001No ratings yet

- SP-2092 - GRP Specification Qualification and ManufacturingDocument47 pagesSP-2092 - GRP Specification Qualification and Manufacturingchandana kumar100% (2)

- Plastic and SyntheticsDocument104 pagesPlastic and SyntheticsShah ChenzenNo ratings yet

- 42crmo4 EnglishDocument3 pages42crmo4 Englisheduardomanar1224No ratings yet

- Beams: Diagrams and Formulas For Various Loading ConditionsDocument34 pagesBeams: Diagrams and Formulas For Various Loading ConditionsgaganNo ratings yet

- Reactions of Copper (Edited, 10 Sept 2023)Document5 pagesReactions of Copper (Edited, 10 Sept 2023)Rose-AnnMirambilNo ratings yet

- Wye BranchesDocument8 pagesWye BranchesbarukomkssNo ratings yet

- Developments in the Interpretation of Power Transformer Dissolved Gas Analysis Results 论文Document162 pagesDevelopments in the Interpretation of Power Transformer Dissolved Gas Analysis Results 论文Jicheng PiaoNo ratings yet

- Solid State Physics - Ii: Dr. N.Balasundari Assistant Professor Physics Department Sri K.G.S Arts College SrivaikundamDocument112 pagesSolid State Physics - Ii: Dr. N.Balasundari Assistant Professor Physics Department Sri K.G.S Arts College SrivaikundamGamma FactsNo ratings yet

- BS EN 13765 2010 - Mangueiras Termoplásticas para Transferecia de Hidrocarb, Solventes e QuimicosDocument28 pagesBS EN 13765 2010 - Mangueiras Termoplásticas para Transferecia de Hidrocarb, Solventes e QuimicosJoice100% (3)

- 42CrMo4 (EN 10083 3)Document2 pages42CrMo4 (EN 10083 3)GABRIEL IORDACHINo ratings yet

- Roll Compaction As An Alternative To Spray-Drying ForDocument6 pagesRoll Compaction As An Alternative To Spray-Drying ForDeebNo ratings yet

- Alginate: DR Avreet SandhuDocument58 pagesAlginate: DR Avreet Sandhuwaheguru13he13No ratings yet

- Technical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesDocument117 pagesTechnical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesJankoNo ratings yet

- Chile Wish List (Desmond Pilcher)Document8 pagesChile Wish List (Desmond Pilcher)Ogalde LuisNo ratings yet

- 2002-4.5 Effect of Shrinkage PDFDocument29 pages2002-4.5 Effect of Shrinkage PDFMy Dad My WorldNo ratings yet

- Cussons Boiler Instructon ManualDocument32 pagesCussons Boiler Instructon Manualjakakolenk100% (1)

- Aluminum Glass and Windows For QuotationDocument2 pagesAluminum Glass and Windows For Quotationjarellano08No ratings yet