Professional Documents

Culture Documents

Cable Capacity - Example Calculating 300 MM

Uploaded by

Nedunuri.Madhav MurthyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Capacity - Example Calculating 300 MM

Uploaded by

Nedunuri.Madhav MurthyCopyright:

Available Formats

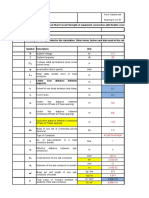

Calculation example for 300 mm2

Parameters used for current carrying capacity as per IEC 287-1-1 and 287-2-1 Operating Frequency Operating Voltage LL Operating Voltage LN Ambient Temp. Air Ambient Temp. Ground cable maximum operating temp. Thermal resitivity earth Thermal resitivity concrete Thermal resitivity XLPE Thermal resitivity PVC Duct outer diameter Duct inner diameter Duct material 60 13,80 7,97 50 40 90 2 1 3,5 6 160 150 PVC Hz kV kV C C C K.m/W K.m/W K.m/W K.m/W mm mm

Cable type: copper conductor single-core unarmoured in trefoil configuration (Saudi Cable Catalouge for R AC at 90C and Geometry) conductor cross-sectional area 70 mm.sq. 95 mm.sq. 120 mm.sq. 150 mm.sq. 185 mm.sq. 300 mm.sq. tan for Wd for Wd 0,004 2,5 Rdc20 0,2680 0,1930 0,1530 0,1240 0,0991 0,0601 Rac at 90C 0,3420 ohm/km 0,2470 ohm/km 0,1960 ohm/km 0,1600 ohm/km 0,1280 ohm/km 0,0800 ohm/km cond. Diameter 9,90 mm 11,80 mm 13,30 mm 14,70 mm 16,40 mm 20,80 mm Thickness of XLPE 4,5 mm 4,5 mm 4,5 mm 4,5 mm 4,5 mm 4,5 mm Thickness of screen 2,25 mm 1,80 mm 1,95 mm 2,25 mm 2,30 mm 2,50 mm

RAC at 90C Conductor diameter Thickness of XLPE Thickness of screen Thickness of PVC Overall diameter Diameter of trefoil

0,08 20,8 4,5 2,5 2,1 39 84

/km mm mm mm mm mm mm

Ductbank geometry

4 7

3 6 9

Ductbank X (width) Ductbank Y (height) L LG

730 730 1500 1290

mm mm mm mm

8th cable/duct center distance to ground distance from ground to ductbank center

Calculation Procedure

1.4.1.1 from IEC 287-1-1

= 90 40 = 50 (difference betwen maximum operating temperature of the conductor and ambient temperature) Wd is neglected for voltage levels less than 60 kV as per table 3 in IEC 287-1-1 R is R AC = 0.00008 /m (AC resistance at maximum operating temperature of 90C) = 0.08 (assupmtion as not all parameters are available and it accounts for range of sheath losses) n = 3 (number of single-core cables within a duct for T4) n = 1 (number of single-core cables under jacket for T 3) T2 is equal zero since the cable is unarmoured T1 = 0,200 T3 = 0,109 T4 = 4,586

I = 202,9 A cable capacity is 4850 MVA

2.1.1.1 from IEC 287-2-1

T = 3,5 t1 = 4,5 dc = 20,8 T1 = 0,200

thermal resistivity of insulation (XLPE) thickness of insulation diameter of conductor

2.1.3 from IEC 287-1-1

T = 6 t3 = 2,1 Da = 34,8 T3 = 0,109

thermal resistivity of cable jacket (PVC) thickness of jacket diameter of cable under jacket

2.2.7.1 from IEC 287-2-1

U = 1,87 V = 0,312 Y = 0,0037 m = 50 De = 84 T4 = 0,361

constant as per table 4 IEC 287-2-1 constant as per table 4 IEC 287-2-1 constant as per table 4 IEC 287-2-1 temperature of medium filling the duct diameter of trefoil configuration

2.2.7.2 from IEC 287-2-1

T = 6 Do = 160 Dd = 150 T4 = 0,062

thermal resistivity of duct material (PVC) outer diameter of duct inner diameter of duct

2.2.7.3 from IEC 287-2-1 algerbic correction for T'''4 for cables in ducts N: number of loaded cables!

N=6 e = 2 c = 1 u = LG/rb = 3,215 LG = 1290 rb = 401

number of ducts with loaded cables thermal resistivity of earth thermal resistivity of concrete

distance from surface to center of ductbank equivalent radius of concrete ductbank

part 1 of T4 = 1,753

2.2.3.2 from IEC 287-2-1 Tc for multiple cables in duct not touching

2.2.3.2 from IEC 287-2-1 Tc for multiple cables in duct not touching

c = 1

thermal resistivity of concrete

u = 2 x L/De = 18,750 L = 1500 De = 160

3 6 9

distance from surface to center of cable to be calcualted (position 8) outer diameter of duct

4 7

d83/d83 = 5,51 d84/d84 = 9,42 d86/d86 = 9,42 d87/d87 = 14,32 d89/d89 = 14,32 part 2 of T4 = 2,410 T4 = 4,586

d83 distance to cable 3 in mirror position, d83 distance to to cable 3

You might also like

- Transmission Line Design CalcDocument38 pagesTransmission Line Design CalcparmenderNo ratings yet

- Acceptance and Presentment For AcceptanceDocument27 pagesAcceptance and Presentment For AcceptanceAndrei ArkovNo ratings yet

- Tech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCDocument34 pagesTech Spec - 6.3&10MVA With OLTC &SCADA-compatible-RTCCkushal BNo ratings yet

- Earthing Calculations for 110KV SwitchyardDocument8 pagesEarthing Calculations for 110KV SwitchyardGarmangh GersNo ratings yet

- Earthing CalculationDocument6 pagesEarthing CalculationMKNo ratings yet

- 500SQMM-Buried Cable Current Carrying Capacity - RevisedDocument2 pages500SQMM-Buried Cable Current Carrying Capacity - RevisedBijaya Kumar MohantyNo ratings yet

- EARTHING DESIGN CALCULATIONDocument10 pagesEARTHING DESIGN CALCULATIONarafinNo ratings yet

- Calculation of Earthing Sys.Document12 pagesCalculation of Earthing Sys.Rania Fathy Mohammed100% (4)

- 13.8Kv Cable Sizing Calculation Construction of New 380/132Kv S/S AD-DAWADMI BSP (9037)Document14 pages13.8Kv Cable Sizing Calculation Construction of New 380/132Kv S/S AD-DAWADMI BSP (9037)Arun dasNo ratings yet

- DSLP (Control Room) DhamraiDocument3 pagesDSLP (Control Room) DhamraiarafinNo ratings yet

- EDP/LRP Well Intervention System OverviewDocument22 pagesEDP/LRP Well Intervention System OverviewJerome LIKIBINo ratings yet

- CBIP-Future AC DC TransmissionDocument74 pagesCBIP-Future AC DC TransmissionkrcdewanewNo ratings yet

- 230kv Cable Sizing 1Document6 pages230kv Cable Sizing 1Thirunavukkarasu VaratharajanNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Earthing calculation for NGR panelDocument4 pagesEarthing calculation for NGR panelnaran19794735No ratings yet

- Best Practices - Earthing Installations - Myths & FactsDocument43 pagesBest Practices - Earthing Installations - Myths & FactskapilNo ratings yet

- Insulation Level and Clearances For 230 KV Air Insulated SubstationDocument6 pagesInsulation Level and Clearances For 230 KV Air Insulated SubstationDaniel ChristianNo ratings yet

- 33KV Earthmat 1designDocument195 pages33KV Earthmat 1designVelavan Annamalai100% (1)

- DEBA-DD-EL-CC-3141-0.1-flexible Conductor Size CalculationDocument4 pagesDEBA-DD-EL-CC-3141-0.1-flexible Conductor Size Calculationjie zhangNo ratings yet

- 132 KV Aluminium Tube Bus Sizing CalculaDocument12 pages132 KV Aluminium Tube Bus Sizing CalculakamaleshsNo ratings yet

- 132kv Cables For Transformer Feeder, Cables in Duct at 9029Document4 pages132kv Cables For Transformer Feeder, Cables in Duct at 9029Muhammad MahmudNo ratings yet

- 18th Floor Snag ListDocument1 page18th Floor Snag ListNedunuri.Madhav MurthyNo ratings yet

- EarthmatDocument7 pagesEarthmatHeather CarterNo ratings yet

- Sa2009-001608 en Rel670 CT Calculation ExampleDocument7 pagesSa2009-001608 en Rel670 CT Calculation ExampleinsanazizNo ratings yet

- Detailed Syllabu Ssubstaiion DesignDocument10 pagesDetailed Syllabu Ssubstaiion Designwaqqar shaikhNo ratings yet

- Aluminium Conductor Sizing - 275kVDocument10 pagesAluminium Conductor Sizing - 275kVsitifarhaniNo ratings yet

- Dokumen - Tips Cymcap 605Document36 pagesDokumen - Tips Cymcap 605gerrzen64No ratings yet

- Design Procedure Block Diagram Earthing CalculationDocument17 pagesDesign Procedure Block Diagram Earthing CalculationMauricio Cesar Molina ArtetaNo ratings yet

- Design of Earthing System For 230 KV High Voltage Substation by ETAP 12.6 SoftwareDocument4 pagesDesign of Earthing System For 230 KV High Voltage Substation by ETAP 12.6 SoftwareEditor IJTSRD100% (1)

- MOM of ETA Works On 13-03-14-QC2Document5 pagesMOM of ETA Works On 13-03-14-QC2Nedunuri.Madhav MurthyNo ratings yet

- Siemens - CCDocument11 pagesSiemens - CCtrymskvedaNo ratings yet

- Short Circuit Current CalculationDocument7 pagesShort Circuit Current CalculationKalyan RanjanNo ratings yet

- Thermal resistance calculation methods for determining submarine cable current capacityDocument11 pagesThermal resistance calculation methods for determining submarine cable current capacityardiwilagagunNo ratings yet

- Marketing Management NotesDocument115 pagesMarketing Management NotesKajwangs DanNo ratings yet

- TSWF - 900.2 - Earthing Calculation For 110kV OHTL - Rev2Document4 pagesTSWF - 900.2 - Earthing Calculation For 110kV OHTL - Rev2Shinekhuu99No ratings yet

- SCF Calculation and Clearance Check for Equipment BusDocument7 pagesSCF Calculation and Clearance Check for Equipment BusMOLI_RABI_DIYANo ratings yet

- 380kV CT-VT Calculation C4 Rev D 17.12.09Document137 pages380kV CT-VT Calculation C4 Rev D 17.12.09was00266No ratings yet

- EarthingDocument8 pagesEarthingboopelectraNo ratings yet

- Underground CablesDocument50 pagesUnderground CablesSanjeet KumarNo ratings yet

- MMPX 403 Parametr ListDocument30 pagesMMPX 403 Parametr ListOğuz Kağan ÖkdemNo ratings yet

- Schneider Electric Cahier Technique 151Document24 pagesSchneider Electric Cahier Technique 151Anonymous BwLfvuNo ratings yet

- Design Selection of CT and PT' Effective For Transmission LinesDocument4 pagesDesign Selection of CT and PT' Effective For Transmission LinesEditor IJTSRDNo ratings yet

- BMT Check List - XLSXDocument6 pagesBMT Check List - XLSXNedunuri.Madhav MurthyNo ratings yet

- As D SW SP 4600 3Document9 pagesAs D SW SP 4600 3Odipiyo Paul100% (2)

- Station Grounding CalculationDocument7 pagesStation Grounding CalculationhamgaiNo ratings yet

- CT & PT Sizing Calculation for Bandreah 115/13.8kV SubstationDocument110 pagesCT & PT Sizing Calculation for Bandreah 115/13.8kV SubstationJay WinNo ratings yet

- Mechanical Short Circuit Strength Calculation for Equipment Connection with Flexible ConductorDocument12 pagesMechanical Short Circuit Strength Calculation for Equipment Connection with Flexible Conductoranoop13No ratings yet

- 850 KVAR 400v.doc - 400V Capacitor Bank - SpecDocument10 pages850 KVAR 400v.doc - 400V Capacitor Bank - Specdeepthik27No ratings yet

- Transient Phenomena in Electrical Power Systems: International Series of Monographs on Electronics and Instrumentation, Vol. 24From EverandTransient Phenomena in Electrical Power Systems: International Series of Monographs on Electronics and Instrumentation, Vol. 24No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- MOM of MEP Meeting 16 11 2012 - XLSXDocument2 pagesMOM of MEP Meeting 16 11 2012 - XLSXNedunuri.Madhav MurthyNo ratings yet

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringFrom EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo ratings yet

- CH 4 - Consolidated Techniques and ProceduresDocument18 pagesCH 4 - Consolidated Techniques and ProceduresMutia WardaniNo ratings yet

- 33KV Earthmat 1designDocument212 pages33KV Earthmat 1designVelavan AnnamalaiNo ratings yet

- Modern Approach To Earthing System Design and Its AnalysisDocument7 pagesModern Approach To Earthing System Design and Its AnalysisDoly DamanikNo ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- 220kV-400Kv-345KV Details of CableDocument26 pages220kV-400Kv-345KV Details of CableDhanaji Wakade100% (1)

- Motor Protection Circuit Breaker Design BasicsDocument12 pagesMotor Protection Circuit Breaker Design Basicsjustog_12No ratings yet

- Aluminium Pipe Bus PDFDocument6 pagesAluminium Pipe Bus PDFaviral mishraNo ratings yet

- PLCCDocument9 pagesPLCCkpr_02161371No ratings yet

- Cal-Mn Dastur T2117 Rev 2Document4 pagesCal-Mn Dastur T2117 Rev 2Shubham BaderiyaNo ratings yet

- Improving 110kV Transformer Insulation Structure for Electric Field AnalysisDocument4 pagesImproving 110kV Transformer Insulation Structure for Electric Field AnalysisCristian Camilo Silva GuevaraNo ratings yet

- Swing Angle CalculationDocument4 pagesSwing Angle CalculationRajas Alshi100% (1)

- Working Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceDocument1 pageWorking Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceMeghavahinaNo ratings yet

- Design Brief For 300kV CT & VTDocument43 pagesDesign Brief For 300kV CT & VTSantoshNo ratings yet

- Example Calculating 300 MMDocument7 pagesExample Calculating 300 MMSathaporn MolisakulmongkolNo ratings yet

- Answer Key of Revision Worksheet TA-2Document6 pagesAnswer Key of Revision Worksheet TA-2Nedunuri.Madhav MurthyNo ratings yet

- 1B 2 1 Types Fire PumpsDocument25 pages1B 2 1 Types Fire Pumpsharoub_nasNo ratings yet

- Draft Letter - High RiseDocument1 pageDraft Letter - High RiseNedunuri.Madhav MurthyNo ratings yet

- Local Conveyance Reimbursement FormDocument1 pageLocal Conveyance Reimbursement FormNedunuri.Madhav MurthyNo ratings yet

- ResumeDocument2 pagesResumeNedunuri.Madhav MurthyNo ratings yet

- Travel Expence StatementDocument1 pageTravel Expence StatementNedunuri.Madhav MurthyNo ratings yet

- Toilet No 15MM 20MM 15Mm Insulation T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14 T15 T16 Actual Rate of Each Toilet From Old MeasurementDocument1 pageToilet No 15MM 20MM 15Mm Insulation T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14 T15 T16 Actual Rate of Each Toilet From Old MeasurementNedunuri.Madhav MurthyNo ratings yet

- 1B 2 1 Types Fire PumpsDocument25 pages1B 2 1 Types Fire Pumpsharoub_nasNo ratings yet

- 02-Construction Manager Civil BuildingsDocument2 pages02-Construction Manager Civil BuildingsNedunuri.Madhav MurthyNo ratings yet

- AHU and Toilet Snag ListDocument6 pagesAHU and Toilet Snag ListNedunuri.Madhav MurthyNo ratings yet

- Accoustic Results SummaryDocument1 pageAccoustic Results SummaryNedunuri.Madhav MurthyNo ratings yet

- Noise TestDocument2 pagesNoise TestNedunuri.Madhav MurthyNo ratings yet

- 014 Annxr To ANC IL & FS Ducting Etc QTNDocument1 page014 Annxr To ANC IL & FS Ducting Etc QTNNedunuri.Madhav MurthyNo ratings yet

- 014 Annxr To ANC IL & FS Ducting Etc QTNDocument1 page014 Annxr To ANC IL & FS Ducting Etc QTNNedunuri.Madhav MurthyNo ratings yet

- Baance Floor Integration Schedule For Final Sign OffDocument1 pageBaance Floor Integration Schedule For Final Sign OffNedunuri.Madhav MurthyNo ratings yet

- Transmittal Note 1254 - (As Built DWG) - DADocument17 pagesTransmittal Note 1254 - (As Built DWG) - DANedunuri.Madhav MurthyNo ratings yet

- Load CalculationDocument1 pageLoad CalculationNedunuri.Madhav MurthyNo ratings yet

- Balance Works Planning-Qc2Document2 pagesBalance Works Planning-Qc2Nedunuri.Madhav MurthyNo ratings yet

- Order Details: Order ID: SAP14050587113 Order Date: Mon 5th May 2014 12:26pmDocument1 pageOrder Details: Order ID: SAP14050587113 Order Date: Mon 5th May 2014 12:26pmNedunuri.Madhav MurthyNo ratings yet

- Scan Copy of NBC 2005 ClauseDocument1 pageScan Copy of NBC 2005 ClauseNedunuri.Madhav MurthyNo ratings yet

- ChillerDocument20 pagesChillerNedunuri.Madhav MurthyNo ratings yet

- Simple Tutorial For Using JDBC PDFDocument8 pagesSimple Tutorial For Using JDBC PDFAntonio BarrosNo ratings yet

- Baance Floor Integration Schedule For Final Sign OffDocument1 pageBaance Floor Integration Schedule For Final Sign OffNedunuri.Madhav MurthyNo ratings yet

- Suggestion SchemeDocument9 pagesSuggestion SchemeNedunuri.Madhav MurthyNo ratings yet

- Sabarmati Capital Tower-2 Sanitary Fixtures Bill of QuantitiesDocument8 pagesSabarmati Capital Tower-2 Sanitary Fixtures Bill of QuantitiesNedunuri.Madhav MurthyNo ratings yet

- Excel TipsDocument30 pagesExcel Tipshedda14No ratings yet

- OPIM101 4 UpdatedDocument61 pagesOPIM101 4 UpdatedJia YiNo ratings yet

- Amos Code SystemDocument17 pagesAmos Code SystemViktor KarlashevychNo ratings yet

- Superior University: 5Mwp Solar Power Plant ProjectDocument3 pagesSuperior University: 5Mwp Solar Power Plant ProjectdaniyalNo ratings yet

- "Corbel" - Concrete Corbel Analysis: Program DescriptionDocument4 pages"Corbel" - Concrete Corbel Analysis: Program DescriptioniuliandurdureanuNo ratings yet

- GSM Multi-Mode Feature DescriptionDocument39 pagesGSM Multi-Mode Feature DescriptionDiyas KazhiyevNo ratings yet

- 10 Appendix RS Means Assemblies Cost EstimationDocument12 pages10 Appendix RS Means Assemblies Cost Estimationshahbazi.amir15No ratings yet

- Youtube AlgorithmDocument27 pagesYoutube AlgorithmShubham FarakateNo ratings yet

- ECED Lab ReportDocument18 pagesECED Lab ReportAvni GuptaNo ratings yet

- Nuxeo Platform 5.6 UserGuideDocument255 pagesNuxeo Platform 5.6 UserGuidePatrick McCourtNo ratings yet

- Factors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawatDocument26 pagesFactors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawathumeragillNo ratings yet

- LeasingDocument2 pagesLeasingfollow_da_great100% (2)

- TransformerDocument50 pagesTransformerبنیاد پرست100% (8)

- Exp19 Excel Ch08 HOEAssessment Robert's Flooring InstructionsDocument1 pageExp19 Excel Ch08 HOEAssessment Robert's Flooring InstructionsMuhammad ArslanNo ratings yet

- Savable Data Page - Its Configuration, Usage & ExecutionDocument20 pagesSavable Data Page - Its Configuration, Usage & ExecutionsurmanpaNo ratings yet

- 20220720-MODIG-Supply Chain Manager (ENG)Document2 pages20220720-MODIG-Supply Chain Manager (ENG)abhilNo ratings yet

- High Uric CidDocument3 pagesHigh Uric Cidsarup007No ratings yet

- Whats The Average 100 M Time For An Olympics - Google SearchDocument1 pageWhats The Average 100 M Time For An Olympics - Google SearchMalaya KnightonNo ratings yet

- Fleck 3150 Downflow: Service ManualDocument40 pagesFleck 3150 Downflow: Service ManualLund2016No ratings yet

- Specialized Government BanksDocument5 pagesSpecialized Government BanksCarazelli AysonNo ratings yet

- Lirik and Chord LaguDocument5 pagesLirik and Chord LaguRyan D'Stranger UchihaNo ratings yet

- Experienced Leadership Driving Growth at Adlabs EntertainmentDocument38 pagesExperienced Leadership Driving Growth at Adlabs EntertainmentvelusnNo ratings yet

- Harry Styles: The Rise of a Pop StarDocument9 pagesHarry Styles: The Rise of a Pop StarBilqis LaudyaNo ratings yet

- Forecasting AssignmentDocument1 pageForecasting AssignmentVarun Singh100% (1)

- Stellar Competent CellsDocument1 pageStellar Competent CellsSergio LaynesNo ratings yet

- Current Affairs Q&A PDF June 9 2023 by Affairscloud 1Document21 pagesCurrent Affairs Q&A PDF June 9 2023 by Affairscloud 1Yashika GuptaNo ratings yet