Professional Documents

Culture Documents

Tehncial Specification FOR: Specification No. CSC-55/DH/UH/P&D/2010-2011

Uploaded by

AMIT GUPTAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tehncial Specification FOR: Specification No. CSC-55/DH/UH/P&D/2010-2011

Uploaded by

AMIT GUPTACopyright:

Available Formats

_______________________________________________________________________

Specification No. CSC- 55/DH/UH/P&D/2010-2011

TEHNCIAL SPECIFICATION FOR HT AERIAL BUNCHED CABLE WITH XLPE INSULATION

Issue Month: Sep. 2010

Common Specifications Committee UHBVN &DHBVN

Page 1 of 10

_______________________________________________________________________

TECHNICAL SPECIFICATIONS FOR X-LINKED POLYPTHYLENE INSULATED AND PVC SHEATHED H.T. AERIAL BUNCHED CABLES.

1.

SCOPE: This specification covers manufacture, testing before dispatch, supply and delivery of ISI marked, 11 KV grade XLPE insulated screened all Aluminium conductor and PVC sheathed power cables conforming to IS-7098 (PartIi)/1985 with up to date amendments, suitable for solidly earthed system manufactured with dry cure technology (Nitrogen gas i.e with inert gas curing during using CCV system or with STOPLAS).

2.

APPLICABLE STANDARDS The cable covered under this specification shall conform in all respect with the latest editions of IS-14255: 1995, IS:7098 (Part-II)/1985, IS-398 (part-4) 1979, IS:10810(series)& IS: 8130-1984 or IEC equivalent thereof. The aluminium conductor complying to IS: 8130-1984 shall be used.

3.

CLIMATIC CONDITIONS: The material to be supplied against this specification shall be suitable for satisfactory operation under the following climatic Conditions i) Location At various locations in the state of Haryana 60 -5 40

Maximum ambient temperature (oC) Minimum ambient air temperature (oC) Maximum average daily ambient temperature (oC) v) Maximum yearly weighed average ambient 32 o temperature ( C) vi) Maximum altitude above mean sea level (m) 1000 vii) Minimum Relative Humidity (%) 26 viii) Maximum Relative Humidity (%) 95 ix) Average no of Rainy days/ year 120 x) Average annual rainfall 900 mm xi) Maximum wind pressure 195 kg/m sq. The material shall be for use in moderately hot and humid tropical ii) iii) iv) climate, conducive to rust and fungus growth 4. CONDUCTORS: The Aluminium conductors shall comply with the requirements as specified in IS-8130-1984 with up to date amendments. The stranded conductor

shall be clean and reasonably uniform in size and shape and its surface shall be free from sharp edges. Not more than two joints shall be allowed in any of the wires form and every complete length of conductor and no joint shall be within 300 mm of any other joint in the same layer. Joints shall be brazed, silver soldered or electric or gas welded. No joint shall be made in the conductor once, it has been stranded.

Page 2 of 10

_______________________________________________________________________

5.

INSULATION: The insulation shall be chemically cross linked polyethylene conforming to the physical, electrical and ageing properties as required in the specification, cross-linking may be done by exposure to organize peroxide with nitrogen curing CCV line, method with the intention to ensure lowest free formation. Only natural unfilled compound shall be used for insulation of cables. The average thickness of insulation when measured in

accordance with relevant clause of the specification shall not be less than the standard thickness value specified. The smallest of the measured

values of thickness shall not fall below the standard thickness values as specified in IS:7098 (Part-II) / 1985 by more than 0.1+0.1 standard thickness in mm. 6. SCREENING: The screening of insulated cables shall consist of conductor screening and insulation screening. i) Screening materials: Two types of materials may be used for screening of cables non-metallic and metallic. ii) Conductor screening: Conductor screening shall be non-metallic and shall consist of either semiconducting compound or a layer of extruded-semi-conducting linked ploythine compound of thickness not less than 0.5mm. iii) Insulation screening: The insulation screening shall consist of non-metallic semi-conducting part in combination with a metallic part. Non-metallic part shall be applied either directly over the insulation of each core and shall consist of either a semiconducing tape or a layer of extruded semi-conducting compound or a combination of these materials. iv) Metallic Screening The metallic part shall be applied over the individual core. Metallic

screening shall consist of copper tape sheath and shall be non-magnetic when applied to either in single core or multi-core cables. For single core cables, armouring shall constitute the metallic part of the screening. 7. OUTER SHEATH: Over the armouring the cable shall be provided with extruded PVC outer sheath. The composition of the PVC compound for outer sheath shall be Pre-Type ST2 of IS-5831-1984. The colour of the outer sheath shall be black. The average thickness of the sheath shall not be less than the

standard values specified in the IS when measured as laid in IS-7098 (PartII) / 1985. The smallest thickness of the measured values of sheath shall

Page 3 of 10

_______________________________________________________________________

not fall below the standard value, (s) specified, by more than 0.2+0.2 (ts) mm. 8. CORE IDENTIFICATION: The core identification shall be done by providing coloured strip under Copper Tape. 9. MESSENGER WIRE: Messenger wire, shall consist of Aluminium alloy wires. Aluminium alloy wires, shall be as per IS:398 (Part-IV) / 1978 and wing shall be tested as per relevant IS. 10. LAYING UP: Three Power Cores shall be twisted over bare messenger wire with right hand direction of lay. This will form the Aerial Bunched Cable. 11. 11.1 TESTS: Copies of the type test certificates in respect of all the type-tests as per IS:7098 (Part-2) / 1985 for similar type of XLPE cables, from any Government recognized testing labs shall be submitted along with the tender. 11.1.2 LIST OF TYPE TESTS: a) TESTS ON CONDUCTOR: i) ii) iii) b) c) Tensile test (for Aluminium) Wrapping test (for Aluminium) Resistance test

Test for thickness of insulation and sheath. Physical tests for insulation. i) ii) iii) iv) v) Tensile strength and elongation at break. Ageing in air oven. Hot test. Shrinkage test. Water absorption (Gravimetric)

d)

Physical tests for outer sheath:i) ii) iii) iv) Tensile strength and elongation at break. Ageing in air oven. Shrinkage test. Hot deformation.

e) f) g) h)

Bleeding and blooming test (for outer sheath). Partial discharge test. Bending test. Dielectric power factor test: i) ii) As a function of voltage As a function of temperature

Page 4 of 10

_______________________________________________________________________

i) j) k) l) m) 11.2

Insulation resistance (Volume resistivity) test. Heating cycle test. Impulse withstand test. High voltage test. Flammability test List of type test for messenger wire: a) Breaking load test on individual Aluminium Alloy wire. b) c) Resistance test. Elongation test.

12.2. ACCEPTANCE TESTS: The following shall be carried out as acceptance tests: a) b) c) d) e) f) g) h) i) 13. Tensile test (for Aluminium) Wrapping test (for Aluminium) Conductor resistance test. Test for thickness of insulation and sheath. Partial discharge test (for screened cables only) High voltage test. Hot set test for insulator. Tensile strength and elongation at break test for insulation and sheath. Insulation resistance (Volume resistively) test ROUTINE TESTS: The following shall be carried out as routine tests: a) b) c) Conductor resistance test (for Aluminium and copper) Partial discharge test (for screened cables only) High voltage test. Type test / acceptance test / routine tests and or other test required as per relevant Indian Standard shall be got conducted. 14. INSPECTION: An authorized representative of the Nigam shall inspect, examine and test the equipment/material in respect of quality, size and ratings as per relevant ISS/IEC with latest amendments at the manufacturers works during or after the manufacture of goods prior to dispatch on receipt of a clear notice of minimum two weeks in advance to be reckoned from the date of receipt of the same by the purchaser. No material will be allowed to be dispatched without prior inspection and approval. The inspecting officer of the

purchaser may also inspect the material during the course of manufacture. In case, inspection of any consignment is waived off by the purchaser, the supplier will be required to furnish the requisite test certificates (for acceptance as well as routine tests) for approval. It will be the responsibility of the supplier to make adequate arrangements for testing of material at

Page 5 of 10

_______________________________________________________________________

their works without any additional charge to the purchaser.

All testing

instruments and appliances will be made available and material destroyed/consumed during testing will be to the account of the supplier. The purchase reserves the right to carry out Type Test as per Indian Standard Specifications with latest version thereof. These tests will be

carried out at an Independent & recognized test house/agency/laboratory. All expenses whatsoever for carrying out these tests shall be to the suppliers account. The purchaser has the right to have the tests carried out at any Govt./Recognized Test agency in case of dispute in quality, size and ratings as per relevant ISS. 15 FAKE INSPECTION CALLS In case the supplier makes a fake inspection call i.e., the material is not found ready by the Inspecting Officer deputed by the Nigam for inspection, the supplier shall be liable to pay the expenses incurred by the Nigam on this account subject to minimum of a fixed penalty of Rs. 20,000/- for each such fake call made by him. 16. GUARANTEE / WARRANTEE The supplier shall be responsible to replace, free of cost, with no transportation or insurance cost to the Purchaser, up to destination, the whole or any part of the material which in normal and proper use proves the defective in quality or workmanship, subject to the condition that the defect is noticed within 78 months from the date of receipt of material in stores or 72 months from the date of commissioning whichever period may expire earlier. The consignee or any other officer of Nigam actually using the material will give prompt notice of each such defect to the supplier. The replacement shall be effected by the supplier within a reasonable time, but not, in any case, exceeding 45 days. The supplier shall, also, arrange to remove the defective within a reasonable period, but not exceeding 45 days from the date of issue of notice in respect thereof, failing which, the purchaser reserve the right to dispose of defective material in any manner considered fit by him (Purchaser), at the sole risk and cost of the supplier. Any sale proceeds of the defective material after meeting the expenses incurred on its custody, disposal handling etc., shall however be credited to the suppliers account and set off against any outstanding dues of the purchaser against the supplier. The warranty for 72/78 months shall be one time. 17. SEQUENTIAL MARKING: Supplier shall provide non erasable sequential marking on one core of AB Cable at every one metre distance before assembly of different cores to

Page 6 of 10

_______________________________________________________________________

form the cable. However, the length of cable for acceptance shall be based on length of finished cable and not on the basis of sequential marks. 18. PACKING & MARKING: The cable shall be supplied in suitable non-returnable wooden drums of suitable size in standard lengths subject to a tolerance of +/- 5%. The cable shall be wrapped with polythene under wooden covering. Each meter

length shall be embossed with the trade name of manufacturer and the work UHBVN CABLE. The ends of the cable shall be sealed by means of non-hygroscopic sealing material. In addition to this each drum shall carry the following information either stenciled on flange or label attached to it. a) b) c) d) e) f) g) h) i) j) k) l) m) n). 19 Manufacturers name. Trade mark, if any. A reference to ISS i.e. IS-7098 (Part-II) / 1985. Length of the cable on the drum. Voltage grade and type of the cable. Colour of outer sheath. Nominal cross-sectional area of the cable conductor. Purchase order No. & Date. Name and address of consignee. Number of cores. Gross weight of packed and net weight of the power cable. Drum No. & its direction of rotation (with an arrow) Year of manufacture. ISI MARK. ISI mark cable shall be preferred. FAKE INSPECTION CALLS In case the supplier makes a fake inspection call i.e., the material is not found ready by the Inspecting Officer deputed by the Nigam for inspection, the supplier shall be liable to pay the expenses incurred by the Nigam on this account subject to minimum of a fixed penalty of Rs. 20,000/- for each such fake call made by him. 20. GUARANTEE / WARRANTEE The supplier shall be responsible to replace, free of cost, with no transportation or insurance cost to the Purchaser, up to destination, the whole or any part of the material which in normal and proper use proves the defective in quality or workmanship, subject to the condition that the defect is noticed within 78 months from the date of receipt of material in stores or 72 months from the date of commissioning whichever period may expire earlier. The consignee or any other officer of Nigam actually using the material will give prompt notice of each such defect to the supplier. The

Page 7 of 10

_______________________________________________________________________

replacement shall be effected by the supplier within a reasonable time, but not, in any case, exceeding 45 days. The supplier shall, also, arrange to remove the defective within a reasonable period, but not exceeding 45 days from the date of issue of notice in respect thereof, failing which, the purchaser reserve the right to dispose of defective material in any manner considered fit by him (Purchaser), at the sole risk and cost of the supplier. Any sale proceeds of the defective material after meeting the expenses incurred on its custody, disposal handling etc., shall however be credited to the suppliers account and set off against any outstanding dues of the purchaser against the supplier. The warranty for 72/78 months shall be one time. 21. CHALLENGE CLAUSE The material offered/received after the inspection by the authorized inspecting officer may again be subjected to the test for losses or any other parameter from any Testing House/in-house technique of the Nigam & the results if found deviating un-acceptable or not complying to approved GTP's the bidder shall arrange to supply the replacement within thirty (30) days of such detection at his cost including to & fro transportation. In addition to this penalty @10% of cost of the inspected lot of material shall be imposed.

22.

SCHEDULE OF PARTICULARS:-

GUARANTEED

AND

GUIDING

TECHNICAL

The tenderers must supply the detailed guaranteed and other technical particulars as detailed in Appendix-I. For values, use of Dash Do Blank or As per ISS/IEC will not be entertained.

General Manager/P&D Cum-Member Secretary CSC UHBVN Panchkula.

Page 8 of 10

_______________________________________________________________________

APPENDIX-I

GUARANTEED TECHNICAL PARTICULARS FOR HT AERIAL BUNCHED CABLE WITH CROSS - LINKED POLYETHYLENE (XLPE) INSULATION & BARE MESSENGER WIRE (FOR NEUTRAL & EARTHING)

S.N.

Particulars

HT Aerial Bunched Cables Size-1 Size-2 Size-3 Size.. so on

1 2 3 i) ii) iii) iv) v)

vi) vii) viii) ix) 4. i) ii) iii)

iv) v) vi) vii) 5 i) ii)

iii) 6

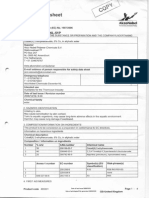

Makers name & address Rated voltage Phase conductor details No. of phase conductors Nominal cross-sectional area of each conductor-mm No. & size of strands (mm) Minimum tensile strength of each strand-N/mm Diameter of compacted conductor along with tolerance (mm). Approximate mass (Kg/Km) Maximum DC resistance at 20o C (Ohm/Km) Insulation thickness (mm) Standard to which this material conforms Messenger (Neutral conductor) Nominal sectional area of each conductor in mm No. & size of strands (mm) Diameter of compacted conductors along with tolerance (in mm) Approx. mass (Kg/Km) Minimum Tensile strength in KN Max. DC resistance at 20o C (Ohm/Km) Standard specification to which this material conform Insulation of phase conductor Material Whether all properties as mentioned in the technical Specifications are guaranteed if not indicate deviations in properties Standard specification to which this material shall conform Finished cable (complete bunched cable) Overall diameter (approx.) in mm

Page 9 of 10

i)

_______________________________________________________________________

ii) 7. i) ii) iii) 8 9 i) ii) 10. 11 12. 13. 14 15

Total mass (approx.) in Kg/Km Drum Tare weight of drum Whether drum is wheel mounted Standard specification to which drum shall conform Standard length of each cable and its tolerance Total length of cable in a drum and its tolerance Mass of finished cable in a drum and its tolerance Whether material bears ISI certification mark Serial number of ISI license and its validity Max. Continuous current carrying capacity Max. Continuous conductor temperature due to load Embossing Any other particulars

(Suppliers Name & Address)

Page 10 of 10

You might also like

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 11kv CablesDocument46 pages11kv CablesS.k. RathNo ratings yet

- LTX Lpe Cable RevDocument9 pagesLTX Lpe Cable RevRakesh ShinganeNo ratings yet

- Tech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Document6 pagesTech - Spec.-Aerial Bunched Cable-XLPE Insulated H.T. Cable.Bilal AhmadNo ratings yet

- Technical Specification of Control CableDocument5 pagesTechnical Specification of Control CableBknboy PaliNo ratings yet

- Is 10418 Technical Specification of XLPE Insulated LT CablesDocument4 pagesIs 10418 Technical Specification of XLPE Insulated LT CablesManoj AgarwalNo ratings yet

- HTXLPESPEC2006Document11 pagesHTXLPESPEC2006Faazil FairoozNo ratings yet

- Technical SpecificationDocument7 pagesTechnical Specificationshivam dwivediNo ratings yet

- FEWA LV Cable SpecsDocument46 pagesFEWA LV Cable Specsjtwani100% (2)

- Specification of HT CablesDocument5 pagesSpecification of HT Cablesankit_3084No ratings yet

- CSC XxxxixDocument10 pagesCSC XxxxixAshish bhattNo ratings yet

- Disc IsulatorDocument11 pagesDisc IsulatorganeshNo ratings yet

- Acsr Conductor: Engineering DepartmentDocument8 pagesAcsr Conductor: Engineering DepartmentpvenkyNo ratings yet

- Ti SPC Ohe Inscom 107Document44 pagesTi SPC Ohe Inscom 107mukeshhNo ratings yet

- SpecificationsDocument5 pagesSpecificationsAnonymous mcHqIfbnV1No ratings yet

- Tech SpecificationsDocument47 pagesTech Specificationssureshn829No ratings yet

- Technical - Specifications - 2023 11 22 16 25 30Document7 pagesTechnical - Specifications - 2023 11 22 16 25 30ls csNo ratings yet

- Cathodic Protection 2015Document21 pagesCathodic Protection 2015ainunNo ratings yet

- Technical Specifications 2c X 4 mm2 4C X 6mm2 XLPE 2025Document7 pagesTechnical Specifications 2c X 4 mm2 4C X 6mm2 XLPE 2025cricket storiesNo ratings yet

- Tech - Spec. 1.1KV Grade Control Cable-2008Document4 pagesTech - Spec. 1.1KV Grade Control Cable-2008Pratik SarkarNo ratings yet

- CSC 115R 1Document15 pagesCSC 115R 1walid kawsarNo ratings yet

- Technical Specifications and GTP For 11KV XLPE Cable SP 574Document13 pagesTechnical Specifications and GTP For 11KV XLPE Cable SP 574hafizrahimmitNo ratings yet

- Ti SPC Ohe Inscom 1070Document23 pagesTi SPC Ohe Inscom 1070hardeepsingh_08No ratings yet

- Is 7098 Part I 1998Document17 pagesIs 7098 Part I 1998Sanjeev DhariwalNo ratings yet

- 0 Line 13 Conductor Zebra Used in Transmission LinesDocument9 pages0 Line 13 Conductor Zebra Used in Transmission LinesPavithra ShivanNo ratings yet

- APTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedDocument13 pagesAPTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedAshutosh SharmaNo ratings yet

- Technical Specifications For Aerial BunchedDocument5 pagesTechnical Specifications For Aerial BunchedNazriNo ratings yet

- Medium Voltage Composite InsulatorsDocument14 pagesMedium Voltage Composite Insulatorsdeepthik27No ratings yet

- Techni - DPC WireDocument4 pagesTechni - DPC WirevivekNo ratings yet

- Section-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPEDocument5 pagesSection-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPESandeep SharmaNo ratings yet

- 0.9. OPGW - Tech - Discription For OPGWDocument12 pages0.9. OPGW - Tech - Discription For OPGWgiorgis072No ratings yet

- CSC-XII 1 C Is 7098 Part 2Document8 pagesCSC-XII 1 C Is 7098 Part 2Ashish bhattNo ratings yet

- 03 Long Rod Porcelain Insulators e 2219Document25 pages03 Long Rod Porcelain Insulators e 2219Velu SamyNo ratings yet

- 22 Dead-End & Suspension InsulatorsDocument16 pages22 Dead-End & Suspension Insulatorsrye_eeNo ratings yet

- 5 Clamps Connectors 220 400kv SsDocument12 pages5 Clamps Connectors 220 400kv SsJaswanth SaiNo ratings yet

- Opgw SpecificDocument21 pagesOpgw SpecificASH TVNo ratings yet

- Technical Specification of Dog ConductorDocument6 pagesTechnical Specification of Dog ConductorSupriyo Podder75% (4)

- Cables Specifications VFDocument13 pagesCables Specifications VFraiutkarshNo ratings yet

- NTPC Spec Cable....Document4 pagesNTPC Spec Cable....Mutharasan VishnuNo ratings yet

- FEWA LV Joints & TerminationsDocument13 pagesFEWA LV Joints & TerminationsMuhammad RazaNo ratings yet

- Tech. Spec. For ConductorDocument26 pagesTech. Spec. For ConductorbinodeNo ratings yet

- Technical Specification For 1.1 KV Grade Single Core 400 Sq. MM LT Un-Armoured Xlpe Cable 1 .0. ScopeDocument8 pagesTechnical Specification For 1.1 KV Grade Single Core 400 Sq. MM LT Un-Armoured Xlpe Cable 1 .0. ScopePrakash RoutNo ratings yet

- Techinical Specification of Polymer 11 KV & 33 KV Pin InsulatorDocument14 pagesTechinical Specification of Polymer 11 KV & 33 KV Pin InsulatordamlanNo ratings yet

- 04 HW Accs Zebra Conductor PDFDocument23 pages04 HW Accs Zebra Conductor PDFelsayedNo ratings yet

- Medium Voltage CableDocument7 pagesMedium Voltage Cableakheel201No ratings yet

- Technical Specification For Aac / Acsr ConductorsDocument8 pagesTechnical Specification For Aac / Acsr ConductorsDeepeshMaliNo ratings yet

- Section-Viii: Composite Long Rod InsulatorDocument33 pagesSection-Viii: Composite Long Rod Insulatorsaravanan jNo ratings yet

- Technical Specifications: 4. General Design and Constructional FeaturesDocument4 pagesTechnical Specifications: 4. General Design and Constructional FeatureskeyurNo ratings yet

- 11kv Disc Insulator GTP and SpecificationDocument10 pages11kv Disc Insulator GTP and SpecificationSatyaNo ratings yet

- Electrical Tender SpecficationDocument40 pagesElectrical Tender SpecficationtrivedimechNo ratings yet

- 12 SDMS 01rev1Document16 pages12 SDMS 01rev1sardarmkhanNo ratings yet

- 3 Silicone Rubber InsulatorsDocument24 pages3 Silicone Rubber Insulatorsdecorindo2002100% (1)

- Section 5 Solid Core Post Type InsulatorsDocument5 pagesSection 5 Solid Core Post Type Insulatorsthumula.rameshNo ratings yet

- Technical Specification - Cast Resin - v1Document13 pagesTechnical Specification - Cast Resin - v1ramprathap23No ratings yet

- Annex (C) Technical Specifications For Overhead Line ConductorsDocument15 pagesAnnex (C) Technical Specifications For Overhead Line ConductorsshahpinkalNo ratings yet

- 47 TS For Armoured 75 Ohm Coaxial Cable For PLCCDocument8 pages47 TS For Armoured 75 Ohm Coaxial Cable For PLCChiralalnhpcNo ratings yet

- XLPE Power Cable 11 & 33 KVDocument9 pagesXLPE Power Cable 11 & 33 KVArjun M KumarNo ratings yet

- User Guide For E-Registration of VAT & Entry TaxDocument29 pagesUser Guide For E-Registration of VAT & Entry TaxAMIT GUPTANo ratings yet

- I Semester 3 Year LL.B./III Semester 5 Year B.A. LL.B./B.B.A. LL.B. Examination, December 2014 ConstitutionDocument3 pagesI Semester 3 Year LL.B./III Semester 5 Year B.A. LL.B./B.B.A. LL.B. Examination, December 2014 ConstitutionAMIT GUPTANo ratings yet

- Litigation Statistics-Up To 30 Sept. 2016Document12 pagesLitigation Statistics-Up To 30 Sept. 2016AMIT GUPTANo ratings yet

- Property LawDocument3 pagesProperty LawAMIT GUPTANo ratings yet

- II Semester of 3 Year LL.B./VI Semester of 5 Year B.A. LL.B./B.B.A. LL.B. Examination, June/July 2014 Family Law - Ii: Mohammaden Law and Indian Succession ActDocument4 pagesII Semester of 3 Year LL.B./VI Semester of 5 Year B.A. LL.B./B.B.A. LL.B. Examination, June/July 2014 Family Law - Ii: Mohammaden Law and Indian Succession ActAMIT GUPTANo ratings yet

- d6 Constitutional LawDocument3 pagesd6 Constitutional LawAMIT GUPTANo ratings yet

- I Semester 3 Yr. LL.B./V Semester 5 Yr. B.A.LL.B./B.B.A.LL.B. Examination, December 2014 Law of Torts and Consumer Law (Course - Iii)Document3 pagesI Semester 3 Yr. LL.B./V Semester 5 Yr. B.A.LL.B./B.B.A.LL.B. Examination, December 2014 Law of Torts and Consumer Law (Course - Iii)AMIT GUPTANo ratings yet

- First Semester of 3 Years LL.B. /fifth Semester of 5 Years B.A. LL.B./ B.B.A. LL.B. Examination, June/July 2014 Criminal Law - I Indian Penal CodeDocument3 pagesFirst Semester of 3 Years LL.B. /fifth Semester of 5 Years B.A. LL.B./ B.B.A. LL.B. Examination, June/July 2014 Criminal Law - I Indian Penal CodeAMIT GUPTANo ratings yet

- First Semester of Three Year LL.B./Third Semester of Five Year B.A.LL.B./B.B.A.LL.B. Examination, December 2013 Indian Constitutional Law (Course - Ii)Document4 pagesFirst Semester of Three Year LL.B./Third Semester of Five Year B.A.LL.B./B.B.A.LL.B. Examination, December 2013 Indian Constitutional Law (Course - Ii)AMIT GUPTANo ratings yet

- Indian Penal CodeDocument2 pagesIndian Penal CodeAMIT GUPTANo ratings yet

- Cobalt Safety Data SheetDocument8 pagesCobalt Safety Data SheetAMIT GUPTANo ratings yet

- First Semester of Three Year LL.B. / Fifth Semester of 5 Yrs. B.A. LL.B. / B.B.A. LL.B. Examination, June/July 2014 Law of Torts (Course - Iii)Document4 pagesFirst Semester of Three Year LL.B. / Fifth Semester of 5 Yrs. B.A. LL.B. / B.B.A. LL.B. Examination, June/July 2014 Law of Torts (Course - Iii)AMIT GUPTANo ratings yet

- First Semester Three Year LL.B./Fifth Semester Five Year B.A. LL.B./B.B.A. LL.B Examination, January 2012 CRIMINAL LAW - I (Indian Penal Code) (Course - V)Document4 pagesFirst Semester Three Year LL.B./Fifth Semester Five Year B.A. LL.B./B.B.A. LL.B Examination, January 2012 CRIMINAL LAW - I (Indian Penal Code) (Course - V)AMIT GUPTANo ratings yet

- First Semester of Three Year LL.B./Fifth Semester of Five Year B.A.LL.B./ B.B.A. LL.B. Course Examination, December 2013 Criminal Law I Indian Penal Code (Course V)Document3 pagesFirst Semester of Three Year LL.B./Fifth Semester of Five Year B.A.LL.B./ B.B.A. LL.B. Course Examination, December 2013 Criminal Law I Indian Penal Code (Course V)AMIT GUPTANo ratings yet

- BTX m60 MsdsDocument10 pagesBTX m60 MsdsAMIT GUPTANo ratings yet

- CD 0105Document3 pagesCD 0105AMIT GUPTANo ratings yet

- How To Use Washing MachineDocument1 pageHow To Use Washing MachineAMIT GUPTANo ratings yet

- Price Schedule - Term SheetDocument1 pagePrice Schedule - Term SheetAMIT GUPTANo ratings yet

- EUR RECOMMEND REUSE STEEL PRODUCTS Design - Guide 2020Document234 pagesEUR RECOMMEND REUSE STEEL PRODUCTS Design - Guide 2020MNo ratings yet

- Event CodesDocument149 pagesEvent CodesCoque de LunaNo ratings yet

- Class 10 - Electricity - Term IDocument6 pagesClass 10 - Electricity - Term IravilullaNo ratings yet

- Week 8 Pumps and Earthing System NotesDocument18 pagesWeek 8 Pumps and Earthing System NotesMohammed SaqibNo ratings yet

- Central: BCV47 NPN Silicon Darlington TransistorDocument2 pagesCentral: BCV47 NPN Silicon Darlington TransistorВалерий ДолынкаNo ratings yet

- Syllabus For Physics of Semiconductor DevicesDocument1 pageSyllabus For Physics of Semiconductor DevicesSanjeev YdvNo ratings yet

- 3300 Proximity Transducer System: DescriptionDocument18 pages3300 Proximity Transducer System: DescriptionSuvek KumarNo ratings yet

- HV Protection Relays Setting Calculation Rev 4 PDFDocument58 pagesHV Protection Relays Setting Calculation Rev 4 PDFMohideen SikanderNo ratings yet

- PowerPoint PresentationDocument5 pagesPowerPoint Presentationscghvjb100% (1)

- A 59 ConductorsDocument2 pagesA 59 ConductorsPRAGATHI REDDYNo ratings yet

- Strain, Force, and PressureDocument22 pagesStrain, Force, and PressureOnur Deniz NarinNo ratings yet

- ED Lesson PlanDocument5 pagesED Lesson PlanGeetha MNo ratings yet

- Wheatstone BridgeDocument4 pagesWheatstone BridgeTasnim RahmanNo ratings yet

- Mock Test Paper 8Document6 pagesMock Test Paper 8Ravi Kanth M NNo ratings yet

- Measurement of Stator Resistance TestDocument4 pagesMeasurement of Stator Resistance TestS.DharanipathyNo ratings yet

- Avr1513 PDFDocument130 pagesAvr1513 PDFluisNo ratings yet

- Physics 23 Jul by Razz..Document3 pagesPhysics 23 Jul by Razz..Ajay KunduNo ratings yet

- EECT Lab ManualDocument4 pagesEECT Lab ManualBlaze fireNo ratings yet

- Electrical and Magnetic MaterialDocument14 pagesElectrical and Magnetic MaterialVishwajeet DhanwadeNo ratings yet

- SCHLEICH - EN - Bedienungsanleitung SurgeWinDocument55 pagesSCHLEICH - EN - Bedienungsanleitung SurgeWinRolando LoayzaNo ratings yet

- Vahle F Seri̇si̇ BaraDocument24 pagesVahle F Seri̇si̇ Barahalkaya777No ratings yet

- Katalog Gromjobranska ZaštitaDocument275 pagesKatalog Gromjobranska ZaštitaMuharem HoriicNo ratings yet

- Input CircuitsDocument34 pagesInput Circuitsvadithya1515No ratings yet

- Abbreviated Component Maintenance Manual 810211, 810218, 810220, 810223Document10 pagesAbbreviated Component Maintenance Manual 810211, 810218, 810220, 810223ChristianNo ratings yet

- Landauer Buttiker Formalism PDFDocument15 pagesLandauer Buttiker Formalism PDFJacobNo ratings yet

- Chapter 7 - Electricity (Students Copy)Document28 pagesChapter 7 - Electricity (Students Copy)Faizah Nur ZaNo ratings yet

- Zelio Relay Rumc2ab1f7Document5 pagesZelio Relay Rumc2ab1f7Luis DeibisNo ratings yet

- ASTM C 168 Standard Terminology Relating To Thermal InsulationDocument6 pagesASTM C 168 Standard Terminology Relating To Thermal InsulationRyan Lasaca100% (1)

- EE305Document19 pagesEE305api-3853441No ratings yet

- Tutorial 1 - 3 PhaseDocument4 pagesTutorial 1 - 3 PhaseJiyah NajiyahNo ratings yet