Professional Documents

Culture Documents

Quality Bulletin - November 22, 2013

Uploaded by

Dwi DarsonoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Bulletin - November 22, 2013

Uploaded by

Dwi DarsonoCopyright:

Available Formats

QUALITY BULLETIN

Friday, November 22th , 2013

1. API 650 Welded Steel Tan ! For "il Stora#e

1. $eneral This standard covers material, design, fabrication, erection and testing requirements for vertical, cylindrical, aboveground, closed and open top welded steel storage tanks in various sizes and capacities for internal pressure approximating atmospheric pressure. The tanks shall have entire bottom uniformly supported, non-refrigerated, and maximum operating temperature of 2 !.

2. %aterial! "ost common plates used for the construction shall be #$T" #2%&, #&' or any suitable higher strength carbon steel plate as desired. (ormal design metal temperature shall be assumed to be )* ! above the lowest ) day mean ambient temperature in the locality where the tank is to be installed. +late used for the reinforcement of the opening shall be of the same material as the shell plate to which it is installed. ,t shall be as thick as the primary plate. $hell nozzle and manway material shall be equal or greater strength and of compatible material. +late manufacturer shall submit the mill test data including the toughness at design metal temperature. !or materials with minimum tensile strength less than - , arc welding electrodes shall conform to .- xx series. psi , manual shielded metal

Page 2 of 8

3.1 &oint! Tack welds are not considered to have strength value. !ull fillet welds are required for plates of &/)' in 0*mm1 thick. +lates with thickness more than * mm, the weld shall not be less than )/& of the thinner plate thickness at the 2oint, but not less than * mm. $ingle lap welds are used for bottom and roof plate welds. 3ap weld 2oints shall not be less than *t of the thinner plate but need not be more than ) in 02* mm1. 4ertical shell 2oints shall be butt 2oints with complete penetration and fusion that provides the same quality of deposited metal on both inside and outside the weld surface. 4ertical 2oints in ad2acent shell courses shall not be in alignment. #n offset of at least *t shall be adopted, where t is the thicker plate thickness at the 2oint. 5orizontal $hell 2oints shall be similar to vertical 2oint. The top angles shall be 2oined by double lap weld. 6utt weld full penetration bottom 2oint shall be used normally with the annular ring. # minimum of 2 in 0* mm1 pro2ection beyond outside edge of shell shall be provided.

PT. Tetra Pak Stainless Equipment Jl. Raya Pulo Gebang Km.3 Cakung Jakarta 13950, Indonesia Telp. +62-21 48700967 (Hunting) Tetra Pak Internal

Page 3 of 8

3.2 &oint '(ontd.) $hell to bottom fillet weld shall not be more than 7 in 0)2 mm1 if the shell is )2 mm or less. ,t shall be less than t, the thinner section at the 2oint. "inimum two weld passes are required. 8oof and top angle 2oints shall be welded with continuous full fillet weld. Top angle 0horizontal leg1 may extend either inside or outside.

*. +ottom Plate 6ottom plate shall be of at least 9 in 0' mm1, exclusive of any corrosion allowance. ,t shall pro2ect at least ) in 02* mm1 beyond outside edge of the shell. &.* #nnular 6ottom +lates This shall be at least 2: in 0' surface is required. mm1 wide. The 2 in 0* mm1 pro2ection beyond outside shell

PT. Tetra Pak Stainless Equipment Jl. Raya Pulo Gebang Km.3 Cakung Jakarta 13950, Indonesia Telp. +62-21 48700967 (Hunting) Tetra Pak Internal

Page 4 of 8

5. Shell ,e!i#n This shall involve calculation for required 0designed1 shell thickness td 0including corrosion allowance for design product, adoption of the nominal thickness of shell t, material selection of the tank, and adopting allowable stress.

;here td is designed shell course thickness 0assumed to be ) ft above the bottom line of the shell course1 in inch, < is the tank diameter in ft, 5 is the height of the product level from the bottom line of the shell course in ft, = is specific gravity of product stored, $d is the design allowable stress in psi and ># is the corrosion allowance for the full life of the tank. tt is the thickness required for the hydro test condition for the particular shell course, and $t is the allowable stress at the hydro test condition and temperature. These formula are allowed for shell diameter less than 2 ft.

6. Shell "-enin#! "an-way necks, nozzle necks, and shell plate opening shall be uniform and smooth, with rounded corners. (o reinforcement is generally required for nozzles 2 in and smaller. +ermanent attachment welds shall not be closer than & in from horizontal shell 2oint seams, nor closer than ' in from vertical 2oints, insert plate 2oints or reinforcement plate fillet welds. &.) 8oofs 8oof plates shall be &/)' in 0* mm1 minimum. $elf supported roof may require thicker plate. $upported cone roof plate shall not be rigidly attached to supporting members. 8oof plate shall be attached to the top angle. $upported cone roof slope shall be ? in 02 mm1 in )2 in 0& mm1.

8afters shall be spaced so that in the outer ring, their centers are not more than '.2% ft 0)%% mm1 measured along the circumference. The maximum spacing of the inner ring rafters is *.* ft 0)'* mm1. 8oof columns can be steel pipe, which has to be sealed with provision of draining and venting.

PT. Tetra Pak Stainless Equipment Jl. Raya Pulo Gebang Km.3 Cakung Jakarta 13950, Indonesia Telp. +62-21 48700967 (Hunting) Tetra Pak Internal

Page 5 of 8

.. Wind /oad on Tan ! @verturning stability shall be checked. ;ind velocity is assumed as ) mph 0)' km/hr1.

The wind load on vertical surface may be assumed as & lb/sq ft. 3oad on pro2ected cylindrical area shall be )% lb/sq ft. #nchor spacing shall be maximum ) ft apart.

0. Weldin# #cceptable weld processes shall beA $hielded metal arc =as metal arc !lux-cored arc $ubmerged arc .lectro-slag

The welding may be performed manually, automatic, semi-automatic. The quality assurance shall be as per #$". +4 >ode, ;elding, $ec ,B.

0.1. Weldin# Pre1a2tion! ;elding shall not be done on moist or wet surfaces ,t shall not be performed in high wind conditions 0unless protected, shielded1 ,f the metal temperature is -&2 ! and t exceeds ).2* in 0&2 mm1, preheating is required. "ulti-layer welds require removal of slag and deposits before next layer is welded. #ll weld edges must merge with plate surface without sharp angle. "aximum acceptable undercut in vertical 2oint shall allowed up to )/': in 0 .: mm1 and )/&2 in 0 .% mm1 for horizontal butt 2oints. Tack welds shall be removed before finishing the 2oint. 3ow hydrogen electrode shall be used for $"#; process for welds )2 mm and thick.

0.2. Shell 3eldin# "isalignment in completed vertical 2oint over */% in 0)' mm1 thick shall not exceed ) C of plate thickness with a maximum of .)2* in 0& mm1. !or less thick 2oints it shall be limited to . ' in 0).' mm1. Doints over ).* in 0&- mm1 thick shall have the weld pass not exceeding ? in 0)% mm1 and minimum pre-heat shall be 2 ! 0) >1.

;elds attaching nozzles, man-ways, other openings shall be visually examined followed by "+ or +T after the stress relief treatment but before hydro test.

PT. Tetra Pak Stainless Equipment Jl. Raya Pulo Gebang Km.3 Cakung Jakarta 13950, Indonesia Telp. +62-21 48700967 (Hunting) Tetra Pak Internal

Page 6 of 8

$hell to bottom weld shall be checked visually followed by "+ or +T, diesel test or right angle vacuum test. #lternate method shall be pressure testing the volume between the inside and outside welds to )* psi 0) bar1 applying soap solution to the face of fillet weld. Tank bottom shall be tested using vacuum box, tracer gas test or external float test or combination of them. 8einforcing pad shall be pneumatic pressure tested with )* psig pressure between shell and reinforcement on each opening.

4. ,imen!ional Toleran1e! The maximum out of plumb ness of the top relative to bottom of shell may not exceed )/2 of the total tank height. >oncrete ring walls shall be level within E/- )/% in 0& mm1 any & ft circumference and within ' mm in total circumference, measured from average elevation.

10. 5adio#ra-hi1

10.1. 6erti1al Shell Weld!7 6utt welds ) mm and thinner, one spot in first ) ft of each type and thickness and for each welder and thereafter one additional spot in each additional ) ft. #tleast 2*C of

the spots shall be at 2unctions of verticals and round seam 2oints, minimum two per tank. #dditional one spot in each bottom ring vertical. +lates greater than ) mm to ) in 02* mm1, same as above plus all 2unctions. #dditional two spots in all bottom ring verticals. +lates thicker than ) in 02* mm1, full radiography of all verticals plus all 2unctions. 6utt welds around periphery of insert nozzles and man-ways shall be fully radiographed.

10.2. 8ori9ontal Shell Weld!7 @ne spot in first ) ft for all thickness without regard to welder, there after one spot each additional 2 ft.

10.3. Tan +ottom Ann2lar rin#7 <ouble butt weld 2oints, one spot on ) C of radial 2oints and preferable spot shall be near the shell.

PT. Tetra Pak Stainless Equipment Jl. Raya Pulo Gebang Km.3 Cakung Jakarta 13950, Indonesia Telp. +62-21 48700967 (Hunting) Tetra Pak Internal

Page 7 of 8

11. 6i!2al a11e-tan1e o: de:e1t (o visible crater or surface cracks or arc strikes are acceptable. Fndercut acceptable shall be within limits indicated under *.2. +orosity acceptable up to a cluster size of &/&2 02.* mm1 in diameter and one in each : in 0) mm 1 length of welds.

12. ;<ternal Floatin# 5oo:7 <ecks 0double and diaphragm1 designed for drainage shall have minimum slope of &/)' in 0* mm1 in )2 in 0& mm1.

The pontoon roofs shall have sufficient buoyancy to remain afloat on a specific gravity product of .- and with primary drains inoperative for following conditionsA ) in 02* mm 1 rainfall in 2: hours period with roof intact. $ingle deck 0 diaphragm1 and any two ad2acent compartment punctured in single deck pontoon types with no water or live load. 8oof <rainsG +rimary drain may be hose, 2ointed or siphon type, check valves required on pontoon and pan type roof, and minimum roof drain size as & in for a tank of )2 ft dia and less and : in for tank of more than )2 ft diameter. 8oof support leg shall be provided as pipe leg with perforated bottom. The lengths may be ad2usted from roof top. ,t shall support the roof weight and live loads of 2* lb per sq ft. #t least one man way of 2: in 0' mm1 diameter shall be provided.

>entering and anti- rotation device shall be provided. !lexible seal between roof periphery and shell shall be provided.

PT. Tetra Pak Stainless Equipment Jl. Raya Pulo Gebang Km.3 Cakung Jakarta 13950, Indonesia Telp. +62-21 48700967 (Hunting) Tetra Pak Internal

Page 8 of 8

2. Sy!tem o: Fit! and Toleran1e!

The standard reference temperature is 2 dimensions defined by the system. <ue to the inevitable inaccuracy of manufacturing methods a part cannot be made precisely to s given dimension, the difference between maximum and minimum limit of size is the toleran1e. ;hen two parts are to be assembled, the relation resulting from the difference between their sizes before assembly is called a :it. > for industrial measurements and consequently for

3. Form2la :or 1al12latin# /ead An#le o: Thread

PT. Tetra Pak Stainless Equipment Jl. Raya Pulo Gebang Km.3 Cakung Jakarta 13950, Indonesia Telp. +62-21 48700967 (Hunting) Tetra Pak Internal

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Riverside Dilemma (Extra Credit)Document7 pagesRiverside Dilemma (Extra Credit)Odaro Osayimwen0% (2)

- Offset CrankDocument1 pageOffset CrankDwi DarsonoNo ratings yet

- Ingredients and Formulation of Laundry DetergentDocument34 pagesIngredients and Formulation of Laundry DetergentMuhammad Usman Hameed80% (5)

- SQA-Hess's Law QuestionsDocument4 pagesSQA-Hess's Law QuestionsWidya GrantinaNo ratings yet

- 6 1 UpDocument102 pages6 1 Upsoraandreea20No ratings yet

- Asme B30.9 - FinalDocument3 pagesAsme B30.9 - FinalDavidNaulaNo ratings yet

- BrosurDocument14 pagesBrosurDwi DarsonoNo ratings yet

- Einscan-Se: User ManualDocument37 pagesEinscan-Se: User ManualDwi DarsonoNo ratings yet

- Template To Dynamic AXDocument3 pagesTemplate To Dynamic AXDwi DarsonoNo ratings yet

- Sae-Mechanical Engineering - Vehicle DesignDocument39 pagesSae-Mechanical Engineering - Vehicle Designapi-3712636No ratings yet

- R/3 Number Description Manufacturers ID: O-RING VITON ID-106X4.0 O-Ring Viton Id-11X2.5 O-RING VITON ID-193X4.0Document6 pagesR/3 Number Description Manufacturers ID: O-RING VITON ID-106X4.0 O-Ring Viton Id-11X2.5 O-RING VITON ID-193X4.0Dwi DarsonoNo ratings yet

- Blank SizeDocument1 pageBlank SizeDwi DarsonoNo ratings yet

- Raw Material MasterDocument1 pageRaw Material MasterDwi DarsonoNo ratings yet

- Aprizal Pratama: Training Autodesk Inventor Professional 2012 Level: EssentialDocument1 pageAprizal Pratama: Training Autodesk Inventor Professional 2012 Level: EssentialDwi DarsonoNo ratings yet

- Sertifikat DeaDocument1 pageSertifikat DeaDwi DarsonoNo ratings yet

- Assignment Form - Individua KOSONGlDocument1 pageAssignment Form - Individua KOSONGlDwi DarsonoNo ratings yet

- Mektek IIDocument15 pagesMektek IIDwi DarsonoNo ratings yet

- Mektek IIIa-Momen GayaDocument28 pagesMektek IIIa-Momen GayaDwi DarsonoNo ratings yet

- Refrigeration SystemsDocument50 pagesRefrigeration SystemsDwi DarsonoNo ratings yet

- Moment of Inertia - 2 PDFDocument0 pagesMoment of Inertia - 2 PDFsam1619No ratings yet

- AdapterDocument1 pageAdapterDwi DarsonoNo ratings yet

- Front View Car PhotoDocument1 pageFront View Car PhotoDwi DarsonoNo ratings yet

- Universal ViseDocument5 pagesUniversal ViseDwi DarsonoNo ratings yet

- Assembly1 detail drawing scale 1/5Document1 pageAssembly1 detail drawing scale 1/5Dwi DarsonoNo ratings yet

- Ci Rod GuideDocument1 pageCi Rod GuideDwi DarsonoNo ratings yet

- Ci Rod GuideDocument1 pageCi Rod GuideDwi DarsonoNo ratings yet

- CS Bracket Design Produced in Autodesk Educational SoftwareDocument1 pageCS Bracket Design Produced in Autodesk Educational SoftwareDwi DarsonoNo ratings yet

- Inventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine Cylinder CoverDocument1 pageInventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine Cylinder CoverDwi DarsonoNo ratings yet

- CS Bracket Design Produced in Autodesk Educational SoftwareDocument1 pageCS Bracket Design Produced in Autodesk Educational SoftwareDwi DarsonoNo ratings yet

- Flywheel ShaftDocument1 pageFlywheel ShaftDwi DarsonoNo ratings yet

- Inventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine Cylinder CoverDocument1 pageInventorwizard: Miniature Model Hot Air Engine Horizontal Stirling Engine Cylinder CoverDwi DarsonoNo ratings yet

- Fan Bracket Design CAD DrawingDocument1 pageFan Bracket Design CAD DrawingDwi DarsonoNo ratings yet

- Miniature Model Hot Air Engine CrankrodDocument1 pageMiniature Model Hot Air Engine CrankrodDwi DarsonoNo ratings yet

- Assembly BaseDocument1 pageAssembly BaseDwi DarsonoNo ratings yet

- SlideDocument1 pageSlideDwi DarsonoNo ratings yet

- Excimer Lasers: Edited by Ch. K. RhodesDocument275 pagesExcimer Lasers: Edited by Ch. K. RhodesSujay SwainNo ratings yet

- Alimodian National Comprehensive High School: Grade 7-Matter SUMMATIVE TEST-Acids and BasesDocument2 pagesAlimodian National Comprehensive High School: Grade 7-Matter SUMMATIVE TEST-Acids and BasesCaryl Ann C. Sernadilla0% (1)

- Technical Data Sheet: Wynn's Diesel Turbo CleanerDocument2 pagesTechnical Data Sheet: Wynn's Diesel Turbo CleanerLeon Alexander WilliamsNo ratings yet

- Solar Oven Challenge ReportDocument7 pagesSolar Oven Challenge Reportapi-311233754No ratings yet

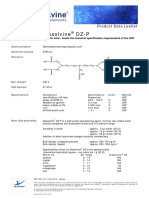

- Dissolvine DZ P PDLDocument2 pagesDissolvine DZ P PDLizzybjNo ratings yet

- Srivastava DissertationDocument144 pagesSrivastava DissertationleNo ratings yet

- Production of Low Cost Self Compacting Concrete Using Bagasse AshDocument10 pagesProduction of Low Cost Self Compacting Concrete Using Bagasse AshENgřMuhăɱɱadRiǺzAhɱadNo ratings yet

- CIMACDocument66 pagesCIMACJarot PrakosoNo ratings yet

- VERSAMUL - Product BulletinDocument2 pagesVERSAMUL - Product BulletinIgorCencičNo ratings yet

- w4g Book1a r6Document99 pagesw4g Book1a r6milker100% (1)

- Assignment 1Document3 pagesAssignment 1Yeleti FamilyNo ratings yet

- Chemistry Lab Seating PlanDocument5 pagesChemistry Lab Seating PlanPranav EdaraNo ratings yet

- Bollhoff Rivkle SFC Inserts For Composite Material Catalog PDFDocument5 pagesBollhoff Rivkle SFC Inserts For Composite Material Catalog PDFClifford BernardNo ratings yet

- EfkaPB2720 TDSDocument2 pagesEfkaPB2720 TDSSebastian GonzalezNo ratings yet

- Proses ManufakturDocument5 pagesProses ManufakturAchmad HabibieNo ratings yet

- ABB Conductivity CellDocument2 pagesABB Conductivity CellBhaskar KumarNo ratings yet

- Thermodynamic Fundamentals of Refrigeration, Cryogenics and Low Temperature Physics Problems For ColloquiumDocument27 pagesThermodynamic Fundamentals of Refrigeration, Cryogenics and Low Temperature Physics Problems For ColloquiumPawel WNo ratings yet

- Adblue FH4 PDFDocument45 pagesAdblue FH4 PDFAhmad BaharNo ratings yet

- Module in General ChemistryDocument28 pagesModule in General Chemistrysiobe batumbakalNo ratings yet

- Safety Data Sheet (SDS) : According To GHSDocument7 pagesSafety Data Sheet (SDS) : According To GHSzejackalNo ratings yet

- Explosion Welding: A Solid-State Process for Joining Dissimilar MetalsDocument23 pagesExplosion Welding: A Solid-State Process for Joining Dissimilar MetalsAnurag SinghNo ratings yet

- Inspection GuidelinesDocument67 pagesInspection GuidelinesMohammed Amjad Ali67% (3)

- Lab Exercises Intro Geochemistry InstrumentsDocument54 pagesLab Exercises Intro Geochemistry InstrumentsAreva FateehaNo ratings yet

- MSE Admission and Degree RequirementsDocument6 pagesMSE Admission and Degree Requirementsdeathbuddy_87No ratings yet