Professional Documents

Culture Documents

Energy Cost Optimization Through The Implementation of Cogeneration and Grid Interconnection

Uploaded by

sunitharajababuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Cost Optimization Through The Implementation of Cogeneration and Grid Interconnection

Uploaded by

sunitharajababuCopyright:

Available Formats

ENERGY COST OPTIMIZATION THROUGH THE IMPLEMENTATION OF COGENERATION AND GRID INTERCONNECTION

MOHAMMED A. DASHASH *, Manager REFAAT MAHFOUDHI, Ph.D., Cogen Lead Eng.

SAUDI ARAMCO KINGDOM OF SAUDI ARABIA Adopt technological development and use the SUMMARY With increasing awareness of energy best modern technologies conservation and environmental protection, the Arab World is moving to further improve energy At least two factors plead for this direction. On one conversion efficiency. hand, the four-hour time zone difference from The equivalent of over 2.7 MM bbl is being daily Eastern to Western Arab World makes it easy to burnt to fuel the thermal power plants that exchange power. On the other hand, this will help to represent 92% of the total Arab power generation. reduce the reserve capacity and save on This adds up to close to one billion barrels annually. corresponding Capital investment, fuel, and O&M At a conservative 30$ per barrel, this represents a expenses. There are already three distinct subdaily cost of over $81 Million. groups being interconnected in North Africa, within In this paper we will introduce two strategies with the Gulf countries, and in the other Middle East the ultimate objective to cut-off up to half of the Arab Countries. The same benefits will be current fuel consumption. maximized by connecting the Arab Countries power pool to Europe through the MEDRING system. Firstly, Cogeneration Technology is able to improve Reaching the mentioned objectives is not only a thermal efficiency from the current average of less major contribution to energy conservation but also than 25% to up to 80%. Just 1% improvement in leads intrinsically to better environmental power plant thermal efficiency represents 3 million protection. $/day in fuel cost savings. In addition, a wellIndex Terms Cogeneration, Energy Conservation, Power Generation, Efficiency, Grid Interconnection. designed and operated cogeneration plant will: Reduce unfriendly emissions by burning less fuel as a result of higher thermal efficiency Increase the decentralization of electrical generation Improve the reliability of electricity supply I. INTRODUCTION With the recent substantial increases of the fuel prices, finding strategies to lower the domestic oil consumption is becoming a first priority, not only for the net importers, but also for the oil exporter countries. This reality is also applicable for the Arab World where increasing awareness of energy conservation and environmental protection are being noticed, and pushing to further improve energy conversion efficiency. In fact, on one side the region major oil producers have seen a greater interest to save energy and export the high valued surplus of hydrocarbon products. On the other side, importer countries are taking all means to reduce their dependence on liquid and gas fuels to generate electricity. This paper is a contribution proposing two approaches to reach these goals and optimize the power generation within the Arab world. It is proven now, that cogeneration technology is able to bring the thermal efficiency from the current average of less than 25% to more than 80%. Saudi Arabia experience of implementing cogeneration will be

As an example, the Kingdom of Saudi Arabias experience of implementing cogeneration will be presented, in particular within its hydrocarbon facilities and desalination plants. This will include the existing facilities and the planned and on-going projects. Secondly, by interconnecting the power networks of all the adjacent Arab countries, the following benefits could be reached: Reduce generation reserves and enhance the system reliability Improve the economic efficiency of the electricity power systems Provide power exchange and strengthen the supply reliability

1-4244-0493-2/06/$20.00 2006 IEEE.

highlighted, both within its industrial hydrocarbon facilities and in the desalination plants. The second approach consists of integrating the individual grids into a single and reliable power pool. The substantial time zone difference from Eastern to Western Arab World makes it easy to exchange power during peak and low demand periods. This will also help reducing the reserve capacity and save on corresponding capital investment, fuel, and O&M expenses.

oil processing plants are all of them major power consumers, at the same time they need substantial quantities of high pressure steam.

36% power Efficiency 40% 54% 4% loss 90% fuel 129 % fuel 39% fuel Efficiency 90%

36% power

100 % fuel

29% loss

II. COGENERATION: CONCEPT & MODES Cogeneration is the sequential production of two or more forms of energy (i.e., electricity and heat, or electricity and water) from a common fuel source (i.e., natural gas or liquid fuel). Figure 1 illustrates a typical example of fuel savings expected from Cogeneration as compared to the separate generation of power and steam. To the left side of Figure 1, we have a traditional separate generation of steam and power with a typical assumption of 40% efficiency to generate electricity and 90% efficiency for a boiler supplying high pressure steam. On the right we have a cogeneration system that needs a fuel quantity referred to as 100% to generate a certain amount of power and heat. To get the same outputs from both systems, the separate generation system will need 29% more fuel than for cogeneration. Modern Cogeneration systems can achieve thermal efficiencies of up to 82%, making them far superior to traditional simple cycle power generation, which achieve a maximum of 40% in thermal efficiency. As the cost of fuel rises, the economic benefits of Cogeneration increase. In parallel, the new environmental requirements will be easier to meet as a result of utilizing less fuel. Cogeneration is used under different modes and technologies, depending on the target application. The main applications found today in the Arab World are the following: First, the combined cycle power plants using gas and steam turbines and leading to 45-50% thermal efficiency; Second, the desalination plants using either gas or steam turbines to supply electricity and heat to the MultiStage-Flash (MSF) desalination process and leading to 70-82% efficiency; Finally, the oil and gas plants where gas turbines are matched with Heat Recovery Steam Generators (HRSG) leading to 70-80% thermal efficiency. It is proven that petroleum industry is one of the most suitable industrial fields where cogeneration has a high potential of success. In fact, gas plants, refineries, and

35% heat

35% heat

(a) Separate Generation

Fig 1:

(b) Cogeneration

Typical example of fuel saving from Cogen

III. POWER GENERATION IN THE ARAB WORLD In this paragraph, we will present an overview of power generation in the Arab World with some key statistics on the current load demand and forecast growth, as well as the impact on fuel consumption. The total installed capacity is forecasted to increase form the current 121 GW to over 200 GW by year 2015 (Table 1). As shown in the power generation categories breakdown (Figure 2), 92% of this energy is obtained through thermal power plants burning fossil fuels [1]. For some countries, as for the Gulf region, this portion actually reaches 100%. Except for the few countries with some Hydro resources making less than 10% of the total capacity, all the others use technologies that burn fossil fuels to run their power plants. These plants have simple cycle thermal efficiencies as low as 13%, and even the new most efficient ones barely exceed 40%.

Table 1: Generation forecast and corresponding fuel cost in the Arab World

Instal. Year Cap. (GW) 2004 2015 121 203 Peak Load (GW) 98 170 Res. Cap. (%) 23 20 Fuel (MMbbl per Day) 2.7 4.5 Fuel Cost (Million$ per day) 81 136

As per Table 1, the ratio between the installed capacity and the peak load reflects the reserve capacity used for planned and unplanned outages. Even with 20%, forecasted for 2015, this ratio is still relatively high,

meaning that this portion of the resources is not used in an optimal way. Assuming a conservative figure of $30 for one barrel of crude oil, $81 MM is the fuel cost currently supported to run these power plants. By 2015, these figures are expected to double. Considering not only the major economic impact, but also the emission effect on the environment, energy conservation has become a high priority issue in the Arab world.

power plants are relatively recent and use new equipment with high performance technology.

GW

60 52 28 0 2004 2010 2015 2020 43 60

Diesel: 2.5% C.Cycle: 6%

Hydro: 8.5% Steam: 45%

Fig 3

Power demand forecast in Saudi Arabia

Gas: 38%

Fig 2:

Repartition of power generation types in the Arab World

One way to contribute resolving this problem is through cogeneration new technology. By burning less fuel, cogeneration will not only help meeting the goals regarding energy conservation, but also substantially reduce the unfriendly emissions in the atmosphere. As for the high reserve capacity, the grid interconnection is the way to improve the situation. ISSUE Low Efficiency High Reserve Capacity SOLUTION Cogeneration Grid Interconnection

Recent studies involving Saudi Arabias overall capacity, including Saudi Electricity Company (SEC) power plants, desalination plants and other power generators, revealed that if the average thermal efficiency was 45% rather that the current 29%, the savings on fuel would be $1.38 Billion per year (Table 2). This amount jumps to $3 Billion by 2020. This is based on the conservative assumption of an average fuel cost of $1.34 per MM Btu. The Unit cost of fuel is the weighted average of the current fuel mix including natural gas, diesel, and Heavy Fuel Oil (HFO). To the Kingdom of Saudi Arabia, Diesel cost is considered to be relatively expensive with $2.75 per MMBtu. The study revealed that 45% overall power generation efficiency Kingdom-wide is achievable if all new plants are built for cogeneration, with either steam export to industrial parks or to water desalination facilities. Table 2: Thermal efficiency impact on fuel cost

2004 Thermal efficiency (%) 29 28 1.34 3,870 45 28 1.34 2,490 1,380 2020 29 60 45 60

IV. CASE STUDY: SAUDI ARABIA COGENERATION IMPLEMENTATION Saudi Arabia is a natural example where the need to implement cogeneration has imposed itself within the oil and gas industry, desalination plants and in combined cycle power plants. The Kingdom of Saudi Arabias total generation capacity is approximately 31 GW. Out of that, 7 GW representing 23%, is supplied through cogeneration. As shown on Figure 3, the Kingdoms peak demand is forecasted to grow from the current 28 GW, to reach 60 GW by year 2020, based on annual average increase of 5%. Currently, power generation in Saudi Arabia uses 57% of gas fuel and 43% of liquid fuels that include Diesel, Crude Oil and Fuel Oil. The average thermal efficiency is higher than that of the Arab World but still around 34%. This is mainly due to that fact that many of the

Power Generated (GW) Unit Fuel Cost (composite; MBtu) Annual Fuel Cost ($MM / Yr) Fuel Savings ($MM / Yr)

1.34 1.34 8,290 5,340 2,950

Existing Facilities The Saudi Arabia Kingdoms existing cogeneration facilities can be segregated as per Table 3 into the desalination plants supplying over 3400 MW. The Saudi Electricity Company with 2 power plants totals 3 GW and the remaining 1 GW is generated by other large industries, including Saudi Aramco Company. Saudi Aramco has an ambitious on-going plan to implement cogeneration within its hydrocarbon facilities that will be adding over 1,700 MW.

Capacity (MW) Desalination Pants Combined Cycle Saudi Aramco Others Industries 3,425 3,000 155 910

Notes

The Arab world countries have a time zone difference of four (4) hours between the extreme west and east. This represents a major incentive to interconnect the power networks as the peak demands are not simultaneous in different countries. The power system interconnection has the following major benefits: 1. Avoid over building power generation facilities and thus reduce capital investment as well as reduce the overall fuel demand Share of reserves among the systems Improve system reliability Reduce Operating and Maintenance costs Improve efficiency Reduce pollution and meet national and international standards Help implement new emerging technologies

6 SWCC Plants (12%) Riyadh + Rabigh PPs Abqaiq Plant + RTR Yanbu Marafiq Desal.

Table 3: Existing Facilities Cogeneration in K.S.A.

2. 3. 4. 5. 6. 7.

Future Plans This section addresses future cogeneration plans where many projects are under construction or have been approved for short term implementation. For Saudi Aramco, the current peak load is approximately 2.8 GW, and is expected to exceed 3.5 GW by 2010. Then, a steady 3% annual increase is anticipated, to reach about 5 GW by 2020. With this continuing load growth, cogeneration is expected to be part of all future plants and facilities. In fact, Saudi Aramco has conducted a comprehensive study on selected gas plants and refineries to reduce the energy cost that the company bares to run these facilities. The results proved that cogeneration can lead to annual savings of 54% to 60%. By end of 2006, on-going projects will deliver over 1,700 MW (Table 4). Table 4: Cogeneration future plans in K.S.A.

Capacity (MW) Saudi Aramco Desalination Pants Sadaf Marafiq-Jubail 1,750 5,000 250 2,400 Completion 2004 / 2006 2010 2005 2007

Table 5: Current and forecast reserve capacity

Year Installed Capacity (GW) Reserve Capacity (%) 1990 2004 2015 Forecast 203 20

74 33

121 23

The current reserve capacity of the Arab countries is close to 23% of the total installed capacity of 121GW (Table 5). Lowering this value from the expected 20% to the more acceptable value of 12% through grid interconnection, will not only save a capital cost of 11 billion dollars by not building an additional capacity of 12 GW, but will also have major impact on reducing fuel burning pollution. An optimal grid interconnection can help reach this goal and eliminate the equivalent emission released from about 9 million cars. Table 6: Distribution of power generation capacity in the Arab World

Capacity (GW) Capacity (%) 49 34 17

Regarding the desalination plants, Saudi Arabia will consolidate its world leading position by building 5,000 MW over the next five (5) years. Other large companies are getting involved into Cogen, like the SADAF (one of the companies under SABIC, Saudi Basic Industries Corporation), 250 MW project and Marafiq 2,400 MW planned for the Jubail industrial area. V. ELECTRICAL NETWORKS INTERCONNECTION

GCC Countries Middle East North Africa

59 42 20

Table 6 below shows the distribution of the Arab World generation capacity among three distinct groups: GCC, North Africa and the other Middle East countries. The GCC region has the highest generation capacity, which satisfies the areas oil and gas large industrial base.

Together, Saudi Arabia and Egypt represent near 41% of the total capacity. Only for these two (2) countries, the avoidance of building 10% of their total installed capacity projected for year 2015 will save around $5 billion US in Capital Costs. The grid interconnection is being achieved following the geographical distribution. Starting with the GCC interconnection including the six Gulf Countries. Then, the EIJLST interconnection including Egypt, Iraq, Jordan, Lebanon, Syria and Turkey. Finally, the North African Arab countries are already interconnected together, but there is still room to increase the power capacity that can be exchanged. On the other hand, many preliminary studies are already seriously considering the eventual interconnection of the European Electrical grid through the Mediterranean Ring called MEDRING. It is very important to finalize and coordinate the overall Arab system within a reliable single power pool, and adopt the highest international standards, before integrating the European grid through Spain, Italy and Turkey. VI. CONCLUSION As a summary, we first introduced the Cogeneration concept leading to improved energy utilization by burning less fuel and reducing unfriendly emissions. Then, we gave an overview of power generation statistics in the Arab World, underlining the fact that more that 92% of its generation is obtained by burning the equivalent of close to one billion barrels of crude oil annually with poor thermal efficiencies. As an example to improve this situation, we presented a case study involving Saudi Arabia and its leading role into cogeneration implementation. We covered its existing facilities that already make 24% of its total generation, and shed some light on the future plans. Finally, we introduced the power system interconnection between Arab countries as a must and basic contribution to reach the objectives regarding energy conservation and the tighter environmental regulation from national and international standards. A coordinated action can lower the reserve Capacity to 12%, and save 11 billion dollars on Capital Cost, in addition to the fuel, Operating and Maintenance, and other expenses. References [1] M. Badawi, Towards an Arab Power Market: Options and Challenges. May 2002. Report prepared by the Direction of Technical Division, Arab Fund for Economic and Social Development Kuwait.

You might also like

- Voltage Depending Load Models. Validation by Voltage Step TestsDocument6 pagesVoltage Depending Load Models. Validation by Voltage Step TestssunitharajababuNo ratings yet

- Design Objectives For Spring Mechanism Generator Circuit Breaker With High ReliabilityDocument6 pagesDesign Objectives For Spring Mechanism Generator Circuit Breaker With High ReliabilitysunitharajababuNo ratings yet

- Web - Itu.edu - TR Yumakk Downloads Lab Notes Distance Protection v1Document6 pagesWeb - Itu.edu - TR Yumakk Downloads Lab Notes Distance Protection v1sunitharajababuNo ratings yet

- Simulation With Controlled Fourier Spectrum Shifting For Efficient Computation of Power System TransientsDocument5 pagesSimulation With Controlled Fourier Spectrum Shifting For Efficient Computation of Power System TransientssunitharajababuNo ratings yet

- Pesgm2006 000102Document6 pagesPesgm2006 000102sunitharajababuNo ratings yet

- HDP Based Optimal Control of A Grid Independent PV SystemDocument6 pagesHDP Based Optimal Control of A Grid Independent PV SystemsunitharajababuNo ratings yet

- Estimation of Transformer Saturation Characteristics From Inrush Current WaveformsDocument1 pageEstimation of Transformer Saturation Characteristics From Inrush Current WaveformssunitharajababuNo ratings yet

- A Concept For Dual Gaseous and Electric Energy Transmission: P. Favre-Perrod, Student Member, IEEE, and A. BitschiDocument7 pagesA Concept For Dual Gaseous and Electric Energy Transmission: P. Favre-Perrod, Student Member, IEEE, and A. BitschisunitharajababuNo ratings yet

- Lightning Characterization For Flashover Rate Calculation of Overhead Transmission LinesDocument6 pagesLightning Characterization For Flashover Rate Calculation of Overhead Transmission LinessunitharajababuNo ratings yet

- Effects of Multi-Objective Genetic Rule Selection On Short-Term Load Forecasting For Anomalous DaysDocument7 pagesEffects of Multi-Objective Genetic Rule Selection On Short-Term Load Forecasting For Anomalous DayssunitharajababuNo ratings yet

- A Double Logarithmic Approximation of Carson's Ground-Return ImpedanceDocument1 pageA Double Logarithmic Approximation of Carson's Ground-Return ImpedancesunitharajababuNo ratings yet

- Reality Check Initiative On The Equivalency of 8/20 Versus 10/350 Waveforms For Testing Surge-Protective DevicesDocument8 pagesReality Check Initiative On The Equivalency of 8/20 Versus 10/350 Waveforms For Testing Surge-Protective DevicessunitharajababuNo ratings yet

- Pesgm2006 000078Document6 pagesPesgm2006 000078sunitharajababuNo ratings yet

- Pesgm2006 000091Document8 pagesPesgm2006 000091sunitharajababuNo ratings yet

- Wide-Area Robust H /H Control With Pole Placement For Damping Inter-Area OscillationsDocument7 pagesWide-Area Robust H /H Control With Pole Placement For Damping Inter-Area OscillationssunitharajababuNo ratings yet

- Modeling of VSC-HVDC and Control Strategies For Supplying Both Active and Passive SystemsDocument6 pagesModeling of VSC-HVDC and Control Strategies For Supplying Both Active and Passive SystemssunitharajababuNo ratings yet

- Analysis of Wide-Area Frequency Measurement of Bulk Power SystemsDocument8 pagesAnalysis of Wide-Area Frequency Measurement of Bulk Power SystemssunitharajababuNo ratings yet

- Design of A Fast Transient Stability Control Scheme in Power SystemDocument8 pagesDesign of A Fast Transient Stability Control Scheme in Power SystemsunitharajababuNo ratings yet

- Assessing The Competitiveness of Loss Allocation Methods in A Deregulated Electricity MarketDocument8 pagesAssessing The Competitiveness of Loss Allocation Methods in A Deregulated Electricity MarketsunitharajababuNo ratings yet

- Pesgm2006 000082Document1 pagePesgm2006 000082sunitharajababuNo ratings yet

- Strategic Bidding in Electricity Spot Markets Under Uncertainty: A RoadmapDocument8 pagesStrategic Bidding in Electricity Spot Markets Under Uncertainty: A RoadmapsunitharajababuNo ratings yet

- Optimization of Storage Devices For Regenerative Braking Energy in Subway SystemsDocument6 pagesOptimization of Storage Devices For Regenerative Braking Energy in Subway SystemssunitharajababuNo ratings yet

- Hybrid HVDC Converters and Their Impact On Power System Dynamic PerformanceDocument6 pagesHybrid HVDC Converters and Their Impact On Power System Dynamic PerformancesunitharajababuNo ratings yet

- A Wavelet Power Based Algorithm For Synchronous Generator ProtectionDocument6 pagesA Wavelet Power Based Algorithm For Synchronous Generator ProtectionsunitharajababuNo ratings yet

- Pesgm2006 000073Document1 pagePesgm2006 000073sunitharajababuNo ratings yet

- New Market Power Driven Multistage Trans-Mission Expansion Strategy in Power MarketsDocument8 pagesNew Market Power Driven Multistage Trans-Mission Expansion Strategy in Power MarketssunitharajababuNo ratings yet

- Robust Non-Communication Line Protection Scheme Using Novel QuantitiesDocument8 pagesRobust Non-Communication Line Protection Scheme Using Novel QuantitiessunitharajababuNo ratings yet

- Unit Commitment With Primary Frequency Regulation ConstraintsDocument1 pageUnit Commitment With Primary Frequency Regulation ConstraintssunitharajababuNo ratings yet

- Optimization of MPPT Step Si in Stand-Alone Solar Pumping SystemsDocument6 pagesOptimization of MPPT Step Si in Stand-Alone Solar Pumping SystemssunitharajababuNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CESC Budge Budge VT ReportDocument51 pagesCESC Budge Budge VT ReportMainak Dutta100% (8)

- Solar Power Monitoring SystemDocument8 pagesSolar Power Monitoring SystemDebayani MishraNo ratings yet

- Ae430 450MC 144Document2 pagesAe430 450MC 144RafiurRahmanNo ratings yet

- Termicki Proracun Parnog KotlaDocument1 pageTermicki Proracun Parnog KotlavjakovljevicNo ratings yet

- FINAL EXAMINATION ME 213 (2nd COVID EDITION)Document2 pagesFINAL EXAMINATION ME 213 (2nd COVID EDITION)Joshua S. LanzaderasNo ratings yet

- Traina 250Wp PDFDocument2 pagesTraina 250Wp PDFSherifImamNo ratings yet

- Combustion CurveDocument18 pagesCombustion CurvesriNo ratings yet

- Datasheet - Mục III.6 Tuabin Và BOP -67 Cảm Biến Hall Hãng Emerson PR9376Document2 pagesDatasheet - Mục III.6 Tuabin Và BOP -67 Cảm Biến Hall Hãng Emerson PR9376namdongvan8143No ratings yet

- Thin Film Solar Cell WikiDocument7 pagesThin Film Solar Cell Wikivishrao1984No ratings yet

- Study On Transparent Solar Cells For Windows That Generate ElectricityDocument13 pagesStudy On Transparent Solar Cells For Windows That Generate Electricityhari ananthagiriNo ratings yet

- Animated Soot BlowerDocument15 pagesAnimated Soot BlowerPrudhvi RajNo ratings yet

- Zytech Solar PanelsDocument16 pagesZytech Solar PanelsTorres_raycoNo ratings yet

- FM Module I - Turbines - Note - PPTDocument52 pagesFM Module I - Turbines - Note - PPT916 Maneesh nn ME BNo ratings yet

- Design of Single Cylinder 4-Stroke Diesel EngineDocument10 pagesDesign of Single Cylinder 4-Stroke Diesel EngineNidishNo ratings yet

- 46 50 A Review On Solar Tracking SystemsDocument5 pages46 50 A Review On Solar Tracking SystemsHussein RamadanNo ratings yet

- Pi Pingshan II InternetDocument4 pagesPi Pingshan II Internetnguyenhuutan91No ratings yet

- Top End Overhaul Parts List.Document3 pagesTop End Overhaul Parts List.Shabbir AhmedNo ratings yet

- Windsor Steampac WB Boiler Brochure 2019Document2 pagesWindsor Steampac WB Boiler Brochure 2019AnthonyNo ratings yet

- Criteria Critical Line List For Formal Analysis Using CAESAR - PipestressDocument2 pagesCriteria Critical Line List For Formal Analysis Using CAESAR - PipestressSargunam SankaravadivelNo ratings yet

- Flow Pabrik AmmoniaDocument1 pageFlow Pabrik AmmoniafaishalmiftahulhudaNo ratings yet

- 17 181 FirstSolar Thompson PDFDocument33 pages17 181 FirstSolar Thompson PDFGideon Oyibo0% (1)

- Study On Solar Power PlantDocument26 pagesStudy On Solar Power PlantPrakash MarathiNo ratings yet

- AwardedBiomass2014 04-30Document6 pagesAwardedBiomass2014 04-30Norman OrbienNo ratings yet

- Solution To Exam No. 2Document5 pagesSolution To Exam No. 2mozam haqNo ratings yet

- Report On Visit: Boiler and Oil Burner ServiceDocument4 pagesReport On Visit: Boiler and Oil Burner ServiceGaurav MaithilNo ratings yet

- Ma TP2 01+Document251 pagesMa TP2 01+Arvind ShuklaNo ratings yet

- Diesel Generator Sets Inventory ListingDocument4 pagesDiesel Generator Sets Inventory ListingIvan DumontNo ratings yet

- Comparison of Concentrated Solar Power and Photovoltaic TechnologiesDocument3 pagesComparison of Concentrated Solar Power and Photovoltaic TechnologiesItraru Emmanuel MundugoNo ratings yet

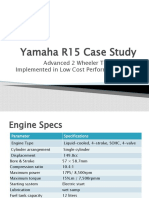

- Yamaha R15 Case Study: Advanced 2 Wheeler Technologies Implemented in Low Cost Performance BikesDocument10 pagesYamaha R15 Case Study: Advanced 2 Wheeler Technologies Implemented in Low Cost Performance BikesAdinath UpadhyeNo ratings yet

- Assignment 2: Mechanical Engineering Dept. CEME NUST 1Document4 pagesAssignment 2: Mechanical Engineering Dept. CEME NUST 1HajiasifAliNo ratings yet