Professional Documents

Culture Documents

Multisus 2 For Windows: Operation Manual

Uploaded by

SteveAbonyiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multisus 2 For Windows: Operation Manual

Uploaded by

SteveAbonyiCopyright:

Available Formats

BARTINGTON INSTRUMENTS

Operation Manual

Multisus 2 for Windows

Bartington Instruments Ltd 10 Thorney Leys Business Park Witney OXON OX28 4GG England Tel: +44 1993 706565 Fax: +44 1993 774813

Specifications may be subject to slight alteration without prior notice. This system is not qualified for use in explosive atmospheres or life support systems. Consult Bartington Instruments for advice. The copyright of this document is the property of Bartington Instruments Ltd. The document is supplied on the condition that it is to be treated commercially confidential and it may not therefore be disclosed to any third party without the written authorisation of the Managing Directors of Bartington Instruments.

OM1131 Issue 5 Page 1 of 21

BARTINGTON INSTRUMENTS

CONTENTS

Title

Page

Installation

1 2 3 4 5 6 7 8 9

Introduction Starting Up MS2B Dual Frequency Sensor MS2C Core Logging Sensor MS2E Surface Scanning Sensor MS2G Single Frequency Sensor Equipment Drift Printing and Plotting Data Saving and Opening Data

4 5 8 11 13 15 18 20 21

OM1131 Issue 5 Page 2 of 21

BARTINGTON INSTRUMENTS

INSTALLATION

MULTISUS 2 is supplied on CD and will run under Windows '95, '98, 2000 and Windows NT 3.51 or higher MULTISUS 2 requires a Windows PC with a CD ROM drive, an available serial port and optional printer connected. The minimum and recommended system requirements are: Minimum Free hard disk space RAM Processor 2 Mb 8 Mb 486 66 MHz Recommended 16 Mb Pentium 150 MHz

Note: the installation files may be copied to a network drive and installed from there. To install the MULTISUS 2 software: 1 2 3 4 Ensure you are running Windows Close all other applications. Put the supplied disk in your CDROM drive. Select this drive in File Manager or Explorer Expand the compressed software by doubleclicking on the selected file in File Manager and select 'Unzip'. This creates a number of files including one called setup.exe Double click on the file 'setup.exe', which was copied into your selected temporary directory. Please be patient while the software is installed. Follow the on screen instructions. When the installation is complete, you will be notified by a small screen prompt. Store the installation disks in a safe place.

If warnings or errors are generated during installation try installing the software again. If prompted ''Do you want to overwrite existing files?' select YES. Follow the instructions in Chapter 2 'Starting Up' to run the program. To avoid errors in calculations with decimal values, the keyboard input language should be set to English and decimal values should be entered using a point and not a comma.

OM1131 Issue 5 Page 3 of 21

BARTINGTON INSTRUMENTS

INTRODUCTION

MULTISUS is purpose designed software for interfacing the MS2 Susceptibility System with a Windows personal computer. It allows measurements on single samples and whole cores to be recorded and stored on file. The software is able to compensate for: equipment drift; container susceptibility; and core diameter.

The software can also calculate: volume and mass specific susceptibility; and frequency dependent susceptibility.

Users may wish to compile the susceptibility data in other software, such as spreadsheets and word processors, for further analysis and graphs. The MULTISUS for Windows data files are easily imported directly into these. As detailed in this Operation Manual, it is necessary to compensate for instrument drift during a sequence of measurements if the optimum precision is to be obtained. This is accomplished by making an air measurement before and after each sample or series of measurements. The instrument drift is assumed to be linear during the measurement period and can be subtracted from the measured values. The software corrects the data after each measurement for single samples and at the end of a series of measurements for drill cores. Each measurement is time stamped to allow the correction to be applied. It is particularly important to apply corrections before leaving the equipment for long periods during a sequence of measurements as the assumption that the drift is linear with time is only valid over relatively short periods. For cores it is only possible to make an air measurement and apply the corrections at the end of the core measurement sequence. The main section of this Operation Manual explains the different stages within the five sensor options in the MULTISUS for Windows software. These refer to: MS2B Dual Frequency Sensor; MS2C Core Logging Sensor; MS2E Surface Scanning Sensor; MS2G Single Frequency Sensor.

Further information is provided on printing susceptibility data from MULTISUS, saving data to disk and opening and amending existing data files. Reference should also be made to the 'Operation Manual for MS2 Susceptibility System'. MULTISUS 2 incorporates the following changes compared with version 1.09: 1 2 3 4 5 the MS2G sensor has been included; the sign of the frequency dependence of susceptibility has been corrected; the latest correction curve for coil/core diameter ratio is included; data averaging is provided for single samples; and new short-cut and function key operations are provided.

OM1131 Issue 5 Page 4 of 21

BARTINGTON INSTRUMENTS

2

1.

STARTING UP

Before running Multisus, it must be installed into a suitable directory on the hard disk from the installation disks supplied. Running the software from a floppy disk is not recommended. Connect the RS232 socket on the MS2 meter to the serial port of the personal computer (PC) using the cable supplied. You may use a gender changer at the PC end. If hardcopy is required, connect the PC to a printer and configure this within Windows. Connect the MS2 meter to the required sensor and switch the meter to SI or CGS units, 1.0 or 0.1 scale and set the M/Z toggle switch to its central position. Switch the MS2 meter on and use the M (Measure) button to take a reading to check the MS2 to sensor connection. On the PC, make sure Windows is running. Select Program from the Start button and select Multisus 2. Wait for the main MULTISUS window to appear. This may take 5 -10 seconds on faster machines and 1 -2 minutes on older, slower PCs. Now choose an item from the menu bar depending on what you intend to do:

2.

3.

4.

5.

7.

File New measurements using the MS2 -a sub menu allows you to choose a particular sensor (MS2B, MS2C, MS2E or MS2G). Click on the option of your choice:

Serial Port Configure and test communications with the MS2 and sensor:

Check Drift Monitor equipment drift versus time -a sub menu allows you to choose a particular sensor (MS2B, MS2C, MS2E or MS2G):

OM1131 Issue 5 Page 5 of 21

BARTINGTON INSTRUMENTS

Help Display information about this version of MULTISUS. 8. Note that when you finish, the program should be exited by choosing 'Exit' on the File menu. Do not exit Windows or switch off the computer before choosing this option, otherwise data may be lost. Exiting MULTISUS will also free memory resources on your PC allowing your other applications to run better.

It may be necessary to set up the choice of serial port and baud rate. Select Serial Port, Setup Baud Rate and Port... from the menu to display the configuration screen:

The usual setting for the baud rate should be '1200'. Select the number of the serial port the meter is connected to. This may be indicated on the connector at the rear of the PC, but is typically '1' or '2'. Click on OK. On Choosing Serial Port, Test Communications, you will be asked to confirm that the MS2 is switched on and connected to the selected PC serial port. Click on OK to display the Serial Port Communications Test screen:

OM1131 Issue 5 Page 6 of 21

BARTINGTON INSTRUMENTS

Click on Zero or Measure and compare the data with the MS2 meter display. If no data is received after clicking on Measure, a warning message is displayed. Make sure the meter is turned on. Check the cable connections and choice of serial port. The following page shows the main MULTISUS screen.

MULTISUS for Windows Main Window

OM1131 Issue 5 Page 7 of 21

BARTINGTON INSTRUMENTS

3 MS2B DUAL FREQUENCY SENSOR

On choosing File, New Data File, MS2B Dual Frequency Sensor you will be asked to confirm that the MS2 meter is connected and switched on. You will then be presented with the setup screen. 1. Type in a name for the batch of samples. This can contain up to 50 alpha-numeric characters including spaces and punctuation and is used as a label for printed susceptibility data. Enter a drift warning level (greater than zero). This value sets a maximum drift between two air readings and MULTISUS will alert you if this is exceeded. It only serves as a warning and does not affect the calculated data. Select Volume or Mass Specific measurements. Volume specific, using the standard 10ml sample container is the default. You will be able to specify the sample volume or weight on a subsequent screen. Select whether you require automatic correction for the container susceptibility. If 'Automatic' is selected, you will be asked, on a subsequent screen, to enter the container susceptibility or measure it directly. Select the unit of measurement set on the meter (SI or CGS). Select the scale set on the meter (0.1 or 1.0) Click on OK to continue. If you selected volume specific measurements you will be asked to choose an option from: 10 ml cylindrical bottle; 23 mm cubic box; 1 inch cube; 1 inch length x 1 inch diameter core; 20 ml cylindrical bottle; or user defined container volume

2.

3.

4.

5. 6. 7. 8.

and click on OK. If you selected mass specific measurements you will be asked to enter the mass of the empty container in grams (greater than zero). 9. If you selected automatic susceptibility correction, a screen will be displayed which allows you to either: Enter the container susceptibility directly in the appropriate units - type a value and click on OK ; or Measure the container susceptibility - click on Start Measurement and take a series of air and container measurements. A calculated container susceptibility is displayed which can be accepted, or rejected and undertaken again. Then click OK.

These MS2B settings will be stored between MULTISUS sessions and saved in data files, but can be changed for each new batch.

OM1131 Issue 5 Page 8 of 21

BARTINGTON INSTRUMENTS

MULTISUS for Windows MS2B Sensor Setup You will be asked to make sure there is no sample in the sensor. Once you have checked this, click on OK - the meter will be zeroed and the measurement screen displayed. You are now ready to start making measurements. 10. 11. Enter the sample reference (up to 25 alpha-numeric characters). If you selected mass specific measurements, press Tab and enter the sample weight in grams to one decimal place. Click on the Start Measurement button on the screen and the averaging screen will be displayed. i. ii. iii. iv. v. Remove the sample and press the First Air or Reset Zero button if required. Place the sample in the sensor. Press the Sample button to take a single measurement. Remove the sample from the sensor. Press the Last Air button to take another air reading. Corrections (volume or mass, drift and, if selected, container susceptibility) are applied. Please read notes in Chapter 8 on Equipment Drift. You may save this value or take further air and sample readings, an average will be calculated. If you have the tick box checked, you will be able to accept or reject any reading. Press the Save Value / Average button to return to the measurement screen. Pressing Cancel returns you to the measurement screen without saving a sample value.

12.

vi.

vii. viii.

13. 14.

The susceptibility value will be displayed in the results table. Repeat from 10. for additional samples.

You can re-measure samples by entering an existing sample reference and clicking on the Start Measurement button.

OM1131 Issue 5 Page 9 of 21

BARTINGTON INSTRUMENTS

Making any of the following selections will, after a warning prompt, re-zero the meter: Changing the measurement range; Changing the frequency Clicking on the Reset Zero button.

Changing the frequency and entering previous sample references will allow the frequency dependent susceptibility to be calculated.

MULTISUS for Windows MS2B Data and Measurement Forms OM1131 Issue 5 Page 10 of 21

BARTINGTON INSTRUMENTS

MS2C CORE LOGGING SENSOR

On choosing File, New Data File, MS2C Core Logging Sensor you will be asked to confirm that the MS2 meter is connected and switched on. You will then be presented with the setup screen. 1. Type in a reference name for the core. This can contain up to 50 alpha-numeric characters including spaces and punctuation and is used as a label for printed susceptibility data. Enter a drift warning level (greater than zero). This value sets a maximum drift between two air readings and MULTISUS will alert you if this is exceeded. It only serves as a warning and does not affect the calculated data. Select the interval required and the unit of measurement. Enter the core and sensor diameter in millimetres (Core Diameter < Sensor Diameter) Select diameter correction, if required. This correction uses the relationship between the reading obtained and the sensor to core diameter ratio shown in the MS2 operation manual to normalise the measurement to true volume susceptibility. The correction is applied, together with the drift correction when the Apply Correction button is selected. Select the unit of measurement set on the meter (SI or CGS). Select the scale set on the meter (0.1 or 1.0) Click on OK to continue.

2.

3. 4. 5.

6. 7. 8.

These MS2C settings will be stored between MULTISUS sessions and saved in data files, but can be changed for each new core.

MULTISUS for Windows -MS2C Sensor Setup You will be asked to make sure there is no sample in the sensor. Once you have checked this, click on OK - the meter will be zeroed and the measurement screen displayed. You are now ready to start making measurements.

OM1131 Issue 5 Page 11 of 21

BARTINGTON INSTRUMENTS

9. Place the core in the sensor. 10. Alter the depth value and interval only if required. 11. Press the Measure button on the screen and wait for the value to be displayed in the table. 12. Move the core to the next position and repeat from 10. The measurements are displayed in the table and on a graph. Corrections (drift and, if selected, diameter) can be applied at any time. Uncorrected data is indicated by data cells in the table are shaded pale red. Please read notes in Chapter 8 on Equipment Drift. Making any of the following selections will, after a warning prompt, re-zero the meter: changing the measurement range; and clicking on the Reset Zero button.

MULTISUS for Windows MS2C Data and Measurement

OM1131 Issue 5 Page 12 of 21

BARTINGTON INSTRUMENTS

MS2E SURFACE SCANNING SENSOR

On choosing File, New Data File, MS2E Core Logging Sensor you will be asked to confirm that the MS2 meter is connected and switched on. You will then be presented with the setup screen. 1. Type in a reference name for the core. This can contain up to 50 alpha-numeric characters including spaces and punctuation and is used as a label for printed susceptibility data. Enter a drift warning level (greater than zero). This value sets a maximum drift between two air readings and MULTISUS will alert you if this is exceeded. It only serves as a warning and does not affect the calculated data. Select the interval required and the unit of measurement. Select alignment -core axis or strata. This information is saved in the file for future reference. Select the unit of measurement set on the meter (SI or CGS). Select the scale set on the meter (0.1 or 1.0) Click on OK to continue.

2.

3. 4.

5. 6. 7.

These MS2E settings will be stored between MULTISUS sessions and saved in data files, but can be changed for each new core.

MULTISUS for Windows MS2E Sensor Setup You will be asked to make sure the sensor is removed from the sample. Once you have checked this, click on OK -the meter will be zeroed and the measurement screen displayed. You are now ready to start making measurements. 8. 9. 10. Place the sensor on the core surface. Alter the position and interval only if required. Press the Measure button on the screen and wait for the value to be displayed in the table.

11. Move the sensor to the next position and repeat from 9. OM1131 Issue 5 Page 13 of 21

BARTINGTON INSTRUMENTS

The measurements are displayed in the table and on a graph. Drift correction can be applied at any time. Uncorrected data are indicated by pale red shading of the data cells. Please read notes in Chapter 8 on Equipment Drift. Making any of the following selections will, after a warning prompt, re-zero the meter: changing the measurement range; and clicking on the Reset Zero button.

MULTISUS for Windows MS2E Data and Measurement

OM1131 Issue 5 Page 14 of 21

BARTINGTON INSTRUMENTS

MS2G SINGLE FREQUENCY SENSOR

On choosing File, New Data File, MS2G Single Sample Sensor you will be asked to confirm that the MS2 meter is connected and switched on. You will then be presented with the setup screen. 1. Type in a name for the batch of samples. This can contain up to 50 alpha-numeric characters including spaces and punctuation and is used as a label for printed susceptibility data. Enter a drift warning level (greater than zero). This value sets a maximum drift between two air readings and MULTISUS will alert you if this is exceeded. It only serves as a warning and does not affect the calculated data. Select whether you require automatic correction for the container susceptibility. If 'Automatic' is selected, you will be asked, on a subsequent screen, to enter the container susceptibility or measure it directly. Select the unit of measurement set on the meter (SI or CGS). Select the scale set on the meter (0.1 or 1.0). Click on OK to continue. If you selected automatic susceptibility correction, a screen will be displayed which allows you to either: enter the container susceptibility directly in the appropriate units -type a value and click on OK; or measure the container susceptibility -click on Start Measurement and take a series of air and container measurements. A calculated container susceptibility is displayed which can be accepted, or rejected and undertaken again. Then click on OK.

2.

3.

4. 5. 6. 7.

These MS2G settings will be stored between MULTISUS sessions and saved in data files, but can be changed for each new batch.

MULTISUS for Windows MS2G Sensor Setup You will be asked to make sure there is no sample in the sensor. Once you have checked this, click on OK - the meter will be zeroed and the measurement screen displayed. You are now ready to start making measurements.

OM1131 Issue 5 Page 15 of 21

BARTINGTON INSTRUMENTS

8. 9.

Enter the sample reference (up to 25 alpha-numeric characters). Enter the fill height of the sample and, if this is less than 25mm, the fill correction factor will be calculated for correcting the results during measurements. Click on the Start Measurement button on the screen and the averaging screen will be displayed. Remove the sample and press the First Air or Reset Zero button if required. Place the sample in the sensor. Press the Sample button to take a single measurement. Remove the sample from the sensor. Press the Last Air button to take another air reading. Drift and fill height corrections are applied. Please read notes in Chapter 8 on Equipment Drift. You may save this value or take further air and sample readings, an average will be calculated. If you have the tick box checked, you will be able to accept or reject any reading. Press the Save Value / Average button to return to the measurement screen. Pressing Cancel returns you to the measurement screen without saving a sample value. The susceptibility value will be displayed in the results table. Remove the sample from the sensor and repeat from 8. for additional samples.

10.

i. ii. iii. iv. v. vi.

vii. viii. 11. 12.

You can re-measure samples by entering an existing sample reference and clicking on the Measure button. Making any of the following selections will, after a warning prompt, re-zero the meter: changing the measurement range; and clicking on the Reset Zero button.

OM1131 Issue 5 Page 16 of 21

BARTINGTON INSTRUMENTS

MULTISUS for Windows MS2G Data and Measurement

OM1131 Issue 5 Page 17 of 21

BARTINGTON INSTRUMENTS

7 EQUIPMENT DRIFT

The time taken for each series of measurements should be as short as possible. A small equipment drift will occur during measurements due mainly to temperature changes. When measuring low values of susceptibility the drift may be significant and it is necessary to correct the results to remove the effect. The measurement of air before and after each sample measurement or core sequence allows the estimated air value at the time of the sample measurement to be subtracted from the measured value. When measurements are made manually the average of the air before and after the sample measurement is subtracted from the measured value. The program uses a time stamp to correct the readings assuming a constant drift rate between air measurements. The MULTISUS software is supplied with a facility to check the drift of the system by taking continuous air measurements. This data may be useful in diagnosing whether there is excessive equipment drift occurring or if there is significant interference from an external source. On choosing Check Drift, you can select the type of sensor to undertake an automatic series of readings: MS2B Dual Frequency Sensor; MS2C Core Logging Sensor; MS2E Surface Scanning Sensor; MS2G Single Frequency Sensor.

You will be asked to confirm that the MS2 meter is connected and switched on. You will then be presented with the setup screen.

1. Select the unit of measurement set on the meter (SI or CGS). 2. Select the scale set on the meter (0.1 or 1.0) 3. Click on OK to continue. You will be asked to make sure there is no sample in the sensor. Once you have checked this, click on OK - the meter will be zeroed and the test screen displayed. You are now ready to start the equipment drift test. 4. Click on the Start button on the screen. The meter will take multiple air readings at fixed time intervals. 5. Click on Stop to end the drift test (it will end automatically after 1,500 readings). 6. Print or save the data (see Chapters 9 and 10).

OM1131 Issue 5 Page 18 of 21

BARTINGTON INSTRUMENTS

MULTISUS for Windows Drift Test

OM1131 Issue 5 Page 19 of 21

BARTINGTON INSTRUMENTS

8 PRINTING AND PLOTTING DATA

You can print data and plot simple graphs (MS2C, MS2E and Equipment Drift only) from MULTISUS. The data may be imported into other applications to create more elaborate charts or to undertake numerical analysis or additional formatting (see Chapter 9). You may print data and plot the graphs from any measurement or equipment drift screen: Choose File, Print Data or File, Print Plot from the MULTISUS main screen menu bar. The Windows printer screen will be displayed where you may choose and configure a printer connected to your PC. You may also select multiple copies.

OM1131 Issue 5 Page 20 of 21

BARTINGTON INSTRUMENTS

SAVING AND RE-OPENING DATA

You can save data from MULTISUS in special comma separated MULTISUS files (SUS file extension). You may save data at any time from measurement or equipment drift screens: Choose File, Save or File, Save As... from the MULTISUS main screen menu bar. The Windows Save As screen will be displayed if Save As was selected or no filename is known. You may open and display an existing MULTISUS data file: 1. Choose File, Open... 2. Select the SUS file from the Windows open file screen. 3. Click on Open. The type of sensor (or equipment drift test) will be read from the file as well as the previous measurement settings such as unit of measurement, scale and drift warning level. You can add to measurement data, but not to equipment drift data. Clicking on the Start button for the latter clears the existing drift data. Make sure that the settings on the MS2 meter are the same as those on the display screen before attempting to add data to an existing file. The meter will be reset and zeroed before any additional data is added.

OM1131 Issue 5 Page 21 of 21

You might also like

- Condensed Intro To Tesla Transformers - Eric DollardDocument59 pagesCondensed Intro To Tesla Transformers - Eric Dollard~ScaLaR~100% (4)

- Artcam Reference Manual 2018Document393 pagesArtcam Reference Manual 2018SwadhinNo ratings yet

- Rui Silva Monaco TPS Webinar PresentationDocument18 pagesRui Silva Monaco TPS Webinar PresentationHidajeta ĐedovićNo ratings yet

- WGS 84Document175 pagesWGS 84rtallenNo ratings yet

- OMNI 3D v12Document24 pagesOMNI 3D v12Christhofer Omar Urquizo QuirozNo ratings yet

- Manual EPLAN - Manual Software Eplan P8 - InicianteDocument132 pagesManual EPLAN - Manual Software Eplan P8 - InicianteLuiz Ushijima100% (4)

- CMT User ManualDocument150 pagesCMT User Manualdineshanbalagan100% (4)

- Cargomax 2.1: User'S ManualDocument197 pagesCargomax 2.1: User'S ManualNicu ScutaruNo ratings yet

- Pit DesignDocument96 pagesPit DesignStajic Milan100% (2)

- Superstrings TheoryDocument31 pagesSuperstrings TheorySteveAbonyiNo ratings yet

- Ovation Developer Studio WIN60 00Document306 pagesOvation Developer Studio WIN60 00Hải Đăng NguyễnNo ratings yet

- CCURE 9000 - Monitoring Station ManualDocument45 pagesCCURE 9000 - Monitoring Station ManualWaleed Pervaiz Mughal100% (2)

- Service Tool ManualDocument95 pagesService Tool ManualAdıl SurekNo ratings yet

- Crest LED Lighting Catalogue 2015Document98 pagesCrest LED Lighting Catalogue 2015SteveAbonyiNo ratings yet

- Outline: Combining GPS & Cellular Network Measurements For PositioningDocument9 pagesOutline: Combining GPS & Cellular Network Measurements For PositioningMuhammad Niyas N SNo ratings yet

- Measutal-Digital Deflection Gauge PDFDocument22 pagesMeasutal-Digital Deflection Gauge PDFsobolama100% (2)

- Wireless Sensor Networks Unit I Characteristic Requirements For WsnsDocument47 pagesWireless Sensor Networks Unit I Characteristic Requirements For WsnssulakchanaNo ratings yet

- Atoll 3.4.1 General Features Radio 5G NRDocument114 pagesAtoll 3.4.1 General Features Radio 5G NRmdanishaminNo ratings yet

- Refraction Seismic MethodDocument15 pagesRefraction Seismic MethodCamilleVegaNo ratings yet

- Developing Low-Cost Intelligent Wireless Sensor Networks For Aquatic EnvironmentsDocument6 pagesDeveloping Low-Cost Intelligent Wireless Sensor Networks For Aquatic EnvironmentsSathish KumarNo ratings yet

- Terrawatt LaserDocument69 pagesTerrawatt LaserSteveAbonyiNo ratings yet

- S1TBX TOPSAR Interferometry With Sentinel-1 TutorialDocument21 pagesS1TBX TOPSAR Interferometry With Sentinel-1 TutorialSantiago El Mago MouradianNo ratings yet

- Operation Manual For Ms2 Magnetic Susceptibility System: OM0408 ISSUE 36PAGE 1 OF 64Document64 pagesOperation Manual For Ms2 Magnetic Susceptibility System: OM0408 ISSUE 36PAGE 1 OF 64SteveAbonyiNo ratings yet

- Upower Analog 2Q08 Calpoly SM FinalDocument36 pagesUpower Analog 2Q08 Calpoly SM FinalSteveAbonyiNo ratings yet

- Grad601 Magnetic Gradiometer: Operation Manual ForDocument45 pagesGrad601 Magnetic Gradiometer: Operation Manual ForSteveAbonyiNo ratings yet

- Atbd M 1Document93 pagesAtbd M 1SteveAbonyiNo ratings yet

- Fluxgate Magnetometer Circuit DiagramDocument1 pageFluxgate Magnetometer Circuit DiagramSteveAbonyiNo ratings yet

- 18 Lock in AmplifiersDocument20 pages18 Lock in AmplifiersSteve AbonyiNo ratings yet

- AMEBA DARPA-SN-17-12 ProposersDay For Posting 16dec2016Document4 pagesAMEBA DARPA-SN-17-12 ProposersDay For Posting 16dec2016Steve AbonyiNo ratings yet

- Elrec Terra Manual GBDocument77 pagesElrec Terra Manual GBSaraNo ratings yet

- Lab 02 - Seismic Data QCDocument6 pagesLab 02 - Seismic Data QCapi-323770220No ratings yet

- Software Seismik Refraksi Dan ReflaksiDocument29 pagesSoftware Seismik Refraksi Dan Reflaksihendri sulistiawanNo ratings yet

- Ultrasonic Sensor - Wikipedia, The Free EncyclopediaDocument3 pagesUltrasonic Sensor - Wikipedia, The Free Encyclopediamuna222No ratings yet

- Ultrasonic DetectorDocument2 pagesUltrasonic DetectorRev. Matthew100% (3)

- FGEFluxgateMagnetometerManual PDFDocument18 pagesFGEFluxgateMagnetometerManual PDFKhông Có GìNo ratings yet

- Propuesta COLT 147A 151B KESTREL CUEUNCA 2020Document1 pagePropuesta COLT 147A 151B KESTREL CUEUNCA 2020juanNo ratings yet

- Antenna Synthesis ReportDocument10 pagesAntenna Synthesis Reportesraahabeeb63No ratings yet

- The Magnetic SurveyDocument15 pagesThe Magnetic Surveymelannie adanteNo ratings yet

- Mag-01H Magnetic Inclination/Declination Magnetometer.Document8 pagesMag-01H Magnetic Inclination/Declination Magnetometer.sarveshchandraNo ratings yet

- Konelab 20iDocument58 pagesKonelab 20isat1977No ratings yet

- Airgun ArraysDocument21 pagesAirgun ArraysGianni PavanNo ratings yet

- Configuring Satelline Radios in Leica Viva GNSS: 1. Overview of Satelline Compatibility and Radio ProtocolsDocument3 pagesConfiguring Satelline Radios in Leica Viva GNSS: 1. Overview of Satelline Compatibility and Radio ProtocolsYerd RamirezNo ratings yet

- DgpsDocument1 pageDgpsInder MukhopadhyayNo ratings yet

- Effective MagnetometerDocument17 pagesEffective MagnetometercartamenesNo ratings yet

- DGPSDocument5 pagesDGPSMARCO SILVANo ratings yet

- Matrix Physic NoteDocument68 pagesMatrix Physic Notefarliya100% (3)

- Feedback 56-200Document2 pagesFeedback 56-200Fahad Rasool100% (1)

- Frequency Selective SurfaceDocument28 pagesFrequency Selective SurfaceErdogan Kaygan100% (1)

- 428XL Brochure Sercel PDFDocument12 pages428XL Brochure Sercel PDFAndrés FelipeNo ratings yet

- V Series (HE7300V - 7301V - 1500V - 1501V)Document7 pagesV Series (HE7300V - 7301V - 1500V - 1501V)Erly Muñoz100% (1)

- Tutorial IE3DDocument22 pagesTutorial IE3Dhesoyamyecgaa0% (1)

- DTMFDocument26 pagesDTMFherlindasurkanie367100% (2)

- SeaSonde v2 SpecificationDocument2 pagesSeaSonde v2 SpecificationQualitas RemosNo ratings yet

- Felcom18 19 BrochureDocument2 pagesFelcom18 19 Brochurejeffry.firmansyah0% (1)

- Fluxgate Sensor Data Sheet - FMS 100Document2 pagesFluxgate Sensor Data Sheet - FMS 100JalalNo ratings yet

- Patch Antenna Design Using MICROWAVE STUDIODocument5 pagesPatch Antenna Design Using MICROWAVE STUDIOnehajnitNo ratings yet

- MagnetometerDocument16 pagesMagnetometerButnariu CodrutNo ratings yet

- Seatel 4009-33 VsatDocument180 pagesSeatel 4009-33 VsatHidalgo FrancoNo ratings yet

- GEOP 501: Designing 3-D Land Seismic SurveysDocument59 pagesGEOP 501: Designing 3-D Land Seismic SurveysMark MaoNo ratings yet

- A Brief History of Sensor NetworksDocument49 pagesA Brief History of Sensor Networksmuneebali100% (1)

- Magnetic Surveying For Buried Metallic ObjectsDocument8 pagesMagnetic Surveying For Buried Metallic ObjectsV100% (4)

- GPS Speed Sensor User Guide GS202 Programmable by SINOGAUGEDocument2 pagesGPS Speed Sensor User Guide GS202 Programmable by SINOGAUGEcastellano_rNo ratings yet

- Errors GPSDocument3 pagesErrors GPSAmmar FaisalNo ratings yet

- Thermopile PDFDocument10 pagesThermopile PDFCH DinuNo ratings yet

- OM1131 Iss 6 Multisus2 For WindowsDocument24 pagesOM1131 Iss 6 Multisus2 For WindowsAndri WardonoNo ratings yet

- 110758-W2-US LCR-Meter Operating Instructions enDocument13 pages110758-W2-US LCR-Meter Operating Instructions enadamatozNo ratings yet

- UV Dosimeter Manual - v08Document37 pagesUV Dosimeter Manual - v08David ShermanNo ratings yet

- RASNE Software ManualDocument15 pagesRASNE Software ManualefasaravananNo ratings yet

- GSM&GPRS Signal Strength Meter SWGPRS023 - User ManualDocument20 pagesGSM&GPRS Signal Strength Meter SWGPRS023 - User ManualFlorin NagyNo ratings yet

- SainSmart DDS Manual Software (140417)Document27 pagesSainSmart DDS Manual Software (140417)Isidro MendozaNo ratings yet

- tài liệu về Cello của hãng technologDocument26 pagestài liệu về Cello của hãng technologTung NguyenNo ratings yet

- Product User Guide: Vaccine Temperature Monitoring SystemDocument9 pagesProduct User Guide: Vaccine Temperature Monitoring SystemSlavaNo ratings yet

- SD 3 Manualpart 2Document55 pagesSD 3 Manualpart 2guilhem.barthelemyNo ratings yet

- Curvex 3 Nano cx3040 m44Document16 pagesCurvex 3 Nano cx3040 m44RAHUL KIRAN DUSANENo ratings yet

- Waterpurifier: Mobile Drinking Water Treatment SystemDocument4 pagesWaterpurifier: Mobile Drinking Water Treatment SystemSteveAbonyiNo ratings yet

- Thermocam WebDocument1 pageThermocam WebSteveAbonyiNo ratings yet

- Cancer Killer EngDocument9 pagesCancer Killer EngSteveAbonyiNo ratings yet

- Photovoltaic R&D in Germany: First-Class Research Partnerships Ensure A Sustainable EdgeDocument2 pagesPhotovoltaic R&D in Germany: First-Class Research Partnerships Ensure A Sustainable EdgeSteveAbonyiNo ratings yet

- TStipsDocument2 pagesTStipsSteveAbonyiNo ratings yet

- LIDAR Lite Data SheetDocument2 pagesLIDAR Lite Data SheetSteveAbonyiNo ratings yet

- Gtai PV Manufacturers Gtai 150813 TRDocument2 pagesGtai PV Manufacturers Gtai 150813 TRSteveAbonyiNo ratings yet

- Tsin STRDocument2 pagesTsin STRSteveAbonyiNo ratings yet

- LLLT of Eye and BrainDocument19 pagesLLLT of Eye and BrainSteveAbonyiNo ratings yet

- Skull 2013Document11 pagesSkull 2013SteveAbonyiNo ratings yet

- 2213 ISE PI e World Record Solar CellDocument6 pages2213 ISE PI e World Record Solar CellSteveAbonyiNo ratings yet

- Teslahighfrequency Coil PDFDocument156 pagesTeslahighfrequency Coil PDFMartin OngNo ratings yet

- LM80 Results CREE LedDocument40 pagesLM80 Results CREE LedSteveAbonyiNo ratings yet

- ZMP - 1131232 Osram Led TubeDocument4 pagesZMP - 1131232 Osram Led TubeSteveAbonyiNo ratings yet

- NEC Projector Lt265 ManualDocument145 pagesNEC Projector Lt265 ManualSteveAbonyiNo ratings yet

- Munkafüzet Megoldásai - Nyelvtan - Leckék Szavai 1-6 Stage English - in - 20 - Minutes - A - DayDocument31 pagesMunkafüzet Megoldásai - Nyelvtan - Leckék Szavai 1-6 Stage English - in - 20 - Minutes - A - Daykovaron80No ratings yet

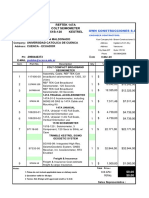

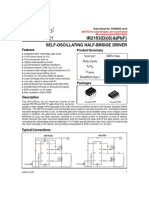

- Ir 2153Document9 pagesIr 2153SteveAbonyiNo ratings yet

- Quotation StreetlightDocument12 pagesQuotation StreetlightSteveAbonyiNo ratings yet

- English in 20 Minutes A Day (1-6)Document289 pagesEnglish in 20 Minutes A Day (1-6)Anonymous wVxfrbkz9100% (2)

- Force On An Asymmetric Capacitor (Antigravity Ufo, Army Report Arl-Tr-3005)Document38 pagesForce On An Asymmetric Capacitor (Antigravity Ufo, Army Report Arl-Tr-3005)SteveAbonyiNo ratings yet

- Quotation StreetlightDocument12 pagesQuotation StreetlightSteveAbonyiNo ratings yet

- XKeyscore Slideshow Leaked by The GuardianDocument32 pagesXKeyscore Slideshow Leaked by The GuardianMatthew Keys100% (2)

- Montauk ProjectDocument8 pagesMontauk ProjectSteveAbonyiNo ratings yet

- H.A.W.System Vehicle H.A.W.System Vehicle: Hydrogen CarDocument2 pagesH.A.W.System Vehicle H.A.W.System Vehicle: Hydrogen CarSteveAbonyiNo ratings yet

- Getting Started With Mastercam SolidsDocument78 pagesGetting Started With Mastercam SolidsKRATOS_SNo ratings yet

- Manual For Evaluation Instrument of COPPA 2nd Edition (2017)Document11 pagesManual For Evaluation Instrument of COPPA 2nd Edition (2017)ramesh babuNo ratings yet

- Delcam - ArtCAM 2010 Insignia TrainingCourse EN - 2010Document134 pagesDelcam - ArtCAM 2010 Insignia TrainingCourse EN - 2010akaki leqvinadzeNo ratings yet

- MS WORD Keyboard KeysDocument30 pagesMS WORD Keyboard KeysRamakrishnan VijayakumaranNo ratings yet

- ENVI Classic Tutorial: Map CompositionDocument18 pagesENVI Classic Tutorial: Map CompositionGualberto Machaca MendietaNo ratings yet

- TU TransView User Manual ENUDocument126 pagesTU TransView User Manual ENULuis FernandoNo ratings yet

- Sap Gui HelpDocument75 pagesSap Gui HelprnvvNo ratings yet

- Okular ManualDocument23 pagesOkular ManualgregdsNo ratings yet

- Sso Program Explanations en PDFDocument487 pagesSso Program Explanations en PDFHugo ChavezNo ratings yet

- Exp 9Document10 pagesExp 9samruddha shedgeNo ratings yet

- Fiberizer Software ManualDocument40 pagesFiberizer Software ManualKiều Hoàng AnhNo ratings yet

- UPSentry Smart 2000 For Mac OSX 10.1 (EN)Document8 pagesUPSentry Smart 2000 For Mac OSX 10.1 (EN)gabrielmpfNo ratings yet

- ECG Viewer Manager - Prince 180D, PC-80D User Manual V1.8Document35 pagesECG Viewer Manager - Prince 180D, PC-80D User Manual V1.8Brian JonesNo ratings yet

- Viewspec Pro™ User Manual: Asd Document 600555 Rev. ADocument28 pagesViewspec Pro™ User Manual: Asd Document 600555 Rev. ACESAR CHAMBINo ratings yet

- Dreamweaver CS5.5 Tutorial - How To Design A Website With Dreamweaver CS 5.5Document14 pagesDreamweaver CS5.5 Tutorial - How To Design A Website With Dreamweaver CS 5.5alibrownNo ratings yet

- Winpep 7 User Guide PDFDocument170 pagesWinpep 7 User Guide PDFcesarNo ratings yet

- WinCC V4 Manual Part 3 - 3Document422 pagesWinCC V4 Manual Part 3 - 3www.otomasyonegitimi.comNo ratings yet

- Ms Word Parts and FunctionsDocument26 pagesMs Word Parts and FunctionsFelmarNo ratings yet

- BSANHS Enrollment SystemDocument13 pagesBSANHS Enrollment SystemReynOcampoNo ratings yet

- Winalc: Measuring Run Versine/ Longitudinal Level CompensationDocument34 pagesWinalc: Measuring Run Versine/ Longitudinal Level CompensationSuciu FlorinNo ratings yet