Professional Documents

Culture Documents

NEST - Solar Power Plants - An Introduction

Uploaded by

Rohit Raj RanganathanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NEST - Solar Power Plants - An Introduction

Uploaded by

Rohit Raj RanganathanCopyright:

Available Formats

NEST Solar Power Plant Project Implementation

Solar Power Plant Engineering & Planning Noble Energy Solar Technologies Ltd (NEST), is setting the standard for utility-grade photovoltaic (PV) power plants, incorporating advanced PV modules, and inverter and power management technologies, while providing real-time monitoring, control, and fault management. There is no "ready-made" solution for optimal system performance. For this reason, NEST built a team of experienced solar professionals to design, build and operate highly customized and efficient solar power plants. NESTs engineering team has field-proven expertise in all engineering fields relevant to solar PV power applications, including mechanical engineering, thermal engineering, structural engineering, electrical engineering, and civil and environmental engineering. Experienced solar project managers drive projects from start to completion and within specification, budget and schedule, keeping NESTs customers informed at all times. NEST project managers monitor, control and report scheduled progress via frequent meetings and coordinate with customers and major suppliers to meet the schedule. At NEST, all aspects of solar engineering, planning and documentation are done inhouse. From the application through permitting and final inspection, NEST offers all the required engineering and administrative services to its customers in a single, comprehensive package. Procurement and Balance of System (BoS) NEST partners with leading component suppliers to procure equipment for its solar power plants, and works with power providers to deliver clean, renewable, and cost-effective energy to the grid. Most of our BoS components are produced by our affiliate companies, resulting in a reliable and affordable supply chain. Module Partnerships As part of an integrated system, the solar modules are crucial to the overall efficiency of a solar power plant. Only state-of-the-art solar modules are used in the construction of our utility scale systems. The NEST R&D department is constantly working on innovative technologies and applications in the field of solar technology. For this it is necessary to analyze the solar modules and their energy yield. The solar modules are responsible for a high performance ratio and economical operation of the system.

Noble Energy Solar Technologies Ltd. From the Sun, for the People

Disclaimer: This document is confidential. The user is requested to control the information shared in this document

Page 1 of 7

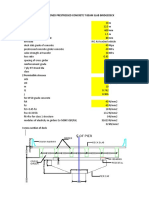

Balance of System (BoS) components the remaining elements of a photovoltaic system PV power plants are highly flexible and can be configured for varying capacity using modular concepts that can be adapted to local conditions. Photovoltaic modules produce electricity as direct current (DC). To transport, convert, and feed this electrical power into the national grid, other essential support components are needed. These secondary parts are called the Balance of System (BOS) components of a solar power plant. BoS components include inverters, solar cables, substructure, monitoring devices, and other items. The following BoS components are necessary for a grid-connected power plant: Substructure and mounting hardware for the modules Wiring for electrical connections between modules and inverters Inverter system Grid access equipment

Inverter Systems - the heart of your solar power plant NESTs PV power plants generate direct current (DC) which is then transformed into alternating current (AC) and fed into the grid through the inverter.

The optimal performance of the inverter is crucial for the overall efficiency of the photovoltaic system. It is important that the output of the inverter match the power frequency and voltage of the utility grid. NEST's inverters constantly and automatically monitor and adjust those parameters for optimal performance at all times.

The failure of an inverter component can cause significant production yield losses at the system level. NEST inverters are fitted with a comprehensive set of safety, redundancy and control features that allow the solar power system to continue operating even in the unlikely event of a component failure. In such a case, a sophisticated control circuit automatically assigns a working device to the functions of the damaged device and logs relevant data for later analysis. With those unique features, NEST inverters minimize the impact of a technical problem on the overall system efficiency. SMA Inverter system worlds No.1 All the inverter systems integrated into NEST PV power plants are built to our specifications by SMA Technologie AG, which is one of the largest inverter manufacturers in the world.

Noble Energy Solar Technologies Ltd. From the Sun, for the People

Disclaimer: This document is confidential. The user is requested to control the information shared in this document

Page 2 of 7

We are using inverter models that feature excellent robustness and efficiency through an improved MPP tracking algorithm and extensive remote monitoring capabilities. We are working closely with several inverter companies, to develop new inverter systems, which are specially suited to the characteristics of varying types of advanced solar modules. All inverters are calibrated on-site to give optimum system performance. The long-term operation of the devices is covered by a comprehensive warranty and maintenance program of the manufacturer. Utility-Grade Power Management Unit NEST uses popular brand Power Management Units (PMU) that constitute the important step in central inverter technology. Made out of different performance blocks for AC input and integrated with proven interface, the PMUs perform ideally under all irradiance conditions. PMU has been specifically designed for large-scale solar PV power plant operation and provides for high performance, reliability, and ease of operation. All system components are tested for quality and reliability in order to meet the high demands of large-scale and utility-grade power plant applications. We may use PADCON PMU, which is the highest-capacity PV inverter available on the market and can feed directly into 6 to 33kV medium-voltage power grid, depending upon the optimization strategy for the system. PADCON AMC 2500C also offers maximum output through Maximum Power Point Tracking (MPPT) and Active Grid Control using reactive power compensation technologies. Padcon's Central Box and suitable Interface are used to collect DC power and present it to the PADCON PMU. This Interface also allows the real time Management System to flexibly feed power to one or both of the 1.25MW inverters within the PADCON PMU. This, in turn, allows optimizing the operating efficiency and yield of the plant in very low irradiance conditions and throughout a greater portion of the day and year than other PV systems designs. In the scenario of constantly changing inverter technology, we adopt new and innovative technologies to stay ahead in the performance at low operative costs. For usability and convenience, the PMU includes an embedded controller which informs the user on the status of critical system components and implements an automated system diagnosis as required. Further, PMU can also be mounted and commissioned rapidly and includes secure plug-in contacts on both the DC voltage and the AC voltage sides. NEST uses PMUs that are compliant with European Norms DIN EN 61000-6-4: 2002-08, DIN EN 61000-6-2: 2002-08, DIN EN 50178: 1998-04 as well as with IEC 61000-3-4: 1998-10. The substructure of a NEST solar power plant is built strong and reliable NESTs structural system has been refined and proven through years of installations in harshest climates and conditions of any geographical regions. The design is inherently

Noble Energy Solar Technologies Ltd. From the Sun, for the People

Disclaimer: This document is confidential. The user is requested to control the information shared in this document

Page 3 of 7

flexible in that it can be tailored for each projects unique conditions thus enabling the lowest cost solution. Advantages of the NEST substructure: Optimum orientation of the solar modules: Accurate linear (laser) alignment of the modules allows for the same incidence of light for every solar module. The module rows are positioned in a calculated distance from each other, such that they do not cast a shadow on one another during the morning and evening hours. Preservation of vegetation: Through the low degree of ground sealing by the substructure and due to the semi-opaque generator block continuous preservation of vegetation is ensured. Unlimited length of the module rows: Through systematic construction by means of custom-developed machinery the plant is accurately positioned on the ground, exact to the millimeter, which allows for unlimited size of the plant.

The vertical steel poles (I-beams) and horizontal perlins are of heavy industrial design and quality. NESTs substructure design can withstand the thermal stress caused by repeated changes in high and low temperatures along with exposure to high humidity. The structural system is designed to meet the requirements of the 2006 International Building Code (IBC) and ASCE7-05 for wind speeds not to exceed 90mph, as well as international safety standards. Due to its inherently modular design, higher wind speeds can be accommodated. NEST low-loss electrical wiring In an advanced solar PV power plant, there is no such thing as "just the wiring". Every electrical connection introduces an additional contact resistance, and thus additional losses in the circuit. Therefore, the quality of the wiring and connectors has a significant influence on the overall system performance.

For DC transmission lines from modules to the inverter we use special UVresistant solar cable wiring harness, double isolated (IEC 60228/IEC 60664). The entire DC aggregation system is designed for low losses between modules and inverter and high durability in hot conditions. NEST also uses high quality connectors which are manufactured using a special process that virtually eliminates contact resistance.

The electrical connectivity scope of NESTs solar power plants includes: Interconnection of modules to strings Interconnection of strings to sub-arrays Interconnection of sub-arrays to arrays Interconnection of array generators to inverter DC input channel providing a medium voltage AC output channel from the Power Management Units to the grid interconnect

Noble Energy Solar Technologies Ltd. From the Sun, for the People

Disclaimer: This document is confidential. The user is requested to control the information shared in this document

Page 4 of 7

Construction NEST and its worldwide partners offer integrated installation services supported by experienced construction crews and project managers. Most of our construction workmen are NEST trained team to insure high quality and on-schedule completion. NEST also provides all the labor, construction equipment, and leadership necessary to build its solar power plants, up to the grid connection and commissioning. NEST is supported by the Indian and other overseas affiliates to mobilize and execute EPC services in a way that is unmatched in the industry. The construction of a NEST solar power plant can be divided into phases as follows: 1. Site preparation for construction work 2. Assembly of heavy duty steel and supporting beams using automated machinery, GPS and laser measurement systems 3. Mounting of solar modules on the substructure using special rigging components 4. Installation and inverters of electrical systems, cabling,

5. Final system check ensuring that the solar power plant is ready for grid connection Highly Qualified Work Force and Construction Leadership NEST construction teams are organized by installation task, with each having a single experienced team foreman, and a specific role to play in the overall installation process. Each team works and trains together to continually improve installation rates and efficiencies. Team members are rotated through the various installation steps to keep them fresh and focused. Team foremen have direct lines of communication with each other, and with the home project management office to keep the project moving efficiently. For the most part, NEST teams move efficiently through a project with no oversight required by the customer. Logistics are handled by the home office, with materials delivered to the site in a justin-time fashion to minimize the costs and risks of damage. The entire process from ground-breaking to commissioning is simple and efficient, and has been refined through the installation of previous solar power plants. Commissioning and Plant Certification

Noble Energy Solar Technologies Ltd. From the Sun, for the People

Disclaimer: This document is confidential. The user is requested to control the information shared in this document

Page 5 of 7

NEST provides complete medium voltage AC collection systems including breakers, disconnects, switches, protective relays and metering, cabling, underground conduit and pole up to the grid interconnection.

NESTs commissioning process includes setting up the inverters, programming the telecommunication and interconnection equipment, and running test programs before operation. Finally, performance testing and plant certification are completed to ensure that the solar power plant meets the intended performance targets for capacity, generation, and availability. Operations and Maintenance Services Building on years of experience managing solar power plants across Europe, NEST offers comprehensive operations and maintenance services. By operating and maintaining the power plants that we build, we can offer the highest levels of reliability, efficiency, and availability to our customers, as well as providing longer warranty periods and improved performance guarantees. NEST is capable of operating and maintaining its customers solar power plants for the duration of their design service life of 25 years. Our comprehensive program can be tailored to the customers unique needs and can include all activities required to safely provide power at the guaranteed parameters: Administration and coordination, including activities in connection with utility or customer authorities, local law or safety officials, or insurance companies. Monitoring and control, including ongoing monitoring of plant performance and operational parameters by NEST personnel and instant access to plant performance from our data base. Quarterly and annual plant inspections of the protective measures in accordance with applicable regulations. Maintenance and recalibration work by qualified professionals and in accordance with manufacturers' specifications. Repair work by qualified and authorized professionals. Grounds keeping and appropriate care of the plant cover on the entire site. Periodic module, cabinetry and ventilation system cleaning. Securing, monitoring and inspection of the premises.

Real Time Management System be in control, all the time Solar monitoring systems increase the up-time of solar power plants by shortening the time necessary to detect component or system malfunctions.

Noble Energy Solar Technologies Ltd. From the Sun, for the People

Disclaimer: This document is confidential. The user is requested to control the information shared in this document

Page 6 of 7

NEST solar power plants employ extensive remote monitoring features which allow NEST customers to access critical solar system performance data at any time. NESTs IT partner team also has the expertise to develop customized software solutions dedicated to NESTs customers applications.

Further, by utilizing NESTs proven and fully integrated real time Management System, NEST can manage all necessary operations and maintenance for its customers over the 25 year lifetime of the plant. By doing so we provide the best long term reliability, performance, and efficiency, maximizing the profitability of our customers solar power investments.

-----------End of document-----------

Noble Energy Solar Technologies Ltd. From the Sun, for the People

Disclaimer: This document is confidential. The user is requested to control the information shared in this document

Page 7 of 7

You might also like

- Intelligent: Optimal Solar SolutionsDocument4 pagesIntelligent: Optimal Solar SolutionsFerran Vilella ArroyoNo ratings yet

- LOI-SPV 55 KWPDocument13 pagesLOI-SPV 55 KWPEntomic Chemicals100% (2)

- Photovoltaic Inverter White PaperDocument10 pagesPhotovoltaic Inverter White PapergubiliNo ratings yet

- 1SDC007351B0201 TC Solar LV MV 2017 - LRDocument96 pages1SDC007351B0201 TC Solar LV MV 2017 - LRLucianNo ratings yet

- Timeport Alternative EnergyDocument7 pagesTimeport Alternative Energytimeport24No ratings yet

- 50 KW Solar - Project - by Nept SolarDocument13 pages50 KW Solar - Project - by Nept SolarShailendra Kumar VermaNo ratings yet

- Stat ComDocument3 pagesStat ComYasir ButtNo ratings yet

- Siemens Power Engineering Guide 7E 54Document1 pageSiemens Power Engineering Guide 7E 54mydearteacherNo ratings yet

- Smart Grids and The New Age of Energy - EEPDocument11 pagesSmart Grids and The New Age of Energy - EEPvetsasNo ratings yet

- Flexible control for PV power plantsDocument2 pagesFlexible control for PV power plantsIeremeiov VladimirNo ratings yet

- 120 Ds Standardcompliantcomponentsfrphotovoltaicapplications en 2945Document24 pages120 Ds Standardcompliantcomponentsfrphotovoltaicapplications en 2945PiZarezČetrnaestNo ratings yet

- Emerson Solar: Utility Scale PV Inverter SystemsDocument16 pagesEmerson Solar: Utility Scale PV Inverter Systemskrish79No ratings yet

- 120 Ds Standardcompliantcomponentsfrphotovoltaicapplications en 2945 201701171054541374Document24 pages120 Ds Standardcompliantcomponentsfrphotovoltaicapplications en 2945 201701171054541374cc_bauNo ratings yet

- Literature Review of Wireless Sensor Network for Monitoring Solar PanelsDocument19 pagesLiterature Review of Wireless Sensor Network for Monitoring Solar PanelsRaja AritonangNo ratings yet

- Project Proposal DelhiDocument27 pagesProject Proposal DelhiTarun RathoreNo ratings yet

- Information About PVDocument12 pagesInformation About PVpasistNo ratings yet

- Modified Algorithm For Drift Avoidance in PV System Using Neural NetworkDocument6 pagesModified Algorithm For Drift Avoidance in PV System Using Neural NetworkIIR indiaNo ratings yet

- White Paper EnOcean Product IntegrationDocument8 pagesWhite Paper EnOcean Product Integrationfernando_mart859243No ratings yet

- Photovoltatic System Management For Smart Home Energy Management SystemDocument50 pagesPhotovoltatic System Management For Smart Home Energy Management SystemDinesh KumarNo ratings yet

- Large Photovoltaic Power Plant Design: ResearchDocument9 pagesLarge Photovoltaic Power Plant Design: ResearchMardi RahardjoNo ratings yet

- Subha FinalDocument45 pagesSubha FinalbalaNo ratings yet

- Delta ManualDocument392 pagesDelta Manualnkapnangluther3099No ratings yet

- Terco PST2200 ENGDocument28 pagesTerco PST2200 ENGWak TacuNo ratings yet

- Intelligent PV Module For Grid-Connected PV System PDFDocument8 pagesIntelligent PV Module For Grid-Connected PV System PDFAnjas WibisanaNo ratings yet

- Solutions For Solar Energy PDFDocument88 pagesSolutions For Solar Energy PDFbacuoc.nguyen356No ratings yet

- Modelling and Simulation of PV On Grid System ProducingDocument8 pagesModelling and Simulation of PV On Grid System ProducingPat Tab3No ratings yet

- Ac Modules and Solar Power ElectronicsDocument4 pagesAc Modules and Solar Power ElectronicsShivalika SinghNo ratings yet

- Latest Updated Electrical ENGINEERING & DESIGNDocument92 pagesLatest Updated Electrical ENGINEERING & DESIGNShivani GuptaNo ratings yet

- ABB 1SDC007350B0203 - Low Voltage Products - Solutions For Solar Energy PDFDocument88 pagesABB 1SDC007350B0203 - Low Voltage Products - Solutions For Solar Energy PDFbacuoc.nguyen356No ratings yet

- Photovoltaic Installation GuideDocument14 pagesPhotovoltaic Installation GuideCarlos Samaniego100% (2)

- Solar Micro ControllerDocument18 pagesSolar Micro ControllerElangovanNo ratings yet

- MPPT Charge Controller ThesisDocument4 pagesMPPT Charge Controller ThesisBrittany Brown100% (2)

- New Impetus - Drive Technology For The Chemical IndustryDocument16 pagesNew Impetus - Drive Technology For The Chemical IndustryssNo ratings yet

- Review On Power Quality of Hybrid Renewable Energy SystemDocument7 pagesReview On Power Quality of Hybrid Renewable Energy SystemIJRASETPublicationsNo ratings yet

- Efficiency and Safety For Large-Scale Photovoltaic InstallationsDocument8 pagesEfficiency and Safety For Large-Scale Photovoltaic InstallationsGheorghe SerbanNo ratings yet

- t030 CH 1 en PDFDocument6 pagest030 CH 1 en PDFJosé100% (1)

- Solar SystemsDocument8 pagesSolar SystemsFiveCent NickelNo ratings yet

- Adaptive Pole Placement Damping Oscillation Simple Power SystemDocument6 pagesAdaptive Pole Placement Damping Oscillation Simple Power SystemGunNandaTianPurnamaNo ratings yet

- 1 MW Onix Solar Project Report PDFDocument13 pages1 MW Onix Solar Project Report PDFankit100% (2)

- 1 MW Onix Solar Project ReportDocument13 pages1 MW Onix Solar Project ReportankitNo ratings yet

- MW Onix Solar Project Report PDFDocument13 pagesMW Onix Solar Project Report PDFankitNo ratings yet

- Anupam Vinay Surin 12PS05F P & Es, NitkDocument20 pagesAnupam Vinay Surin 12PS05F P & Es, NitkchethanNo ratings yet

- 1 MWP SPP Techno Commercial Proposal PDFDocument10 pages1 MWP SPP Techno Commercial Proposal PDFanil1216kumarNo ratings yet

- Development of Bidirectional Net Meter in Grid Connected Solar PV System For Domestic ConsumersDocument5 pagesDevelopment of Bidirectional Net Meter in Grid Connected Solar PV System For Domestic ConsumersHariprasad RNo ratings yet

- 207kWp Solar Power Proposal for Waterford SchoolDocument9 pages207kWp Solar Power Proposal for Waterford Schooljpsingh75100% (1)

- Smart SolarDocument4 pagesSmart SolarMaruthi KalpaguriNo ratings yet

- © 2004 Cummins Power Generation All Copies Are Uncontrolled: Application Manual - Liquid Cooled Generator SetsDocument3 pages© 2004 Cummins Power Generation All Copies Are Uncontrolled: Application Manual - Liquid Cooled Generator SetsRainier AyapNo ratings yet

- Smart Grid: Power Electronics Technology: AbstractDocument4 pagesSmart Grid: Power Electronics Technology: AbstractMohammed Wasay MudassirNo ratings yet

- Dual Axis Solar Panel ComponentsDocument11 pagesDual Axis Solar Panel ComponentsRaj Kothari MNo ratings yet

- Keylios Tracker 2022Document8 pagesKeylios Tracker 2022Lucas de MedeirosNo ratings yet

- Chapter One Smps InverterDocument10 pagesChapter One Smps Inverterolawale gbadeboNo ratings yet

- Design a 1.5kVA Pure Sine Wave Inverter with Wireless ControlDocument49 pagesDesign a 1.5kVA Pure Sine Wave Inverter with Wireless Controlemmanuel akojiNo ratings yet

- PV IotDocument9 pagesPV IotYOUNESS ATIFINo ratings yet

- WEG Solutions For Solar Energy 50020791 enDocument12 pagesWEG Solutions For Solar Energy 50020791 enHADJENE NoussaibaNo ratings yet

- Powerit MV Air Insulated Motor Control: Featuring Advance and Safegear TechnologyDocument72 pagesPowerit MV Air Insulated Motor Control: Featuring Advance and Safegear TechnologyRaja Bharath DonthiNo ratings yet

- R08-002 - Design and Sizing of Solar Photovoltaic - 240124 - 162025Document125 pagesR08-002 - Design and Sizing of Solar Photovoltaic - 240124 - 162025TECH CHO3013No ratings yet

- Schneider Electric Utility Scale Brochure PDFDocument24 pagesSchneider Electric Utility Scale Brochure PDFwildan_dzulqarnainNo ratings yet

- FuseSystems Primer EN 201601250853041546Document90 pagesFuseSystems Primer EN 201601250853041546cicobumNo ratings yet

- Faculty ProfileDocument2 pagesFaculty ProfileRohit Raj RanganathanNo ratings yet

- Marketing Channel Strategy in Rural Emerging Markets Ben NeuwirthDocument40 pagesMarketing Channel Strategy in Rural Emerging Markets Ben NeuwirthPrakhar DadhichNo ratings yet

- Become A Life Long Networker - Diversify Your NetworkDocument3 pagesBecome A Life Long Networker - Diversify Your NetworkRohit Raj RanganathanNo ratings yet

- Little Black Book of ConnectionDocument132 pagesLittle Black Book of ConnectionSrder tetd100% (3)

- Become A Life Long Networker - Diversify Your NetworkDocument3 pagesBecome A Life Long Networker - Diversify Your NetworkRohit Raj RanganathanNo ratings yet

- Lead Gel Battery Safety-ElinchromeDocument4 pagesLead Gel Battery Safety-ElinchromeRohit Raj RanganathanNo ratings yet

- Important Word List For Gre and GmatDocument79 pagesImportant Word List For Gre and Gmatruchit707No ratings yet

- R Cheat Sheet: 1. Basics 4. Input and Export of DataDocument4 pagesR Cheat Sheet: 1. Basics 4. Input and Export of DataRohit Raj Ranganathan100% (1)

- Cy250 Hub Motor KitDocument3 pagesCy250 Hub Motor KitRohit Raj RanganathanNo ratings yet

- Thrive Energy Solar Power PackDocument2 pagesThrive Energy Solar Power PackRohit Raj RanganathanNo ratings yet

- Solar LED Home Lighting SystemDocument2 pagesSolar LED Home Lighting SystemRohit Raj RanganathanNo ratings yet

- THRIVE Mini Home Lighting System TS 11 2012 Rev00 MCDocument4 pagesTHRIVE Mini Home Lighting System TS 11 2012 Rev00 MCRohit Raj RanganathanNo ratings yet

- Low Maintenance Reliable: 3 Days AutonomyDocument2 pagesLow Maintenance Reliable: 3 Days AutonomyRohit Raj RanganathanNo ratings yet

- 60 Hours Affordable Cost: of Home Lighting atDocument2 pages60 Hours Affordable Cost: of Home Lighting atRohit Raj RanganathanNo ratings yet

- Thrive Energy Desk LightDocument2 pagesThrive Energy Desk LightRohit Raj RanganathanNo ratings yet

- Auroville Solar Domestic Power Storage PresentationDocument12 pagesAuroville Solar Domestic Power Storage PresentationRohit Raj RanganathanNo ratings yet

- AN3471 Freescale Induction Fan Motor ControlDocument24 pagesAN3471 Freescale Induction Fan Motor ControlRohit Raj RanganathanNo ratings yet

- Waggle by David ZingerDocument68 pagesWaggle by David ZingerRohit Raj RanganathanNo ratings yet

- Lead Gel Battery Safety-ElinchromeDocument4 pagesLead Gel Battery Safety-ElinchromeRohit Raj RanganathanNo ratings yet

- A Guide To Understanding Battery SpecificationsDocument3 pagesA Guide To Understanding Battery SpecificationswijayanataNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 T651 148Document2 pagesAalco Metals LTD Aluminium Alloy 6082 T6 T651 148Rohit Raj RanganathanNo ratings yet

- Checklist of Mandatory Documentation Required by IATF 16949 enDocument3 pagesChecklist of Mandatory Documentation Required by IATF 16949 enKristof MC100% (1)

- 00 Basement Foundation LayoutDocument1 page00 Basement Foundation LayoutrendaninNo ratings yet

- What Is Design ThinkingDocument20 pagesWhat Is Design ThinkingPrathamesh PittuleNo ratings yet

- Melbourne Business School Library Project Management BibliographyDocument8 pagesMelbourne Business School Library Project Management BibliographyAndre Joseph Fournier0% (1)

- GPA CalculatorDocument1 pageGPA CalculatorImtinanShaukatNo ratings yet

- Ebook PDF Engineering Graphics Essentials 5th Edition by Kirstie PlantenbergDocument61 pagesEbook PDF Engineering Graphics Essentials 5th Edition by Kirstie Plantenbergdeborah.sheehan548100% (40)

- Yield Stress Sa 240 304Document1 pageYield Stress Sa 240 304faizalNo ratings yet

- Seismic Performance Assessment Methodology Volume 1Document340 pagesSeismic Performance Assessment Methodology Volume 1JuanAlfaroRodríguezNo ratings yet

- Online ShoppingDocument54 pagesOnline ShoppingVaryam Pandey50% (6)

- Panel LG Display Lc320eun-Sem2 0Document36 pagesPanel LG Display Lc320eun-Sem2 0Carlos ChNo ratings yet

- C&matlab 18-19 17213Document53 pagesC&matlab 18-19 17213rajeshNo ratings yet

- Resource Planning of A Colony Project Using PrimaveraDocument6 pagesResource Planning of A Colony Project Using PrimaveraSheikh Ubaid100% (1)

- MP RDC Profile English VersionDocument39 pagesMP RDC Profile English VersionNP METALPROTECTIONNo ratings yet

- Internship Program - I IP-I (IP201) Final PresentationDocument27 pagesInternship Program - I IP-I (IP201) Final PresentationSaurav ChoudhuryNo ratings yet

- EGD Lab ManualDocument15 pagesEGD Lab ManualRajesh ANo ratings yet

- VAIBHAV SAWANT BE MBA Supply Chain ConsultantDocument3 pagesVAIBHAV SAWANT BE MBA Supply Chain ConsultantVaibhavSawantNo ratings yet

- Glass Block Technical PresentationDocument16 pagesGlass Block Technical PresentationJothika JothikaNo ratings yet

- Basic Requirement About Roof For SolarDocument2 pagesBasic Requirement About Roof For SolarShreeCementNo ratings yet

- General Electric - Breaker CodigoDocument1 pageGeneral Electric - Breaker CodigoJoel Paucar RuizNo ratings yet

- Construction Materials and TestingDocument24 pagesConstruction Materials and TestingJames NeoNo ratings yet

- List of UniversitasDocument40 pagesList of UniversitasMuhamad Erlangga SaputraNo ratings yet

- Uav Design - Part IiDocument1 pageUav Design - Part IiPradeep KumarNo ratings yet

- Pavement Design: SEPTEMBER, 2006 Road Design Manual 7-0Document18 pagesPavement Design: SEPTEMBER, 2006 Road Design Manual 7-0amofaevansNo ratings yet

- PT I Girder Design 20mDocument18 pagesPT I Girder Design 20msamirbendre1No ratings yet

- Instruments Used in Engineering DrawingDocument15 pagesInstruments Used in Engineering Drawingasus nyahendraNo ratings yet

- ITP Box Setting On CHB or Macro WallDocument3 pagesITP Box Setting On CHB or Macro WallRitchie OcampoNo ratings yet

- PMI-ANSI Standards Development and The Scheduling StandardDocument28 pagesPMI-ANSI Standards Development and The Scheduling Standard1meander23No ratings yet

- Fundamentals of Earthquake Engineering: Those Familiar With Newmark - S and RosenDocument1 pageFundamentals of Earthquake Engineering: Those Familiar With Newmark - S and RosenBladimir Jesús Ccama Cutipa0% (1)

- Gujarat Technological University: Aeronautical EngineeringDocument16 pagesGujarat Technological University: Aeronautical EngineeringNiik StarNo ratings yet

- Syed Sohail Hamid Zaidi: A: Technical Aspects and Areas of ExpertiseDocument13 pagesSyed Sohail Hamid Zaidi: A: Technical Aspects and Areas of ExpertiseAfrasyab KhanNo ratings yet