Professional Documents

Culture Documents

FL2 DPF

Uploaded by

zayarmyint_uOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FL2 DPF

Uploaded by

zayarmyint_uCopyright:

Available Formats

Lesson 2 Component Description

Diesel Particulate Filter (DPF)

Overview

Diesel particulate are typically soot particles with adherent hydrocarbons, sulphate and other condensed compounds. Legally a particulate is anything in the exhaust stream that can be captured on a filter paper at 52 C. Soot particles are called PM (particulate matter). Combustion quality is dependent on how the mixture of oxygen and fuel, is formed. Soot production is inherent in the diesel combustion process. Particles are formed in the rich mixture zones of the combustion process. Soot itself has no harmful effects on the human organism. Pollutants such as Hydro Carbons are deposited on the soot particles and in this way harmful soot particles are formed. HC (hydrocarbon) emissions are essentially the emissions of unburned fuel and oil. Due to the high temperatures found in a diesel engine combustion chamber there is little unburned fuel left from correctly injected fuel. The major source of hydrocarbons is from the portion of unburned fuel exposed in the injector orifices. In addition some hydrocarbons can be sourced from the engine lubricating oil. Diesel Emissions In order to meet increasingly stringent emission standards, exhaust gas after treatment has increased in significance for diesel engines, despite the progress made with regard to engine modifications. NOTE: On vehicles from 2008MY an optional Diesel Particulate Filter (DPF) is available". The 07MY non-DPF system will also continue to be available, and the DPF is not required to comply with EU4.

The introduction of direct fuel injection, an increase in systems pressure and advances in engine management systems has significantly improved the performance, economy, and refinement of diesel engines. Also of significance is the reduction of exhaust gas emissions, the maximum levels of which have to be continuously improved to meet with changes in legislation. High injection pressures, nozzle design, timed commencement of injection and improved combustion chamber design have lowered the CO, HC, and diesel particulate emissions to a large extent. The Nox emissions produced by an excess of air during combustion are effectively reduced by exhaust gas Reticulation systems which are constantly being optimised. The oxidation catalytic converter, in use for some years, represents the first stage of exhaust gas after treatment. It further reduces HC and CO emissions. Diesel Particulate Matter Diesel emission standards for passenger vehicles were first introduced in 1989. To meet these original standards, diesel fuel emissions were reduced to 1.1g/km. The introduction of EU stage III emissions standards in 1999 saw a further reduction in diesel emissions to 0.05g/km. The EU standard IV sees the introduction of a 0.025g/km upper limit for diesel emissions. The above values apply to light vehicles (cars) This limit can only be reached by advances in fuel delivery and exhaust management technology. The noxious effect of diesel particulate matter is a result of absorption of unburnt or partially burnt hydrocarbons. In addition fuel and lubricant oil aerosols (solid or liquid substances finely distributed in gasses) and sulphate(depending on the sulphur content of the fuel) bind with the soot.

Technical Training

159

Diesel Particulate Filter (DPF)

Lesson 2 Component Description

The collected particulate matter, if not removed, can create an obstruction to exhaust gas flow. The particles

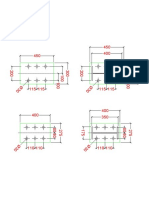

DPF components

are removed by a regeneration process which incinerates the particles.

7 5

E68715

1 2 3 4

Temperature sensor Oxygen sensor Differential pressure sensor High pressure sensor pipe

5 6 7

Low pressure sensor pipe Diesel particulate filter Temperature sensor

160

Technical Training

Lesson 2 Component Description

Diesel Particulate Filter (DPF)

Diesel Particulate Filter

The particulate emissions are the black fumes emitted from the diesel engine under certain load conditions. The emissions are a complex mixture of solid and liquid components with the majority of the particulate being carbon micro spheres on which hydrocarbons from the engine's fuel and lubricant condense. The DPF system comprises the following components: Diesel particulate filter DPF control software incorporated into the Engine Control Module (ECM) Differential pressure sensor. Temperature sensors x2

Diesel Particulate Filter

The DPF is located in the exhaust system, downstream of the catalytic converter. A major feature of the DPF is its ability for regeneration. Regeneration is the burning of particulate trapped by the filter to prevent obstruction to the free flow of exhaust gasses. The regeneration process takes place at calculated intervals and is not noticeable by the driver of the vehicle. Regeneration is most important, since an overfilled filter can damage the engine through excessive exhaust back pressure and can itself be damaged or destroyed. The material trapped in the filter is in the most part carbon particles with some absorbed hydrocarbons.

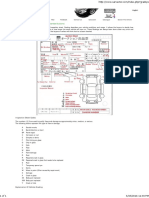

E68716

A B C

Front face closed cells Side view gas flow Rear face closed cells

Technical Training

161

Diesel Particulate Filter (DPF)

Lesson 2 Component Description

The DPF uses a filter technology based on a filter with a catalytic coating. The DPF is made from silicon carbide housed in a steel container and has excellent thermal shock resistance and thermal conductivity properties. The DPF is designed for the engine's operating requirements to maintain the optimum back pressure requirements. The porous surface of the filter consists of thousands of small parallel channels positioned in the longitudinal direction of the exhaust system. Adjacent channels in the filter are alternately plugged at the end. This design forces the exhaust gasses to flow through the porous filter walls, which act as the filter medium. Particulate matter which are too big to pass through the porous surface are collected and stored in the channels. The regeneration process uses NO2 to remove the particles from the DPF. The NO2 is generated by the catalytic converter upstream of the DPF. The catalytic converter produces temperatures in excess of 250C (482F) at which point the regeneration process is started DPF regeneration is controlled by the temperature of the exhaust gasses and the DPF. The DPF includes a wash coat to the filter surface which comprises platinum and other active components and is similar to the catalytic converter. At certain exhaust gas and DPF temperatures the wash coat promotes combustion and incineration of the particles in addition to oxidizing carbon monoxide and hydrocarbon emissions. The exhaust gas and DPF temperatures are controlled by the DPF software located in the ECM. The DPF software monitors the load status of the DPF based on driving style, distance travelled and signals from the differential pressure sensor and temperature sensors. When the particulate loading of the DPF reaches predetermined levels, the DPF is actively regenerated by adjusting, in conjunction with the ECM, various engine control functions such as: fuel injection intake air throttle

EGR turbocharger boost pressure control The regeneration process is possible because of the flexibility of the common-rail fuel injection engine which provides precise control of fuel flow, fuel pressure and injection timing which are essential requirements to promote the efficient regeneration process

Differential pressure sensor

E68718

1 2 3

High pressure connection Low pressure connection Electrical connector

162

Technical Training

Lesson 2 Component Description

Diesel Particulate Filter (DPF)

software uses this comparison, in conduction with other data, to calculate the accumulated amount of trapped particulate. By measuring the pressure difference between the DPF inlet and outlet air flow and the DPF temperature, the DPF software can determine if the DPF is becoming blocked and requires regeneration The diesel particulate filter provides a certain resistance to the exhaust gas flow. This leads to a pressure difference in the exhaust pressure upstream of the downstream of the diesel particulate filter. NOTE: A DPF is recognised as overloaded if the differential pressure under certain operating conditions exceeds the overload limit calculated by the ECM. In the worst-case scenario the system may start regeneration attempts but be unable to complete them. These attempts are counted by the ECM. If the maximum number of regeneration attempts is reached, this results in a fault entry the next time the ignition is switched on. The monitoring system performs the following checks by means of the diesel particulate differential pressure sensor: Plausibility check Diesel particulate filter efficiency Diesel particulate filter overloaded Diesel particulate filter clogged Monitoring of the maximum regeneration attempts in the lower load range.

E59691

The differential pressure sensor is located in the engine compartment, on the lower RH side of the bulkhead at turbo level. The sensor is located on two studs and secured with nuts The differential pressure sensor is used by the DPF software to monitor the condition of the DPF. Two pipe connections on the sensor are connected by pipes to the inlet and outlet ends of the DPF. The pipes allow the sensor to measure the inlet and outlet pressures of the DPF. As the amount of particulate trapped by the DPF increases, the pressure at the inlet side of the DPF increases in comparison to the DPF outlet. The DPF Differential Pressure Sensor Reference voltage Signal voltage Fault Symptoms

Value Approx 5V 0.5-4.5V see chart

Technical Training

163

Diesel Particulate Filter (DPF)

Lesson 2 Component Description

Differential Pressure Sensor DTC P2002

Value Diesel Particulate Filter Efficiency Below Threshold Particle Filter Soot mass quantity above maximum threshold. Any faults in the air path system must be rectified before a service regeneration is carried out. There is a risk of thermal damage to the DPF filter otherwise. Fault Symptoms: "DPF FULL VISIT DEALER" Message displayed on cluster Torque derate Fault Diagnosis and Rectification: Particle filter soot mass quantity above maximum threshold, Carry out DPC forced static regeneration procedure using manufacturer approved diagnostic system Drive Cycle: Warm engine until coolant temperature is above 65C Carry out dynamic service regeneration Re check DTC

DPF FULL VISIT DEALER

Possible faults

Continuous low load town driving. Boost pressure leaks. EGR Valve Stuck open. Air leaks

P244B Diesel Particulate Filter Differential Pressure Too Fault Diagnosis and Rectification: - Engine protection High active Check for additional related DTCs and refer to the relevant DTC index NOTE: A relatively clean DPF will return a voltage of approximately 0.5V. This rises to approximately 4.5V for a full DPF. If the differential pressure sensor returns a voltage of 4.5V or more to the ECM, and if all other conditions are met, regeneration of the DPF will occur. In the event of a fault, the engine power output is reduced by the ECM by means of a reduction in the injected fuel quantity and EGR will be switched off.

Temperature Sensors

Two temperature sensors are used in the DPF system. One is located in the turbocharger outlet elbow, adjacent to the HO2S and the second sensor is located in the DPF inlet. The sensors measure the temperature of exhaust gas exiting the turbocharger and before it passes through the DPF and provides the information needed to calculate the DPF temperature. The information is used, in conjunction with other data, to estimate the amount of accumulated particulate and to control the DPF temperature.

164

Technical Training

Lesson 2 Component Description

Diesel Particulate Filter (DPF)

Upstream Temperature Sensor

The sensor is located at the catalytic converter. The temperature sensor informs the ECM as to the temperature of the exhaust gases after they have passed through the turbo, upstream of the catalytic converter. The sensor is a NTC type resistor, which measures the temperature of the exhaust gases. The resistance, and so the voltage drop at the sensor will alter depending on exhaust gas temperature.

E48497

Upstream Temperature Sensor (NTC) 20 C 400C Reference voltage Signal Fault Diagnosis DTC P244D 210-230Ohms 480-500Ohms 5V 0.2-4.8

Electrical Resistance

Exhaust Temperature Too High For Particulate Filter Regeneration Fault Diagnosis and Rectification: particulate filter pre temperature sensor circuit - Voltage above upper limit .Refer to electrical circuit diagrams and check particle filter pre temperature sensor circuit for short to power Exhaust Temperature Too Low For Particulate Filter Regeneration Rectification: Particulate filter pre temperature sensor circuit - Voltage below lower limit Refer to electrical circuit diagrams and check particle filter pre temperature sensor circuit for short to ground or open circuit Fault Symptoms: Reduced engine performance MIL On Open Circuit in Wiring or Component , Inspect wiring & connectors for signal, damage, water ingress, corrosion. Suspect Exhaust Gas Temperature sensor. Replace sensor EGR closed. MIL On. Limp home mode. Regeneration stops

P244C-

P0545 Exhaust Gas temperature sensor voltage below lower limit

Default

Technical Training

165

Diesel Particulate Filter (DPF)

Lesson 2 Component Description

Downstream Temperature Sensor

To prevent this from leading to the diesel particulate filter becoming blocked or even destroyed completely, regeneration must be initiated before a critical saturation point is reached. The engine management system initiates active regeneration prematurely if the conditions are particularly favourable (for example when driving on a motorway). On the other hand, active regeneration is delayed if possible in the event of unfavourable conditions.

E48497

The downstream sensor is identical in construction as the upstream temperature sensor. This sensor informs the ECM of the temperature of the exhaust gasses down stream from the catalytic converter, which allows the increase in temperature caused by catalytic combustion to be ascertained. The exhaust gas temperature must be at least 600C for the soot particles to burn; temperature is detected by the exhaust gas temperature sensor and transmitted to the ECM. The exhaust temperature before the particulate filter is used as an input variable for calculation by the ECM, taking into account the values of other relevant variables. Depending on the calculated exhaust temperature, the ECM then decides whether the regeneration process can be initiated or not. In the event of a fault, the ECM reverts to a substitute value 350C.

The regeneration strategy determines the regeneration measures to be carried out and their timing, depending on the diesel particulate mass in the filter and on the operating state of the engine.

Engine-based measures for increasing the exhaust gas temperature

In the event of a regeneration request, the injection and intake systems and turbo are switched to other parameters. The individual interventions needed to achieve the necessary exhaust gas temperature depend on the engine operating conditions. In the case of diesel engines, the exhaust gas temperature level required for regeneration (550 ... 650 C) is only achieved in standard mode with high engine speeds at the Wide Open Throttle (WOT) limit. Important engine-based measures for increasing the exhaust gas temperature are advanced (during combustion) or

Regeneration strategy

When the diesel particulate mass increases in the filter, active generation must be initiated in good time. As the filter becomes more saturated, the heat energy released during diesel particulate combustion increases and the peak temperatures in the filter rise.

retarded (after combusting) post-injections delay to retarded main injection partial throttling of the intake air Depending on the engine operating conditions, one or several of these measures are implemented during the regeneration process.

166

Technical Training

Lesson 2 Component Description

Diesel Particulate Filter (DPF)

Active regeneration intervals

Determination of the time interval for regeneration depends to a large extent on the emissions of untreated diesel particulate and the size of the diesel particulate filter. Usually, active regeneration takes place between 850 ... 1700 km. An active regeneration process usually takes around 10 ... 20 minutes, depending on the engine operating conditions.

Active regeneration generally occurs every 528 miles (850km) although this is dependant on how the vehicle is driven. For example, if the vehicle is driven at low loads in urban traffic regularly, active regeneration will occur more often. This is due to the rapid build-up of particulate in the DPF than if the vehicle is driven at high speeds when passive regeneration will have occurred. The DPF software incorporates a mileage trigger which is used as back-up for active regeneration. If active regeneration has not been initiated by a back pressure signal from the differential pressure sensor, regeneration is requested based on distance travelled. Active regeneration of the DPF is commenced when the temperature of the DPF is increased to the combustion temperature of the particles. The DPF temperature is raised by increasing the exhaust gas temperature. This is achieved by introducing post-injection of fuel after the pilot and main fuel injections have occurred. This is determined by the DPF software monitoring the signals from the two DPF temperature sensors to establish the temperature of the DPF. Depending on the DPF temperature, the DPF software requests the ECM to perform either one or two post-injections of fuel. The first post-injection of fuel retards combustion inside the cylinder which increases the temperature of the exhaust gas. The second post-injection of fuel is injected late in the power stroke cycle. The fuel partly combusts in the cylinder, but some unburnt fuel also passes into the exhaust where it creates an exothermic event within the catalytic converter, further increasing the temperature of the DPF The active regeneration process takes approximately 20 minutes to complete. The first phase increases the DPF temperature to 500C (932F). The second phase further increases the DPF temperature to 600C (1112F) which is the optimum temperature for particle combustion.

DPF Regeneration

Regeneration is the burning of particulate collected in the particulate filter (DPF). The increase in exhaust gas temperature is achieved by a variety of engine related measures. Diesel particulate filter regeneration can be divided into two programmes Active regeneration Passive regeneration

Active Regeneration

WARNING: Care should be taken when working within the vicinity of the particulate filter as it can reach temperatures of up to 1000 C during the regeneration process. Exhaust gas temperature must be at least 600C for the soot particles to burn; temperature is detected by the DPF exhaust gas temperature sensor and transmitted to the ECM. Active regeneration starts when the particulate loading of the DPF reaches a threshold as monitored or determined by the DPF control software. The threshold calculation is based on driving style, distance travelled and back pressure signals from the differential pressure sensor.

Technical Training

167

Diesel Particulate Filter (DPF)

Lesson 2 Component Description

This temperature is then maintained for 15-20 minutes to ensure complete incineration of the particles within the DPF. The incineration process converts the carbon particles to carbon dioxide and water. The active regeneration temperature of the DPF is closely monitored by the DPF software to maintain a target temperature of 600C (1112F) at the DPF inlet. The temperature control ensures that the temperatures do not exceed the operational limits of the turbocharger and the catalytic converter. The turbocharger inlet temperature must not exceed 830C (1526F) and the catalytic converter brick temperature must not exceed 800C (1472F) and the exit temperature must remain below 750C (1382F). NOTE: If regeneration has commenced it will be completed, regardless of the operating condition of the engine. Regeneration can only be stopped by shutting off the engine. Or if a sensor and actuator fault is detected. NOTE: During regeneration the system may produce a strong smell (due to heat generation) this is normal and can be ignored. During the active regeneration process the following ECM controlled events occur: The turbocharger is maintained in the fully open position. This minimizes heat transmission from the exhaust gas to the turbocharger and reduces the rate of exhaust gas flow allowing optimum heating of

the DPF. If the driver demands an increase in engine torque, the turbocharger will respond by closing the vanes as necessary. The throttle is partially closed as this assists in increasing the exhaust gas temperature and reduces the rate of exhaust gas flow which has the effect of reducing the time for the DPF to reach the optimum temperature The Exhaust Gas Reticulation (EGR) valve is closed. The use of EGR decreases the exhaust gas temperature and therefore prevents the optimum DPF temperature being achieved NOTE: The regeneration process will not take place if the ROOF (run out of fuel) strategy is active or if less than 8 litres of fuel in the fuel tank. If, due to vehicle usage and/or driving style, the active regeneration process cannot take place or is unable to regenerate the DPF, the dealer can force regenerate the DPF. This is achieved by either driving the vehicle until the engine is at its normal operating temperature and then driving for a further 20 minutes at speeds of not less than 30 mph (48 km/h)

Passive Regeneration

Passive regeneration requires no special engine management intervention and occurs during normal engine operation. The passive regeneration involves a slow conversion of the particulate matter deposited in the DPF into carbon dioxide. This process is active when the DPF temperature reaches 250C (482F) and is a continuous process when the vehicle is being driven at higher engine loads and speeds During passive regeneration, only a portion of the particulate matter is converted into carbon dioxide. This is due to the chemical reaction process which is only effective within the normal operating temperature range of 250C to 500C (482F to 932F).

168

Technical Training

Lesson 2 Component Description

Diesel Particulate Filter (DPF)

Above this temperature range the conversion efficiency of the particulate into carbon dioxide increases as the DPF temperature is raised. These temperatures can only be achieved using the active regeneration process.

When the supervisor module issues a regeneration request, the co-ordinator module requests EGR cut-off and a regeneration specific turbocharger boost pressure control. It then waits for a feedback signal from the EGR system confirming that the EGR valve is closed.

Diesel Particulate Filter Control

The DPF requires constant monitoring to ensure that it is operating at its optimum efficiency and does not become blocked. The ECM contains DPF software which controls the monitoring and operation of the DPF system and also monitors other vehicle data to determine regeneration periods and service intervals. The DPF software can be divided into three separate control software modules; a DPF supervisor module, a DPF fuel management module and a DPF air management module These three modules are controlled by a fourth software module known as the DPF co-ordinator module. The co-ordinator module manages the operation of the other modules when an active regeneration is requested. The DPF supervisor module is a sub-system of the DPF co-ordinator module.

When the EGR valve is closed, the co-ordinator module initiates requests to increase engine load by controlling the intake air temperature and pressure. Once confirmation is received that intake conditions are controlled or a calibration time has expired, the co-ordinator module then changes to a state awaiting an accelerator pedal release manoeuvre from the driver. If this occurs or a calibration time has expired, the co-ordinator module generates a request to control fuel injections to increase exhaust gas temperature.

DPF Fuel Management Module

The DPF air management module controls the following functions: EGR control Turbocharger boost pressure control Intake air temperature and pressure control. During active regeneration, the EGR operation is disabled and the closed-loop activation of the turbocharger boost controller is calculated. The air management module controls the air in the intake manifold to a predetermined level of pressure and temperature. This control is required to achieve the correct in-cylinder conditions for stable and robust combustion of the post injected fuel. Restricting the air intake during DPF regeneration has the following functions: Increase in engine load Slower combustion Reduction in the mass of air taken in A reduction in the speed of the exhaust gases and therefore an increase in the time for which the gases are in the catalytic converter

DPF Co-ordinator Module

The DPF co-ordinator module reacts to a regeneration request from the supervisor module by initiating and co-ordinating the following DPF regeneration requests: EGR cut-off Turbocharger boost pressure control Engine load increase Control of air pressure and temperature in the intake manifold Fuel injection control

Technical Training

169

Diesel Particulate Filter (DPF)

Lesson 2 Component Description

The module controls the intake air temperature by actuating the EGR throttle and by adjustment of the turbocharger boost pressure control

Engine Oil Dilution

Engine oil dilution can occur due to small amounts of fuel entering the engine crankcase during the post-injection phases. This has made it necessary to

Fault with DPF

If the DPF becomes blocked the pressure differential sensor will register a high pressure diagnostic trouble code (DTC) with the ECM, the malfunction indicator lamp (MIL) will be illuminated and the limp home mode activated. A blocked DPF can be a result of: Excessive soot particles production Multiple failed regeneration events Mechanical or electrical failure of a related system or sub-system (for example EGR valve stuck open, charge air system leak, fuel injectors) Important any air leaks in the intake system will cause serious damage to the DPF CAUTION: The catalytic coatings on the converter (Diesel Oxidation Catalyst - DOC) and DPF can be poisoned if non-specified fuels/oils are used, and that this can result in the vehicle becoming non-compliant with tailpipe emissions regulations. In addition, if the vehicle is waded and the engine is stopped with the exhaust well under water, it obviously will fill with dirty river/pond/lake/sea water which can also poison the coatings. In such an instance, to ensure that the ability to regenerate the DPF is maintained, it is recommended that the DPF is replaced

introduce a calculation based on driving style to reduce oil service intervals if necessary. The driver is alerted to the oil service by a message in the instrument cluster. The DPF software monitors the driving style and the frequency of the active regeneration and duration. Using this information a calculation can be made on the engine oil dilution. When the DPF software calculates the engine oil dilution has reached a predetermined threshold (fuel being 7% of engine oil volume) a service message is displayed in the instrument cluster. Depending on driving style, some vehicles may require an oil service before the designated interval. If an service message is displayed, the vehicle will be required have a full service and the service interval counter will be reset. NOTE: Post-injections result in high oil dilution and must therefore be kept within limits. To avoid excessively high oil dilution, a minimum driving distance has to be maintained between two regeneration cycles approx. 528 miles (850 km). Increased oil consumption and reduced fuel quality (high sulphur content), as well as high fuel consumption accelerate the build-up of ash in the DPF, shortening regeneration intervals more quickly. If the minimum distance between regeneration cycles, currently 528 miles (850 km), cannot be adhered to, this is detected by the diesel particulate differential pressure sensor, and the DPF warning is switched on. The DPF will require a drive cycle forced by the diagnostic equipment.

Diesel Particulate Filter Side Effects

The following section details some side effects caused by the active regeneration process.

170

Technical Training

Lesson 2 Component Description

Diesel Particulate Filter (DPF)

Fuel consumption

During the active regeneration process of the DPF, there will be an increase in fuel consumption.

However, because active regeneration occurs infrequently, the overall effect on fuel consumption is approximately 2%. The additional fuel used during the active regeneration process is accounted for in the instantaneous and average fuel consumption displays in the instrument cluster.

Instrument Cluster Indications

1

E90739

For drivers who make regular short journeys at low speeds, it may not be possible to efficiently regenerate the DPF. In this case, the DPF software will detect a blockage of the DPF from signals from the differential pressure sensor and will alert the driver as follows The driver will be alerted to this condition by a message 'DPF FULL' accompanied by a handbook symbol. As detailed in the Owners Handbook, the driver should

drive the vehicle until the engine is at its normal operating temperature and then drive for a further 20 minutes at speeds of not less than 30 mph (48 km/h). regeneration of the DPF is indicated to the driver by the 'DPF FULL' message no longer being displayed. If the DPF software detects that the DPF is still blocked, the message will change to 'DPF FULL VISIT DEALER', the driver should take the vehicle to an authorized dealer to have the DPF regenerated.

Technical Training

171

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- English 3 Links To Reading Assignments 1Document13 pagesEnglish 3 Links To Reading Assignments 1zayarmyint_uNo ratings yet

- Bolt and NUTDocument1 pageBolt and NUTDedijumaediNo ratings yet

- Min Ko Naing Book - Final PDFDocument65 pagesMin Ko Naing Book - Final PDFzayarmyint_uNo ratings yet

- Proposed Architectural Work For 2 Storey Domentar (Ngwe Pin Lae Zone) Ground Floor PlanDocument9 pagesProposed Architectural Work For 2 Storey Domentar (Ngwe Pin Lae Zone) Ground Floor Planzayarmyint_uNo ratings yet

- Base Plate Detail DrawingDocument1 pageBase Plate Detail Drawingzayarmyint_uNo ratings yet

- ESE Lightning Arrestor JMVDocument2 pagesESE Lightning Arrestor JMVnilanchal patraNo ratings yet

- My Body: Learning ObjectivesDocument3 pagesMy Body: Learning ObjectivesDurwin Juancho Dc DangilanNo ratings yet

- 2 - Sikament-520 BA - PDS - GCC - (01-2018) - 2 - 1Document3 pages2 - Sikament-520 BA - PDS - GCC - (01-2018) - 2 - 1zayarmyint_uNo ratings yet

- Deep Hole DiggingDocument11 pagesDeep Hole Diggingzayarmyint_uNo ratings yet

- NIST Overview of ESEDocument20 pagesNIST Overview of ESEzayarmyint_uNo ratings yet

- SR - No 9 Water Supply Guide LineDocument21 pagesSR - No 9 Water Supply Guide Linezayarmyint_uNo ratings yet

- Wartsila RTA96C Engine Technology ReviewDocument24 pagesWartsila RTA96C Engine Technology ReviewVolodymyr SavchukNo ratings yet

- Arlington A Low ResDocument1 pageArlington A Low Reszayarmyint_uNo ratings yet

- Areas ClasificadasDocument8 pagesAreas Clasificadasedin64No ratings yet

- Fire Safety InspectionsDocument12 pagesFire Safety Inspectionszayarmyint_uNo ratings yet

- ျပဇာတ္ - ပဒုမျပဇာတ္ (ဦးပုည)Document3 pagesျပဇာတ္ - ပဒုမျပဇာတ္ (ဦးပုည)zayarmyint_uNo ratings yet

- OPW Installation and Maintenance Instructions: 331, 332-AST Direct Fill Spill ContainerDocument2 pagesOPW Installation and Maintenance Instructions: 331, 332-AST Direct Fill Spill Containerzayarmyint_uNo ratings yet

- 7) Hydro TestDocument3 pages7) Hydro TestPramod AthiyarathuNo ratings yet

- Inspections AuditsDocument4 pagesInspections Auditszayarmyint_uNo ratings yet

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizNo ratings yet

- Fire Safety ManualDocument75 pagesFire Safety Manualzayarmyint_u100% (1)

- Fire Safety Procedure For Housing ProvidersDocument20 pagesFire Safety Procedure For Housing Providerszayarmyint_uNo ratings yet

- DEA GuidelinesDocument2 pagesDEA GuidelinesKawsar AlamNo ratings yet

- The Accord InspectionDocument7 pagesThe Accord InspectionShamsul IslamNo ratings yet

- Bulk PaymentDocument7 pagesBulk Paymentzayarmyint_uNo ratings yet

- ေဒါက္တာသန္းထြန္း - ငါေျပာခ်င္သမွ်ငါ႔အေၾကာင္းDocument157 pagesေဒါက္တာသန္းထြန္း - ငါေျပာခ်င္သမွ်ငါ႔အေၾကာင္းVan DooNo ratings yet

- Fire Protection and Prevention For Construction CKLSTDocument2 pagesFire Protection and Prevention For Construction CKLSTzayarmyint_uNo ratings yet

- Carvector - Car Sales From JapanDocument1 pageCarvector - Car Sales From Japanzayarmyint_uNo ratings yet

- AccountsDocument9 pagesAccountszayarmyint_uNo ratings yet

- FIL-notification English A4Document19 pagesFIL-notification English A4zayarmyint_uNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- InsulatorDocument6 pagesInsulatorMuhammad AftabuzzamanNo ratings yet

- European Steel Standards PDFDocument2 pagesEuropean Steel Standards PDFMeikaNo ratings yet

- XCMG XE215C, XE230C, XE260C Hydraulic Excavators Operating ManualDocument154 pagesXCMG XE215C, XE230C, XE260C Hydraulic Excavators Operating ManualEmmanuel Garcia Ozan94% (16)

- enDocument40 pagesenRegistr Registr91% (11)

- 07a3ec02 Fluid Mechanics and Hydraulic Machinery PDFDocument8 pages07a3ec02 Fluid Mechanics and Hydraulic Machinery PDFfotickNo ratings yet

- Flange Coupling DesignDocument16 pagesFlange Coupling DesignJaspreet KhattraNo ratings yet

- Dge 169Document6 pagesDge 169Krittika ChandranNo ratings yet

- Development of Groundwater Monitoring Wells in Granular AquitmentsDocument16 pagesDevelopment of Groundwater Monitoring Wells in Granular AquitmentsJose Luis Nava HernandezNo ratings yet

- Shaper Planer and SlotterDocument21 pagesShaper Planer and SlotterBharathiraja MoorthyNo ratings yet

- Thermax Single Effect Hot Water Driven ChillerDocument12 pagesThermax Single Effect Hot Water Driven ChillerKetan ChandravadiyaNo ratings yet

- Analytical Solution For A Deep Tunnel Excavated in A Porous Elasto-Plastic Material Considering The Effects of Seepage Forces PDFDocument14 pagesAnalytical Solution For A Deep Tunnel Excavated in A Porous Elasto-Plastic Material Considering The Effects of Seepage Forces PDFSaphal LamichhaneNo ratings yet

- Chapter 11: Transformation in AlloysDocument48 pagesChapter 11: Transformation in AlloysbadaboyNo ratings yet

- Section 05505 METAL FABRICATIONS PDFDocument13 pagesSection 05505 METAL FABRICATIONS PDFIm ChinithNo ratings yet

- 5.1 Combustion of OilDocument6 pages5.1 Combustion of Oilkcp1986No ratings yet

- E155-00 Aluminum & Magnesium CastingsDocument4 pagesE155-00 Aluminum & Magnesium Castingschitti409No ratings yet

- Engineering Standard Specification For Steam TracingDocument53 pagesEngineering Standard Specification For Steam Tracingkaruna346100% (1)

- ARE Non-Stick Utensils Safe For HumanDocument13 pagesARE Non-Stick Utensils Safe For HumanSoft TechNo ratings yet

- ACS800 GeneralDocument14 pagesACS800 GeneralAnonymous AMQMyB2EbNo ratings yet

- Lesson 6-GlassDocument32 pagesLesson 6-Glasslewis imaNo ratings yet

- Study of Prefabrication in IndiaDocument6 pagesStudy of Prefabrication in IndiaSayed WafiNo ratings yet

- 2-Basic Concepts of Corrosion Science and EngineeringDocument31 pages2-Basic Concepts of Corrosion Science and EngineeringMarwin G CrispinoNo ratings yet

- Capital CostDocument2 pagesCapital CostRajibDebNo ratings yet

- MOS For Bituminous Protective Coating Water ProofingDocument5 pagesMOS For Bituminous Protective Coating Water ProofingHussam WaleedNo ratings yet

- Consolidated Undrained Triaxial Compression Test For Cohesive SoilsDocument11 pagesConsolidated Undrained Triaxial Compression Test For Cohesive SoilsNikhilNo ratings yet

- Reason Not To Refill The Old Expired Fire Extinguisher 1Document3 pagesReason Not To Refill The Old Expired Fire Extinguisher 1swapnilmanwtkarNo ratings yet

- 1.sanitary Wastewater MOSDocument13 pages1.sanitary Wastewater MOSarshad iqbal0% (1)

- 080 Chlorine AlkalineDocument6 pages080 Chlorine AlkalineChristian CoboNo ratings yet

- Biomechanics Design Lab Presentation FINALDocument27 pagesBiomechanics Design Lab Presentation FINALLinh PhanNo ratings yet

- Lincoln Electric Pro Cut 80Document39 pagesLincoln Electric Pro Cut 80ArturoNo ratings yet

- Leather Technology I PDFDocument19 pagesLeather Technology I PDFSundarapandiyan Sundaramoorthy100% (1)