Professional Documents

Culture Documents

CIP 21 - Loss of Air Content in Pumped Concrete

Uploaded by

Namburu Somanadh0 ratings0% found this document useful (0 votes)

29 views0 pagesLong vertical sections of concrete pump booms can cause significant loss of entrained air in pumped concrete due to the weight of the concrete causing slugs to slide down the pipe. As the concrete hits elbows or horizontal surfaces, the air bubbles in the slug expand greatly and then collapse, reducing the air content. Maintaining continuous flow and avoiding steep downward sections can help minimize air loss. Additional precautions like inserting loops in the hose or using a slide gate at the discharge can further reduce air loss from pumping.

Original Description:

Air content in concrete

Original Title

21p Air Content

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLong vertical sections of concrete pump booms can cause significant loss of entrained air in pumped concrete due to the weight of the concrete causing slugs to slide down the pipe. As the concrete hits elbows or horizontal surfaces, the air bubbles in the slug expand greatly and then collapse, reducing the air content. Maintaining continuous flow and avoiding steep downward sections can help minimize air loss. Additional precautions like inserting loops in the hose or using a slide gate at the discharge can further reduce air loss from pumping.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views0 pagesCIP 21 - Loss of Air Content in Pumped Concrete

Uploaded by

Namburu SomanadhLong vertical sections of concrete pump booms can cause significant loss of entrained air in pumped concrete due to the weight of the concrete causing slugs to slide down the pipe. As the concrete hits elbows or horizontal surfaces, the air bubbles in the slug expand greatly and then collapse, reducing the air content. Maintaining continuous flow and avoiding steep downward sections can help minimize air loss. Additional precautions like inserting loops in the hose or using a slide gate at the discharge can further reduce air loss from pumping.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

CIP 21 - Loss of Air Content in Pumped Concrete

WHAT is Air Loss in Pumping?

Increasingly, specifiers are requiring concrete to be

tested for air content at the discharge end of concrete

pumps at the point of placement in the concrete struc-

ture. In some cases it is observed that air contents are

much lower than that in samples tested at discharge

from the truck chute. It is normal to find a loss of about

0.5 to 1.0 percent air as concrete is conveyed through

a pump. However, with long boom pumps have the

boom in an orientation with a long, near vertical down-

ward section of pipe, the air content at discharge may

be less than half of that of the concrete going into the

pump hopper. When the boom is upward or horizontal,

or if there is a 12-ft (3.6-m) section of rubber hose

placed horizontally at the discharge end, there gener-

ally is no significant loss of air. Certainly, air loss through

a pump doesnt occur every time. However, it does

occur often enough to be considered seriously until

better solutions are developed.

There are several mechanisms involved, but air loss

will occur if the weight of concrete in a vertical down-

ward section of pipe is sufficient to overcome frictional

resistance to allow a slug of concrete to slide down the

pipe. As the slug of concrete slides down the pipe, it

develops a vacuum on the upper end that greatly ex-

pands the size of the air bubbles; and when the con-

crete hits an elbow in the boom or a horizontal surface,

the bubbles collapse. The effect of this impact can be

demonstrated by dropping concrete 15 or 20 ft (4.5 to

6 m). The loss of air can be further exacerbated due to

the transition from a high pressure in the pump to a

near vacuum condition in the pump line.

Most field experience suggests that air loss is greatest

with high cement content, flowable concrete mixtures

which slide down easier; however, air loss has also

been experienced in mixtures with a moderate cement

factor at about 500 lb/yd

3

(300 kg/m

3

) and moderate

To minimize the loss of air of concrete through a pump

procedures should attempt to keep concrete from sliding

down the line under its own weight. Ensure that there

si a continuous stream of concrete within the pump

and inside the pumpline. Where possible, avoid vertical

or steep downward boom sections. Be cautious with

high slump, and particularly with high cementitious

content mixtures. Steady, moderately rapid pumping

may help somewhat to minimize air loss, but will not

solve most problems.

HOWto Prevent Air Loss?

slump. Loss of air content in pumped concrete will not

reduce freeze thaw durability of concrete as long as

the air void system is not compromised.

The air loss due to pumping can be determined by

measuring the air content of samples discharged from

the ready mixed concrete truck and at discharge from

the pump. Testing concrete as discharged from the

pump alongside the pump will require the most critical

boom configuration that will cause the highest loss of

air content. If concrete at a higher air content, to com-

pensate for this loss, is placed at a less critical, more

horizontal boom configuration, the concrete placed in

the structure will be at a high air content and lower

strength.

WHY is Air Lost?

Figure 1: A vertical pump boom configuration can

result in loss of entrained air in concrete

1992, 2005

PRECAUTIONS

Conduct a pre-pour conference in accordance with the

agenda outlined in CIP 32 with the contractor, pump

operator, and ready mixed concrete supplier present.

Discuss the necessity for care in pumping air entrained

concrete, and list the precautions to take when pumping

air-entrained concrete. Maintain communication

between all parties during the placement process.

a) Before the pour, plan alternative pump locations and

decide what will be done if air loss occurs. Be

prepared to test for air content frequently.

b) Sampling from the end of a pump line can be very

difficult and potentially hazardous. Wear proper

personal protective equipment. Never sample the

initial concrete through the pump line. It is

recommended that sampling be done from the

concrete placed in the structure as opposed to the

end of a pump line.

c) Sample the first load on the job after pumping 3 or 4

cubic yards (2 to 3 m

3

). Temper it to the maximum

permissible slump. Swing the boom over near the

pump to get the maximum length of vertical

downward pipe and drop the sample in a wheel

barrow. If air is lost, take precautions and sample to

measure air content at the point of placement.

d) If air loss occurs, do not try to solve the problem by

increasing the air content delivered to the pump be-

yond the upper specification limit. High air content

concrete with low strength could, or almost surely

will, be placed in the structure if boom angles are

reduced or somewhat lower slump concrete is

pumped.

e) Research has indicated that when the loss of air

content is not too high (less than about 3%), the air

void system in the concrete may still be adequate

for freeze-thaw resistance of concrete. This is be-

cause most of the air lost is the larger air bubbles

that do not significantly affect the durability of con-

crete.

a) Try inserting a loop in the pipeline just before the

rubber hose. (Do not do this unless pipe clamps are

designed to comply with all safety requirements).

This method helps, but wont be a perfect solution.

In some cases it may cause an increase in the air

content.

b) Use a slide gate at the end of the rubber hose to

restrict discharge and provide resistance.

c) Use of a 6-ft. (2-m) diameter loop in the rubber

hose with an extra section of rubber hose is reported

to be a better solution than (a) or (b).

d) Lay 10 or 20 ft. (3 to 6 m) of hose horizontally on

deck pours. This doesnt work in columns or walls

and requires additional labor to manage the extra

hose.

e) Reduce the rubber hose size from 5 to 4 in. (125 to

100 mm). A transition pipe of length 4 feet (1.2 m)

or longer should be used to avoid blockages.

Figure 2: Loop in pump boom

References

1. Yingling, James; G.M. Mullings; and R.D. Gaynor, Loss of

Air Content in Pumped Concrete, Concrete International,

Volume 14, Number 10, October 1992, pp. 57-61.

2. ACI 304.2R, Placing Concrete by Pumping Methods, Ameri-

can Concrete Institute, Farmington Hills, MI.

3. Hoppe, Julian J., Air Loss in Free-Falling Concrete, Que-

ries on Concrete, Concrete International, June 1992, p. 79.

4. Gorsha, Russel P., Air Loss in Free-Falling Concrete,

Queries on Concrete, Concrete International, August 1992, p.

71.

5. Effects of Pumping Air Entrained Concrete, Washington Ag-

gregates and Concrete Association, March 20, 1991, 12 pp.

6. Dyer, R.M., An Investigation of Concrete Pumping Pressure

and the Effects on the Air Void System of Concrete, Masters

Thesis, Department of Civil Engineering, University of Wash-

ington, Seattle, Washington, 1991.

7. Hover, K.C., Phares, R.J., Impact of Concrete Placing

Method on Air Content, Air-Void System Parameters, and

Freeze-Thaw Durability, Transportation Research Record

1532, Transportation Research Board, Washington, DC.

You might also like

- Air Entrainment and ConcreteDocument6 pagesAir Entrainment and Concretemanish_shashikantNo ratings yet

- Factors Which May Influence Air ContentDocument4 pagesFactors Which May Influence Air ContentAnonymous ouZFaSBRNo ratings yet

- When To Challenge Petrographic Reports - tcm45-347346Document4 pagesWhen To Challenge Petrographic Reports - tcm45-347346Dan TranNo ratings yet

- Case Studies in Construction Materials: S. Talukdar, R. HeereDocument6 pagesCase Studies in Construction Materials: S. Talukdar, R. HeereAmin ZuraiqiNo ratings yet

- Air Entrained ConcreteDocument3 pagesAir Entrained Concrete7vortex9No ratings yet

- Concrete Slump TestDocument5 pagesConcrete Slump TestcabbieNo ratings yet

- ACPA City Street Pavement DesignDocument8 pagesACPA City Street Pavement DesignFelipe Fernández100% (1)

- CIP29-Vapor Retarders Under Slabs On GradeDocument2 pagesCIP29-Vapor Retarders Under Slabs On Grade7774R105No ratings yet

- Understanding The Pumpability of ConcreteDocument14 pagesUnderstanding The Pumpability of Concretecesarale100% (1)

- Chute Spillway Aerators - Mcphee Dam Model/Prototype ComparisonDocument10 pagesChute Spillway Aerators - Mcphee Dam Model/Prototype ComparisonDavi HernandezNo ratings yet

- Measurement of Air Content in Concrete by Pressure Air MethodDocument2 pagesMeasurement of Air Content in Concrete by Pressure Air Methodvenkateswara rao pothinaNo ratings yet

- Best Practices For Concrete Sidewalk Construction: by Balvant RajaniDocument6 pagesBest Practices For Concrete Sidewalk Construction: by Balvant RajaniTherese AraymondNo ratings yet

- Control of Air Content in Concrete: Portland Cement AssociationDocument8 pagesControl of Air Content in Concrete: Portland Cement AssociationBhupesh MulikNo ratings yet

- Mix Design and Pumped ConcreteDocument13 pagesMix Design and Pumped ConcreteLimbu Niwa Lawahang100% (1)

- Air and Gas Drilling NewDocument19 pagesAir and Gas Drilling Newabdul wahabNo ratings yet

- Astm - C1579Document7 pagesAstm - C1579Diego Bonadiman100% (1)

- Reducing Air Bubble Formation in High Performance ConcreteDocument11 pagesReducing Air Bubble Formation in High Performance Concretesplyc12No ratings yet

- Chapter F-4 Drilling FluidsDocument21 pagesChapter F-4 Drilling FluidsbjgunterjaredNo ratings yet

- Analytical and Experimental Investigation of The Critical Length in Casing-Liner OverlapDocument17 pagesAnalytical and Experimental Investigation of The Critical Length in Casing-Liner OverlapHamza HamzaNo ratings yet

- Auxiliary VentilationDocument20 pagesAuxiliary VentilationNikhil Asha JainNo ratings yet

- Ventilation of Long TunnelsDocument13 pagesVentilation of Long TunnelsClifford Allen CooperNo ratings yet

- EvapORATIVE CoolING Split SysTEMDocument5 pagesEvapORATIVE CoolING Split SysTEMasdthuNo ratings yet

- Lecture 06 Pumped Sprayed-1Document8 pagesLecture 06 Pumped Sprayed-1Zaid HabibuNo ratings yet

- Testing Application Standard No 112-95Document12 pagesTesting Application Standard No 112-95batteekhNo ratings yet

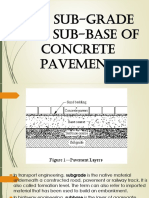

- The Sub-Grade and Sub-Base of Concrete PavementDocument16 pagesThe Sub-Grade and Sub-Base of Concrete PavementPatrick TaylorNo ratings yet

- Chapter 2 Concrete ManualDocument10 pagesChapter 2 Concrete ManualnguyenkhachiepvnNo ratings yet

- AdmixturesDocument8 pagesAdmixturesHaroon AkbarNo ratings yet

- 4ADworkbook9 DTS2 CementingDocument6 pages4ADworkbook9 DTS2 CementingSamad Ali SiddiquiNo ratings yet

- Buried Pipe: A. Trench Design and Burial DepthsDocument6 pagesBuried Pipe: A. Trench Design and Burial DepthsjosethompsonNo ratings yet

- Compaction of Concrete Methods, Defects & ImportaDocument12 pagesCompaction of Concrete Methods, Defects & ImportaHusnain Khan100% (1)

- SuperplasticizersDocument5 pagesSuperplasticizersRaj RatnamNo ratings yet

- Diagnostic Fracture Injection Test (DFIT)Document20 pagesDiagnostic Fracture Injection Test (DFIT)Mvrnaidu Mithra100% (1)

- Road-Tunnels TP06 Road Tunnel Portal EmissionsDocument16 pagesRoad-Tunnels TP06 Road Tunnel Portal EmissionsALARP (Arnold Dix)No ratings yet

- Mix Design of Concrete and Properties of Green ConcreteDocument32 pagesMix Design of Concrete and Properties of Green ConcreteShuvanjan Dahal100% (9)

- Fluidos Neumaticos de PerforacionDocument12 pagesFluidos Neumaticos de PerforaciondollyNo ratings yet

- Vacuum Concreting: Advantages-Techniques With EquipmentsDocument9 pagesVacuum Concreting: Advantages-Techniques With EquipmentsnadirshahNo ratings yet

- Civil Engineering Interview Questions and Answers - Part 3 PDFDocument2 pagesCivil Engineering Interview Questions and Answers - Part 3 PDFSiva2sankarNo ratings yet

- Performance Analysis of Air-Entrained ConcreteDocument27 pagesPerformance Analysis of Air-Entrained ConcreteHazbullah ShajiNo ratings yet

- Admixtures and Shotcrete DurabilityDocument7 pagesAdmixtures and Shotcrete DurabilityMulyawan WIdiasmanNo ratings yet

- Air-Entraining Admixtures For Concrete 11Document60 pagesAir-Entraining Admixtures For Concrete 11qaisalkurdyNo ratings yet

- Workability of ConcreteDocument30 pagesWorkability of ConcreteAdnan Jadoon100% (1)

- Shot CreteDocument8 pagesShot CreteayeshakynaNo ratings yet

- Mix Design For Pumped Concrete With PPC, OPC, OPC FlyashDocument8 pagesMix Design For Pumped Concrete With PPC, OPC, OPC FlyashSandeep AggarwalNo ratings yet

- Basics of Indoor Pool Air DistributionDocument4 pagesBasics of Indoor Pool Air DistributionNebojsa GolubovicNo ratings yet

- Under Water Concreting MethodsDocument8 pagesUnder Water Concreting MethodsSam PitraudaNo ratings yet

- Chapter 09 Air and Gas DrillingDocument55 pagesChapter 09 Air and Gas DrillingAbrar HassanNo ratings yet

- Lippold Harder Silowalls Worldcement 11 2004Document5 pagesLippold Harder Silowalls Worldcement 11 2004Uttam Kumar GhoshNo ratings yet

- Glossary of Terms - Concrete DataDocument11 pagesGlossary of Terms - Concrete DataarsalanzzNo ratings yet

- Rubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Document15 pagesRubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Haresh JoganiNo ratings yet

- Rubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Document15 pagesRubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1EdgarDavidDiazCamposNo ratings yet

- Concrete Mix RatiosDocument5 pagesConcrete Mix RatiosCarlos MensahNo ratings yet

- Bituminous Road Constructions StepsDocument17 pagesBituminous Road Constructions StepsBilal Ahmed Barbhuiya67% (3)

- Air Deck TechniqueDocument9 pagesAir Deck TechniqueVenkata Ramana100% (1)

- Ce472w ReportDocument9 pagesCe472w Reportapi-285359294No ratings yet

- Primary Cementing OperationsDocument46 pagesPrimary Cementing OperationsMohammadFidiAbganisHermawan0% (1)

- Full FM 5-428 Concrete MasonryDocument337 pagesFull FM 5-428 Concrete MasonrycitizenkanegNo ratings yet

- Compressor Seal Selection Justification t32-18Document12 pagesCompressor Seal Selection Justification t32-18Pedro Diaz100% (1)

- Auxillary VentilationDocument5 pagesAuxillary VentilationVihari RahulNo ratings yet

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- VB6555 - Videoteknika Bullet Camera - Data SheetDocument3 pagesVB6555 - Videoteknika Bullet Camera - Data SheetNamburu SomanadhNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Forum Registration FormDocument1 pageForum Registration FormNamburu SomanadhNo ratings yet

- Constrn - Spec. 12.0 Steel PontoonDocument2 pagesConstrn - Spec. 12.0 Steel PontoonNamburu SomanadhNo ratings yet

- Taller InglesDocument11 pagesTaller InglesMartín GonzálezNo ratings yet

- PotwierdzenieDocument4 pagesPotwierdzenieAmina BerghoutNo ratings yet

- RAN16.0 Optional Feature DescriptionDocument520 pagesRAN16.0 Optional Feature DescriptionNargiz JolNo ratings yet

- Service Index PDF - PHP Content Id 2378053&content Tid 388906138&content Type TempDocument2 pagesService Index PDF - PHP Content Id 2378053&content Tid 388906138&content Type Tempshiripalsingh0167No ratings yet

- People Vs Gonzales-Flores - 138535-38 - April 19, 2001 - JDocument10 pagesPeople Vs Gonzales-Flores - 138535-38 - April 19, 2001 - JTrexPutiNo ratings yet

- Options TraderDocument2 pagesOptions TraderSoumava PaulNo ratings yet

- Assignment 1Document3 pagesAssignment 1Bahle DlaminiNo ratings yet

- Adv Tariq Writ of Land Survey Tribunal (Alomgir ALo) Final 05.06.2023Document18 pagesAdv Tariq Writ of Land Survey Tribunal (Alomgir ALo) Final 05.06.2023senorislamNo ratings yet

- General Nursing Council of Zambia: Summary of Results For Each School December 2019 Qualifying Examinations SessionDocument15 pagesGeneral Nursing Council of Zambia: Summary of Results For Each School December 2019 Qualifying Examinations SessionAndrew LukupwaNo ratings yet

- Weak VerbsDocument3 pagesWeak VerbsShlomoNo ratings yet

- Assets Book Value Estimated Realizable ValuesDocument3 pagesAssets Book Value Estimated Realizable ValuesEllyza SerranoNo ratings yet

- (Mr. Nigel West, Oleg Tsarev) TRIPLEX Secrets Fro (B-Ok - Xyz)Document377 pages(Mr. Nigel West, Oleg Tsarev) TRIPLEX Secrets Fro (B-Ok - Xyz)conbeNo ratings yet

- Morals and Dogma of The Ineffable DegreesDocument134 pagesMorals and Dogma of The Ineffable DegreesCelephaïs Press / Unspeakable Press (Leng)86% (7)

- (East Central and Eastern Europe in the Middle Ages, 450-1450_ vol. 21) Paul Milliman-_The Slippery Memory of Men__ The Place of Pomerania in the Medieval Kingdom of Poland-Brill Academic Publishers (.pdfDocument337 pages(East Central and Eastern Europe in the Middle Ages, 450-1450_ vol. 21) Paul Milliman-_The Slippery Memory of Men__ The Place of Pomerania in the Medieval Kingdom of Poland-Brill Academic Publishers (.pdfRaphael BraunNo ratings yet

- WN On LTC Rules 2023 SBDocument4 pagesWN On LTC Rules 2023 SBpankajpandey1No ratings yet

- Relativity of ContractsDocument7 pagesRelativity of ContractsCristy C. Bangayan100% (1)

- Sri Lskhmi BharatgasDocument2 pagesSri Lskhmi BharatgasMytreyi AtluriNo ratings yet

- RA-070602 - REGISTERED MASTER ELECTRICIAN - Manila - 9-2021Document201 pagesRA-070602 - REGISTERED MASTER ELECTRICIAN - Manila - 9-2021jillyyumNo ratings yet

- Quality Audit Report TemplateDocument3 pagesQuality Audit Report TemplateMercy EdemNo ratings yet

- Descartes and The JesuitsDocument5 pagesDescartes and The JesuitsJuan Pablo Roldán0% (3)

- Gouri MohammadDocument3 pagesGouri MohammadMizana KabeerNo ratings yet

- California Department of Housing and Community Development vs. City of Huntington BeachDocument11 pagesCalifornia Department of Housing and Community Development vs. City of Huntington BeachThe Press-Enterprise / pressenterprise.comNo ratings yet

- Anglais OverconsumptionDocument3 pagesAnglais OverconsumptionAnas HoussiniNo ratings yet

- Action Plan Templete - Goal 6-2Document2 pagesAction Plan Templete - Goal 6-2api-254968708No ratings yet

- Prof. Sujata Patel Department of Sociology, University of Hyderabad Anurekha Chari Wagh Department of Sociology, Savitribaiphule Pune UniversityDocument19 pagesProf. Sujata Patel Department of Sociology, University of Hyderabad Anurekha Chari Wagh Department of Sociology, Savitribaiphule Pune UniversityHarish KumarNo ratings yet

- Asking Who Is On The TelephoneDocument5 pagesAsking Who Is On The TelephoneSyaiful BahriNo ratings yet

- RF05 UAMS and School ConcernsDocument8 pagesRF05 UAMS and School ConcernsAngel Ann Pascua LuibNo ratings yet

- NegotiationDocument29 pagesNegotiationNina LeeNo ratings yet

- Winning From Within - SummaryDocument4 pagesWinning From Within - SummaryShraddha Surendra100% (3)

- COVID19 Management PlanDocument8 pagesCOVID19 Management PlanwallyNo ratings yet