Professional Documents

Culture Documents

Oil Sump Pit

Uploaded by

Irshad KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Sump Pit

Uploaded by

Irshad KhanCopyright:

Available Formats

DOC.

NO:

ALIF ENGINEERS AND PLANNERS

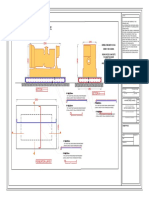

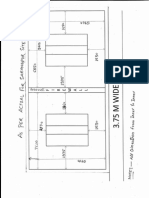

Design calculation For Burnt Oil pit

M2011EP008A-88

REV R0

Design as a uncracked section as per IS 3370 Oil capacity = 35000 Litres. Taking 30% more = 40250 Litres Volume of tank required = 40.3 CuM Cap. of tank Volume Density of oil Data: = 4 x 4 x 2.7 0.80

2.7

3.70

= 43.2 CuM OK = 0.9 T/m3 4.40

For M25 and Fe 500 9 N/mm2 ( IS 456 Table 21) For M25 concrete 150 N/mm2 ( IS 3370 Part II - Table 2)

Perm Stress in concrete (c) = Perm Stress in steel (t) m = 280/3c mc/t = 11 =

= nc / (d-nc)

therefore nc =

0.62 d 0.79 2.08

a = d - nc/3

= 0.79 d

therefore j =

MR = b nc c/2 a = 2.08 bd2 Density of soil = 1.70 T/m3

therefore Q =

Angle of repose = 10 deg

Ka =

0.7

Case I - When tank is full. (Neglecting earth pressure) Using design charts of IS 3370 Part IV - considering top and bottom hinged. As per Table 1 IS 3370 (Part IV) - 1967 a = height of wall = b = Width of wall = c = Width of wall = c/a = 1.2 b/a = 3.7 m 4.4 m 4.4 m 1.2 Density of liquid w = 0.9 Depth of wall below ground = 3.4 m

Moment coefficients (Taking Maxm values) for b/a = 1.25 Mx = 0.030 -0.010 My = 0.019 -0.045 Table 6 - IS 3370 Part IV

Sterling Wilson Ltd.

DOC.NO:

ALIF ENGINEERS AND PLANNERS

Design calculation For Burnt Oil pit

M2011EP008A-88

REV R0

Maximum Horizontal moment = Mx w a ^3 = 0.030 x 0.9 x 2.7 ^3 = 0.53 TM (Inside face) Maximum Horizontal moment = Mx w a ^3 = 0.010 x 0.9 x 2.7 ^3 = 0.18 TM (Outside face) Maximum Vertical moment = My w a ^3 = 0.045 x 0.9 x 2.7 ^3 = 0.8 TM (Outside face) Maximum Vertical moment = My w a ^3 = 0.019 x 0.9 x 2.7 ^3 = 0.34 TM (Inside face) Case II - When tank is empty (Full earth pressure) Soil pressure Ka = 0.70 x 1.70 = 1.2 T/m2 Oil press. Vert. Moment Oil Press. Horzt. Moment

Using design charts of IS 3370 Part IV - considering top and bottom hinged. As per Table 1 IS 3370 (Part IV) - 1967 Moment coefficients (Taking Maxm values) for b/a = 1.25 Mx = 0.030 -0.010 My = 0.019 -0.045 Table 1 - IS 3370 Part IV Soil Press.

Maximum Horizontal moment = Mx w a ^3 = 0.030 x 1.2 x 3.2 ^3 = 1.18 TM (Outside face) Maximum Horizontal moment = Mx w a ^3 = 0.010 x 1.2 x 3.2 ^3 = 0.39 TM (Inside face) Maximum Vertical moment = My w a ^3 = 0.045 x 1.2 x 3.2 ^3 = 1.77 TM (Inside face) Maximum Vertical moment = My w a ^3 = 0.019 x 1.2 x 3.2 ^3 = 0.75 TM (Outside face)

Horzt. Moment

Soil Press. Vert. Moment

c c c c Sterling Wilson Ltd. 2

c c c c

DOC.NO:

ALIF ENGINEERS AND PLANNERS

Design calculation For Burnt Oil pit

M2011EP008A-88

REV R0

Depth of wall required = Sqrt ( M/Q b) d Required Provided d d = 1.77 x 10 2.08 x 1000 = 92 Provide overall depth = 200 mm

7

c c c c

c c c c 0.100 x

= 200 - 25 -

12 = 163 mm

Shear due to oil pressure will cause tension in walls and slab. Shear coefficients (Taking Maxm values) for b/a = Sx = 0.512 = = = Table 7 - IS 3370 Part IV Coefficient x w x a^2 0.512 x 0.90 x 3.3592 2.7 ^2 (depth of oil considered) 1.25

Tension in wall

Area of horzt. steel required = M-Tx / t j d + T/t (For Maxm Values of BM) Horizontal steel outside face Ast1 Ast1 = Ast1 + Ast2

= M-Tx / t j d = = 1.18 x 10 ^7 - 3.36 x 10^4 x 100 150 x 10 0.79 ^7 x 151 467.22 mm2 `

Ast2

= T/t = 3.36 x 10 ^4 150 = 220 mm2 = = Ast1 + Ast2 467 + 219.7 = 687 mm2

Total Ast

Horizontal steel inside face = Ast1 + Ast2 Ast1 0.53 x 10 ^7 = 150 x 10 0.79 ^7 x 151 = Ast2 Total Ast = = = = Provide Y 12 @ 295 mm2 3 x 10 ^4 150 224 mm2 Ast1 + Ast2 295 + 223.9 = 519.3 mm2 686.9 mm2 OK `

150 c/c

Ast provided =

754 mm2 >

Sterling Wilson Ltd.

DOC.NO:

ALIF ENGINEERS AND PLANNERS

Design calculation For Burnt Oil pit

M2011EP008A-88

REV R0

Area of Vertical steel required = M / t j d (For Maxm values of BM) Vertical steel (Outside face) Vertical steel (Inside face) Provide Y Provide Y 12 @ 12 @ = = 0.8 x 10 ^7 150 x 10 0.79 ^7 x 1.77 x 10 ^7 150 x 10 0.79 ^7 x 163 163 = 410 mm2 = 900 mm2

100 c/c 100 c/c

Ast provided = 1131 mm2 (Inside face) Ast provided = 1131 mm2 (Outside face) (Cl. 7.1 IS 3370 part IV) (10% reduction for HYSD steel)

2

Mimimum steel required 0.3 for 100mm to 0.2% for 450mm For thickness of 200 mm mimimum steel shall be =0.244 % 0.244 x

Minm Area of steel required = Design of top slab. Thick = 100 Loads Span = 4.20 m Self weight Live Load Total Load

200 x 1000 = 489 mm < 1131 100 4.40

OK

d = 65 mm

= 0.100 x 2.5 = 0.25 T/m2 = 0.1 T/m2 = 0.35 T/m2 1.0 = x = 0.056 Table 26 IS 456

2

Designing as a two way slab for Ly/Lx = Maximum BM

0.056 x 0.35 x 4.20

= 0.35 TM

Area of steel required = M-Tx / t j d + T/t (For Maxm Values of BM) Ast1 required = = Ast2 0.35 x 10 ^7 - 3.36 x 10^4 x 100 150 x 10 0.79 ^7 x 65 12.678 mm2 = = Total Ast Provide Y 10 @ = = 3.36 x 10 ^4 150 224 mm2 Ast1 + Ast2 12.7 + 223.9 = 236.6 mm2 236.6 mm2 OK p= 0.200 % `

200 c/c

Ast provided =

393 mm2 > For

Provide minm reinforcement in bottom of slab Ast = 0.2 x Provide Y 1000 x 100 = 200 mm2 100 10 @ 200 c/c Ast provided =

100 mm

393 mm2 > 200 mm2 OK

Sterling Wilson Ltd.

DOC.NO:

ALIF ENGINEERS AND PLANNERS

Design calculation For Burnt Oil pit

200 Thick d= 170

M2011EP008A-88

REV R0

Design of base slab. Critical - when tank is full Weight of Roof slab Weight of wall Weight of oil Weight of base slab Total Load Upward pressure Net pressure

= 0.10 x 4.40 x = 4 x 4.40 x = 2.7 x 4.00 x = 0.2 x 4.90 x = = 85.65 T 85.65 / 4.90 0.9 x 1.0

2

4.40 0.20 4.00 4.90

x 2.5 = x 2.5 3.4 x 0.9 = x 2.5 =

4.84 x 2.5 38.9 12.01

T = 29.92 T T T

= 3.57 T/m2 2.7 0.2 x

(250mm projection on each side) 2.5 = 0.64 T/m2

= 3.6

Designing as a two way slab for Ly/Lx =

x = 0.056

Table 26 IS 456

2

Maximum BM causing tension on liquid side =

0.056 x 0.64 x 4.40

= 0.69 TM

Area of steel required = M-Tx / t j d + T/t (For Maxm Values of BM) Ast1 required = = Ast2 0.69 x 10 ^7 - 3.36 x 10^4 x 100 150 x 10 0.79 ^7 x 170 175.09 mm2 = = Total Ast = = Provide Y 10 @ 3.36 x 10 ^4 150 224 mm2 Ast1 + Ast2 223.9 = 399.0 mm2 399.0 mm2 OK p= 0.244 % `

175 +

150 c/c

Ast provided =

524 mm2 > For

Provide minm reinforcement in bottom of slab Ast = 0.25x 1000 x 100 Provide Y 10 @ 200 = 488 mm2 150 c/c Ast provided =

200 mm

524 mm2 > 488 mm2 OK

Sterling Wilson Ltd.

You might also like

- Burnt Oil Pit-R1Document6 pagesBurnt Oil Pit-R1Irshad KhanNo ratings yet

- Design of Foundation 6/8 MVA Power TransformerDocument2 pagesDesign of Foundation 6/8 MVA Power TransformerSujit Rasaily0% (2)

- Cable Trench MainDocument17 pagesCable Trench MainAchin Achena100% (6)

- Transformer Foundation DesignDocument13 pagesTransformer Foundation Designengage4u202067% (3)

- Cable Trench IS 456Document43 pagesCable Trench IS 456Dharaneshskumar67% (3)

- Trench DesignDocument8 pagesTrench Designprasadnn2001No ratings yet

- RC Cable Trench WallsDocument10 pagesRC Cable Trench WallsAnonymous UUw70xirblNo ratings yet

- Design of Transformer Foundation Transformer Detail: Ref DRG NoDocument16 pagesDesign of Transformer Foundation Transformer Detail: Ref DRG Nottbharat67% (3)

- 160MVA TRFRFDNDocument23 pages160MVA TRFRFDNSohan Lal JainNo ratings yet

- For Detail of Section TB 0 332 316 004Document43 pagesFor Detail of Section TB 0 332 316 004MUKESH KUMARNo ratings yet

- Transformer Foundation Along With Blast WallDocument11 pagesTransformer Foundation Along With Blast Wallkrmurali2000No ratings yet

- 132kv Building - Calculations (R1)Document42 pages132kv Building - Calculations (R1)Vijith29No ratings yet

- DG FoundationDocument4 pagesDG Foundationbollasudarshan100% (2)

- Annexure Ii: Design of Box Type CulvertDocument7 pagesAnnexure Ii: Design of Box Type Culvertrohit100% (1)

- Detailed Design Calculations of 132kv Transformer Foundation 1Document9 pagesDetailed Design Calculations of 132kv Transformer Foundation 1Azam Islam Khan100% (3)

- Cable Trench DesignDocument24 pagesCable Trench DesignIrshad Khan100% (1)

- Foundation F1 Design CalculationDocument30 pagesFoundation F1 Design CalculationvasudhaNo ratings yet

- 33 KV E Pole DesignDocument40 pages33 KV E Pole DesignSri Gaja Govind BabuNo ratings yet

- 10.0m LIGHTING POLES - Concrete Design BS8110Document7 pages10.0m LIGHTING POLES - Concrete Design BS8110Nicoleta cristianNo ratings yet

- SubstationDocument73 pagesSubstationShubham MittalNo ratings yet

- Ventellation CalcualtionDocument6 pagesVentellation CalcualtionSantoshNo ratings yet

- Technical Specification Compliance HT - 1 Panel - 24072020 - Smart Electric (ABB)Document48 pagesTechnical Specification Compliance HT - 1 Panel - 24072020 - Smart Electric (ABB)Muthu KumaranNo ratings yet

- Substation DesignDocument2 pagesSubstation Designeric bargasNo ratings yet

- 10.14 Mva Transformer Foundation: Input Data Rebar Work Footing SizeDocument3 pages10.14 Mva Transformer Foundation: Input Data Rebar Work Footing SizeDesign explorer olomizanaNo ratings yet

- Lighting SLDDocument1 pageLighting SLDParthasarathy SarathyNo ratings yet

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- Wind Ananlysis Calculation For MR Pankaj Pachlore: 8.5 + 3 11.5 Between 1.5 & 10 MDocument9 pagesWind Ananlysis Calculation For MR Pankaj Pachlore: 8.5 + 3 11.5 Between 1.5 & 10 Mhitesh gandhiNo ratings yet

- Soak Pit Design CalculationDocument4 pagesSoak Pit Design CalculationHarsha Gavini80% (5)

- KK Spun India Limited: Municipal Corporation Katni EgisDocument2 pagesKK Spun India Limited: Municipal Corporation Katni EgisPankaj Kumar100% (1)

- Design of The PoleDocument7 pagesDesign of The Polevirous08No ratings yet

- GT TRANSFORMER Soak Pit Sizing.Document1 pageGT TRANSFORMER Soak Pit Sizing.Thangarajan NagarajanNo ratings yet

- 230kV DS Foundation DesignDocument5 pages230kV DS Foundation Designelkhalfi100% (1)

- Design of Base PlateDocument3 pagesDesign of Base Plateravi4paperNo ratings yet

- Structure CalculationDocument163 pagesStructure CalculationSUSOVAN BISWASNo ratings yet

- UG SumpDocument5 pagesUG SumpvishnuNo ratings yet

- Mecgale: Consider Base Mva Consider Base KVDocument6 pagesMecgale: Consider Base Mva Consider Base KVvenkateshbitraNo ratings yet

- D.G Set FoundationDocument27 pagesD.G Set Foundationurs_harji100% (2)

- 12.5 MVA Transformer Design (Latest)Document4 pages12.5 MVA Transformer Design (Latest)Amarjit KulkarniNo ratings yet

- Client Comment Response - DG FoundationDocument7 pagesClient Comment Response - DG FoundationAnnelzNo ratings yet

- Staad Report - BracketDocument7 pagesStaad Report - BracketsanjeevNo ratings yet

- Transformer Foundation DesignDocument13 pagesTransformer Foundation DesignAUNGPSNo ratings yet

- RC WALLS & Base Raft Design-R2Document96 pagesRC WALLS & Base Raft Design-R2Moideen Sunaif Mustafa100% (1)

- Wind Load Calculation With 0.3W EffectDocument19 pagesWind Load Calculation With 0.3W EffectPradip NikamNo ratings yet

- Wind Load Calculations Upload 1Document18 pagesWind Load Calculations Upload 1arvnndNo ratings yet

- Load Calculation For Air Compressor BuildingDocument27 pagesLoad Calculation For Air Compressor BuildingLandon Mitchell100% (1)

- Base of Generator PDFDocument1 pageBase of Generator PDFHayman Ahmed100% (1)

- Isolated Footing Design: Forces DetailsDocument7 pagesIsolated Footing Design: Forces DetailsMukhlish AkhatarNo ratings yet

- Isolated Foundation Calculation (ACI 318M-95) : Input DataDocument7 pagesIsolated Foundation Calculation (ACI 318M-95) : Input DatadhawanaxitNo ratings yet

- All Type of Footing DesignDocument23 pagesAll Type of Footing DesignAyazAkram100% (6)

- Design Calc Sheet - Septic Tank Rev1 15-03-09 - 200Document12 pagesDesign Calc Sheet - Septic Tank Rev1 15-03-09 - 200Bok MortegaNo ratings yet

- Trafo Found DesignDocument6 pagesTrafo Found DesignIrshad Khan100% (1)

- Wind Coefficient Calculation1Document29 pagesWind Coefficient Calculation1Hemant Sonawadekar0% (1)

- Design of Water Tank-311207Document32 pagesDesign of Water Tank-311207Uttam Kumar GhoshNo ratings yet

- Box+Culvert+by+R S VasneyDocument10 pagesBox+Culvert+by+R S VasneyfwrconsultantNo ratings yet

- Wind Load CalculationDocument98 pagesWind Load CalculationAnonymous HJ7hmihhNo ratings yet

- OHSRDocument48 pagesOHSRsachingadage100% (2)

- Design (With CB+FP)Document36 pagesDesign (With CB+FP)Subir KundaNo ratings yet

- RCC & Steel ChimneyDocument84 pagesRCC & Steel Chimneyhemantkle2u100% (1)

- Design of Rectangular Water TankDocument268 pagesDesign of Rectangular Water Tankchetanmale89% (28)

- New Doc 30Document5 pagesNew Doc 30Irshad KhanNo ratings yet

- Drawings of GIS, SEC-4, GurgaonDocument62 pagesDrawings of GIS, SEC-4, GurgaonIrshad Khan100% (1)

- 1367 6 PDFDocument20 pages1367 6 PDFIrshad Khan100% (1)

- The Code Corner No. 15Document3 pagesThe Code Corner No. 15Irshad KhanNo ratings yet

- Baseplate t3p 18 07Document3 pagesBaseplate t3p 18 07Irshad KhanNo ratings yet

- Are 12 PDFDocument105 pagesAre 12 PDFIrshad KhanNo ratings yet

- Retaining Wall ProposalDocument2 pagesRetaining Wall ProposalIrshad KhanNo ratings yet

- Steel ConnectionDocument18 pagesSteel ConnectionIrshad KhanNo ratings yet

- Code of Conduct For Intemediaries Including Consultants / Agents / Business Partners / VendorsDocument2 pagesCode of Conduct For Intemediaries Including Consultants / Agents / Business Partners / VendorsIrshad KhanNo ratings yet

- Name of Vendor: Contact Person TEL: Alif Engineers and PlannersDocument1 pageName of Vendor: Contact Person TEL: Alif Engineers and PlannersIrshad KhanNo ratings yet

- M.Raje Structural Consultants Pvt. LTDDocument2 pagesM.Raje Structural Consultants Pvt. LTDIrshad KhanNo ratings yet

- COVER Burnt Oil PitDocument1 pageCOVER Burnt Oil PitIrshad KhanNo ratings yet

- Is 13920 1993Document24 pagesIs 13920 1993structuralengineersNo ratings yet

- D 800 Cover 40 Bar Dia FCK 50 Fy 500 SDocument2 pagesD 800 Cover 40 Bar Dia FCK 50 Fy 500 SIrshad KhanNo ratings yet

- Is 2502 1963Document31 pagesIs 2502 1963Lokesh SharmaNo ratings yet

- Wasim CVDocument2 pagesWasim CVIrshad KhanNo ratings yet

- Intumescent PaintDocument2 pagesIntumescent PaintIrshad Khan100% (1)

- Revised Foundation For 315 Mva Transformer. 28-10-09 - ModelDocument1 pageRevised Foundation For 315 Mva Transformer. 28-10-09 - ModelIrshad KhanNo ratings yet

- PortalDocument1 pagePortalIrshad KhanNo ratings yet

- PortalDocument1 pagePortalIrshad KhanNo ratings yet

- Civil Specification Vol-IIIDocument266 pagesCivil Specification Vol-IIIIrshad KhanNo ratings yet

- Car LiftDocument4 pagesCar LiftIrshad KhanNo ratings yet

- Axially Loaded ColumnsDocument33 pagesAxially Loaded Columnsyunuswsa0% (2)

- Typ. Detail of Plinth ProtectionDocument1 pageTyp. Detail of Plinth ProtectionIrshad KhanNo ratings yet

- Typ. Detail of Plinth ProtectionDocument1 pageTyp. Detail of Plinth ProtectionIrshad KhanNo ratings yet

- Alif Engineers and Planners ProfileDocument5 pagesAlif Engineers and Planners ProfileIrshad KhanNo ratings yet

- Bot 0001Document1 pageBot 0001Irshad KhanNo ratings yet

- Dimention of TraffoDocument1 pageDimention of TraffoIrshad KhanNo ratings yet

- Mixdesign M25Document9 pagesMixdesign M25Irshad KhanNo ratings yet

- Base Plate For Thickness CalculationsDocument7 pagesBase Plate For Thickness CalculationsyunuswsaNo ratings yet

- Lesson Plan Thermo - NewDocument4 pagesLesson Plan Thermo - Newविशाल पुडासैनीNo ratings yet

- Pile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesDocument4 pagesPile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesRuemu Godwin InikoriNo ratings yet

- Chapter 3Document49 pagesChapter 3Mohnish Wadhwa0% (1)

- Permeability AssignmentDocument2 pagesPermeability AssignmentJejomar MotolNo ratings yet

- Pertemuan Kedua Dan Ketiga AKMDocument45 pagesPertemuan Kedua Dan Ketiga AKMJohan NicholasNo ratings yet

- Structural MembersDocument33 pagesStructural MembersALZHAMMER MANUPACNo ratings yet

- Computational Geomechanics: 2 International Symposium On 27 April - 29 April 2011, Cavtat-Dubrovnik, CroatiaDocument8 pagesComputational Geomechanics: 2 International Symposium On 27 April - 29 April 2011, Cavtat-Dubrovnik, CroatiaAnonymous THPwEcLPNo ratings yet

- Revised Summative Test Based On TOS Science 3 2021Document6 pagesRevised Summative Test Based On TOS Science 3 2021Henry Kahal Orio Jr.100% (1)

- User Guide To Nzs 4230:2004Document83 pagesUser Guide To Nzs 4230:2004Siva KumarNo ratings yet

- Intake DesignDocument1 pageIntake Designpushkar078No ratings yet

- Dissertation - Leong Dong Guo - 12631 - Ce PDFDocument103 pagesDissertation - Leong Dong Guo - 12631 - Ce PDFkmskskq100% (1)

- SimCentral Simulation Platform Thermodynamics Reference GuideDocument113 pagesSimCentral Simulation Platform Thermodynamics Reference GuideBelmederNo ratings yet

- Nbs Building Science 138Document180 pagesNbs Building Science 138Deviprasad B SNo ratings yet

- Von Mises Stress 1Document5 pagesVon Mises Stress 1alphadingNo ratings yet

- PT 2023 Past QuestionDocument7 pagesPT 2023 Past QuestionTSOG MHNo ratings yet

- Chapter6 Development LengthDocument13 pagesChapter6 Development LengthYo Fangirls100% (1)

- Sayers OCRDocument164 pagesSayers OCRWellington Paro Tuito50% (2)

- Challenger 874-1074-1274 Rogator Liquid System Parts Manual (PDF, Eng, 40 MB)Document908 pagesChallenger 874-1074-1274 Rogator Liquid System Parts Manual (PDF, Eng, 40 MB)abdul KadirNo ratings yet

- Chap9 NPT Grand Canonical Ensemble v04Document12 pagesChap9 NPT Grand Canonical Ensemble v04Paramita HaldarNo ratings yet

- Evaporator: Department of Chemical EngineeringDocument16 pagesEvaporator: Department of Chemical EngineeringspidyNo ratings yet

- Tests of Reinforced Concrete Continuous Deep Beams: Aci Structural Journal Technical PaperDocument9 pagesTests of Reinforced Concrete Continuous Deep Beams: Aci Structural Journal Technical PaperpicottNo ratings yet

- Manual de Propietario PDF Valve PumpDocument1 pageManual de Propietario PDF Valve PumpJulio Enrique AravenaNo ratings yet

- Reinforced Concrete I Midterm Exam: C20 - S420 D 4cmDocument1 pageReinforced Concrete I Midterm Exam: C20 - S420 D 4cmAhmad ThaherNo ratings yet

- Design of - ESR (200KL)Document33 pagesDesign of - ESR (200KL)sanju middya100% (1)

- Demand of Pharmaceutical Facility Functionality - Validation and Qualification of HVAC SystemDocument17 pagesDemand of Pharmaceutical Facility Functionality - Validation and Qualification of HVAC Systemraju1559405No ratings yet

- Reviewer 1Document81 pagesReviewer 1jerickNo ratings yet

- Autonext Study Material 2 (Cooling System)Document9 pagesAutonext Study Material 2 (Cooling System)SouravNo ratings yet

- Modelling of Airflow in Wood Kilns: UBC Mechanical Engineering CFD Modelling Process Simulations LTDDocument75 pagesModelling of Airflow in Wood Kilns: UBC Mechanical Engineering CFD Modelling Process Simulations LTDMô Dion100% (1)

- Duct PipeDocument8 pagesDuct PipeVermer FabregasNo ratings yet

- The Pressure Loss Coefficient of A Gauze in Compressible FlowDocument2 pagesThe Pressure Loss Coefficient of A Gauze in Compressible FlowJie China100% (1)