Professional Documents

Culture Documents

Adhesion Testing Methods - AGA

Uploaded by

pbp2956Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adhesion Testing Methods - AGA

Uploaded by

pbp2956Copyright:

Available Formats

Adhesion Testing Methods

Additional Tests

Adherence Test

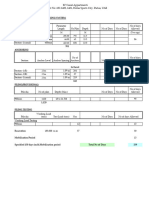

Figure 52: Stout Knife Test

Testing of the zinc coating adherence to the steel is achieved using a stout knife. The steps used in this test are listed below and a photo of the test being performed can be seen in Figure 52. The coating shall be deemed not adherent if it flakes off and exposes the base metal in advance of the knifepoint. The test is not an attempt to pare or whittle the zinc coating. If the coating is adherent the knife should put a slight mark in the zinc metal surface, but should not cause any delamination of the coating layers. Adhesion Test with a Stout Knife

Push down point of stout knife Coating must not flake off exposing the base metal Do not perform at edges or corners of the product No paring or whittling with knife is acceptable

Bending Test

The hot-dip galvanized coating on a steel bar must withstand bending without flaking or peeling when the bending test is preformed in accordance with the specifications in ASTM A 143. There are various tests used to assess the ductility of steel when subjected to bending. One test may include the determination of the minimum radius or diameter required to make a satisfactory bend. Another test may include the number of repeated bends that the material can withstand without failure when it is bent through a given angle and over a definite radius. Rebar is commonly bent prior to the hot-dip galvanizing process. Steel reinforcing bars bent cold prior to hotdip galvanizing should be fabricated to a bend diameter equal to or greater than the specified value in ASTM A 767/A 767M. However, steel reinforcing bars can be bent to diameters tighter than the specified values if they are stress relieved at a temperature of 900 to 1050 F (480 to 560 C) for one hour per inch (25mm) of diameter.

Chromating Test

The specification to determine the presence of chromate on zinc surfaces is ASTM B 201. This test involves placing drops of a lead acetate solution on the surface of the product, waiting 5 seconds, and then blotting it gently. If this solution creates a dark deposit or black stain, then there is unpassivated zinc present. A clear result indicates the presence of a chromate passivation coating.

Embrittlement Test

When there is suspicion of potential embrittlement of a product, it may be necessary to test a small group of the products to measure the ductility. These tests are usually destructive to the zinc coating and possibly to the product as well. Products suspected of embrittlement shall be tested according to the specification ASTM A 143. Depending on the service conditions the product will be exposed to, one of three embrittlement tests may need to be performed. These embrittlement tests include the similar bend radius test, sharp blow test, and steel angle test. The embrittlement test uses a known force to provide a stress that should be lower than the yield stress of the part. If there is a fracture or permanent damage created during the testing process, the parts must be rejected.

You might also like

- HDG Additional TestsDocument3 pagesHDG Additional TestsMehman NasibovNo ratings yet

- Additional Tests: Adherence TestDocument3 pagesAdditional Tests: Adherence TestMehman NasibovNo ratings yet

- Inspection of The Hot Dipped Galvanizing ProcessDocument5 pagesInspection of The Hot Dipped Galvanizing ProcessIrinaNo ratings yet

- ASTM A 153 Zinc Coating On Iron and Steel HardwareDocument2 pagesASTM A 153 Zinc Coating On Iron and Steel Hardwarevelmurug_balaNo ratings yet

- Bend Testing: Job Knowledge 73Document3 pagesBend Testing: Job Knowledge 73kevin herryNo ratings yet

- Galvanizing Procedure (5400)Document5 pagesGalvanizing Procedure (5400)Syed Muzammil100% (2)

- Bend Test SummaryDocument4 pagesBend Test SummaryManish MNo ratings yet

- 2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsDocument9 pages2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsKapa SandeepNo ratings yet

- Bend TestDocument2 pagesBend TestFsNo ratings yet

- C 1002 - 00 QzewmditmdaDocument4 pagesC 1002 - 00 QzewmditmdaHumberto GutierrezNo ratings yet

- It0704 29Document3 pagesIt0704 29Anonymous avGU1iNo ratings yet

- Inspection of HDG.Document71 pagesInspection of HDG.Mritunjay100% (1)

- Astm F680Document3 pagesAstm F680urielgamizNo ratings yet

- 1 Specification For Hot Dip Zinc Galvanization of Steel (Rolled & Fabricated) ScopeDocument8 pages1 Specification For Hot Dip Zinc Galvanization of Steel (Rolled & Fabricated) ScopeRajneesh KatochNo ratings yet

- Providing High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForDocument8 pagesProviding High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForIsraelNo ratings yet

- Hot Dip GalvanizingDocument110 pagesHot Dip GalvanizingCandy KendeeNo ratings yet

- Adhesion TestDocument3 pagesAdhesion TestAhmed AllamNo ratings yet

- 03 Specification PDFDocument8 pages03 Specification PDFSihamaSihamNo ratings yet

- A143-Safeguarding Against EmbrittlementDocument3 pagesA143-Safeguarding Against EmbrittlementpokeyballNo ratings yet

- Mechanical Testing: Notched Bar or Impact Testing. Part IIDocument4 pagesMechanical Testing: Notched Bar or Impact Testing. Part IIMehmet Soysal100% (1)

- Zinc-Coated Steel Doors and Frames: (Galvanized/Galvannealed)Document4 pagesZinc-Coated Steel Doors and Frames: (Galvanized/Galvannealed)abualamalNo ratings yet

- Galling and ControlDocument2 pagesGalling and ControlpradeepysNo ratings yet

- Corrosion Testing TCR Engineering IndiaDocument9 pagesCorrosion Testing TCR Engineering Indiaelangopi89No ratings yet

- Et Ohe 13Document15 pagesEt Ohe 13hardeepsingh_0850% (2)

- ASTM Specifications - American Galvanizers AssociationDocument9 pagesASTM Specifications - American Galvanizers Associationwinarnob100% (1)

- Highlight HDG Inspection CoursaaaaaaaaaaaaaaaaaDocument44 pagesHighlight HDG Inspection CoursaaaaaaaaaaaaaaaaaAyman Hamed MalahNo ratings yet

- Specification For Hot Dip GalvanizingDocument10 pagesSpecification For Hot Dip GalvanizingKyaw Kyaw Aung100% (1)

- Astm A 384Document2 pagesAstm A 384Shandy HaykalzNo ratings yet

- Stud WeldingDocument7 pagesStud WeldingHooke10No ratings yet

- Adhesion Test - Applicable For Coatings Formed During Hot Dip GalvanizingDocument2 pagesAdhesion Test - Applicable For Coatings Formed During Hot Dip GalvanizingRaviprakash ChauhanNo ratings yet

- Mechanical Testing - Notched Bar or Impact TestingDocument7 pagesMechanical Testing - Notched Bar or Impact TestingFsNo ratings yet

- Ma KemDocument20 pagesMa KemVan Hien LeNo ratings yet

- Testing Material DiscussionDocument3 pagesTesting Material DiscussionZYRA DEE JACONo ratings yet

- Twi Impact TestingDocument17 pagesTwi Impact TestingchungndtNo ratings yet

- SEP - 1390e 1996 07Document3 pagesSEP - 1390e 1996 07Vijayakumar SamyNo ratings yet

- Bolting Galvanized SteelDocument6 pagesBolting Galvanized SteelAli VarmazyarNo ratings yet

- Corrosion TestsDocument3 pagesCorrosion TestsbalakaleesNo ratings yet

- Hardness Test ME 272 Experiment #4: ScenarioDocument4 pagesHardness Test ME 272 Experiment #4: ScenarioCekodok CelopNo ratings yet

- Lecture 2 - Test For SteelDocument55 pagesLecture 2 - Test For SteelKier Lorenz FernandezNo ratings yet

- Cast Duplex Stainless SteelsDocument36 pagesCast Duplex Stainless Steelsxevi00No ratings yet

- ASTM A123 Galv. DFT RequirementDocument8 pagesASTM A123 Galv. DFT Requirementshoaib1985No ratings yet

- HDG Fact Sheet 2017 V4Document6 pagesHDG Fact Sheet 2017 V4Ra'oufAli-zadehNo ratings yet

- A 879 - 00 - QTG3OQ - ISO 8015 Tolerancing StandardsDocument2 pagesA 879 - 00 - QTG3OQ - ISO 8015 Tolerancing Standardsjameswood20No ratings yet

- Bend Test For SteelDocument2 pagesBend Test For SteelSudhanNo ratings yet

- Astm A123 PDFDocument2 pagesAstm A123 PDFবিপ্লব পাল67% (6)

- Astm A123pdf CompressDocument2 pagesAstm A123pdf CompressYugandharNo ratings yet

- Astm A 924Document8 pagesAstm A 924djfreditoNo ratings yet

- Exercise 1.3Document3 pagesExercise 1.3JeffersonTalanNo ratings yet

- 7 Tests That You Need On The Steel StructureDocument6 pages7 Tests That You Need On The Steel StructureBBGNo ratings yet

- AISE No. 7 Specifications For Ladle HooksDocument7 pagesAISE No. 7 Specifications For Ladle HookscadyfemNo ratings yet

- L-05035 - GalvanizingDocument4 pagesL-05035 - GalvanizingNarasimha DvlNo ratings yet

- IS 14246-1995 Galvalume SheetDocument10 pagesIS 14246-1995 Galvalume SheetkumarchemNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalFrom EverandFarm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalRating: 4.5 out of 5 stars4.5/5 (3)

- Effect of C & Cr. On Brightness of Galvanizing SurfaceDocument1 pageEffect of C & Cr. On Brightness of Galvanizing Surfacepbp2956No ratings yet

- Tolerance For CHSDocument1 pageTolerance For CHSpbp2956No ratings yet

- Selecting Statistically Valid Sampling Plans: Dr. Wayne A. TaylorDocument15 pagesSelecting Statistically Valid Sampling Plans: Dr. Wayne A. Taylorpbp2956No ratings yet

- Satrangi Europe 11D 10MDocument6 pagesSatrangi Europe 11D 10Mpbp2956No ratings yet

- Adhesion Tape Specification 51596.Document1 pageAdhesion Tape Specification 51596.pbp2956No ratings yet

- Hydrogen in Petroleum Fractions: Standard Test Method ForDocument4 pagesHydrogen in Petroleum Fractions: Standard Test Method Forpbp2956No ratings yet

- Freezing Points of High-Purity Hydrocarbons: Standard Test Method ForDocument11 pagesFreezing Points of High-Purity Hydrocarbons: Standard Test Method Forpbp2956No ratings yet

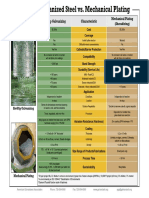

- Hot-Dip Galvanizing Vs Mechanical PlatingDocument2 pagesHot-Dip Galvanizing Vs Mechanical Platingpbp2956No ratings yet

- Inspection of HDG After FabricationDocument27 pagesInspection of HDG After Fabricationpbp2956No ratings yet

- GB 1591 Q420 Steel PropertiesDocument6 pagesGB 1591 Q420 Steel Propertiespbp2956No ratings yet

- Influence of Alloy Elements On Structure and Corrosion ResistanceDocument10 pagesInfluence of Alloy Elements On Structure and Corrosion Resistancepbp2956No ratings yet

- PresentingSixSigma NewDocument56 pagesPresentingSixSigma Newpbp2956No ratings yet

- Flux Skimming PDFDocument6 pagesFlux Skimming PDFpbp2956No ratings yet

- B897 - 03 - Zinc Jumbo BlockDocument4 pagesB897 - 03 - Zinc Jumbo Blockpbp2956No ratings yet

- ASTM 673 Charpy TestDocument2 pagesASTM 673 Charpy Testpbp2956No ratings yet

- Appearance Requirements Batch Galvanized Steel - AGA Dr. GalvaDocument1 pageAppearance Requirements Batch Galvanized Steel - AGA Dr. Galvapbp2956No ratings yet

- Alloy Additions To The Galvanizing Kettle and Their PurposesDocument1 pageAlloy Additions To The Galvanizing Kettle and Their Purposespbp2956No ratings yet

- Presenting SixSigma NewDocument56 pagesPresenting SixSigma Newpbp2956No ratings yet

- bfc34803 Assignment1 Slab Staircasedesign TNTCDocument7 pagesbfc34803 Assignment1 Slab Staircasedesign TNTCRazNo ratings yet

- HILTI Anchor FasteningDocument91 pagesHILTI Anchor FasteningkstayroskNo ratings yet

- Review of Documents On Seismic Strengthening of Existing BuildingsDocument12 pagesReview of Documents On Seismic Strengthening of Existing Buildingsm7j7a7No ratings yet

- Type 180 8000352-03 - REV-DDocument17 pagesType 180 8000352-03 - REV-DTuvia LeNo ratings yet

- 5span Contineous BeamDocument22 pages5span Contineous BeamBilal Ahmed Barbhuiya100% (1)

- Lecture15 - Design and Detailing of RC Shear Walls-Is13920Document16 pagesLecture15 - Design and Detailing of RC Shear Walls-Is13920Rahul SehgalNo ratings yet

- Report On Design Methods With BS-En-SABS For Water Retaining StructuresDocument93 pagesReport On Design Methods With BS-En-SABS For Water Retaining StructuresSanjeev BundhunNo ratings yet

- Specifications: Proposed Two-Storey Residential Building SpecificationDocument5 pagesSpecifications: Proposed Two-Storey Residential Building SpecificationKarl Belleza100% (1)

- RC Desktop Toolkit v2Document14 pagesRC Desktop Toolkit v2Be Seang SeNo ratings yet

- Anchor 2013 Full EnglishDocument62 pagesAnchor 2013 Full EnglishFhjkda LfljkdNo ratings yet

- ShearWallDesign Manual2016Document82 pagesShearWallDesign Manual2016Alfia BanoNo ratings yet

- Publication Hilti RebarDocument234 pagesPublication Hilti RebarRedwan HendiNo ratings yet

- Rebar Cutting List SampleDocument9 pagesRebar Cutting List SampleLarry Niño Lapeciros100% (6)

- Design of ColumnsDocument6 pagesDesign of ColumnsGlenn Enrico AmoloNo ratings yet

- BridgesDocument22 pagesBridgessammy_viorel21100% (2)

- Project Manual: Beverly Hills Civic CenterDocument50 pagesProject Manual: Beverly Hills Civic CenterfastreturnNo ratings yet

- Ci33 1112 Pernos de AnclajeDocument10 pagesCi33 1112 Pernos de AnclajeShadin Asari ArabaniNo ratings yet

- Conservation and Maintenance of Concrete Facades: Technical Possibilities and RestrictionsDocument31 pagesConservation and Maintenance of Concrete Facades: Technical Possibilities and Restrictionsriku_lindholmNo ratings yet

- Lopez - DFI 45th Conference - 2020Document10 pagesLopez - DFI 45th Conference - 2020Thomas GlasbyNo ratings yet

- Invoice 2% MetalDocument4 pagesInvoice 2% Metalnatan makuNo ratings yet

- BoQ Local Clinic Additional BuidlingsDocument26 pagesBoQ Local Clinic Additional BuidlingsswazsurvNo ratings yet

- STRUCT1Document689 pagesSTRUCT1kokueiNo ratings yet

- Production Rates HighwayDocument95 pagesProduction Rates HighwayKshamata DesaiNo ratings yet

- Price ListDocument33 pagesPrice ListAllen MendozaNo ratings yet

- Anchor Calculations For Roof Top TowerDocument46 pagesAnchor Calculations For Roof Top TowerRoseLockerNo ratings yet

- Beam ShoringDocument19 pagesBeam Shoringtaha abu el hanaNo ratings yet

- PRTIND-SESK-DCR-SS-0001 - Design CriteriaDocument16 pagesPRTIND-SESK-DCR-SS-0001 - Design CriteriaPhạm Quốc ViệtNo ratings yet

- Astm A767-09Document5 pagesAstm A767-09poulmackNo ratings yet

- GalvaBar 2pp FAQ 0Document2 pagesGalvaBar 2pp FAQ 0kumarNo ratings yet

- Evaluation of Reinforced Concrete Beam Behavior Using Finite Element Analysis by AbaqusDocument9 pagesEvaluation of Reinforced Concrete Beam Behavior Using Finite Element Analysis by AbaqusDanh NguyễnNo ratings yet