Professional Documents

Culture Documents

Buckling of A Simply Supported Rectangular Plate

Uploaded by

shimul2008Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buckling of A Simply Supported Rectangular Plate

Uploaded by

shimul2008Copyright:

Available Formats

Buckling of a simply supported Rectangular Plate:

The plate of the structure of a ship is divided into relatively small rectangular panel by means of beams or

longitudinal and girders or transverses. These panels have some constraint at their edges, which is

provided by the torsional rigidity of the stiffening members. Consider a section , the deck of a

transversely framed ship, when buckling of the deck occurs the plating takes up the configuration, the

beam twisting. The twisting of the beams provided an edge constraining moment which is a function of

the torsional properties of the rolled sections. Such sections are known to be very weak in torsion, so that

the constraint moment at the edges is likely to be small and consequently the degree of fixity of the edges

of the panel will be small.

A simply supported panel, length l and breadth b, the load being applied in the direction of the length. The

form of the deflection curve of the panel when buckling occurs can be assumed to be

sin sin

m x n y

w A

l b

t t

=

l

b

o

cr

o

cr

This means that the panel will buckle into m half waves in the length and n half wave sin the breadth.

The strain energy due to the bending of the plate is

2

2 2

2 2

0 0

2

l b

D w w

V dxdy

x y

| | c c

= +

|

c c

\ .

} }

2

4 2 2 2

2 2

2 2

0 0

sin sin sin sin

2

l b

DA m n m x n y m x n y

dxdy w A

l b l b l b

t t t t t | |

(

= + =

|

(

\ .

} }

2

4 2 2 2

2 2

8

DblA m n

l b

t | |

= +

|

\ .

If the critical stress is o

cr

then the load on a strip length l and width dy is (o

cr

x t xdy) and the work done

by this load in buckling is

2

0

1

2

l

cr

w

tdy dx

x

o

c | |

|

c

\ .

}

So the total work done is obtained by integrating for all such strips across the breadth of the plate.

Hence, Work done

2

0 0

1

2

b l

cr

w

t dxdy

x

o

c | |

=

|

c

\ .

} }

2 2 2

2 2

2

0 0

1

cos sin

2

b l

cr

A m m x n y

t dxdy

l l b

t t t

o =

} }

2 2 2

8

cr

m A b t

l

t o

=

Now equating the total work done with the strain energy, we get

2

2 2 2 4 2 2 2

2 2

8 8

cr

m A b t DblA m n

l l b

t o t | |

= +

|

\ .

2

2 2 2 2 2

2 2

8

cr

m A b t m n

l l b

t o | |

= +

|

\ .

2

2 2

2 cr

D b n l

m

b t l m b

t

o

| |

= +

|

\ .

The least value of buckling stress is required, and this it will be seen is associated with n = 1, which

means that the panel buckles into one half wave in the breadth, so that

2

2

2

1

cr

D b l

m

b t l m b

t

o

| |

= +

|

\ .

It remains now to find the value of m which will make the above equation a minimum. This can be done

by differentiating with respect to m and equating to zero.

2

2 2

1 1

2 0

cr

d D b l b l

m

dm b t l m b l m b

o t | || |

= + =

| |

\ .\ .

For maximum and minimum. Multiplying out the brackets

2 2

2 3 2

1 1 1

0

b l

m

l m m m b

+ =

4

4

4

,

l l

m m

b b

= =

The wave length is l/m so that this is equal to b. A long panel of plating therefore buckles into a number

of square panels. This will only be true if l is an exact multiple of b and, if this is not so, the panel will

buckle into the nearest whole number of half waves which will make the critical stress a minimum.

Another approach to the problem is to assign various values to m in equation below

2

2

2

1

cr

D b l

m

b t l m b

t

o

| |

= +

|

\ .

2

1 b l

k m

l m b

| |

= +

|

\ .

and calculates the value of the quantity multiplying

(t

2

D/b

2

t). This may be conventionally called k. The

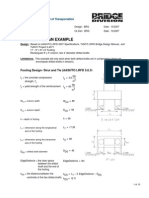

values of k have been worked and shown in table below.

m Vales of K for l/b

1 2 3 4 5 6 7 8

1 4.0 6.25 11.1 18.1 27.4

2 6.25 4.0 4.65 6.25 8.41 11.1

3 11.1 4.65 4.0 4.31 5.16 6.25 7.6 9.2

4 18.1 6.025 4.31 4.0 4.2 4.65 5.4 6.25

These results for k have been plotted in figure below as curves for constant values of m against the ratio

l/b.

1 2 3 4 5 6 7 8

0

5

10

15

20

k

l/b

m = 1

m = 2

m = 3

m = 4

Consider the curves for m = 1, these gives the least value of k at l/b = 1 but at some position between l/b

= 1 and l/b = 2 the curves intersects that for m = 2. At this position the plate would buckle indifferently

into one or two half waves. Similarly between l/b = 2 and 3, the curve for m = 2 intersect that for m =3 in

which case the plate buckles indifferently with two of three half waves and so on. All theses curves are

tangent to a line k = 4 and it will seen that when the length of the plate is an exact multiple of the breadth,

the value for k for minimum buckle stress is 4. Where the length of the plate is not exact multiple of

breadth , the values of k is a little greater than 4 abut as l/b increases the amount by which k exceeds in

this case diminishes.

As a general working rule, it can be assumed that k is 4 and the critical stress becomes

2

2

4

cr

D

b t

t

o =

Case Study:

(a) When the length (l) of the panel is less than the breadth (b), and here it will be noted that m must be

equal to unity

2

2

2 cr

D b l

b t l b

t

o

| |

= +

|

\ .

After re arrange

2

2 2

2 2

1

cr

D l

l t b

t

o

| |

= +

|

\ .

Now it is possible to examine the relative merits of stiffening a large sheet of plating in the longitudinal

direction or transvers direction.

Largest sheet of plating, length, L and breadth B is stiffened by

(i) Longitudinal, spaced b apart. The buckling of the plating between the stiffeners is then

2

2

4

cr

D

b t

t

o =

(ii) The stiffeners is turned round, so that there are now transverse stiffeners spaced b apart, it

will seen that the buckling strength of the plating between stiffeners is obtained from

By putting l = b and b = B

2

2 2

2 2

1

cr

D l

l t b

t

o

| |

= +

|

\ .

2

2 2

2 2

1

cr

D b

b t B

t

o

| |

= +

|

\ .

In ship structures the ratio b/B would be about 1/6, so that the term in the brackets is not greatly different

from unity, and from this it can be concluded that the buckling strength of the plating with longitudinal

stiffening is nearly four times as great when transvers stiffening is employed. This shows the great

advantages of longitudinal over transvers stiffening in ship structure and the trend in the modern ships is

to use the former type of stiffening in nearly all classes of ships. Apart from the intrinsic advantages of

using this type of stiffening to increase the buckling strength of the plating, it also has the advantages of

preventing the development of permanent set in the plating in welded ships where there is a greater

tendency to have initial unfairness. Classification Societies almost compel the structural designer to use

longitudinal stiffening in welded ships by imposing quite severe penalties on the scantlings of bottom

plating, for example, when transverse framing is employed.

Problem : Breadth of Panel = 15 Ft.

Stiffener Spacing = 30 inch

P late thickness = 0.6 inch

E =13500 Tons/inch^2

3 3

2 2

2 2

13500 0.6

267 / 13500 / , 0.3

12(1 ) 12(1 0.3 )

Et

D tons in in E tons in v

v

( = = = = =

(a) Longitudinal Stiffeners:

( )

2 2

2

2 2

4 4 267

19.5 /

30 0.6

cr

long

D

tons in

b t

t t

o

= = =

(b) Transverse Stiffeners:

( )

2 2

2 2 2 2

2 2 2 2

267 2.5

1 1 5.15

30 0.6 15

cr

transvers

D b

b t B

t t

o

| | | |

= + = + =

| |

\ . \ .

(c) Ratio of buckling Stress in two cases:

( )

( )

19.5

3.78 4.0

5.15

cr

long

cr

transvers

o

o

= = ~

Influence of longitudinal stiffeners on the buckling strength of

plating:

In order to develop the full buckling strength of a panel of plating between stiffeners, it is important that

the stiffeners themselves should remain rigid so as to provided support to the small panels. If a large sheet

of plating stiffened by longitudinal members is considered, there is the possibility that the sheet as whole

may buckle, and this possibility will now be examined. Consider a sheet of plating simply supported

round it edges, length l and breadth b, as shown in Fig below. If this sheet buckles, then the equation for

the whole surface can be written

sin sin

x y

w A

l b

t t

=

To some extent this assumption for the deflection of the stiffened panel is an approximation, since if a

section through the plating is considered the deflection curve would probably be more accurately

represented by the Figure below, because the influence of the stiffeners is to restraint the plating at the

attachment to the stiffeners.

The strain energy of the bending of the stiffened panel consists of that of the plating, plus in this case the

additional strain energy of the stiffeners. The rigidity of the stiffeners are represented by the moment of

inertia I may be difficult to define, but it will be assumed that it is possible to put a value to I which

should really include the influence of a certain breadth of plating to which the stiffeners is attached.

Assuming that I represents the increased moment of inertia provided by one stiffener, then

2

2

2

0

2

l

EI w

Stain energy of stiffener dx

x

| | c

=

|

c

\ .

}

2 4

2 2

4

0

sin sin

2

l

EI A x y

dx

l l b

t t t

=

}

4 2

2

3

sin

4

EIA y

l b

t t

=

The value of y in this expression should be that appropriate to the particular stiffener. If there are n evenly

spaced stiffeners, then the value of y for the p

th

stiffeners is y

p

= pb/(n+1), so that

4 2

2

3

sin

4 1

EIA p

Strain energy of stiffeners

l n

t t

=

+

To obtain the total strain energy this requires summing for all the stiffeners. Thus

4 2

2

3

1

sin

4 1

p n

p

EIA p

Strain energy of all stiffeners

l n

t t

=

=

=

+

It can be shown that

2

1

1

sin

1 2

p n

p

p n

n

t

=

=

+

=

+

4 2

3

( 1)

8

EIA n

Strain energy of stiffeners

l

t +

=

The strain energy of bending of plate is

2

4 2

2 2

1 1

8

DblA

Strain energy of bending of plate

l b

t | |

= +

|

\ .

The work done by the critical load on the plate will be given by the following equation with m = 1,

2 2 2

8

cr

m A b t

l

t o

=

but to this must be added the work done by the load on the stiffeners. If a is the additional area provided

by one stiffeners, then

2

0

2

l

cr

a w

work done on one stiffener dx

x

o c | |

=

|

c

\ .

}

2 2

2 2

2

0

cos sin

2

l

cr

a A x y

dx

l l b

o t t t

=

}

2 2

2

sin

4

cr

aA y

l b

t o t

=

2 2

2

1

sin

4 1

p n

cr

p

aA p

For all stiffeners work done

l n

t o t

=

=

=

+

2 2

( 1)

8

cr

aA n

l

t o +

=

Now equating total work done to the total strain energy

2

2 2 2 2 4 2 4 2

2 2 3

( 1) ( 1) 1 1 ( 1)

8 8 8 8

cr cr

btA n aA n DblA EIA n

l l l b l

t o t o t t + + + | |

+ = + +

|

\ .

From this it will be seen that

2

2 2

2 2 2

1 1 ( 1)

( 1)

cr

EI n

Dbl

l b l

bt a n

t

o

+ | |

+ +

` |

\ .

)

=

+ +

For economical design from a buckling point of view, the critical stress determined from above equation

should be equal to the critical stress for a panel of platting between two stiffeners. The breadth of small

panel will be b/(n+1) and the corresponding buckling stress will be

2 2

2

4 ( 1)

cr

D n

b t

t

o

+

=

And if the buckling stress for the two modes of failure is to be same,

2

2 2

2 2 2

2 2

2

1 1 ( 1)

4 ( 1)

( 1)

EI n

Dbl

l b l

D n

b t bt a n

t

t

+ | |

+ +

` |

\ .

+

)

=

+ +

Having decided upon the required buckling stress for a particular problem for a plate of given principal

dimensions and thickness, it is possible to determine the value of n. An equation involving two unknowns

a and I would be obtained from the above equation. Unless a relation existed between I and a it would not

be possible to solve for I completely. The best away to deal with this would be to assume a as some

percentage of cross sectional area bt of the plate.

Problem:

Consider a sheet of plating 15 ft long, 20ft breadth and 0.6 inch thick, with stiffener spacing 30 inch apart.

L = 15 ft

B = 20 ft

T = 0.6 inch

Stiffener spacing l = 30 inch

3 3

2 2

2 2

13500 0.6

267 / 13500 / , 0.3

12(1 ) 12(1 0.3 )

Et

D tons in in E tons in v

v

( = = = = =

If the stiffeners are spaced longitudinally, then the buckling stress of the plating between stiffeners is

2 2

2

2 2

4 4 267

19.5 /

30 0.6

cr

D

tons in

b t

t t

o

= = =

Let the area of longitudinal is 20% , the area of plating

2

( 1) 0.2 240 0.6 28.8

240

1 7

30

a n in

n

+ = =

= =

2

2 2

2 2 2

1 1 ( 1)

( 1)

cr

EI n

Dbl

l b l

bt a n

t

o

+ | |

+ +

` |

\ .

)

=

+ +

( )

2

2 2

2 2 2

1 1 13500 (7 1)

267 240 180

240 180 180

( 1) 240 0.6 1.2

cr

I

bt a n

t

o

+ | |

+ +

` |

\ .

)

=

+ + =

47.52 32.86

172.8

cr

I

o

+

=

Equating with the buckling strength of the stiffened panel to that for the panel between stiffeners, the

value of I

4

172.8 19.5 47.52

101.1

32.86

I in

= =

A section which would satisfy the requirement is a 7 in. x 3.5 in. x 0.44 in. toe welded angle bar and this

has area of 4.43 in

2

. The total area is (4.43 x 7) = 31.01 which is slightly higher than 28.8 in

2

.

You might also like

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- 13 - 8 Design of 2 Way Slab For PrintingDocument7 pages13 - 8 Design of 2 Way Slab For PrintingAlbert DimayugaNo ratings yet

- Preventive MaintenanceDocument46 pagesPreventive MaintenanceNandhakumarNo ratings yet

- TOS 5 Unit 2c T Beams and L BeamsDocument8 pagesTOS 5 Unit 2c T Beams and L BeamsKshitija100% (1)

- Two Way Slab BestDocument25 pagesTwo Way Slab BestErnest Christian Nanola100% (1)

- Plate Buckling NotesDocument0 pagesPlate Buckling NotesSharyn PolleyNo ratings yet

- The NPL Round Bilge Displacement Hull Series - Bailey 1976Document95 pagesThe NPL Round Bilge Displacement Hull Series - Bailey 1976Salma SherbazNo ratings yet

- Civil Engineering (Objective Questions With Basic Theory)Document115 pagesCivil Engineering (Objective Questions With Basic Theory)Aarushi Publications100% (1)

- AshbyJonesV1 SolutionsDocument43 pagesAshbyJonesV1 SolutionsSadiq Omar100% (1)

- Dredger Design PDFDocument97 pagesDredger Design PDFshimul200883% (6)

- Problems in Flow NetDocument8 pagesProblems in Flow NetanumnedNo ratings yet

- Bearing CapacityDocument20 pagesBearing CapacityJhoan ParedesNo ratings yet

- Fender System DesignDocument13 pagesFender System Designmohdsherwani3147100% (2)

- Fluid Flow in PipesDocument29 pagesFluid Flow in PipesitzGeekInside90% (20)

- Formulae: Two-Way Shear With Negligible Moment TransferDocument7 pagesFormulae: Two-Way Shear With Negligible Moment TransferKory EstesNo ratings yet

- Piping Design and Plant LayoutDocument44 pagesPiping Design and Plant LayoutVp Singh RawatNo ratings yet

- HydrofoilDocument17 pagesHydrofoilshimul2008100% (1)

- Fluid Properties LabDocument18 pagesFluid Properties LabsilasNo ratings yet

- Planing Vessels 1Document13 pagesPlaning Vessels 1Ahmet GelisliNo ratings yet

- Joist SlabDocument13 pagesJoist SlabAhmed Nabil80% (5)

- Shaft Footing ExampleDocument10 pagesShaft Footing Exampleอภิรักษ์ มานะกิจศิริสุทธิNo ratings yet

- Amecrc PDFDocument17 pagesAmecrc PDFshimul2008No ratings yet

- Jib Crane Example ProblemDocument7 pagesJib Crane Example Problemearthboy2u100% (1)

- Two Way SlabDocument19 pagesTwo Way SlabAllysa Joy MoralesNo ratings yet

- Solution Manual For Engineering Electromagnetics and Waves 2nd Edition by Inan PDFDocument6 pagesSolution Manual For Engineering Electromagnetics and Waves 2nd Edition by Inan PDFEcarroll410% (4)

- Column Design EC2Document41 pagesColumn Design EC2Azrai AzizNo ratings yet

- Introduction To Plate BucklinDocument12 pagesIntroduction To Plate BucklinAndré FerreiraNo ratings yet

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- CPED and MatSci PDFDocument3 pagesCPED and MatSci PDFonyxNo ratings yet

- Pamphlet 121 - Explosive Properties - Ed. 3 - 01-2009Document37 pagesPamphlet 121 - Explosive Properties - Ed. 3 - 01-2009sangoi87No ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- NORSOK Structural Steel Fabrication M-101Document67 pagesNORSOK Structural Steel Fabrication M-101Agnes Chong80% (5)

- SNAME 2008 Speed-Power PerformanceDocument7 pagesSNAME 2008 Speed-Power PerformancePriyo Susanto100% (1)

- TUG BoatDocument18 pagesTUG BoatJORGE100% (1)

- BEC701 - Fibre Optic Communication PDFDocument201 pagesBEC701 - Fibre Optic Communication PDFMax DurendNo ratings yet

- Indian Association of Physics Teachers National Standard Examinations 2008 - 2009 Solutions / AnswersDocument7 pagesIndian Association of Physics Teachers National Standard Examinations 2008 - 2009 Solutions / AnswersKshitij SharmaNo ratings yet

- Torsion Tension and Column (11-16)Document33 pagesTorsion Tension and Column (11-16)2011kumarNo ratings yet

- Chapter SevenDocument16 pagesChapter SevenhaymanotNo ratings yet

- MIT2 080JF13 Lecture11Document21 pagesMIT2 080JF13 Lecture11combatps1No ratings yet

- Method of Distribution Coefficients For Bridge Deck AnalysisDocument37 pagesMethod of Distribution Coefficients For Bridge Deck AnalysisChhandak BiswasNo ratings yet

- Torsion Tension and Column (11-16)Document33 pagesTorsion Tension and Column (11-16)Raphael OkudetumNo ratings yet

- ApplicationsDocument11 pagesApplicationsJuan SilvaNo ratings yet

- 06 PlateTheory 10 LargeDeflectionsDocument4 pages06 PlateTheory 10 LargeDeflectionsNoushad Bin JamalNo ratings yet

- RCD Chaptetr 5Document9 pagesRCD Chaptetr 5jereck loquisoNo ratings yet

- Chapter IIDocument5 pagesChapter IIMica BisaresNo ratings yet

- Trap Footing by Ben DavidDocument23 pagesTrap Footing by Ben DavidJeoffrey AlexanderNo ratings yet

- Bending Resistance of A Slender Plate Girder With Longitudinal StiffenerDocument5 pagesBending Resistance of A Slender Plate Girder With Longitudinal StiffenerGogyNo ratings yet

- Colonel. P Nallathambi. ME (Structural Engg), MBA, FIE, FIV, Structural ConsultantDocument7 pagesColonel. P Nallathambi. ME (Structural Engg), MBA, FIE, FIV, Structural ConsultantAhmad AnasNo ratings yet

- MATH Timber Design and Construction MethDocument6 pagesMATH Timber Design and Construction MethHades HadesNo ratings yet

- One-Way and Two-Way SlabsDocument5 pagesOne-Way and Two-Way SlabsMark Kim BadiangNo ratings yet

- CE 412 - Lec 1 Direct Design Method-ADocument118 pagesCE 412 - Lec 1 Direct Design Method-AAlina RafeeqNo ratings yet

- T / (1000 T+ (M 1) Ash) : Bearing Stresses at BendsDocument2 pagesT / (1000 T+ (M 1) Ash) : Bearing Stresses at BendsZakiQureshiNo ratings yet

- Design of SlabDocument33 pagesDesign of SlabFun JinNo ratings yet

- From My Book "Analytical & Computer Methods in Concrete Design" by Engr. Ben DavidDocument34 pagesFrom My Book "Analytical & Computer Methods in Concrete Design" by Engr. Ben DavidJanica Cassandra JesalvaNo ratings yet

- Moment Distribution and Moment Re-DistributionDocument44 pagesMoment Distribution and Moment Re-DistributionJeff Sun100% (1)

- FFF SolutionsDocument152 pagesFFF SolutionsMohammedAL-AthariNo ratings yet

- TorsionDocument22 pagesTorsionDheeraj YalavarthiNo ratings yet

- Moment of ResistanceDocument10 pagesMoment of ResistanceBabaYakeNo ratings yet

- Structures and Materials Section 7 Stress ConcentrationDocument21 pagesStructures and Materials Section 7 Stress ConcentrationAdi Adams AndaroffsaNo ratings yet

- ASS-RDM Cour04Document7 pagesASS-RDM Cour04Tep PuberNo ratings yet

- New Method For Deflection Control of Reinforced Concrete Beams and SlabsDocument18 pagesNew Method For Deflection Control of Reinforced Concrete Beams and SlabsPrince PolarNo ratings yet

- T Beam PDFDocument18 pagesT Beam PDFanupa nayakNo ratings yet

- Indian Association of Physics TeachersDocument12 pagesIndian Association of Physics Teachersskgupta45gwlNo ratings yet

- Fluid Mechanics II: B.S. Mechanical Engineering 4 SemesterDocument80 pagesFluid Mechanics II: B.S. Mechanical Engineering 4 Semesternaeema_58No ratings yet

- Cive1400 200203Document7 pagesCive1400 200203naefmubarakNo ratings yet

- M.SC RC 8 EFMDocument42 pagesM.SC RC 8 EFMObsi Naan JedhaniNo ratings yet

- Electron Beam-Specimen Interactions and Simulation Methods in MicroscopyFrom EverandElectron Beam-Specimen Interactions and Simulation Methods in MicroscopyNo ratings yet

- Grid Generation - Nakamura PDFDocument60 pagesGrid Generation - Nakamura PDFshimul2008No ratings yet

- Planing Analysis Report-V Up To35ktDocument6 pagesPlaning Analysis Report-V Up To35ktshimul2008No ratings yet

- Flow Characterstics of A Transom Stern Ship PDFDocument57 pagesFlow Characterstics of A Transom Stern Ship PDFshimul2008100% (1)

- Update On Van Oortmerssen's Resistance PredictionDocument14 pagesUpdate On Van Oortmerssen's Resistance Predictionshimul2008100% (1)

- Application of Computational Fluid Dynamics To Research Vessel DesignDocument4 pagesApplication of Computational Fluid Dynamics To Research Vessel Designshimul2008No ratings yet

- A Prototype Tool For Multidisciplinary Design Optimization of ShipsDocument8 pagesA Prototype Tool For Multidisciplinary Design Optimization of Shipsshimul2008No ratings yet

- Idemitsu - Mechanic Oil SeriesDocument2 pagesIdemitsu - Mechanic Oil SeriesarieprachmanNo ratings yet

- 4 Forced VibrationDocument108 pages4 Forced Vibrationsolomonrajar100% (2)

- Gas-Vapor Mixtures and Air-Conditioning: Çengel BolesDocument37 pagesGas-Vapor Mixtures and Air-Conditioning: Çengel Boleskebaman1986No ratings yet

- Manual Optica PASCODocument75 pagesManual Optica PASCODennis M RomeroNo ratings yet

- A Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystDocument17 pagesA Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystFrank LordNo ratings yet

- MECHANICAL CONCEPTS TestDocument19 pagesMECHANICAL CONCEPTS TestBob DehnkeNo ratings yet

- Kinetics of MethanationDocument12 pagesKinetics of MethanationGabriela Campos DávilaNo ratings yet

- Dose Reduction Techniques1Document4 pagesDose Reduction Techniques1eltonNo ratings yet

- 1999 Andreozzi - Advanced Oxidation Processes AOP For Water Purification and RecoveryDocument9 pages1999 Andreozzi - Advanced Oxidation Processes AOP For Water Purification and RecoveryHerick Bulhões100% (1)

- PU523 TDS - TremcoDocument2 pagesPU523 TDS - TremcoZerina MoralesNo ratings yet

- Header&pipe Sizes - 00361Document9 pagesHeader&pipe Sizes - 00361JKKNo ratings yet

- TD-SILENT Series: In-Line Mixed Flow Duct Fans Ultra-QuietDocument13 pagesTD-SILENT Series: In-Line Mixed Flow Duct Fans Ultra-QuietJustin ReyesNo ratings yet

- Product Knowledge FRAP SANITARYDocument20 pagesProduct Knowledge FRAP SANITARYFaisal AlepuNo ratings yet

- PCS0316H tcm29-2720Document39 pagesPCS0316H tcm29-2720syailendra dyanNo ratings yet

- Observing Microorganisms Through A MicroscopeSV PDFDocument3 pagesObserving Microorganisms Through A MicroscopeSV PDFFelipe Andrés JorqueraNo ratings yet

- CHEMISTRY - (13th) (POI) Paper-1Document8 pagesCHEMISTRY - (13th) (POI) Paper-1Raju SinghNo ratings yet

- Adge CompiledDocument18 pagesAdge CompiledNovelyn LumboyNo ratings yet

- Me Trology 8Document25 pagesMe Trology 8HARIMETLYNo ratings yet

- Publ 5429Document2 pagesPubl 5429MahmoudNo ratings yet

- Beam 189Document1 pageBeam 189Vinay RaiNo ratings yet

- Solution DPP Nitesh Devnani.Document19 pagesSolution DPP Nitesh Devnani.YUKTESH YuBoNo ratings yet