Professional Documents

Culture Documents

APF Series - Product Page APF 25 To APF 150

Uploaded by

Dan George IIIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APF Series - Product Page APF 25 To APF 150

Uploaded by

Dan George IIICopyright:

Available Formats

Aluminium Floor Flush Heavy Duty

Product description: An all-metal system made of aluminium alloy profiles, highly resistant to rolling loads, distortion and wear. Maintains a virtually flush finish ideal for heavy rolling equipment. Use This Cover For: Applications with heavy rolling loads such as: Fork Iifts with full or pneumatic tires, of a permissible total weight equal to 70 kN (tire adhesion area 20 cm x 20 cm) Trucks wlth pneumatic tires, of a permissible total weight equal to 300 kN Vehicles and goods handling trucks with tires of hard plastics. The permissible load, depending on a tire width, is 6,5 kg per every mm of a tire width. Performance Characteristics: The unique interlocking cover design allows for significant horizontal movement in the floor slab, as well as some vertical deflection, and is designed to withstand heavy and frequent rolling loads. By comparison, conventional cover plates utilizing turnbars are prone to failure when subjected to rolling loads over any length of time due to fatigue in the moving parts. This system is also ideal for areas where significant foot traffic is expected such as malls and airports and is considered extremely low maintenance. The interlocking cover assembly utilizes precision gaskets to eliminate any metal-to-metal noise and to prevent the infiltration of liquids. 3 standard depths are available : 25 mm, 50 mm and 75 mm. MODEL Joint width Overall product height A ( mm ) H ( mm )

Covers 25 to 150 mm

Exposed Overall Movement surfaced product width in mm B ( mm ) C ( mm ) horizontal vertical

H

APF Series

Standard Finishes: This system is available in mill finish. The APF models are supplied factory pre-assembled in standard lengths of 3 m. Specific floor transitions to allow the continuity of the expansion joint covers are factory manufactured as T, L and X sections. Installation Guidelines: A set of installation instructions are systematically supplied together with the materials to the installation company. The blockouts must be prepared to receive the joint cover. It is recommended the cover be leveled on a high strength, non-shrink epoxy bed. The cover assembly is delivered in a fixed position/ width through the use of shipping straps engineered for the specific movement criteria of the project. Center the assembly over the joint opening and fasten in place with supplied mechanical fasteners. Remove shipping strap after attachment. Fill blockout area with nonshrink grout and apply floor finish as required.

B A

APF 25-15

25

15

53

138

+5/-5

+5/-5

APF - Floor to floor

APF 50-25 APF 50-50

B H

50 50 50

25 50 75

77 77 77

199 199 199

+ 10 / - 10 + 13 / - 15 + 10 / - 10 + 13 / - 15 + 10 / - 10 + 13 / - 15

H

APF 50-75

APF 75-25 APF 75-50

75 75 75

25 50 75

110 110 110

232 232 232

+ 15 / - 15 + 21 / - 21 + 15 / - 15 + 21 / - 21 + 15 / - 15 + 21 / - 21

B

APF 25-15

APF 75-75

APFW - Floor to wall

APF 100-25 APF 100-50 APF 100-75

100 100 100

25 50 75

134 134 134

256 256 256

+ 20 / - 20 + 23 / - 30 + 20 / - 20 23 / - 30 + 20 / - 20 + 23 / - 30 Typical project applications: - Small, medium and large all time open shopping centers - Covered galeria and shopping malls - Airport terminals - Train stations - Sport arenas - Storage areas - Industrial facilities - multi-use facilities, etc ...

APF 150-25 APF 150-50 APF 150-75

150 150 150

25 50 75

185 185 185

325 325 325

+ 30 / - 30 + 16 / - 17 + 30 / - 30 + 16 / - 17 + 30 / - 30 + 16 / - 17

You might also like

- Expension Joints Engineering AppliancesDocument30 pagesExpension Joints Engineering AppliancesAcid BurnsNo ratings yet

- Installation Instructions: Landscaping Civils Sport Aq UaDocument84 pagesInstallation Instructions: Landscaping Civils Sport Aq UaIrinel GrăjdeanuNo ratings yet

- Beany Block: Kerb Drainage at Its Most EfficientDocument2 pagesBeany Block: Kerb Drainage at Its Most EfficientMihaela TodiricaNo ratings yet

- C-2107499 - KONE - ESCALATOR - TM110 - Technical - Specification en - USDocument13 pagesC-2107499 - KONE - ESCALATOR - TM110 - Technical - Specification en - USSabeeh KhanNo ratings yet

- Sam McCoy MFG - Catalogue 2004 - 2Document29 pagesSam McCoy MFG - Catalogue 2004 - 2Sam McCoy ManufacturingNo ratings yet

- Disposable Formwork For Ventilated Under-Fl Oor Cavities and For Water Dispersion And/or Collection TanksDocument20 pagesDisposable Formwork For Ventilated Under-Fl Oor Cavities and For Water Dispersion And/or Collection TanksDaliform GroupNo ratings yet

- FlygtDocument4 pagesFlygtToby Hopkins-AllanNo ratings yet

- Migutan EngDocument68 pagesMigutan EngBugmenot05No ratings yet

- Freyssinet Cipec Expansion JointsDocument20 pagesFreyssinet Cipec Expansion JointsIalomiteanu DanNo ratings yet

- Facade Scaffolding: Plettac SL 70/100Document32 pagesFacade Scaffolding: Plettac SL 70/100David Puen100% (1)

- Marley Underground Drainage Aug 08Document17 pagesMarley Underground Drainage Aug 08David Shanks 1No ratings yet

- Formscal CatalogueDocument12 pagesFormscal Cataloguewiggly18No ratings yet

- U Drain SpecDocument4 pagesU Drain Speckenji_sanNo ratings yet

- Select Rainwater Systems for Domestic and Commercial PropertiesDocument4 pagesSelect Rainwater Systems for Domestic and Commercial PropertiesKS LeeNo ratings yet

- Medium Storage Silos C 101460023 EngDocument7 pagesMedium Storage Silos C 101460023 EngBruno100% (1)

- LNT Form WorkDocument12 pagesLNT Form Workprem_k_sNo ratings yet

- AUMUND Bucket Elevator PDFDocument16 pagesAUMUND Bucket Elevator PDFMadhusudhan Gajula100% (5)

- Platform Grating Production & ApplicationsDocument24 pagesPlatform Grating Production & ApplicationsFederico.IoriNo ratings yet

- Contur KatalogDocument48 pagesContur KatalogDang Minh HuongNo ratings yet

- VS TZ100 10 2007Document0 pagesVS TZ100 10 2007adc26No ratings yet

- CS CouvraneufDocument28 pagesCS CouvraneufDan George IIINo ratings yet

- Layher Scaffolding CatalogueDocument10 pagesLayher Scaffolding CataloguefresitoNo ratings yet

- Eflex Cable Conduit Work ProcedureDocument8 pagesEflex Cable Conduit Work ProcedureRaden ArmanadiNo ratings yet

- 4e HydraulischePressenDocument28 pages4e HydraulischePressenTirtheshwar Singh100% (1)

- Pivot Master Floating Roof Drain System PDFDocument4 pagesPivot Master Floating Roof Drain System PDFsusansueNo ratings yet

- Chain ConveyorsDocument4 pagesChain Conveyorsarup11nvNo ratings yet

- Hauraton PDFDocument84 pagesHauraton PDFPavl BoeNo ratings yet

- Lowering SysIng BrochureDocument28 pagesLowering SysIng Brochureadrian_jess007No ratings yet

- BEMO RAIL BV expert rail systems worldwideDocument19 pagesBEMO RAIL BV expert rail systems worldwideTh NattapongNo ratings yet

- Trelleborg - Juntas TransflexDocument8 pagesTrelleborg - Juntas TransflexMauricio_Vera_5259No ratings yet

- ACO Qmax OverviewDocument8 pagesACO Qmax OverviewValiNo ratings yet

- ProfilDocument18 pagesProfilAnonymous 6EW2MsFbkNo ratings yet

- 17-07-14 OK - Brochure VAM® TOP PDFDocument8 pages17-07-14 OK - Brochure VAM® TOP PDFsajithv78No ratings yet

- Drilling and Foundation Equipment CatalogueDocument28 pagesDrilling and Foundation Equipment CatalogueMelahat AkyolNo ratings yet

- Geovent CatalogDocument108 pagesGeovent CatalogadnanNo ratings yet

- Bar CouplerDocument6 pagesBar Couplerlwin_oo2435No ratings yet

- Examples of Installation Method: October 2008Document16 pagesExamples of Installation Method: October 2008Krish DoodnauthNo ratings yet

- Prospekt OEBB-Porr FF-System enDocument12 pagesProspekt OEBB-Porr FF-System enH Mahmut DüzenNo ratings yet

- Ateco Alumax Robust LeafletDocument3 pagesAteco Alumax Robust LeafletatecotanksNo ratings yet

- User Manual: International Industry of Metallic Formwork SystemsDocument9 pagesUser Manual: International Industry of Metallic Formwork Systemsjachoijachoi100% (1)

- SP - BBE Belt Bucket Elevators: Development & Manufacturing Company of Electromechanical InstallationsDocument8 pagesSP - BBE Belt Bucket Elevators: Development & Manufacturing Company of Electromechanical InstallationskingNo ratings yet

- HelmDocument60 pagesHelmVennia PapadipoulouNo ratings yet

- Drain Center Pipe Support GuideDocument16 pagesDrain Center Pipe Support GuideminhthanhmosNo ratings yet

- 6 Finisor de Asfalt Pe Senile Volvo Abg9820 47542Document6 pages6 Finisor de Asfalt Pe Senile Volvo Abg9820 47542Farkas Pal100% (1)

- Flexowell - 2013 - EnglischDocument5 pagesFlexowell - 2013 - Englischeduardo_chaban100% (1)

- Bridge GulliesDocument34 pagesBridge GulliesJpolyPolyNo ratings yet

- 16.10 Site Equipment (72dpi)Document24 pages16.10 Site Equipment (72dpi)Jack JeffNo ratings yet

- 4079 Form-Scaff Columns V9 FA WEBDocument16 pages4079 Form-Scaff Columns V9 FA WEBFiona steelNo ratings yet

- Cast in Lifting LoopsDocument8 pagesCast in Lifting LoopsAnonymous 1js1YzeFNo ratings yet

- Hollow Core Planks Application and Design GuideDocument46 pagesHollow Core Planks Application and Design Guidemixi1978100% (1)

- Viking Johnson Maxi FitDocument12 pagesViking Johnson Maxi FitTony GallacherNo ratings yet

- Flygt Vertical Column FAS VersionDocument8 pagesFlygt Vertical Column FAS VersioncomedyboNo ratings yet

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Vetromagic Tutorial Ok 1Document2 pagesVetromagic Tutorial Ok 1Dan George IIINo ratings yet

- 3M Professional Floor Sanding Products Catalog: InnovationDocument28 pages3M Professional Floor Sanding Products Catalog: InnovationDan George IIINo ratings yet

- Woodwork Joints 1917Document53 pagesWoodwork Joints 1917cornel_bursucel7099100% (4)

- Emco DIPLOMAT With Ribbed Carpet Insert - RDocument1 pageEmco DIPLOMAT With Ribbed Carpet Insert - RDan George IIINo ratings yet

- CONIPURHGDocument3 pagesCONIPURHGDan George IIINo ratings yet

- Guide To Vinyl Floor WeldingDocument4 pagesGuide To Vinyl Floor WeldingDan George IIINo ratings yet

- Hertfordshire County MapDocument1 pageHertfordshire County MapDan George IIINo ratings yet

- Area Required in Relation To Footfall PDFDocument1 pageArea Required in Relation To Footfall PDFDan George IIINo ratings yet

- Contract Carpet & Tile ManufacturerDocument11 pagesContract Carpet & Tile ManufacturerDan George IIINo ratings yet

- emco entrance matting load specsDocument1 pageemco entrance matting load specsDan George IIINo ratings yet

- Area Required in Relation To Footfall PDFDocument1 pageArea Required in Relation To Footfall PDFDan George IIINo ratings yet

- Datenblatt Consul 02 GB - KV1Document2 pagesDatenblatt Consul 02 GB - KV1Dan George IIINo ratings yet

- 2tec2 FloorsDocument25 pages2tec2 FloorsDan George IIINo ratings yet

- Create Your Own Custom Carpet Tile Design in 3 StepsDocument1 pageCreate Your Own Custom Carpet Tile Design in 3 StepsDan George IIINo ratings yet

- IHF BASF Certificate 2010Document1 pageIHF BASF Certificate 2010Dan George IIINo ratings yet

- Heavy Duty Aluminium Floor Flush SystemDocument1 pageHeavy Duty Aluminium Floor Flush SystemDan George IIINo ratings yet

- Warranty Tivoli24Document1 pageWarranty Tivoli24Dan George IIINo ratings yet

- Enia Imagebroschuere EnglischDocument20 pagesEnia Imagebroschuere EnglischDan George IIINo ratings yet

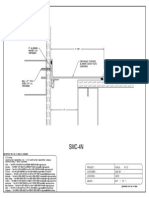

- SMC-4N: Scale: Project: Customer: Location: Job No.: - N.T.S.Document1 pageSMC-4N: Scale: Project: Customer: Location: Job No.: - N.T.S.Dan George IIINo ratings yet

- Installation Instructions For APF SeriesDocument5 pagesInstallation Instructions For APF SeriesDan George IIINo ratings yet

- Vertical and Horizontal Movement Admissions Table For APF SeriesDocument1 pageVertical and Horizontal Movement Admissions Table For APF SeriesDan George IIINo ratings yet

- WelcomeFolder BasicDocument4 pagesWelcomeFolder BasicDan George IIINo ratings yet

- Photo Gallery APFDocument1 pagePhoto Gallery APFDan George IIINo ratings yet

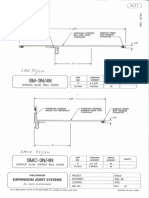

- SMN 100 and SMCN 100Document1 pageSMN 100 and SMCN 100Dan George IIINo ratings yet

- Model Sm/Smc-100 Thru 400 Installation Instructions: Important InformationDocument4 pagesModel Sm/Smc-100 Thru 400 Installation Instructions: Important InformationDan George IIINo ratings yet

- CS CouvraneufDocument28 pagesCS CouvraneufDan George IIINo ratings yet

- SMN 100Document1 pageSMN 100Dan George IIINo ratings yet

- Construction Specialties Acrovyn Protection File002010Document20 pagesConstruction Specialties Acrovyn Protection File002010Dan George IIINo ratings yet

- CSTB Fire Test Report Feb. 2008 - For Acrovyn B - s2 - d0Document4 pagesCSTB Fire Test Report Feb. 2008 - For Acrovyn B - s2 - d0Dan George IIINo ratings yet