Professional Documents

Culture Documents

Noncatalytic Chemical Vapor Deposition of Graphene On High-Temperature Substrates For Transparent Electrodes

Uploaded by

Atul BishtOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Noncatalytic Chemical Vapor Deposition of Graphene On High-Temperature Substrates For Transparent Electrodes

Uploaded by

Atul BishtCopyright:

Available Formats

Applied Physics Letters

Noncatalytic chemical vapor deposition of graphene on high-temperature substrates for transparent electrodes

Jie Sun,1, a) Matthew T. Cole,2 Niclas Lindvall,1 Kenneth B. K. Teo,3 and August Yurgens1

1)

Department of Microtechnology and Nanoscience, Quantum Device Physics Laboratory, Chalmers University of Technology, S-41296 Gothenburg, Sweden 2) Department of Engineering, Electrical Engineering Division, University of Cambridge, 9 JJ Thomson Avenue, CB3 0FA Cambridge, United Kingdom 3) AIXTRON Nanoinstruments Ltd., Swavesey, CB24 4FQ Cambridge, United Kingdom (Dated: 18 December 2011)

A noncatalytic chemical vapor deposition mechanism is proposed, where high precursor concentration, long deposition time, high temperature, and at substrate are needed to grow large-area nanocrystalline graphene using hydrocarbon pyrolysis. The graphene is scalable, uniform, and with controlled thickness. It can be deposited on virtually any nonmetallic substrate that withstands 1000 o C. For typical examples, graphene grown directly on quartz and sapphire shows transmittance and conductivity similar to exfoliated or metalcatalyzed graphene, as evidenced by transmission spectroscopy and transport measurements. Raman spectroscopy conrms the sp2 -C structure. The model and results demonstrate a promising transfer-free technique for transparent electrode production. Graphene, a monolayer of sp 2 carbon atoms, has received much attention. The use of graphene in transparent electronics is one of its most promising applications.1 Apart from its high transparency/conductivity, the exibility and ease of integration on a variety of substrates are obvious advantages. 30-inch graphene has been demonstrated by virtue of the recent advances in chemical vapor deposition (CVD),2 which is compatible with the existing semiconductor technology.3 Nevertheless, the necessity of etching the metal catalyst and transfer of graphene to foreign substrates hampers wide industrialization. Thus, eorts are put into the metal-free growth of graphene on materials including SiO2 ,46 Al2 O3 ,7 MgO,8 etc. To date, however, the graphitization process on dielectrics is poorly understood while the experiments are largely experience based. Recently, we have shown that large-area uniform graphene can be grown on virtually any hightemperature substrates, on Si3 N4 or HfO2 , for instance.9 In this letter, we provide a broader and deeper insight, discussing in detail the growth mechanism of graphene directly on insulators. As an example, we show our results on graphene on quartz and sapphire, hinting at the future prospects of the transfer-free graphene for transparent electrodes. Bulk graphite is usually made at >3000 o C and catalysis is needed to lower the temperature.10 However, nanoscale graphene akes form without any catalysts at merely 1000 o C. For example, carbon black which is produced massively by natural gas pyrolysis1114 is nothing else but chaotically connected graphene akes.11 Although widely used in industry, this process has so far been overlooked for making large-area graphene. Here, we show that macroscopically amorphous carbon black can be turned into textured graphene thin lms when the carbon precursor concentration and growth temperature are high, also requiring a relatively long deposition time and at substrate. Fig. 1(a) illustrates the CVD reactor used in this work. The middle region is heated to 1000 o C while the left and right sides are <600 o C. There is no material deposition in the right zone because of the reduced CH4 decomposition eciency at lower temperature. Carbon black is seen on the left, as an evidence of the CH4 dissociation in the middle zone. The easiest way to distinguish graphene from carbon black is to observe their optical appearances. The as-grown graphene is smooth and, on any high-temperature substrate, keeps its metallic luster (see Fig. 1(b)) for hundreds of layers,9 whereas carbon

a) Electronic

mail: jiesu@chalmers.se.

FIG. 1. (Color online) (a) Schematic of the hot-wall CVD system used in this study, indicating zones where graphene and carbon black are deposited. The arrows indicate the direction of gas ow. (b) Photo of bare 300 nm SiO2 /Si (left) and with coated nominal monolayer graphene (middle) and 70 nm graphite (right). (c) Atomic force microscopy micrograph of the middle sample in (b), where ra 1 nm.

Applied Physics Letters black is dull black even for thinner lms. Fig. 1(b) shows the photo of (right to left) 70 nm thick graphite, monolayer graphene, and the bare substrate (300 nm SiO2 /Si), respectively. The growth recipe is similar to our previous work, where the thickness is controllable from nominally submonolayer to thick graphite.9 Transmission electron microscopy reveals that the middle sample in Fig. 1(b) is composed of primarily 10 nm large monolayer graphene crystallites.15 The high density of grain boundaries is fundamental which results in strong scattering of charge carriers and makes such graphene unsuitable for transistors. Nonetheless, this does not reduce its value for applications where transparency of electrodes (e.g. solar cells/displays) or their thickness (e.g. molecular electronics) are more important than the mobility. Indeed, the optical similarity between this graphene and exfoliated- or Cu-catalyzed monolayer graphene16 is evidenced by ellipsometry measurements.15 Fig. 1(c) is an atomic force microscopy image15 of the middle sample in Fig. 1(b). The arithmetic average roughness ra is 1 nm, which is reasonable for nanocrystalline graphene resting on thermally grown SiO2 (ra is 0.2 nm). Fig. 2 shows the transmission spectra of nominal monolayer graphene deposited on quartz and sapphire.15 . The transmittance of graphene is generally independent of the light wavelength,17 except a dip at 270 nm, which is due to the exciton-shifted van Hove singularity in the graphene density of states.18 After the coating, the transmittances of quartz and sapphire are reduced by 2-3%, values similar to exfoliated graphene.17 The inset of Fig. 2(a) shows the Fourier transform infrared spectroscopy (FTIR) measurements on the same samples. The spectra have no C-related peaks after CVD, implying atomic-scale thickness. The curves before and after graphene growth are very similar (no additional features in 3000-3700 cm1 range),19,20 suggesting the lack of OH groups. This oers an advantage over the wet-transferred graphene, where H2 O is likely to be trapped at the interfaces. The Raman spectra of the graphene on quartz and sapphire are displayed in the inset of Fig. 2(b). The well-dened Raman peaks dierentiate our thin lms from amorphous C (a-C).21 In fact, atomically thin a-C lms have never been realized by CVD.22 The G band centered at 1600 cm1 and the 2D band at 2695 cm1 are well resolved, which are signatures of sp2 graphitic materials. D peaks at 1353 cm1 are also seen. This Raman mode is forbidden in perfect graphitic structure and only becomes active in the presence of disorder.23 In our case, the laser spot is 10 m and covers numerous grain boundaries of the nanocrystalline graphene, which naturally results in large D signals. Consequently, high-order G+D bands at 2946 cm1 are visible. The ratio of D- and G peak heights24 allows estimation of the average distance between defects 7-9 nm, consistent with the grain size 10 nm of our thin lms.15 Hall-bar devices are fabricated from these samples by photolithography.15 Room-temperature four-terminal electrical measurements indicate the sheet

2 resistance Rs of 2.9 and 13 k/ for the quartz- and sapphire-supported graphene, respectively. Again, Rs is comparable to that of standard graphene.18 Thermal dissociation of methane is described as CH4 =C+2H2 (H =75.6 kJ/mol). Although CH4 is one of the most stable organic molecules due to a strong CH bond of 440 kJ/mol,25 the reaction readily occurs at 300 o C and becomes nearly complete at 1300 o C.14 When a metal catalyst is present,2,3,16 both the hydrocarbon decomposition and graphene formation are boosted. Consequently, graphene grows rapidly at a very low hydrocarbon partial pressure.16 Without using metals, which we refer to as noncatalytic graphene CVD,10,26 the deposition requires a much higher methane concentration (200 vs. 0.01 mbar) and longer growth time (30 vs. 5 min).9,16 The graphene thin-lm formation on nonmetallic substrates appears to be dierent from the mechanism common to e.g. metallic thin lms. Indeed, graphene akes are readily formed in the gas mixture surrounding a hot substrate. The akes landing on the substrate can have various fates depending on their sizes. Large enough akes would stick and stay at the surface, reminiscent of the critical-size nuclei in the common thin-lm nucleation theory.27 The smaller akes would not adhere

FIG. 2. (Color online) Transmittance spectra of the noncatalytic CVD graphene on (a) quartz and (b) sapphire. The curves in (b) have superimposed interference fringes from the sapphire substrates. Inserts: (a) FTIR spectra of the quartz and sapphire before and after the noncatalytic graphene growth; (b) Raman spectra (514 nm, 3 mW) of the samples. Gr denotes graphene.

Applied Physics Letters to the substrate strongly enough to sustain high-energy thermal vibrations and would leave the substrate, unless they happened to be near the stable akes (nuclei) that are already present at the surface and make bonds to them. Stacking of the akes on top of each other is improbable because the out-of-plane bonding energy between the akes is lower than their adhesion to the substrate, as in the case of SiO2 ,28,29 impeding formation of the second layer. Reorientation and alignment of the nm-sized akes requires temperatures >2000 o C,30 and is unlikely to occur in our case, resulting in disordered thin lms. In this picture, the usual growth mechanism, when single atoms have some time to diuse along the surface and adjoin the stable nuclei, is somehow suppressed, much likely because of the high temperature and the weak adhesion of single atoms to substrate. Next-layers growth, although initially broken short, is still possible after the rst graphene layer is formed. Due to a lower grapheneto-graphene cohesion energy (compared with the adhesion to SiO2 ),28,29 larger akes would now be needed to make stable islands and initiate the growth of the second layer. In principle, the formation of the second- and subsequent layers should then take longer time compared to the rst one. However, this diculty might be compensated for by many defects and dangling bonds at the surface from a nonideality of the rst-layer coverage,30 resulting in more sites for graphene ake adsorption. Importantly, all this means that the graphene thin lm will grow much quicker with nanoakes forming already in the gas rst, making high precursor pressure and relatively long deposition time crucial. A hot and at substrate helps preventing large porous lumps of carbon black to form,1114 as there are no sites or bonding strength to attach misplaced akes with wrong orientation.15 A similar example can be found in liquid phase deposition, where at substrates help sol particles to form thin lms as opposed to the otherwise favorable clumpy precipitates.19,20 The discussion above can be generalized to explain graphene growth on any nonmetallic substrate that withstands 1000 o C by CVD using hydrocarbons, not limited to CH4 . Obviously, the substrate materials and their preparation play an important role in the growth kinetics. On specially annealed SiO2 where there are possibly less dangling bonds, the growth takes much longer time, but also leads to higher quality of the graphene.31 In summary, we have proposed a noncatalytic graphitization mechanism in graphene CVD directly on arbitrary high-temperature insulating substrates. Four experimental conditionshigh carbon precursor pressure, long growth time, high temperature, and at substrateare needed to modify carbon black deposition into selfassembled nanocrystalline graphene thin lm. The asproduced graphene is uniform, scalable, and has properties similar to standard graphene, as conrmed by transmission, FTIR and Raman spectra, as well as transport measurements. This work should stimulate further

3 studies on graphene grown in metal-free processes which are important for applications involving transparent electrodes.

Zhu, Z. Sun, Z. Yan, Z. Jin, and J. M. Tour, ACS Nano 5, 6472 (2011). 2 S. Bae, H. Kim, Y. Lee, X. Xu, J.-S. Park, Y. Zheng, J. Balakrishnan, T. Lei, H. R. Kim, Y. I. Song, Y.-J. Kim, K. S. Kim, B. Ozyilmaz, J.-H. Ahn, B. H. Hong, and S. Iijima, Nature Nanotechnol. 5, 574 (2010). 3 X. Li, W. Cai, J. An, S. Kim, J. Nah, D. Yang, R. Piner, A. Velamakanni, I. Jung, E. Tutuc, S. K. Banerjee, L. Colombo, and R. S. Ruo, Science 324, 1312 (2009). 4 T. Takami, S. Ogawa, H. Sumi, T. Kaga, A. Saikubo, E. Ikenaga, M. Sato, M. Nihei, and Y. Takakuwa, E-J. Surf. Sci. Nanotechnol. 7, 882 (2009). 5 A. Ismach, C. Druzgalski, S. Penwell, M. Zheng, A. Javey, J. Bokor, and Y. Zhang, Nano Lett. 10, 1542 (2010). 6 J. Hofrichter, B. N. Szafranek, M. Otto, T. J. Echtermeyer, M. Baus, A. Majerus, V. Geringer, M. Ramsteiner, and H. Kurz, Nano Lett. 10, 36 (2010). 7 Y. Miyasaka, A. Nakamura, and J. Temmyo, Jpn. J. Appl. Phys. 50, 04DH12 (2011). 8 M. H. Rummeli, A. Bachmatiuk, A. Scott, F. Borrnert, J. H. Warner, V. Homan, J.-H. Lin, G. Cuniberti, and B. Buchner, ACS Nano 4, 4206 (2010). 9 J. Sun, N. Lindvall, M. T. Cole, K. B. K. Teo, and A. Yurgens, Appl. Phys. Lett. 98, 252107 (2011). 10 A. Oya and H. Marsh, J. Mat. Sci. 17, 309 (1982). 11 J. Biscoe and B. E. Warren, J. Appl. Phys. 13, 364 (1942). 12 L. Fulcheri and Y. Schwob, Int. J. Hydrogen Energy 20, 197 (1995). 13 N. Z. Muradov and T. N. Veziroglu, Int. J. Hydrogen Energy 30, 225 (2005). 14 A. W. Weimer, J. Dahl, J. Tamburini, A. Lewandowski, R. Pitts, C. Bingham, and G. C. Glatzmaier, Proceedings of the 2001 US DOE hydrogen program review NREL/CP-570-30535 (2001). 15 See supplementary material at http://dx.doi.org/10.1063/1.3602921 for details. 16 J. Sun, N. Lindvall, M. T. Cole, K. T. T. Angel, T. Wang, K. B. K. Teo, D. H. C. Chua, J. Liu, and A. Yurgens, IEEE T. Nanotechnol. in press, doi: 10.1109/TNANO.2011.2160729. 17 R. R. Nair, P. Blake, A. N. Grigorenko, K. S. Novoselov, T. J. Booth, T. Stauber, N. M. R. Peres, and A. K. Geim, Science 320, 1308 (2008). 18 F. Bonaccorso, Z. Sun, T. Hasan, and A. C. Ferrari, Nature Photon. 4, 611 (2010). 19 J. Sun and Y. C. Sun, Chin. J. Chem. 22, 661 (2004). 20 S. Jie, H. Lizhong, W. Zhaoyang, and D. Guotong, Mat. Sci. Forum 475-479, 1725 (2005). 21 M. A. Tamor and W. C. Vassell, J. Appl. Phys. 76, 3823 (1994). 22 J. Kotakoski, A. V. Krasheninnikov, U. Kaiser, and J. C. Meyer, Phys. Rev. Lett. 106, 105505 (2011). 23 A. C. Ferrari and J. Robertson, Phys. Rev. B 61, 14095 (2000). 24 M. M. Lucchese, F. Stavale, E. H. M. Ferreira, C. Vilani, M. V. O. Moutinho, R. B. Capaz, C. A. Achete, and A. Jorio, Carbon 48, 1592 (2010). 25 G. I. Kozlov and V. G. Knorre, Combust. Flame 6, 253 (1962). 26 J. K. Yu, S. Ueno, H. X. Li, and K. Hiragushi, J. Europ. Ceramic Soc. 19, 2843 (1999). Some high-temperature dielectrics can be catalytic in powder form; nevertheless, at substrates can hardly dissolve or react with C and therefore play no or weak catalytic role in graphitization. 27 M. Ohring, Materials Science of Thin Films: Deposition and Structure (Academic Press, San Diego, CA, 2002). 28 S. P. Koenig, N. G. Boddeti, M. L. Dunn, and J. S. Bunch, Nature Nanotechnol. 6, 543 (2011). 29 Z. Liu, J. Z. Liu, Y. Cheng, and Q. Zheng, arXiv:1104.1469v1, unpublished. 30 J. Abrahamson, Carbon 11, 337 (1973).

1 Y.

Applied Physics Letters

31 J.

4

Wang, G. Yu, and Y. Liu, J. Am. Chem. Soc. 133, 17548 (2011).

Chen, Y. Wen, Y. Guo, B. Wu, L. Huang, Y. Xue, D. Geng, D.

You might also like

- PropertiesDocument28 pagesPropertiesAnonymous RNlMDeZyosNo ratings yet

- D. C. Elias, R. R. Nair, T. M. G. Mohiuddin, S. V. Morozov, P. Blake, M. P. Halsall, A. C. Ferrari, D. W. Boukhvalov, M. I. Katsnelson, A. K. Geim, K. S. NovoselovDocument20 pagesD. C. Elias, R. R. Nair, T. M. G. Mohiuddin, S. V. Morozov, P. Blake, M. P. Halsall, A. C. Ferrari, D. W. Boukhvalov, M. I. Katsnelson, A. K. Geim, K. S. NovoselovAkhay SamalNo ratings yet

- Boron Nitride Substrates For High Quality Graphene ElectronicsDocument20 pagesBoron Nitride Substrates For High Quality Graphene ElectronicsvskNo ratings yet

- Epl 335: Low Dimensional Physics Term Paper On Graphene: Submitted By: Aishwarya Kumar 2008PH10605Document13 pagesEpl 335: Low Dimensional Physics Term Paper On Graphene: Submitted By: Aishwarya Kumar 2008PH10605GopiKrishnaNo ratings yet

- 04-Graphene Nanosheet, Al2O3 CompositeDocument7 pages04-Graphene Nanosheet, Al2O3 CompositeKaivalya SawantNo ratings yet

- GRAPHENEDocument31 pagesGRAPHENEFaruque AnsariNo ratings yet

- Ref 1Document6 pagesRef 1Aashish SinghalNo ratings yet

- Graphene-Carbon in Two DimensionsDocument21 pagesGraphene-Carbon in Two DimensionsEbru CoşkunNo ratings yet

- Graphene: Status and ProspectsDocument8 pagesGraphene: Status and Prospects朱佳芬No ratings yet

- Role of Kinetic Factors in Chemical Vapor Deposition Synthesis of Uniform Large Area Graphene Using Copper CatalystDocument6 pagesRole of Kinetic Factors in Chemical Vapor Deposition Synthesis of Uniform Large Area Graphene Using Copper CatalystJuancho PachonNo ratings yet

- Graphite Ullman PDFDocument10 pagesGraphite Ullman PDFebalideNo ratings yet

- Raman Spectroscopy of Graphene and Graphite: Disorder, Electron-Phonon Coupling, Doping and Nonadiabatic EffectsDocument11 pagesRaman Spectroscopy of Graphene and Graphite: Disorder, Electron-Phonon Coupling, Doping and Nonadiabatic EffectsArka GhoshNo ratings yet

- Graphene and Its ApplicationDocument11 pagesGraphene and Its ApplicationsnzaimahNo ratings yet

- Ion Beam Based Techniques For Mercury Cadmium Telluride Infrared DetectorsDocument6 pagesIon Beam Based Techniques For Mercury Cadmium Telluride Infrared DetectorsmizugodNo ratings yet

- Seminar Report 2010 - 2011 Graphene Transistor: Silicon SemiconductorDocument25 pagesSeminar Report 2010 - 2011 Graphene Transistor: Silicon SemiconductorcvmgreatNo ratings yet

- Multilayer Graphene Synthesized by CVD Using Liquid Hexane As The Carbon PrecursorDocument4 pagesMultilayer Graphene Synthesized by CVD Using Liquid Hexane As The Carbon PrecursorcrisoforoNo ratings yet

- Zn3p2 Photovolt CellsDocument11 pagesZn3p2 Photovolt CellseveltoncNo ratings yet

- Balandin 2008Document6 pagesBalandin 2008Eder FurlanNo ratings yet

- Raman and XRD Cualo2Document5 pagesRaman and XRD Cualo2El Hadj GueyeNo ratings yet

- Micromachines 11 01128Document11 pagesMicromachines 11 01128gjdapromiseNo ratings yet

- D. Bono Et Al - Intrinsic Susceptibility and Bond Defects in The Novel 2D Frustrated Antiferromagnet Ba2Sn2ZnCr7pGa10-7pO22Document5 pagesD. Bono Et Al - Intrinsic Susceptibility and Bond Defects in The Novel 2D Frustrated Antiferromagnet Ba2Sn2ZnCr7pGa10-7pO22Po48HSDNo ratings yet

- One Nanometer Thin Carbon Nanosheets With Tunable Conductivity and StiffnessDocument5 pagesOne Nanometer Thin Carbon Nanosheets With Tunable Conductivity and StiffnessManav SaxenaNo ratings yet

- Final Repoort NewDocument25 pagesFinal Repoort NewReshma KrishnanNo ratings yet

- Thermal Conductivity of Multiwalled Carbon NanotubesDocument6 pagesThermal Conductivity of Multiwalled Carbon NanotubesAyad DariNo ratings yet

- Superconducting Properties of GranuDocument14 pagesSuperconducting Properties of GranuMehvish TaqiNo ratings yet

- Thermal Transport in Suspended and Supported Monolayer Graphene Grown by Chemical Vapor DepositionDocument7 pagesThermal Transport in Suspended and Supported Monolayer Graphene Grown by Chemical Vapor DepositionTai-Yuan HsuNo ratings yet

- Exchange IomDocument10 pagesExchange Iombreadfalling752No ratings yet

- N Comms 2630Document7 pagesN Comms 2630Alexandre HenriquesNo ratings yet

- Structure, Defects, and Microwave Dielectric Properties of Al-Doped and Al/Nd Co-Doped Ba ND Ti O CeramicsDocument12 pagesStructure, Defects, and Microwave Dielectric Properties of Al-Doped and Al/Nd Co-Doped Ba ND Ti O CeramicsKézia BarretoNo ratings yet

- Copper ElectrorefiningDocument13 pagesCopper ElectrorefiningnatyvaleskaNo ratings yet

- BIG Expanding Graphene Through ChemistryDocument10 pagesBIG Expanding Graphene Through ChemistryPropertywizzNo ratings yet

- Layer Compression and Enhanced Optical Properties of Few-Layer Graphene Nanosheets Induced by Ion IrradiationDocument18 pagesLayer Compression and Enhanced Optical Properties of Few-Layer Graphene Nanosheets Induced by Ion IrradiationCarla Míriam FerreiraNo ratings yet

- Crossover in The Magnetic Properties of Nanostructured MetalsDocument5 pagesCrossover in The Magnetic Properties of Nanostructured MetalsviniciushiperNo ratings yet

- Cs Na SC F6 CR JLCorrDocument19 pagesCs Na SC F6 CR JLCorrFÍSICA ENSINONo ratings yet

- Electrical Properties of SB and Cr-Doped Pbzro - Pbtio - PBMG NB O CeramicsDocument8 pagesElectrical Properties of SB and Cr-Doped Pbzro - Pbtio - PBMG NB O CeramicsrachnaselvamanigmailNo ratings yet

- Xu Et Al - Metal-Insulator Transition in Co-Doped ZnO Magnetotransport Properties - PRB - 73, 205342 (2006)Document5 pagesXu Et Al - Metal-Insulator Transition in Co-Doped ZnO Magnetotransport Properties - PRB - 73, 205342 (2006)sinytellsNo ratings yet

- Review Article: Graphene: A Rising Star On The Horizon of Materials ScienceDocument13 pagesReview Article: Graphene: A Rising Star On The Horizon of Materials ScienceWilliam SkyNo ratings yet

- Surface Enhanced Raman Spectroscopy of GrapheneDocument11 pagesSurface Enhanced Raman Spectroscopy of GrapheneMartín FigueroaNo ratings yet

- High Electron Mobility in Ga (In) Nas Films Grown by Molecular Beam EpitaxyDocument4 pagesHigh Electron Mobility in Ga (In) Nas Films Grown by Molecular Beam EpitaxyvysrilekhaNo ratings yet

- On The Roughness of Single-And Bi-Layer Graphene MembranesDocument9 pagesOn The Roughness of Single-And Bi-Layer Graphene MembranesMateo BallestaNo ratings yet

- Graphene Seminar ReportDocument9 pagesGraphene Seminar ReportAbinaya M CNo ratings yet

- Laser-Vapour Interaction in High-Power CW Nd:YAG Laser WeldingDocument11 pagesLaser-Vapour Interaction in High-Power CW Nd:YAG Laser Weldingkamal touilebNo ratings yet

- Introduction To The Physical Properties of Graphene: Jean-No El FUCHS Mark Oliver GOERBIG Lecture Notes 2008Document69 pagesIntroduction To The Physical Properties of Graphene: Jean-No El FUCHS Mark Oliver GOERBIG Lecture Notes 2008masa24No ratings yet

- Covalent Chemistry in Graphene ElectronicsDocument10 pagesCovalent Chemistry in Graphene ElectronicsJorge OrtegaNo ratings yet

- Observation of Ferromagnetism Above 900 K in Cr-Gan and Cr-AlnDocument14 pagesObservation of Ferromagnetism Above 900 K in Cr-Gan and Cr-AlnIwan Frantino SimbolonNo ratings yet

- Novoselov Lecture, GrapheneDocument26 pagesNovoselov Lecture, GrapheneAhmad QusyairyNo ratings yet

- 1 PDFDocument8 pages1 PDFAnonymous XX9Om322lNo ratings yet

- Graphene From Fundamental-From Fundamental To Future ApplicationsDocument40 pagesGraphene From Fundamental-From Fundamental To Future ApplicationsMustaque Ali100% (2)

- Osswald 2005Document6 pagesOsswald 2005dilla zainudinNo ratings yet

- Thermoelectric Properties of SrTiO3Document6 pagesThermoelectric Properties of SrTiO3Deepanshu SrivastavaNo ratings yet

- Graphene Synthesis and Application For Solar CellsDocument21 pagesGraphene Synthesis and Application For Solar CellsimranakhtarNo ratings yet

- znse Single Crystals: Rapid CommunicationDocument3 pagesznse Single Crystals: Rapid CommunicationAlexanderNo ratings yet

- Seventeen, Jul 2011Document4 pagesSeventeen, Jul 2011emediageNo ratings yet

- Vitali B Prakapenka, Guoyin Shen and Leonid S Dubrovinsky - Carbon Transport in Diamond Anvil CellsDocument14 pagesVitali B Prakapenka, Guoyin Shen and Leonid S Dubrovinsky - Carbon Transport in Diamond Anvil CellsDrebuioNo ratings yet

- 2012 Park - Graphene As Transparent Conducting Electrodes in OrganicDocument8 pages2012 Park - Graphene As Transparent Conducting Electrodes in Organicheri rustamajiNo ratings yet

- Volume 515, Issue 14: Thin Solid FilmsDocument7 pagesVolume 515, Issue 14: Thin Solid FilmsmileivandaNo ratings yet

- DiffusionDocument5 pagesDiffusionCatalin SfatNo ratings yet

- High-Quality Thin Graphene Films From Fast Electrochemical ExfoliationDocument8 pagesHigh-Quality Thin Graphene Films From Fast Electrochemical ExfoliationelectroternalNo ratings yet

- No. AnswerDocument5 pagesNo. AnswerAtul BishtNo ratings yet

- DGBDFGFDocument1 pageDGBDFGFAtul BishtNo ratings yet

- (Paper) Uttarakhand General Knowledge Objective QuestionsDocument8 pages(Paper) Uttarakhand General Knowledge Objective QuestionsAtul BishtNo ratings yet

- Journal of Materials Chemistry C: PaperDocument9 pagesJournal of Materials Chemistry C: PaperAtul BishtNo ratings yet

- Val - Impedance Matching and Matching NetworksDocument27 pagesVal - Impedance Matching and Matching NetworksThatKid FromSouthNo ratings yet

- Wet Etching PDFDocument3 pagesWet Etching PDFAtul BishtNo ratings yet

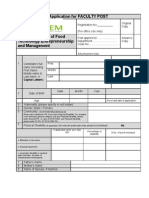

- Application For FACULTY POST 28.1.12Document8 pagesApplication For FACULTY POST 28.1.12Atul BishtNo ratings yet

- Application For FACULTY POST 28.1.12Document8 pagesApplication For FACULTY POST 28.1.12Atul BishtNo ratings yet

- Asi Abs CoeffDocument3 pagesAsi Abs CoeffAtul BishtNo ratings yet

- New Microsoft Office Word DocumentDocument2 pagesNew Microsoft Office Word DocumentAtul BishtNo ratings yet

- Mobile SafetyDocument18 pagesMobile SafetyAtul BishtNo ratings yet

- 20 Things You DidnDocument2 pages20 Things You DidnHussainNo ratings yet

- Csir Arrear DetailsDocument1 pageCsir Arrear DetailsAtul BishtNo ratings yet

- N Solid State PhysicsDocument2 pagesN Solid State PhysicsAtul BishtNo ratings yet

- Net Result June 2011 Roll WiseDocument13 pagesNet Result June 2011 Roll WisewoahboNo ratings yet

- Kerkythea Material Editor Guide 01Document36 pagesKerkythea Material Editor Guide 01sapomasterNo ratings yet

- CONTARE Notes and ReviewerDocument4 pagesCONTARE Notes and ReviewerApong VillegasNo ratings yet

- Day 4 - 10.7-8 Notes HandoutDocument4 pagesDay 4 - 10.7-8 Notes HandoutRusherNo ratings yet

- AP Macroeconomics: About The Advanced Placement Program (AP)Document2 pagesAP Macroeconomics: About The Advanced Placement Program (AP)Adam NowickiNo ratings yet

- Schedule Standard and Syllabus: Section A: Geomorphology and Remote SensingDocument6 pagesSchedule Standard and Syllabus: Section A: Geomorphology and Remote SensingPankaj SharmaNo ratings yet

- G8DDocument61 pagesG8Dvivek1312100% (1)

- Experimental Nucleonics PDFDocument1 pageExperimental Nucleonics PDFEricNo ratings yet

- Topic Categorization Based On User Behaviour in Random Social Networks Using Firefly AlgorithmDocument5 pagesTopic Categorization Based On User Behaviour in Random Social Networks Using Firefly AlgorithmBONFRINGNo ratings yet

- Professional Ethics in Human ValuesDocument25 pagesProfessional Ethics in Human Valuesdips03275% (4)

- Delhi Public School, Agra: The HolocaustDocument3 pagesDelhi Public School, Agra: The Holocaustkrish kanteNo ratings yet

- Topic 3 BatteryDocument40 pagesTopic 3 BatterynisaNo ratings yet

- The Wall Dramaturgical PacketDocument24 pagesThe Wall Dramaturgical PacketMarilo CostaNo ratings yet

- MMW SyllabusDocument13 pagesMMW SyllabusBien TecsonNo ratings yet

- Fossils (DK Smithsonian Handbook) by DKDocument320 pagesFossils (DK Smithsonian Handbook) by DKAnthony Mello71% (7)

- Spiderman EvolutionDocument14 pagesSpiderman EvolutionLuis IvanNo ratings yet

- Meditation Club of RUET Asif EEE 17 PDFDocument2 pagesMeditation Club of RUET Asif EEE 17 PDFShovonNo ratings yet

- Effective Leadership Case Study AssignmentDocument5 pagesEffective Leadership Case Study AssignmentAboubakr Soultan67% (3)

- STaD 01 C 4Document4 pagesSTaD 01 C 4rogeraccuraNo ratings yet

- Design ManagementDocument21 pagesDesign ManagementKarishma Mittal100% (1)

- Chapter 2: Demand, Supply & Market EquilibriumDocument15 pagesChapter 2: Demand, Supply & Market EquilibriumRaja AfiqahNo ratings yet

- Moorish Architecture - KJDocument7 pagesMoorish Architecture - KJKairavi JaniNo ratings yet

- Introduction and Assessment of The Renal - Urological SystemDocument182 pagesIntroduction and Assessment of The Renal - Urological SystemValerie Suge-Michieka100% (1)

- Arup Kumar Mandal (New Format)Document2 pagesArup Kumar Mandal (New Format)sharafat_321No ratings yet

- Books by Amy and Arny MindellDocument24 pagesBooks by Amy and Arny Mindellrameshprema100% (1)

- Exercises 2Document7 pagesExercises 2Taseen Junnat SeenNo ratings yet

- Systematic Survey On Smart Home Safety and Security Systems Using The Arduino PlatformDocument24 pagesSystematic Survey On Smart Home Safety and Security Systems Using The Arduino PlatformGeri MaeNo ratings yet

- Wdnsakn KDniend w5564Document8 pagesWdnsakn KDniend w5564Jo BloNo ratings yet

- Ratten V R (1974) HCA 35 (1974) 131 CLR 510 (25 September 1974)Document20 pagesRatten V R (1974) HCA 35 (1974) 131 CLR 510 (25 September 1974)Freya MehmeenNo ratings yet

- MailEnable Standard GuideDocument53 pagesMailEnable Standard GuideHands OffNo ratings yet

- TestDocument21 pagesTestTri Arini TitisingtyasNo ratings yet