Professional Documents

Culture Documents

Program PT Angrenaje

Uploaded by

Balla AttilaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Program PT Angrenaje

Uploaded by

Balla AttilaCopyright:

Available Formats

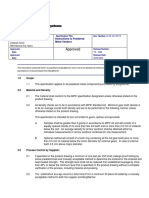

LND-7330757468@CS Name : Unnamed Changed by : Marius

KISSsoft - Release 03-2011L File on: 09.11.2012 at: 22:55:27

Warning : Calculation not consistent. Results are probably not valid !

Important hint: At least one warning has occurred during the calculation: 1-> Contact interference! Notice: The length of the involute of gear 1 is too short. Some proposals: - Change tip form diameter of Gear 2 through Gear 2: Tip chamfer >= 0.0300 mm or Tip circle <= 164.7800 mm - Change reference profile of Gear 1 through: Smaller root radius or larger dedendum.

CALCULATION OF A HELICAL GEAR PAIR

Drawing or article number: Gear 1: 0.000.0 Gear 2: 0.000.0 Calculation method DIN 3990 Method B ------- GEAR 1 -------- GEAR 2 -Power (kW) Speed (1/min) Torque (Nm) Application factor Required service life Gear driving (+) / driven (-) 1. TOOTH GEOMETRY AND MATERIAL (Geometry calculation according ISO 21771) Center distance (mm) Centre distance tolerance Normal module (mm) Pressure angle at normal section () Helix angle at reference circle () Number of teeth Facewidth (mm) Hand of gear Accuracy grade Inner diameter (mm) Inner diameter of gear rim (mm) Material Gear 1: Gear 2: [a] [mn] [alfn] [beta] [z] [b] [Q-DIN3961] [di] [dbi] ------- GEAR 1 -------- GEAR 2 -112.000 ISO 286 Measure js7 2.7500 20.0000 12.0000 23 58 36.00 35.00 right left 8 8 0.00 0.00 0.00 0.00 steel, case-hardened core strength >=25HRC Jominy J=12mm<HRC28 steel, case-hardened core strength >=25HRC Jominy J=12mm<HRC28 ------- GEAR 1 -------- GEAR 2 -HRC 61 HRC 61 430.00 1500.00 1200.00 850.00 206000 0.300 0.00 4.80 20.00 430.00 1500.00 1200.00 850.00 206000 0.300 0.00 4.80 20.00 [P] [n] [T] [KA] [H] 725.0 38.2 + 2.900 1.25 800.00 287.5 96.3 -

18CrNiMo7-6, Case-carburized ISO 6336-5 Figure 9/10 (MQ), 18CrNiMo7-6, Case-carburized ISO 6336-5 Figure 9/10 (MQ),

Surface hardness Fatigue strength. tooth root stress (N/mm) [sigFlim] Fatigue strength for Hertzian pressure (N/mm) [sigHlim] Tensile strength (N/mm) [Rm] Yield point (N/mm) [Rp] Young's modulus (N/mm) [E] Poisson's ratio [ny] Average roughness, Ra, tooth flank (m) [RAH] Mean roughness height, Rz, flank (m) [RZH] Mean roughness height, Rz, root (m) [RZF]

1/7

Tool or reference profile of gear 1 : Reference profile 1.25 / 0.38 / 1.0 ISO 53.2 Profil A Addendum coefficient [haP*] Dedendum coefficient [hfP*] Tip radius factor [rhoaP*] Root radius factor [rhofP*] Tip form height coefficient [hFaP*] Protuberance height factor [hprP*] Protuberance angle [alfprP] Ramp angle [alfKP] Tool or reference profile of gear 2 : Reference profile 1.25 / 0.38 / 1.0 ISO 53.2 Profil A Addendum coefficient [haP*] Dedendum coefficient [hfP*] Tip radius factor [rhoaP*] Root radius factor [rhofP*] Tip form height coefficient [hFaP*] Protuberance height factor [hprP*] Protuberance angle [alfprP] Ramp angle [alfKP] Summary of reference profile gears: Dedendum reference profile (module) [hfP*] Tooth root radius Refer. profile (module) [rofP*] Addendum Reference profile (module) [haP*] Protuberance height (module) [hprP*] Protuberance angle () [alfprP] Buckling root flank height (module) [hFaP*] Buckling root flank angle () [alfKP] Data for Grinding / Honing: Depth of immersion (module) [hgrind*] Radius at cutter head (module) [rgrind*] Type of profile modification: Tip relief (m)

not topping

1.000 1.250 0.000 0.380 0.000 0.000 0.000 0.000

not topping 1.250 0.380 1.000 0.000 0.000 0.000 0.000 1.066 0.100

1.000 1.250 0.000 0.380 0.000 0.000 0.000 0.000

1.250 0.380 1.000 0.000 0.000 0.000 0.000 1.066 0.100

none (only running-in) [Ca] -0.00 oil bath lubrication Oil: ISO-VG 220 Mineral-oil base [nu40] [nu100] [FZGtestA] [roOil] [TS]

-0.00

Lubrication type Type of oil Lubricant base Kinem. viscosity oil at 40 C (mm/s) Kinem. viscosity oil at 100 C (mm/s) FZG-Test A/8.3/90 (ISO 14635-1) Specific density at 15 C (kg/dm) Oil temperature (C) Overall transmission ratio Gear ratio Transverse module (mm) Pressure angle at pitch circle () Working transverse pressure angle ()

220.00 17.50 12 0.895 70.000

[itot] [u] [mt] [alft] [alfwt] [alfwt.e/i] Working pressure angle at normal section () [alfwn] Helix angle at operating pitch circle () [betaw] Base helix angle () [betab] Reference centre distance (mm) [ad] Sum of profile shift coefficients [Summexi] Profile shift coefficient [x] Tooth thickness (Arc) (module) [sn*] Tip alteration (mm) Reference diameter (mm) Base diameter (mm) Tip diameter (mm) (mm) Tip diameter allowances (mm) Tip chamfer / tip rounding (mm) Tip form diameter (mm) (mm) Operating pitch diameter (mm) (mm) Root diameter (mm) Generating Profile shift coefficient Manufactured root diameter with xE (mm) Theoretical tip clearance (mm) Effective tip clearance (mm) [k*mn] [d] [db] [da] [da.e/i] [Ada.e/i] [hK] [dFa] [dFa.e/i] [dw] [dw.e/i] [df] [xE.e/i] [df.e/i] [c] [c.e/i]

------- GEAR 1 -------- GEAR 2 -0.000 2.522 2.811 20.410 17.672 17.700 / 17.644 17.320 11.809 11.267 113.863 -0.6350

0.0000 1.5708

-0.6350 1.1085

-0.117 64.663 60.603 69.929 69.929 / 69.919 0.000 / -0.010 0.000 69.929 69.929 / 69.919 63.605 63.615 / 63.595 57.788 -0.0350 / -0.0549 57.596 / 57.486 0.688 0.909 / 0.801

-0.117 163.063 152.826 164.837 164.837 / 164.827 0.000 / -0.010 0.000 164.837 164.837 / 164.827 160.395 160.420 / 160.370 152.696 -0.6825 / -0.7074 152.435 / 152.297 0.688 0.861 / 0.766

2/7

Active root diameter (mm)

[dNf] 60.923 156.371 [dNf.e/i] 60.938 / 60.911 156.400 / 156.347 Root form diameter (mm) [dFf] 60.982 155.955 (mm) [dFf.e/i] 60.923 / 60.891 155.807 / 155.731 Reserve (dNf-dFf)/2 (mm) [cF.e/i] 0.023 / -0.006 0.335 / 0.270 Addendum (mm) [ha = mn * (haP*+x)] 2.633 0.887 (mm) [ha.e/i] 2.633 / 2.628 0.887 / 0.882 Dedendum (mm) [hf = mn * (hfP*-x)] 3.438 5.184 (mm) [hf.e/i] 3.534 / 3.589 5.314 / 5.383 Roll angle at dFa () [xsi_dFa.e/i] 32.986 / 32.967 23.158 / 23.148 Roll angle to dNa () [xsi_dNa.e/i] 32.986 / 32.967 23.158 / 23.148 Roll angle to dNf () [xsi_dNf.e/i] 6.025 / 5.781 12.464 / 12.370 Roll angle at dFf () [xsi_dFf.e/i] 5.889 / 5.591 11.372 / 11.224 Tooth height (mm) [H] 6.071 6.070 Virtual gear no. of teeth [zn] 24.447 61.649 Normal tooth thickness at tip cyl. (mm) [san] 2.101 2.403 (mm) [san.e/i] 2.031 / 1.983 2.311 / 2.257 Normal spacewidth at root cylinder (mm) [efn] 0.000 0.000 (mm) [efn.e/i] 0.000 / 0.000 0.000 / 0.000 Max. sliding velocity at tip (m/s) [vga] 0.826 0.693 Specific sliding at the tip [zetaa] 0.624 0.746 Specific sliding at the root [zetaf] -2.931 -1.657 Sliding factor on tip [Kga] 0.342 0.287 Sliding factor on root [Kgf] -0.287 -0.342 Pitch on reference circle (mm) [pt] 8.832 Base pitch (mm) [pbt] 8.278 Transverse pitch on contact-path (mm) [pet] 8.278 Lead height (mm) [pz] 955.722 2410.081 Axial pitch (mm) [px] 41.553 Length of path of contact (mm) [ga, e/i] 14.330 (14.387 / 14.249) Length T1-A, T2-A (mm) [T1A, T2A] 3.115( 3.057/ 3.186) 30.884(30.884/30.871) Length T1-B (mm) [T1B, T2B] 9.167( 9.167/ 9.157) 24.832(24.775/24.900) Length T1-C (mm) [T1C, T2C] 9.654( 9.638/ 9.671) 24.345(24.304/24.386) Length T1-D (mm) [T1D, T2D] 11.393(11.335/11.464) 22.606(22.606/22.593) Length T1-E (mm) [T1E, T2E] 17.445(17.445/17.435) 16.555(16.497/16.622) Length T1-T2 (mm) [T1T2] 33.999 (33.942 / 34.057) Diameter of single contact point B (mm) [d-B] 63.316(63.316/63.310) 160.694(160.658/160.735) Diameter of single contact point D (mm) [d-D] 64.746(64.705/64.796) 159.374(159.374/159.366) Addendum contact ratio [eps] 0.941( 0.943/ 0.938) 0.790( 0.795/ 0.783) Minimal length of contact line (mm) [Lmin] 59.982 (mm) Transverse contact ratio Transverse contact ratio with allowances Overlap ratio Total contact ratio Total contact ratio with allowances 2. FACTORS OF GENERAL INFLUENCE Nominal circum. force at pitch circle (N) ------- GEAR 1 -------- GEAR 2 -0.0 0.0 0.0 0.0 0.00 0.0 0.0 0.0 2.45 0.0 0.0 0.000 0.000 0.000 0.000 0.000 [eps_a] [eps_a.e/m/i] [eps_b] [eps_g] [eps_g.e/m/i] 1.731 1.738 / 1.730 / 1.721 0.842 2.573 2.580 / 2.572 / 2.564

[Ft] Axial force (N) [Fa] Radial force (N) [Fr] Normal force (N) [Fnorm] Tangent.load at p.c.d.per mm (N/mm) (N/mm) [w] Only as information: Forces at operating pitch circle: Nominal circumferential force (N) [Ftw] Axial force (N) [Faw] Radial force (N) [Frw] Circumferential speed pitch d.. (m/sec) [v] Running-in value (m) [yp] Running-in value (m) [yf] Correction coefficient [CM] Gear body coefficient (bs= 8.75 mm) [CR] Reference profile coefficient [CBS] Material coefficient [E/Est] Singular tooth stiffness (N/mm/m) [c'] Meshing stiffness (N/mm/m) [cg] The formula for c' and cg at w*KA < 25 is imprecise! Therefore the factors KV, KHb or KHa are to high. Reduced mass (kg/mm) [mRed] Resonance speed (min-1) [nE1] Nominal speed (-) [N] Subcritical range Running-in value (m) [ya] Bearing distance l of pinion shaft (mm) [l] Distance s of pinion shaft (mm) [s] Outside diameter of pinion shaft (mm) [dsh]

0.000

0.00000 0 0.000 0.0 0.000 0.000 0.000

3/7

Load according DIN 3990/1 Figure 6.8 (0:6.8a, 1:6.8b, 2:6.8c, 3:6.8d, 4:6.8e) Without support effect Tooth trace deviation (active) (m) from deformation of shaft (m) Tooth without tooth trace modification Position of Contact pattern: favorable from production tolerances (m) Tooth trace deviation, theoretical (m) Running-in value (m) Dynamic factor Face load factor flank Tooth root Scuffing

[-] [Fby] [fsh*B1] [fma*B2] [Fbx] [yb] [KV] [KHb] [KFb] [KBb] [KHa] [KFa] [KBa] [Kbg] [NL] 0.000

4 0.00 0.00 0.00 0.00 0.0 1.000 0.000 0.000 0.000 1.000 0.000 0.000 0.000 0.000

Transverse load factor - flank - Tooth root - Scuffing Helix angle coefficient scuffing Number of load cycles (in mio.) 3. TOOTH ROOT STRENGTH

------- GEAR 1 -------- GEAR 2 -Calculation of Tooth form coefficients according method: B (Calculate tooth form factor YF with manufacturing addendum mod. xE.e) Tooth form factor [YF] 0.00 0.00 Stress correction factor [YS] 0.00 0.00 Working angle () [alfen] 0.00 0.00 Bending lever arm (mm) [hF] 0.00 0.00 Tooth thickness at root (mm) [sFn] 0.00 0.00 Tooth root radius (mm) [roF] 0.00 0.00 (hF* = 0.000/0.000 sFn* = 0.000/0.000 roF* = 0.000/0.000 dsFn = 0.00/ 0.00 alfsFn = 0.00/ 0.00) Contact ratio factor [Yeps] Helical load factor [Ybet] Effective facewidth (mm) [beff] Nominal shear stress at tooth root (N/mm) [sigF0] Tooth root stress (N/mm) [sigF] Permissible bending stress at root of Test-gear Support factor [YdrelT] Surface factor [YRrelT] Size coefficient (Tooth root) [YX] Finite life factor [YNT] [YdrelT*YRrelT*YX*YNT] Alternating bending coefficient [YM] Stress correction factor [Yst] Limit strength tooth root (N/mm) [sigFG] Permissible tooth root stress (N/mm) [sigFP=sigFG/SFmin] Required safety [SFmin] Safety for Tooth root stress [SF=sigFG/sigF] Transmittable power (kW) [kWRating] 4. SAFETY AGAINST PITTING (TOOTH FLANK) Zone factor [ZH] Elasticity coefficient (N^.5/mm) [ZE] Contact ratio factor [Zeps] Helix angle factor [Zbet] Effective facewidth (mm) [beff] Nominal flank pressure (N/mm) [sigH0] Surface pressure at operating pitch circle (N/mm) [sigHw] Single tooth contact factor [ZB,ZD] Flank pressure (N/mm) [sigH] Lubrication factor Speed factor Roughness factor Material mating factor Finite life factor [ZL] [ZV] [ZR] [ZW] [ZNT] [ZL*ZV*ZR*ZNT] Small amount of pitting permissible (0=no, 1=yes) ------- GEAR 1 -------- GEAR 2 -0.000 0.000 0.000 0.000 35.00 0.00 0.00 0.00 0.000 0.000 0.000 0.000 0.000 0.000 0 0.00 0.00 0.00 0.000 0.000 0.000 0.000 0.000 0.000 0 0.000 0.000

36.00 0.00 0.00 0.000 0.000 0.000 0.000 0.000 1.000 0.00 0.00 1.40 0.00 0.00

35.00 0.00 0.00 0.000 0.000 0.000 0.000 0.000 1.000 0.00 0.00 1.40 0.00 0.00

0.00

4/7

Size coefficient (flank) [ZX] Limit strength pitting (N/mm) [sigHG] Permissible surface pressure (N/mm) [sigHP=sigHG/SHmin] Safety for surface pressure at operating pitch circle [SHw] Required safety [SHmin] Transmittable power (kW) [kWRating] Safety for stress at single tooth contact [SHBD=sigHG/sigH] (Safety regarding nominal torque) [(SHBD)^2] 4b. MICROPITTING ACCORDING TO ISO/TR 15144-1:2010

0.000 0.00 0.00 0.00 1.00 0.00 0.00 0.00

0.000 0.00 0.00 0.00 1.00 0.00 0.00 0.00

Calculation did not run. (Lubricant: Load stage micropitting test is unknown 5. STRENGTH AGAINST SCUFFING Calculation method according DIN3990 0.000 13.795 0.00 1.000 0.00 35.000 0.000 0.000 0.790 0.00 0.00 0.00 0.000 0.00 0.000 0.000 0.00 0.000 2.000 0.000 0.00 0.00 0.00 0.000 0.00 0.000 0.000 0.000 0.000 0.00 1.800 0.000 0.000 13.795 0.00

Lubrication coefficient (for lubrication type) [XS] Relative structure coefficient (Scuffing) [XWrelT] Thermal contact factor (N/mm/s^.5/K) [BM] Relevant tip relief (m) [Ca] Optimal tip relief (m) [Ceff] Effective facewidth (mm) [beff] Applicable circumferential force/facewidth (N/mm) [wBt] Flash factor (K*N^-.75*s^.5*m^-.5*mm) [XM] Pressure angle factor (eps1: 0.000, eps2: 0.941) [Xalfbet] Flash temperature-criteria Tooth mass temperature (C) [theM-B] theM-B = theoil + XS*0.47*theflamax [theflamax] Scuffing temperature (C) [theS] Coordinate gamma (point of highest temp.) [Gamma] [Gamma.A]= -0.677 [Gamma.E]= 0.807 Highest contact temp. (C) [theB] Geometry factor [XB] Load sharing factor [XGam] Dynamic viscosity (mPa*s) [etaM] Coefficient of friction [mym] Required safety [SBmin] Safety factor for scuffing (flash-temp) [SB] Integral temperature-criteria Tooth mass temperature (C) theM-C = theoil + XS*0.70*theflaint Integral scuffing temperature (C) Contact ratio factor Dynamic viscosity (mPa*s) Averaged coefficient of friction Geometry factor Meshing factor Tip relief factor Integral tooth flank temperature (C) Required safety Safety factor for scuffing (intg.-temp.) Safety referring to transferred torque 6. MEASUREMENTS FOR TOOTH THICKNESS Tooth thickness deviation Tooth thickness allowance (normal section) (mm) [As.e/i] Number of teeth spanned Base tangent length (no backlash) (mm) Actual base tangent length ('span') (mm) Diameter of contact point (mm) [k] [Wk] [Wk.e/i] [dMWk.m] [theM-C] [theflaint] [theSint] [Xeps] [etaOil] [mym] [XBE] [XQ] [XCa] [theint] [SSmin] [SSint] [SSL]

------- GEAR 1 -------- GEAR 2 -DIN3967 cd25 DIN3967 cd25 -0.070 / -0.110 0.000 0.000 0.000 / 0.000 0.000 -0.095 / -0.145 0.000 0.000 0.000 / 0.000 0.000 0.000 0.000 0.000 0.000 / 0.000 0.000

Theoretical diameter of ball/pin (mm) [DM] 0.000 Eff. Diameter of ball/pin (mm) [DMeff] 0.000 Theor. dim. centre to ball (mm) [MrK] 0.000 Actual dimension centre to ball (mm) [MrK.e/i] 0.000 / 0.000 Diameter of contact point (mm) [dMMr.m] 0.000 Diametral measurement over two balls without clearance (mm)

5/7

Actual dimension over balls (mm) Theor. dimension over two pins (mm) Actual dimension over rolls (mm)

[MdK] [MdK.e/i] [MdR] [MdR.e/i]

0.000 0.000 / 0.000 0.000 0.000 / 0.000 0.000 0.000 / 0.000 0.000 4.320 4.250 / 4.210 112.000 0.000 0.018 0.011 0.018 / / / /

0.000 0.000 / 0.000 0.000 0.000 / 0.000 0.000 0.000 / 0.000 0.000 3.048 2.953 / 2.903 /112.000 0.000 -0.018 -0.011 -0.018

Chordal tooth thickness (no backlash) (mm) ['sn] Actual chordal tooth thickness (mm) ['sn.e/i] Reference chordal height from da.m (mm) [ha] Tooth thickness (Arc) (mm) [sn] (mm) [sn.e/i] Backlash free center distance (mm) [aControl.e/i] Backlash free center distance, allowances (mm) [jta] Centre distance allowances (mm) [Aa.e/i] Circumferential backlash from Aa (mm) [jt_Aa.e/i] Radial clearance (mm) [jr] Circumferential backlash (transverse section) (mm) [jt] Torsional angle for fixed gear 1 () Normal backlash (mm) [jn] 7. GEAR ACCURACY According DIN 3961: Accuracy grade Profile form deviation (m) Profile slope deviation (m) Total profile deviation (m) Helix form deviation (m) Helix slope deviation (m) Total helix deviation (m) Normal base pitch deviation (m) Single pitch deviation (m) Difference between adjacent pitches (m) Total cumulative pitch deviation (m) Cumulative circular pitch deviation over

0.000 / 0.000 0.0000 /0.0000 0.000 / 0.000

------- GEAR 1 -------- GEAR 2 -8 16.00 12.00 20.00 11.00 17.00 20.00 15.00 15.00 19.00 53.00 33.00 37.00 22.00 44.00 18.00 58.00 25.00 18.00 50.00 31.36 12.24 65.00 8 16.00 12.00 20.00 11.00 17.00 20.00 16.00 16.00 20.00 62.00 39.00 43.00 25.00 51.00 22.00 66.00 25.00 20.00 56.00 31.36 11.90 72.00

[Q-DIN3961] [ff] [fHa] [Ff] [ffb] [fHb] [Fb] [fpe] [fp] [fu] [Fp] z/8 pitches (m) [Fpz/8] Concentricity deviation (m) [Fr] Tooth Thickness Variation (m) [Rs] Total radial composite deviation (m) [Fi"] Radial tooth-to-tooth composite deviation (m) [fi"] Total tangential composite deviation (m) [Fi'] Tangential tooth-to-tooth composite deviation (m) [fi'] According DIN 58405 (Precision Mechanics): Tooth-to-tooth composite error (m) [fi"] Composite error (m) [Fi"] Axis alignment error (m) [fp] Flank direction error (m) [fbeta] Concentricity deviation (m) [Trk, Fr]

Tolerance for alignment of axes (recommendation acc. ISO/TR 10064, Quality 8) Maximum value for deviation error of axis (m) [fSigbet] 26.03 Maximum value for inclination error of axes (m) [fSigdel] 52.07 8. ADDITIONAL DATA Maximal possible centre distance (eps_a=1.0) [aMAX] Torsional stiffness (MNm/rad) [cr] Mean coeff. of friction (acc. Niemann) [mum] Wear sliding coef. by Niemann [zetw] Power loss from gear load (kW) [PVZ] Weight - calculated with da (g) [Mass] Moment of inertia (System referenced to wheel 1): calculation without consideration of the exact tooth shape single gears ((da+df)/2...di) (kgm) [TraeghMom] System ((da+df)/2...di) (kgm) [TraeghMom] 9. DETERMINATION OF TOOTHFORM Data for the tooth form calculation : Calculation of Gear 1 113.983 0.000 0.000 0.000

0.0

0.0

0.00 0

0.00 0

6/7

Tooth form, Gear 1, Step 1: automatic (final treatment) haP*= 1.002, hfP*= 1.250, rofP*= 0.380 Calculation of Gear 2 Tooth form, Gear 2, Step 1: automatic (final treatment) haP*= 1.016, hfP*= 1.250, rofP*= 0.380

REMARKS: - Specifications with [.e/i] imply: Maximum [e] and Minimal value [i] with consideration of all tolerances Specifications with [.m] imply: Mean value within tolerance - For the backlash tolerance, the center distance tolerances and the tooth thickness deviation are taken into account. Shown is the maximal and the minimal backlash corresponding the largest resp. the smallest allowances The calculation is done for the Operating pitch circle.. - Details of calculation method: cg according to method B KV according to method B KHb, KFb according method C KHa, KFa according to method B End report lines: 495

7/7

You might also like

- Calculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationDocument10 pagesCalculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationM036No ratings yet

- CX1Document7 pagesCX1acceleron8No ratings yet

- KissoftDocument7 pagesKissoftGopi Krishnan VNo ratings yet

- Helical Gear Calculation Using SoftwareDocument10 pagesHelical Gear Calculation Using SoftwareM036No ratings yet

- This Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The CalculationDocument7 pagesThis Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The Calculationpablo_stzNo ratings yet

- Gear Pair 1 GearDocument2 pagesGear Pair 1 GearYunji GuNo ratings yet

- Spur Gearing, Helical Gearing (mm/ISO)Document6 pagesSpur Gearing, Helical Gearing (mm/ISO)oman1148No ratings yet

- Sa Backlash DinDocument3 pagesSa Backlash Dinsantosh kumarNo ratings yet

- Bevel-Gear-Calculation (Bevel-Gear-Pair) : 1. Tooth Geometry and MaterialDocument1 pageBevel-Gear-Calculation (Bevel-Gear-Pair) : 1. Tooth Geometry and MaterialPIRATASANTANANo ratings yet

- Worm DriveDocument6 pagesWorm DriveRavi Kiran MeesalaNo ratings yet

- M1 5xZ59xX-0 3225x25L-RA-1 5VSWK de enDocument2 pagesM1 5xZ59xX-0 3225x25L-RA-1 5VSWK de enYunji GuNo ratings yet

- Gear 40nDocument10 pagesGear 40nSantosh Kumar ReddyNo ratings yet

- Supplement For 6 Cylinder Engine Section PDFDocument910 pagesSupplement For 6 Cylinder Engine Section PDFMayobanex Moya MartinezNo ratings yet

- Corner Cast in Place AnchorDocument7 pagesCorner Cast in Place Anchorwaweng22No ratings yet

- Planetry GearsDocument10 pagesPlanetry Gearsvinu1175No ratings yet

- Kumera Girth Gear Technical ManualDocument12 pagesKumera Girth Gear Technical ManualBhaskar Reddy100% (1)

- Toyo Rubber CouplingDocument14 pagesToyo Rubber CouplingGreg SanjayaNo ratings yet

- Static Calculation For FansDocument4 pagesStatic Calculation For FansBadrul HishamNo ratings yet

- Selection of Ball Screws 1Document4 pagesSelection of Ball Screws 1Minh Trí KnightNo ratings yet

- Type of Calculation Date Customer Name Ref: Roller Chain Drives 29/08/2012 07:50:08 ModelDocument6 pagesType of Calculation Date Customer Name Ref: Roller Chain Drives 29/08/2012 07:50:08 Modelgrupa2904No ratings yet

- Komatsu ®: Model Komatsu WA900-3E0 Komatsu WA1200-6 Caterpillar 993 K (T4) GeneralDocument4 pagesKomatsu ®: Model Komatsu WA900-3E0 Komatsu WA1200-6 Caterpillar 993 K (T4) GeneralGaming BebasNo ratings yet

- Toughcarrier TCH10: Super High Load Capacity Single-Axis ActuatorDocument2 pagesToughcarrier TCH10: Super High Load Capacity Single-Axis ActuatornvkjayanthNo ratings yet

- Shimpo STH SeriesDocument8 pagesShimpo STH SeriesElectromateNo ratings yet

- 20120224043147Document8 pages20120224043147Dương Trương Tấn100% (1)

- Important Hint: at Least One Warning Has Occurred During The CalculationDocument8 pagesImportant Hint: at Least One Warning Has Occurred During The CalculationDemir HamzicNo ratings yet

- Serie 523 - ISO 15552Document69 pagesSerie 523 - ISO 15552NixiusNo ratings yet

- Proračun 4.brzinaDocument11 pagesProračun 4.brzinaJurmanNo ratings yet

- TK-500MB - DB - Rev. 00Document173 pagesTK-500MB - DB - Rev. 00Daniel GómezNo ratings yet

- 175 Own InputDocument8 pages175 Own Inputsantosh kumarNo ratings yet

- Hyundai HDF35 45-3 BrochureDocument6 pagesHyundai HDF35 45-3 BrochurerobertoNo ratings yet

- Chuck SPANNTOP Nova Pull BackDocument8 pagesChuck SPANNTOP Nova Pull BackhungNo ratings yet

- Transmission and Differential SectionDocument245 pagesTransmission and Differential Sectionbillh@optonline.netNo ratings yet

- FZR400 Service Manual Ch23 CorrectedDocument76 pagesFZR400 Service Manual Ch23 CorrectedJoaquin PrietoNo ratings yet

- ENG - Lynx 300-300M - 140916 - SU - E4Document4 pagesENG - Lynx 300-300M - 140916 - SU - E4thyskieNo ratings yet

- 2300rpm Max Output TorqueDocument8 pages2300rpm Max Output TorqueRavi Kiran MeesalaNo ratings yet

- Catalog Gas Turbin MeterDocument3 pagesCatalog Gas Turbin MeterAlvaro Joel Quinteros RochaNo ratings yet

- Lintech 300series 400series SpecsheetDocument4 pagesLintech 300series 400series SpecsheetElectromateNo ratings yet

- Roller Chain Transmission: I II ? 1.0 Input Sectinon Sprocket1 Sprocket2 Project Information Calculation Without ErrorsDocument3 pagesRoller Chain Transmission: I II ? 1.0 Input Sectinon Sprocket1 Sprocket2 Project Information Calculation Without ErrorsChristian Fonseca RodriguezNo ratings yet

- Angrenaj 1 Tabel ProtocolDocument4 pagesAngrenaj 1 Tabel ProtocolFaur DanielNo ratings yet

- Acroba SerManual FA15-30Document190 pagesAcroba SerManual FA15-30Vasile Vrabie100% (4)

- Sugar Beet Conveyor Belt Gear Box-Pinion-11kwDocument4 pagesSugar Beet Conveyor Belt Gear Box-Pinion-11kwShabanali OmraniNo ratings yet

- Workshop Manual - Daihatsu 3 Cyl 993cc EFIDocument182 pagesWorkshop Manual - Daihatsu 3 Cyl 993cc EFIrhozel201082% (11)

- Proračun Vratila 3.brzinaDocument17 pagesProračun Vratila 3.brzinaJurmanNo ratings yet

- Ring Girder (Japan-1)Document26 pagesRing Girder (Japan-1)ewanz89100% (2)

- Service Data: Trimmer/BrushcutterDocument7 pagesService Data: Trimmer/BrushcutterrexNo ratings yet

- O.GB - gp1.gp1: Calculation of A Helical Gear PairDocument102 pagesO.GB - gp1.gp1: Calculation of A Helical Gear PairS.DasguptaNo ratings yet

- 8.12.01.03 - Technical Data CH890Document8 pages8.12.01.03 - Technical Data CH890gytoman100% (1)

- Woo Chang Coupling - 112438 - Paqndr oYtYHS8Document14 pagesWoo Chang Coupling - 112438 - Paqndr oYtYHS8Eng-anwer kadhimNo ratings yet

- Proračun Vratila 2.brzinaDocument17 pagesProračun Vratila 2.brzinaJurmanNo ratings yet

- Data Sheet PumpDocument6 pagesData Sheet PumpEnrico PatechiNo ratings yet

- Stepper Motor OMHT - Series PDFDocument7 pagesStepper Motor OMHT - Series PDFP_I_P_HNo ratings yet

- 1 2Document4 pages1 2William PowellNo ratings yet

- Calculo Flecha TerminadoDocument149 pagesCalculo Flecha TerminadoSebastián ValenciaNo ratings yet

- Iso 527 2 2012 PDFDocument16 pagesIso 527 2 2012 PDFRafael CastroNo ratings yet

- Canada SCC Mexico Nyce or Nom United States NRTLDocument5 pagesCanada SCC Mexico Nyce or Nom United States NRTLHamza saeedNo ratings yet

- Investigation of Micro-Structure and Creep Life Analysis of Centrifugally Cast Fe-Cr-Ni Alloy Reformer TubesDocument5 pagesInvestigation of Micro-Structure and Creep Life Analysis of Centrifugally Cast Fe-Cr-Ni Alloy Reformer TubesOwais MalikNo ratings yet

- Assignment-7question and SolutionDocument3 pagesAssignment-7question and SolutionTusharNo ratings yet

- Lista MateriałówDocument7 pagesLista MateriałówVanessa KowalskaNo ratings yet

- New Pump Connection Scheme (Anudan Yojna)Document15 pagesNew Pump Connection Scheme (Anudan Yojna)souvikbesu89No ratings yet

- 2014 - A.H. GalamaDocument13 pages2014 - A.H. GalamaThong NguyenNo ratings yet

- CAPE Chemistry Mock Exams U2 2015Document19 pagesCAPE Chemistry Mock Exams U2 2015Nicholas CharlesNo ratings yet

- Composite Structures: SciencedirectDocument13 pagesComposite Structures: SciencedirectElsa SandeepNo ratings yet

- 500mL PETG Storage Bottle Reagent Bottle Screw CapDocument9 pages500mL PETG Storage Bottle Reagent Bottle Screw CapPavan AvulaNo ratings yet

- Report On Treatment of Waste WaterDocument7 pagesReport On Treatment of Waste WaterSaptarshi GiriNo ratings yet

- Combined Science Paper 6 Summer 02Document16 pagesCombined Science Paper 6 Summer 02igcsepapersNo ratings yet

- Sos 201Document252 pagesSos 201Oli Yadii Dha100% (1)

- Quizlet FinalSDocument26 pagesQuizlet FinalSCrisna Rivera PundanoNo ratings yet

- Photo-Conversion and Photo-Catalytic Efficiency of Hydrothermally Treated Anatase-Tio Films and NanoparticlesDocument8 pagesPhoto-Conversion and Photo-Catalytic Efficiency of Hydrothermally Treated Anatase-Tio Films and NanoparticlesPatricia BarreraNo ratings yet

- Additives Used in The Production of PET: Antimony Tri-Acetate, CatalystDocument4 pagesAdditives Used in The Production of PET: Antimony Tri-Acetate, CatalystHAmza RiAzNo ratings yet

- ANSI Cast and Ductile Iron Flange Chart Dimensions Pressure Temperature RatingsDocument3 pagesANSI Cast and Ductile Iron Flange Chart Dimensions Pressure Temperature RatingsMohamedGhanemNo ratings yet

- Hospital Waste Management PolicyDocument3 pagesHospital Waste Management PolicyMary Jean GelitoNo ratings yet

- T-BEAMS LecturesDocument31 pagesT-BEAMS LecturesEurydiceNo ratings yet

- MSDS PPCPDocument4 pagesMSDS PPCPSivakumar AmbikapathyNo ratings yet

- CEM-3 Material Generation in PCB Board ManufacturingDocument2 pagesCEM-3 Material Generation in PCB Board ManufacturingpcbboardszNo ratings yet

- LR Weld Certification Guide v1.3 SubscribeDocument24 pagesLR Weld Certification Guide v1.3 SubscribeSergio Jesus SanjurjoNo ratings yet

- Stainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16Document10 pagesStainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16ManuelNo ratings yet

- Periodic Test-I (2021-22) : XII/ Chemistry/1 of 2Document2 pagesPeriodic Test-I (2021-22) : XII/ Chemistry/1 of 2Aryan BhardwajNo ratings yet

- Approved: Materials Engineering SpecificationDocument2 pagesApproved: Materials Engineering SpecificationRonald AraujoNo ratings yet

- d01 PORTAL SPLAPP PDF Useful Informations ScrutinyCases 2013 2014 Faridabad (W) R PDFDocument43 pagesd01 PORTAL SPLAPP PDF Useful Informations ScrutinyCases 2013 2014 Faridabad (W) R PDFAnjali Srivastava100% (1)

- KOST-NDT-MTP-02 ASME B31.3 Process Piping PDFDocument15 pagesKOST-NDT-MTP-02 ASME B31.3 Process Piping PDFmuhammad faiz100% (1)

- Zoznam NoriemDocument4 pagesZoznam NoriemPeter TvardzíkNo ratings yet

- ExcelSheetForCalculationPurposeOnly To MR Subburaman 29 04 23Document4 pagesExcelSheetForCalculationPurposeOnly To MR Subburaman 29 04 23slipformNo ratings yet

- Leaching and Recovery of Gold From Ore in Cyanide Free GlycineDocument11 pagesLeaching and Recovery of Gold From Ore in Cyanide Free GlycineBgo HassanNo ratings yet