Professional Documents

Culture Documents

Thermtrace Regular (TTR) Installation Instructions: Hts Global Technologies GMBH

Uploaded by

Nicolas150956Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermtrace Regular (TTR) Installation Instructions: Hts Global Technologies GMBH

Uploaded by

Nicolas150956Copyright:

Available Formats

HTS Global Technologies GmbH Am Unisys Park 6, D-65843 Sulzbach/Frankfurt, Germany

Version: A

Version of 09.02.2009

Doc. No. : HTS-AX-20-001

ThermTrace Regular (TTR) Installation instructions

The HTS ThermTrace Regular (TTR) series of self-regulating parallel circuit heating cables provide the solution to basic freeze protection applications. They can also be used for process temperature maintenance up to 65 C. They are specially designed for use in potentially explosive gas or combustible dust atmospheres. ATEX: Group II Category 2, EN 60079-0:2006, EN 62086-1:2005, EN 61241-0:2006, EN 61241-1:2004 IEC: Zone 1 or Zone 21, IEC 60079-0:2004, IEC 62086-1:2001, IEC 60079-30-1:2007, IEC 61241-0:2004, IEC 61241-1:2004. Marking Nominal operating voltage of 230 Vac: HTS D-65843 ThermTrace Regular xxTTR-2-BO xx W/m @ 10C 230V / max 254V 0344 II 2GD Ex e II Ty Ex tD A21 T zz C KEMA 08ATEX0159 U see � (lot no) Production year The year of production of the HTS ThermTrace Regular (TTR) is recognizable in the Production-Lot-Number of the cable: FTZD=2004, FTZE=2005, FTZF=2006, FTZG=2007, FTZH=2008, FTZI=2009, FTZJ=2010, FTZK=2011, FTZL=2012 Operating Conditions Minimum installation temperature Minimum start-up temperature Minimum bending radius -55 C -40 C 25 mm Maximum withstand temperature +65 C, power on +85 C, power off

Electrical data 33 I Designation Explanation TT R II 2 III Value 10 13 15 20 25 33 TTR 2 254 Vac BO IV Explanation 10 W/m 13 W/m 15 W/m 20 W/m 25 W/m 33 W/m

Power output rating at 10 C, xx

II III

Cable Series Designation Rated voltage

IV

Overjacket options

BO BOT

Polyolefin overjacket Fluoropolymer overjacket

Temperature class and specified maximum surface temperature T T-class determined by Product classification approach, Ty T6 T5 Specified maximum surface 1 temperature T , zz +80 C +95 C

Rated voltage 254 Vac

Power output rating 10, 13, 15 W/m 20, 25, 33 W/m

Notes: 1 : Established according to EN 62086-1 clause 5.1.11.3 and IEC 60079-30-1 clause 5.1.13.3, exposing the cable to fault Author: N. Kashlan Authorisation : V. Wurm Page 1 de 4

HTS Global Technologies GmbH Am Unisys Park 6, D-65843 Sulzbach/Frankfurt, Germany

Version: A

Version of 09.02.2009

Doc. No. : HTS-AX-20-001

ThermTrace Regular (TTR) Installation instructions

conditions such as exceeding the maximum operating temperature, in power on condition, declared by the manufacturer.

Author: N. Kashlan

Authorisation : V. Wurm

Page 2 de 4

HTS Global Technologies GmbH Am Unisys Park 6, D-65843 Sulzbach/Frankfurt, Germany

Version: A

Version of 09.02.2009

Doc. No. : HTS-AX-20-001

ThermTrace Regular (TTR) Installation instructions

Safety Instructions

The assembly of all heat trace connections must be completed carefully according to the manufacturers installation manual supplied with the connection sets. Connections and terminations for installation with this trace heating cable shall be certified according to the requirements of the applicable standards for their types of protection for potential explosive gas and combustible dust atmospheres, as well as the requirements of EN 62086-1 and IEC 60079-30-1 as integral parts of this trace heating system. For the connection of the HTS ThermTrace Regular series trace heating cables to power certified glands, enclosures and terminals shall be used that are suitable for the application and are correctly installed. The cable glands shall be mounted in an enclosure in such a way that the ingress protection rating IP64 according to EN-IEC 60529 is ensured.

The minimum circuit protection requirements for trace heating systems for use in hazardous areas are as follows: 1. A means of isolating line conductors from the supply; 2. Over-current protection provided for each branch circuit; 3. A means of protecting against earth faults which depend on the type of system earthing (see IEC 60364-3 for definitions). The copper braid must be used as a ground wire, especially as the electrical resistance is less than 18.2 /km. 4. For TT and TN systems: a residual-current protective device for each branch circuit having a rated residual operating current not greater than 300 mA. The device shall have a break time not exceeding 150 ms at five times the rated residual operating current. Values of 30 mA and 30 ms are preferred unless there is evidence that this will result in a marked increase in nuisance tripping. 5. For IT systems: an electrical monitoring device shall be installed to disconnect the supply whenever the electrical resistance is not greater than 50 /V of rated voltage. Installation regulations: When installing on locations where explosive atmospheres may be present, regulations of IEC / EN 60079-14 are applicable. Furthermore in most countries where the product is installed, national regulations may be applicable. Those regulations are mostly obligatory. In Germany VDE 0100, VDE 0721 Part 1 and Part 2A3 must be observed. Thermal safety class 0 based on VDE 0721 Part 2A3, paragraph E10 is achieved through the construction character of the heating cable. General rules on handling heating cables Storage: The heating tapes must be stored in dry and clean places. The storage temperature should be between -55 C and +65 C. Keep ends of trace heaters dry before and during installation.

Handling: Avoid excessive pulling or bending of the tape when winding and unwinding during transport and assembly. To avoid damaging the insulation, exercise care if there are any sharp corners and edges, such as for example on flanges or holding devices. Bending: Never bend the high edge of the tape and never exceed a bending radius of 25 mm. Installation Instructions Before installation: The surface of the pipe must be dry and clean. Check the voltage in the power supply. A deviation from the nominal operating voltage will change the heating power.

Page 3 de 4

HTS Global Technologies GmbH Am Unisys Park 6, D-65843 Sulzbach/Frankfurt, Germany

Version: A

Version of 09.02.2009

Doc. No. : HTS-AX-20-001

ThermTrace Regular (TTR) Installation instructions

The size of the protective equipment may not be larger than the heating tape specifications and must agree with the length of tape to be installed. Circuit breakers of type C in conformance with the EN 60898 standard are recommended. Only carry out the installation at temperature above the specified minimum installation temperature. Before installing any connection to the cable, check the electrical resistance between the bus wires and the braid. It must be at least 10 M for a minimum supply voltage of 500 Vdc. The use of 2500 Vdc megaohmeter is recommended.

De-energise all power circuits before installation or servicing. Only use connection systems that protect the electrical connection and the cable ends against the penetration of water or moisture. The metal sheath/braid of this trace heater must be connected to a suitable earthing terminal. Do not splice the bus wires. This would result in a short circuit. The presence of the trace heaters shall be made evident by the posting of caution signs or markings at appropriate locations and/or at frequent intervals along the circuit.

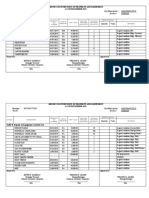

This trace heating cable shall be installed by an electrician trained for installation of trace heating. Unwind the heating cable from the spool in a straight manner and cut to size. Do not exceed the maximum installation circuit lengths. Improper installation or the use of improper components must be avoided to prevent moisture migration which can lead to electrical arcing. Every defective cable or component must be replaced as soon as possible. All gaskets used for the heat trace connections must be replaced after every disassembly. Maximum Circuit Length (m) based on Circuit Breaker Size (Equipment Protection Type C)

Start-up Temp. (C) +10 -15 -30 +10 -15 -30 +10 -15 -30 +10 -15 -30 +10 25TTR -15 -30 33TTR +10 -15 -30

Operating Voltage 254 Vac

16 A 20 A 32 A

10TTR

205 139 120 169 111 94 145 93 77 116 72 55 88 58 45 70 49 43

205 186 150 179 149 124 162 125 106 140 93 77 117 75 64 90 64 52

205 195 195 179 174 174 162 160 160 140 140 110 126 117 100 108 95 82

13TTR

15TTR

20TTR

Page 4 de 4

HTS Global Technologies GmbH Am Unisys Park 6, D-65843 Sulzbach/Frankfurt, Germany

Version: A

Version of 09.02.2009

Doc. No. : HTS-AX-20-001

ThermTrace Regular (TTR) Installation instructions

Typical Installation Methods As applicable, the heating cable may be wound as a spiral around the heated object or longitudinal to the object. Where possible, to ensure a better heat conduction the heating cable shall be applied longitudinal to the pipe and attached along its flat side. The heating cable must be attached to the pipe at max. every 200 mm with temperature resistant adhesive tape. The thermal conductivity of plastic pipes is much lower than the conductivity of metallic pipes. Therefore it is recommended to put aluminium foil under and over the heating cable to enhance heat distribution and prevent local heat accumulation. Simultaneously the lowered heat transfer due to the lower thermal conductivity of the plastic pipe and the lower heat output of the cable is partially compensated. Check that the installed cables are located where heat is required.

!! Never use adhesive tapes that contain plasticizers or made of PVC. Never use cable ties made of metal or nylon !!

On a Pipe

On a Valve

TTR

Pipe 200 mm Adhesive Tape Pipe

TTR

On a Plastic Pipe only

200 mm

Pipe

TTR

Adhesive Tape

Aluminium Foil

On an Elbow

On a Flange

TTR

Adhesive Tape Pipe Insulation

Page 5 de 4

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Trace Heating Thermon Trace Heating Trace Heating CableDocument8 pagesTrace Heating Thermon Trace Heating Trace Heating Cablemajid8080No ratings yet

- Demaroare in Carcasa ElmarkDocument5 pagesDemaroare in Carcasa ElmarkwawinNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Cablu - THDocument6 pagesCablu - THAdrian OprisanNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Electrical Heat Tracing ProcedureDocument8 pagesElectrical Heat Tracing Proceduretndeshmukh100% (1)

- Co2 Weld Machine TroubleshootingDocument12 pagesCo2 Weld Machine TroubleshootingHemantNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- TR-62-Technical Information PDFDocument10 pagesTR-62-Technical Information PDFAlaa RamadanNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- DF PDFDocument8 pagesDF PDFAtif JaveadNo ratings yet

- Eurotrace Installation Instructions: Installation On A PipeDocument6 pagesEurotrace Installation Instructions: Installation On A PipeNicolas150956No ratings yet

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- Electric Surface Heating en (Main Bag House)Document22 pagesElectric Surface Heating en (Main Bag House)Alejandra A. Nuñez Vidal100% (1)

- Heat Tracing InsulationDocument8 pagesHeat Tracing InsulationJessie PimentelNo ratings yet

- Maintenance ManualDocument28 pagesMaintenance ManualnestoriussNo ratings yet

- Installation, Maintenance and Operation Manual: Mineral Insulated (MI) Series Heating SystemsDocument40 pagesInstallation, Maintenance and Operation Manual: Mineral Insulated (MI) Series Heating SystemsnestoriussNo ratings yet

- Mtl700 Series: For Safe Measurement and Control in Hazardous AreasDocument11 pagesMtl700 Series: For Safe Measurement and Control in Hazardous AreasPrithviNo ratings yet

- 3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFDocument11 pages3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFManoj Balla100% (1)

- Cde-1252 DG Em4-Cw R0Document6 pagesCde-1252 DG Em4-Cw R0anamariatoma2009No ratings yet

- Electric Heat Tracing Rev1.0Document12 pagesElectric Heat Tracing Rev1.0draftingisincNo ratings yet

- Linearlight Power Flex Lm10pDocument4 pagesLinearlight Power Flex Lm10pFandy Aditya WiranaNo ratings yet

- PN50207 EHT InstallationDocument16 pagesPN50207 EHT InstallationAbdiel AlvarezNo ratings yet

- UWI 150 TP Owners ManualDocument20 pagesUWI 150 TP Owners Manualajshsu5682No ratings yet

- Explosion Proof Protection Methods StandardsDocument8 pagesExplosion Proof Protection Methods StandardsAmitabhaNo ratings yet

- Eltherm Self Regulating Heating CablesDocument2 pagesEltherm Self Regulating Heating CablesTahseenNo ratings yet

- Quick Connection Terminal Block QTCDocument4 pagesQuick Connection Terminal Block QTCOualid ZaouichNo ratings yet

- GIS Arrester PDFDocument0 pagesGIS Arrester PDFMrC03No ratings yet

- 06-66 70Document5 pages06-66 70Bradley TaylorNo ratings yet

- Electrical Wiring Theory Wiring PracticesDocument2 pagesElectrical Wiring Theory Wiring Practicesdejanbog66100% (1)

- Motan 960Document11 pagesMotan 960DgfdghfghFfdhgfhjgNo ratings yet

- TR88 Ac1e3x2c2000Document24 pagesTR88 Ac1e3x2c2000Xavier MonroyNo ratings yet

- Thermon Heat Tracing PDFDocument12 pagesThermon Heat Tracing PDFanisNo ratings yet

- Heat Cable Installation GuideDocument20 pagesHeat Cable Installation GuidethermaltechnologiesNo ratings yet

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDocument5 pagesSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicNo ratings yet

- Application Note A006: Mounting Considerations For Packaged Microwave SemiconductorsDocument4 pagesApplication Note A006: Mounting Considerations For Packaged Microwave SemiconductorsYung SangNo ratings yet

- 1489 Circuit BreaksersDocument18 pages1489 Circuit Breaksersjulio perezNo ratings yet

- Electrical Heat Tracing - Master PDFDocument49 pagesElectrical Heat Tracing - Master PDFmihai085No ratings yet

- Current Carrying CapacitiesDocument46 pagesCurrent Carrying Capacitiesnagraj204No ratings yet

- Heat Tracing SystemsDocument49 pagesHeat Tracing Systemsamitd_hupar666No ratings yet

- Self-Limiting Heat Tracing Cable Type PSB / HSB : 1 ApplicationDocument2 pagesSelf-Limiting Heat Tracing Cable Type PSB / HSB : 1 ApplicationNicolas150956No ratings yet

- Technical Specification - MCCDocument14 pagesTechnical Specification - MCCKunik Swaroop0% (1)

- Tri CastDocument2 pagesTri CastyoongleiNo ratings yet

- Tep 0066Document7 pagesTep 0066RAMKUMARNo ratings yet

- A Dimensions: (MM) B Recommended Land Pattern: (MM) : WE-FLEX+ Flexible Transformer For DC/DC ConverterDocument5 pagesA Dimensions: (MM) B Recommended Land Pattern: (MM) : WE-FLEX+ Flexible Transformer For DC/DC ConverterlalihifiNo ratings yet

- Features: DF SeriesDocument3 pagesFeatures: DF SeriesgeorgenzNo ratings yet

- Manual ZG0 EngDocument16 pagesManual ZG0 Engeeng_nnabilNo ratings yet

- Variable Frequency Drive Installation Guide: Environmental RequirementsDocument12 pagesVariable Frequency Drive Installation Guide: Environmental RequirementsQOBITNo ratings yet

- Abb Ovr Range TvssDocument16 pagesAbb Ovr Range TvssJJGNo ratings yet

- SM 592.2 Caja de Control ElectromagneticaDocument6 pagesSM 592.2 Caja de Control ElectromagneticaHectorI.GoCaNo ratings yet

- TraceHeat BrochureDocument13 pagesTraceHeat Brochurenick5603No ratings yet

- DatasheetDocument10 pagesDatasheettenisonNo ratings yet

- Distribution Boards Protection DevicesDocument31 pagesDistribution Boards Protection DevicessasikalaNo ratings yet

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Document5 pagesEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783No ratings yet

- Cast Resin Installation & Maintenance ManualDocument20 pagesCast Resin Installation & Maintenance ManualRian KamekNo ratings yet

- Application Note - Thyristor Teaching SystemDocument20 pagesApplication Note - Thyristor Teaching Systemjattends100% (1)

- Iec TS 60079-44 2020Document26 pagesIec TS 60079-44 2020Nicolas150956100% (1)

- Ex Inspections-Potential PitfallsDocument7 pagesEx Inspections-Potential PitfallsNicolas150956No ratings yet

- IEC 61892-7 Ed. 3.0 - 18-1337-CDV - BR NC Comments (2014-01-09)Document4 pagesIEC 61892-7 Ed. 3.0 - 18-1337-CDV - BR NC Comments (2014-01-09)Nicolas150956No ratings yet

- ABB Protecciones RELIONDocument1 pageABB Protecciones RELIONNicolas150956No ratings yet

- 60092-509 - 18 1178 RVCDocument5 pages60092-509 - 18 1178 RVCNicolas150956No ratings yet

- LPG and Electrical InstallationsDocument10 pagesLPG and Electrical InstallationsNicolas150956No ratings yet

- IEC 60079-14 2013 (Ed5.0) Cold FlowDocument2 pagesIEC 60079-14 2013 (Ed5.0) Cold FlowNicolas150956No ratings yet

- PAT Static Solutions CT8700Document1 pagePAT Static Solutions CT8700Nicolas150956No ratings yet

- Compex TTL UkDocument1 pageCompex TTL UkNicolas150956No ratings yet

- LPG and Electrical InstallationsDocument10 pagesLPG and Electrical InstallationsNicolas150956No ratings yet

- RTB Tubing Bundles Installation Guide: Heating Solutions For Instrument and Small-Diameter Process LinesDocument20 pagesRTB Tubing Bundles Installation Guide: Heating Solutions For Instrument and Small-Diameter Process LinesNicolas150956No ratings yet

- Eurotrace Installation Instructions: Installation On A PipeDocument6 pagesEurotrace Installation Instructions: Installation On A PipeNicolas150956No ratings yet

- Intertec Air Cond ExDocument1 pageIntertec Air Cond ExNicolas150956No ratings yet

- Self-Limiting Heat Tracing Cable Type PSB / HSB : 1 ApplicationDocument2 pagesSelf-Limiting Heat Tracing Cable Type PSB / HSB : 1 ApplicationNicolas150956No ratings yet

- MSB Novo Cabo Halogen FreeDocument1 pageMSB Novo Cabo Halogen FreeNicolas150956No ratings yet

- BARTEC Protects People and The Environment by The Safety of Components, Systems and PlantsDocument2 pagesBARTEC Protects People and The Environment by The Safety of Components, Systems and PlantsNicolas150956No ratings yet

- Safety Distances: Definition and ValuesDocument13 pagesSafety Distances: Definition and ValuesNicolas150956No ratings yet

- MSB Novo Cabo Halogen FreeDocument1 pageMSB Novo Cabo Halogen FreeNicolas150956No ratings yet

- Training Global Calendar 2013 - LDDocument1 pageTraining Global Calendar 2013 - LDNicolas150956No ratings yet

- Shipping Applications Tankers IWW: THERMON - . - The Heat Tracing SpecialistsDocument1 pageShipping Applications Tankers IWW: THERMON - . - The Heat Tracing SpecialistsNicolas150956No ratings yet

- Functional Safety Certificate: IEC 61508 Part 1:2010 Clause 6Document2 pagesFunctional Safety Certificate: IEC 61508 Part 1:2010 Clause 6Nicolas150956No ratings yet

- Telehandler New Machine and Pre Delivery Inspection Report PDFDocument1 pageTelehandler New Machine and Pre Delivery Inspection Report PDFMONICA LILIANA DURAN CHACONNo ratings yet

- Catalogue2010 - Overvoltage Protection PDFDocument91 pagesCatalogue2010 - Overvoltage Protection PDFAmadeo AntonioNo ratings yet

- Orbital Wrapping Machine Atis 90: Automatic Machine For Horizontal Packaging With StretchfilmDocument5 pagesOrbital Wrapping Machine Atis 90: Automatic Machine For Horizontal Packaging With StretchfilmEMRE KAAN USTANo ratings yet

- E82-E2Document1 pageE82-E2malves56No ratings yet

- Rheem 2013 Spare Parts ManualDocument199 pagesRheem 2013 Spare Parts ManualNguyen KhaNo ratings yet

- Lift Truck Weight Indicator: Technical Manual GA1035A SeriesDocument36 pagesLift Truck Weight Indicator: Technical Manual GA1035A SeriesAndres NavarroNo ratings yet

- Report On Inventory of Property and EquipmentDocument3 pagesReport On Inventory of Property and EquipmentYzanariz Villaruel75% (4)

- Emerson Operador Ev3200 de Nova Manual InglesDocument25 pagesEmerson Operador Ev3200 de Nova Manual InglesGonzalo PatricioNo ratings yet

- Product Details: Export PageDocument6 pagesProduct Details: Export PagezhenyupanNo ratings yet

- 1 SM401Document55 pages1 SM401Yennhi NguyenNo ratings yet

- When Power Quality Is Life and Death: Technology at WorkDocument2 pagesWhen Power Quality Is Life and Death: Technology at WorkCosmin MihoreanuNo ratings yet

- LAB 2 EmbeddedDocument21 pagesLAB 2 EmbeddedLeonelNo ratings yet

- Project: Layyah Combined Cycle Power Plant: Sub Station: Equipment: Panel Type BAY Ref: DateDocument3 pagesProject: Layyah Combined Cycle Power Plant: Sub Station: Equipment: Panel Type BAY Ref: DatesamlashNo ratings yet

- Frenic Mega CatalogDocument39 pagesFrenic Mega CatalogaditarmandoNo ratings yet

- Repairing IKA Heat - Stir Plate RTC-B BasicDocument3 pagesRepairing IKA Heat - Stir Plate RTC-B BasicSebastian CtaNo ratings yet

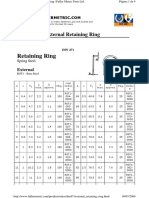

- DIN 471 External Retaining RingDocument4 pagesDIN 471 External Retaining RingCarlitosNo ratings yet

- G200F (D) A、G210F (D) A、G300F (D) A、G390F (D) A、G420F (D) A Owner's ManualDocument40 pagesG200F (D) A、G210F (D) A、G300F (D) A、G390F (D) A、G420F (D) A Owner's ManualVíctor BeltránNo ratings yet

- 15D/18D/20DA-7E: Dimension SpecificationDocument6 pages15D/18D/20DA-7E: Dimension SpecificationАлександр ОлейникNo ratings yet

- 2500 Series Data SheetDocument3 pages2500 Series Data SheetAndika PratamaNo ratings yet

- Inspection Report Dozer: Inspected by Location MBB Site Check PointDocument2 pagesInspection Report Dozer: Inspected by Location MBB Site Check PointkkmechNo ratings yet

- YKC3722MA Microstep Stepping Driver: FeatureDocument2 pagesYKC3722MA Microstep Stepping Driver: FeatureNai GualveNo ratings yet

- ASAS-Pallman-Filters-CrossReference Catalogue 1Document50 pagesASAS-Pallman-Filters-CrossReference Catalogue 1suraj pandey100% (1)

- Third Periodical Test in English and Science 6Document16 pagesThird Periodical Test in English and Science 6aiko idio100% (2)

- SDB CatalugueDocument24 pagesSDB CatalugueHo Van ToanNo ratings yet

- Assembly and Part Drawing: Water-Cooled Diesel EngineDocument2 pagesAssembly and Part Drawing: Water-Cooled Diesel EngineАлександр ЩеблыкинNo ratings yet

- Error MessageDocument1 pageError MessageGany DelanoNo ratings yet

- Agt Tractor Broshure English enDocument6 pagesAgt Tractor Broshure English enLuciusNo ratings yet

- Microprocessor Lab Manual SEM IV 2013Document58 pagesMicroprocessor Lab Manual SEM IV 2013Abir DuttaNo ratings yet

- Vehicle Dynamics Mathematical Analysis ODocument5 pagesVehicle Dynamics Mathematical Analysis OVINOD Y BNo ratings yet

- Emerson ES3Document40 pagesEmerson ES3SanjitDasguptaNo ratings yet