Professional Documents

Culture Documents

E-Chamber Top Plate and Flange Analysis

Uploaded by

Junaid YOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E-Chamber Top Plate and Flange Analysis

Uploaded by

Junaid YCopyright:

Available Formats

Structural Analysis:

C. Pai 9-18-2003

Subject: E-Chamber Top Plate and Flange Strength Analysis.

1. Summaries: a. The tightening torque (from MDC) for the 5/16-18 bolt is about 12 to 15 ft-lb. In this calculation 12 ft-lb (144 in-lb) was used in the model. This torque will induce 2304 lb tension in each bolt. The total clamping force for the whole flange is 27648 lb. In the model this force is simulated by thermal shrink in the bolt element. The contact surface between top plate and flange is modeled by contact element to simulate a compression only condition. The E-chamber assembly is shown in Fig. 1. The finite element model is shown in Fig. 2 and 3. b. The O-ring repelling force from the .01 inches compression is about 320 lb. In the model this force is simulated as pressure applied in the O-ring groove . The clamping force to resist 10 bar (150 psi) internal pressure is about 2385 lb. c. The ratio of total bolt tension to needed clamping force is about 10. d. The initial bolt tensional stress without internal pressure is = 45,283 psi (Fig. 4, 6). When internal pressure applied the tensional stress increased to 46,191 psi (Fig. 5,7). The change in the bolt load is about 2%. e. The maximum contact pressure by the bolt tension is 7600 psi (Fig. 8). When the 10 bar internal pressure applied this pressure will be redistributed and the maximum pressure is 11000 psi (Fig. 9). The gap between the contact surfaces will be opened up about .00043 inches (Fig. 10, 11) in the inner edge of the contact surface. This is a small change compare to the .01 inches compression of the O-ring seal. f. When bolted without internal pressure , the maximum stress in the top plate is around the bolted area, = 26,536 psi (Fig. 12,13). When pressure applied this stress reduced to 25,764 psi (Fig.14,15). This stress is a localized stress due to high local bolting force and the nature of finite element modeling. In the real world this stress will be reduced by washers and rounded corners. The stress in the center and edge of the feedthrough holes is about 13,206 psi (Fig.14,15). 2. Model: A three dimensional, quarter size, ANSYS model (Fig. 1, 2, 3) was built to simulate this structure. The flange contact interface was modeled by contact element to check if gap opening occurred when internal pressure applied. The bolt tension is simulated by thermal shrinkage applied in the bolt. The compression of O-ring was simulated by pressure in the O-ring groove.

3. Materials: a. Top plate : Size: 7.0 O.D, .375 thick. Material: 304 SST E= 30e6 psi = .3 b. Chamber flange: Size: 4.5ID, 7.0 OD, .5 thick, Material: 304L SST E= 30e6 psi = .3 O-ring : No. 2-048 Size: 4-7/8(OD) x 4-1/4 (ID) x .07 (W) Material: Viton E = 2000 psi = .499 5/16-18 Bolt: Size: Nominal dia. 5/16 Cross section area: .0524 in2. Strength of Bolt: Grade 5: 85,000 psi (min).

c.

d.

3. Strength of SST 304: ASME Allowable stress : 15,700 psi Yield stress: 25,000 psi Ultimate stress: 70,000 4. Loading condition: a. Initial condition: Bolted without internal pressure Bolt tension: 27648 lb total from 12 bolts. O-ring compression load: 320 lb. b. Operation condition: Bolted with 10 bar (150 psi) internal pressure.

10

You might also like

- Assignment No.3 Bolted JointsDocument6 pagesAssignment No.3 Bolted JointsYash SahuNo ratings yet

- Main Exam Paper Nov08, Smt211tDocument6 pagesMain Exam Paper Nov08, Smt211tPortia ShilengeNo ratings yet

- Me331-Design of Machine Elements Unit Iii Design of Fasteners and JointsDocument21 pagesMe331-Design of Machine Elements Unit Iii Design of Fasteners and JointsMuthuvel MNo ratings yet

- Strength of Materials PDFDocument35 pagesStrength of Materials PDFromeo08100% (1)

- Assignment 02 - Machine DesignDocument2 pagesAssignment 02 - Machine DesignRatan Sadanandan O MNo ratings yet

- Prelim Emt313nDocument9 pagesPrelim Emt313npaulineNo ratings yet

- Kiln Tyre Load CalculationDocument4 pagesKiln Tyre Load CalculationRadi Gohar50% (2)

- Thick Shell TheoryDocument17 pagesThick Shell TheoryNitin SuryawanshiNo ratings yet

- ES 13 ProbSet 1Document2 pagesES 13 ProbSet 1Sammy Marquez50% (2)

- MD Tut PDFDocument6 pagesMD Tut PDFNelsan PatelNo ratings yet

- Fig. P3.129, P3.130Document4 pagesFig. P3.129, P3.130Alen RustemovicNo ratings yet

- ME C312 Design of Machine Elements Comprehensive ExamDocument2 pagesME C312 Design of Machine Elements Comprehensive ExamARPIT MITTALNo ratings yet

- Defo Mechanics EngineeringDocument7 pagesDefo Mechanics EngineeringGrace PsycheNo ratings yet

- Analysis of Bolt Torquing and Stress CalculationsDocument7 pagesAnalysis of Bolt Torquing and Stress CalculationsEleonor MaderazoNo ratings yet

- Tutorials 2Document3 pagesTutorials 2Daemaro Liv Guud BremmerNo ratings yet

- Thrust Ring - PaperDocument10 pagesThrust Ring - Paperbhathiya01No ratings yet

- بحث الميتالDocument7 pagesبحث الميتالAhmed fahmyNo ratings yet

- Tutorial FastenersDocument2 pagesTutorial FastenersKrm LeoNo ratings yet

- 2006 Int Ansys Conf 349Document14 pages2006 Int Ansys Conf 349mariomatoNo ratings yet

- PRESSURE VESSELS STRESSESDocument5 pagesPRESSURE VESSELS STRESSESAshok PradhanNo ratings yet

- Bearing & Thin WalledDocument17 pagesBearing & Thin WalledEmjay SevillaNo ratings yet

- Piercing Extrusion of Long Hollow Component With Subsidiary TensionDocument4 pagesPiercing Extrusion of Long Hollow Component With Subsidiary TensionDhan CNo ratings yet

- Thin and Thick CylindersDocument6 pagesThin and Thick CylindersRamesh Akula80% (5)

- Bolted Flange ConnectionDocument6 pagesBolted Flange Connectiondip_maanNo ratings yet

- Bolt Torque FormulaDocument24 pagesBolt Torque Formulaماهر زارعي100% (1)

- Determining Wall Thickness For Deepwater PipelinesDocument10 pagesDetermining Wall Thickness For Deepwater Pipelinesbello imamNo ratings yet

- Analysis of Bolt Torquing CalculationsDocument6 pagesAnalysis of Bolt Torquing CalculationsBahtiar YudhistiraNo ratings yet

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- Department of Mechanical Engineering ME-311, Fundamentals of Machine Design Assignment Sheet No.1 1Document6 pagesDepartment of Mechanical Engineering ME-311, Fundamentals of Machine Design Assignment Sheet No.1 1VishnuNo ratings yet

- Department of Mechanical EngineeringDocument1 pageDepartment of Mechanical Engineeringhadhi ahamedNo ratings yet

- Module 4 - Design of Tension MembersDocument30 pagesModule 4 - Design of Tension MembersSreelakshmi GNo ratings yet

- 4d-Ex. Connector Examples: GivenDocument1 page4d-Ex. Connector Examples: GivenadnandjNo ratings yet

- DME Question Bank - 3171917Document4 pagesDME Question Bank - 3171917fgyjnsv786No ratings yet

- Stress Analysis and Design of Bolted Flange Connections UnderDocument11 pagesStress Analysis and Design of Bolted Flange Connections UndervijaygalaxyNo ratings yet

- Assignment For IPEDocument4 pagesAssignment For IPEAbirHasanNo ratings yet

- Investigation of Stresses in Ring Stiffened Circular CylinderDocument5 pagesInvestigation of Stresses in Ring Stiffened Circular Cylinderisraaahmed12No ratings yet

- SwatiNirmala2019 - Article - Analyze The Failure of A Suspension System Ball JointDocument5 pagesSwatiNirmala2019 - Article - Analyze The Failure of A Suspension System Ball JointNikki SinghNo ratings yet

- Unit - 1Document8 pagesUnit - 1Dhileepan KumarasamyNo ratings yet

- Astm Fastener Standards: Download Standards For Fasteners Tests and SpecificationsDocument6 pagesAstm Fastener Standards: Download Standards For Fasteners Tests and Specificationsmechmaster4uNo ratings yet

- Analysis of Bolt TorquingDocument7 pagesAnalysis of Bolt TorquingAlessandro Serafini100% (1)

- Mechanics of Solids-II MEC-206ADocument3 pagesMechanics of Solids-II MEC-206AManish KumarNo ratings yet

- Design Examples for Structural Joints and Wood PanelsDocument24 pagesDesign Examples for Structural Joints and Wood PanelsAlan Peter100% (2)

- Research On Optimization For The Piston Pin and The Piston Pin BossDocument8 pagesResearch On Optimization For The Piston Pin and The Piston Pin BossVinod JunjuNo ratings yet

- Problem Solving Session VDocument10 pagesProblem Solving Session VOmar AhmedNo ratings yet

- Stress, Strain and Relation ExerciseDocument7 pagesStress, Strain and Relation ExerciseHazeq AzaharNo ratings yet

- 1830 - Tutorial 4 Clutches and BrakesDocument3 pages1830 - Tutorial 4 Clutches and BrakesJohn RajNo ratings yet

- Stress and Strength CalculationsDocument21 pagesStress and Strength CalculationsMidas Troy VictorNo ratings yet

- 15 151905 Machine Design IDocument3 pages15 151905 Machine Design IPeeka Prabhakara RaoNo ratings yet

- Ligament Pressure Vessel AnalysisDocument8 pagesLigament Pressure Vessel AnalysisAnnie HillNo ratings yet

- Chain FEA Report: FEA Analyst-Deepto Banerjee Amit KumarDocument5 pagesChain FEA Report: FEA Analyst-Deepto Banerjee Amit KumarDeepto BanerjeeNo ratings yet

- Worked Calculations Non Permanent Fasteners With Naration - PPSXDocument28 pagesWorked Calculations Non Permanent Fasteners With Naration - PPSXTeeNo ratings yet

- Finite Element Simulation of Shot Peening Method To Evaluate The Influence of Peening Parameters On Surface CharacteristicsDocument9 pagesFinite Element Simulation of Shot Peening Method To Evaluate The Influence of Peening Parameters On Surface CharacteristicsSaptarshee MitraNo ratings yet

- Solid Tutorial 7Document9 pagesSolid Tutorial 7Mohammad Afandi Azmi RaifNo ratings yet

- TorquingDocument7 pagesTorquingVicky KumarNo ratings yet

- Functioning of Flange Joints Findings From Full Scale Experiments and Fem AnalysisDocument10 pagesFunctioning of Flange Joints Findings From Full Scale Experiments and Fem AnalysisSpecial Sicim ProcessesNo ratings yet

- RTS DC Servo DriveDocument4 pagesRTS DC Servo DriveJunaid YNo ratings yet

- Trenchless World 2013-06 Unpiggable Pipelines1Document4 pagesTrenchless World 2013-06 Unpiggable Pipelines1Junaid YNo ratings yet

- Asme JMDDocument6 pagesAsme JMDJunaid YNo ratings yet

- Career Opportunities AbroadDocument127 pagesCareer Opportunities AbroadJunaid YNo ratings yet

- CSC Scholarship Procedure - EnglishDocument4 pagesCSC Scholarship Procedure - EnglishHaseeb BalochNo ratings yet

- Seminar of Study in GermanyDocument25 pagesSeminar of Study in GermanyKavish AhmedNo ratings yet

- SolidWorks Motion Study ToolsDocument1 pageSolidWorks Motion Study ToolsJunaid YNo ratings yet

- BeltDocument26 pagesBeltJunaid YNo ratings yet

- 9 ICMS Instructions For AuthorsDocument3 pages9 ICMS Instructions For AuthorsJunaid YNo ratings yet

- FluidsDesignProjectReport DesDocument9 pagesFluidsDesignProjectReport DesJunaid YNo ratings yet

- GMAT Exam SuccessDocument416 pagesGMAT Exam Successkedari007100% (2)

- Analyzing Golf Equipment Sales Data Using Pivot TablesDocument20 pagesAnalyzing Golf Equipment Sales Data Using Pivot Tablesgeologia1000No ratings yet

- MagnesiumDocument3 pagesMagnesiumIsidoro LópezNo ratings yet

- Sheet Metal HintsDocument26 pagesSheet Metal Hintsneeraj kumarNo ratings yet

- 1Document6 pages1vigneshhoysalaNo ratings yet

- Project Report 31Document21 pagesProject Report 31Junaid YNo ratings yet

- Fluid Motion KinematicsDocument7 pagesFluid Motion KinematicsJunaid YNo ratings yet

- New Microsoft Office Word DocumentDocument11 pagesNew Microsoft Office Word DocumentJunaid YNo ratings yet

- Ali Salman 01Document15 pagesAli Salman 01Junaid YNo ratings yet

- Automotive Technology Lab 5Document10 pagesAutomotive Technology Lab 5Azad KiyalNo ratings yet

- FEEDCON - Lesson 10 - Classical Design in The S DomainDocument41 pagesFEEDCON - Lesson 10 - Classical Design in The S DomainJunaid YNo ratings yet

- Ec 10 ADocument4 pagesEc 10 AZargham KhanNo ratings yet

- 55 218Document10 pages55 218Junaid YNo ratings yet

- Control Engineering Lecture 5 OCMS GuideDocument7 pagesControl Engineering Lecture 5 OCMS GuideJunaid YNo ratings yet

- Calculations For Short Circuit Withstand PDFDocument4 pagesCalculations For Short Circuit Withstand PDFWilverCorreaBravoNo ratings yet

- Stray losses in power transformer tank walls and construction partsDocument4 pagesStray losses in power transformer tank walls and construction partsHaris RasoolNo ratings yet

- Lecture 02Document38 pagesLecture 02Junaid YNo ratings yet

- Stray losses in power transformer tank walls and construction partsDocument4 pagesStray losses in power transformer tank walls and construction partsHaris RasoolNo ratings yet

- Lecture 5Document25 pagesLecture 5Junaid YNo ratings yet

- CriticalDocument23 pagesCriticalGeetha ReddyNo ratings yet

- 5100 Series Gas Analyzer: Product Data SheetDocument2 pages5100 Series Gas Analyzer: Product Data SheetSai KamalaNo ratings yet

- Economics and Its NatureDocument4 pagesEconomics and Its NatureElrey IncisoNo ratings yet

- Analytical ExpositionDocument7 pagesAnalytical ExpositionEman FakotNo ratings yet

- Department of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADDocument2 pagesDepartment of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADAbdul MalikNo ratings yet

- Suffolk Bus S92 Schedule Effective 5-2712Document2 pagesSuffolk Bus S92 Schedule Effective 5-2712RiverheadLOCAL67% (6)

- Latex WikibookDocument313 pagesLatex Wikibookraul_apNo ratings yet

- Call For IPSF-EMRO Regional Working Group Subcommittees 2018-19Document4 pagesCall For IPSF-EMRO Regional Working Group Subcommittees 2018-19IPSF EMRONo ratings yet

- Basic Engineering & Site DataDocument13 pagesBasic Engineering & Site DataBalasubramanianNo ratings yet

- Jakob's Ten Usability Heuristics: Nielsen Norman GroupDocument11 pagesJakob's Ten Usability Heuristics: Nielsen Norman GroupPiyush ChauhanNo ratings yet

- Daniel Kipkirong Tarus C.VDocument19 pagesDaniel Kipkirong Tarus C.VPeter Osundwa KitekiNo ratings yet

- Prediction On Miss Mamta Banerjee Honorable CM of West Bengal Much Much Before Result and Election by Indranil RayDocument24 pagesPrediction On Miss Mamta Banerjee Honorable CM of West Bengal Much Much Before Result and Election by Indranil RayIndranil RayNo ratings yet

- NumericalsDocument6 pagesNumericalsaditya dhapodkarNo ratings yet

- Potentiometric TitrationDocument12 pagesPotentiometric TitrationTien Haminh100% (1)

- Sem2 NanoparticlesDocument35 pagesSem2 NanoparticlesgujjugullygirlNo ratings yet

- A Fracture Mechanics Analysis of The Texture of Fried Potato Crust PDFDocument7 pagesA Fracture Mechanics Analysis of The Texture of Fried Potato Crust PDFRomaric OuetchehouNo ratings yet

- MATHEMATICS Compulsory Part Paper 1: Question-Answer BookDocument20 pagesMATHEMATICS Compulsory Part Paper 1: Question-Answer Booknicole wongNo ratings yet

- PVG 32 BobinasDocument64 pagesPVG 32 BobinasSaul CastañedaNo ratings yet

- 574-Article Text-1139-1-10-20170930Document12 pages574-Article Text-1139-1-10-20170930Jhufry GhanterNo ratings yet

- Floor Heating Controls Wiring Instructions for FS and BA Master Weather CompensationDocument12 pagesFloor Heating Controls Wiring Instructions for FS and BA Master Weather Compensationjamppajoo2No ratings yet

- Single Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Document1 pageSingle Core Bonding Cables Are Not in Scope of Supply.: LLC "RKS-Plast"Sunli Karla Sivincha RomeroNo ratings yet

- Manifest Merger Debug ReportDocument14 pagesManifest Merger Debug ReportRam PankhaniyaNo ratings yet

- Cable Percussion Rig ChecksDocument2 pagesCable Percussion Rig Checksargon39No ratings yet

- Philadelphia University Faculty of Engineering and Technology Department of Mechanical EngineeringDocument8 pagesPhiladelphia University Faculty of Engineering and Technology Department of Mechanical EngineeringTamer JafarNo ratings yet

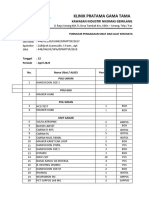

- Pengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuDocument8 pagesPengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuIsma Prasetya WardaniNo ratings yet

- Reformasi Birokrasi Di AustraliaDocument54 pagesReformasi Birokrasi Di Australiazaky ahmadNo ratings yet

- PronunciationDocument5 pagesPronunciationHưng NguyễnNo ratings yet

- Modelacion Fisicomatematica Del Transporte de Metales PesadosDocument11 pagesModelacion Fisicomatematica Del Transporte de Metales PesadosdiegoNo ratings yet

- ZEISS CALYPSO 2021 Flyer Action Software Options ENDocument2 pagesZEISS CALYPSO 2021 Flyer Action Software Options ENnaveensirNo ratings yet

- Module 4 NotesDocument20 pagesModule 4 NotesvijaykumaryadavNo ratings yet