Professional Documents

Culture Documents

Limits Fits

Uploaded by

bathinsreenivasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Limits Fits

Uploaded by

bathinsreenivasCopyright:

Available Formats

1 WORKSHOP

HINTS

AND

TIPS

LIMITS and FITS

an established system of limits and fits removes a great deal of uncertainty from machining and fitting. There is no doubt about results; dimensions can be written condensed as ordinary fractions; and when one is used to ordinary fractions, a good picture is retained of dimensions. Two systems are the Newall and the BS. The latter is the better for

MPLOYING

By GEOMETER

SMALLEST

wide application, but the Newall is strongly recommended to model engineers for simplicity and meeting general requirements. An example will show how easy it is. A force fit is required between a 3/8 in. hole and shaft. One writes, 3/8in. Newall A hole, 3/8 in. Newall F shaft. The picture is retained of 3/8 in. (0.375 in on the micrometer); and looking in a table of Newall limits for the size, an A hole is found to be plus or minus 1/4 thou, while an F shaft is plus 1/2 thou to plus 1 thou. For a running fit, the hole can be left the same, and a Z shaft, say, specified with limits of minus 1/2 thou to minus 3/4 thou. Without such a system, considerable practical experience is needed in deciding dimensions for fits; and these require figures which can look forbidding and destroy the simple picture. Basic rule Systems of limits and fits are arrived at logically, and terms employed are universally acceptedthough not infrequently misused. To get a force fit or a running fit, like those quoted, either the hole or the shaft must vary. In this instance, the shaft varies, and the system is hole basis, as at A. If the opposite were the method and the hole changed size, the system would be shaft basis, as at B. But with this, more fixed size tools like reamers, broaches and gauges would be needed, whereas shafts can easily be varied on lathes and grinders and checked by micrometers. Hole basis being logically decided, hole sizes can vary through their tolerance, as at C, all above the nominal diameter (unilateral), or about the nominal diameter (bilateral). The BS system has both types of holes; but Newall holes are bilateral holes. Thus, one can legitimately

24 DECEMBER 1959

use a new reamer cutting above nominal diameter and an old sharpened one cutting under nominal diameter, each within the tolerance. For unilateral holes, however, strict usefulness ends at the nominal diameter. While fits have several descriptions there are only two basic ones: clearance and interference. The Newall Limits keep these separate; but making a choice from BS tolerances, it must be such as to avoid the contingency at D, the transition fit, which is clearance at one extreme, interference at the other. Correct descriptions for dimensions are as at E. Each hole and shaft has a high and a low limit, and the difference between these is the tolerance-the variation that can be tolerated. The allowance is the minimum possible difference between holes and shafts at their appropriate

ALLOWANCE

/

limits, increasing for both clearance and interference fits. Working midway in the tolerance, of course, gives best average results for all fits. Running fits In the Newall system, the following apply for diameters up to and including 1/2 in. A holes plus or minus 1/4 thou. B holes plus or minus 1/2 thou. F shafts (force tits) plus 1/2 thou to plus 1 thou. D shafts (driving fits) plus 1/4 thou to plus 1/2 thou. P shafts (push fits) minus 1/4thou to minus 3/4 thou. There are three running fits. X shafts (easy running fits for engine work) minus 1 thou to minus 2 thou. Y shafts (for. high speeds and good average machine work) minus 3/4 thou to minus 1-1/4 thou. Z shafts (for fine tool work) minus 1/2 thou to minus 3/4 thou. Above 1/2 in. up to and including 1 in. the following apply. A holes plus 1/2 thou minus 1/4 thou. B holes plus 3/4 thou minus 1/2 thou. F shafts plus 1-1/2 thou to plus 2 thou.D shafts plus 3/4 thou to plus 1 thou. P shafts minus 1/4 thou to minus 3/4 thou. X shafts minus l-1/4thou to minus 2-3/4 thou. Y shafts minus 1 thou to minus 2 thou. Z shafts minus 3/4 thou to minus 1-1/4 thou.

MODEL ENGINEER

CLEARANCE FIT/

INTERFERENCE FIT \

0

B

TOLERANCE TOLERANCE

0

Cl

UNILATERAL BILATERAL

575

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- What Says Doctors About Kangen WaterDocument13 pagesWhat Says Doctors About Kangen Waterapi-342751921100% (2)

- Sample Cross-Complaint For Indemnity For CaliforniaDocument4 pagesSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- Digital SLR AstrophotographyDocument366 pagesDigital SLR AstrophotographyPier Paolo GiacomoniNo ratings yet

- (L. S. Srinath) Advanced Mechanics of Solids 3Document521 pages(L. S. Srinath) Advanced Mechanics of Solids 3Chitrang Bohra92% (26)

- Interferometry PresentationDocument26 pagesInterferometry PresentationbathinsreenivasNo ratings yet

- N2 V Operare ManualDocument370 pagesN2 V Operare Manualramiro0001No ratings yet

- Unit-1 Introduction Management ScienceDocument96 pagesUnit-1 Introduction Management SciencebathinsreenivasNo ratings yet

- Civil Engineering - For WebDocument28 pagesCivil Engineering - For WebbathinsreenivasNo ratings yet

- EBWDocument21 pagesEBWbathinsreenivasNo ratings yet

- DrillingDocument27 pagesDrillingbathinsreenivasNo ratings yet

- Introduction - JRPLDocument1 pageIntroduction - JRPLbathinsreenivasNo ratings yet

- "Fatigue & Fracture Mechanics in Finite Element Analysis": AICTE Sponsored Two Week FDP Programme OnDocument1 page"Fatigue & Fracture Mechanics in Finite Element Analysis": AICTE Sponsored Two Week FDP Programme OnbathinsreenivasNo ratings yet

- 2006 Int Ansys Conf 43Document9 pages2006 Int Ansys Conf 43bathinsreenivasNo ratings yet

- User's Guide: by Typing The Website Address in Any Browser, Then The Following Screen Is VisibleDocument3 pagesUser's Guide: by Typing The Website Address in Any Browser, Then The Following Screen Is VisiblebathinsreenivasNo ratings yet

- 100 20210811 ICOPH 2021 Abstract BookDocument186 pages100 20210811 ICOPH 2021 Abstract Bookwafiq alibabaNo ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- IG Deck Seal PumpDocument3 pagesIG Deck Seal PumpSergei KurpishNo ratings yet

- Eng21 (Story of Hamguchi Gohei)Document9 pagesEng21 (Story of Hamguchi Gohei)Alapan NandaNo ratings yet

- Personal Finance Kapoor 11th Edition Solutions ManualDocument26 pagesPersonal Finance Kapoor 11th Edition Solutions Manualsiennamurielhlhk100% (28)

- Neelima A Kulkarni ResumeDocument3 pagesNeelima A Kulkarni ResumeAcademics LecturenotesNo ratings yet

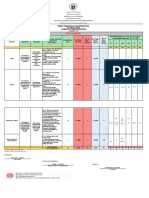

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Document6 pagesRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoNo ratings yet

- International Patient Referral - Part 2 - Revised - 29-04-2010 - 2Document2 pagesInternational Patient Referral - Part 2 - Revised - 29-04-2010 - 2Fatah AssadNo ratings yet

- Assignment 3Document2 pagesAssignment 3Debopam RayNo ratings yet

- OVDT Vs CRT - GeneralDocument24 pagesOVDT Vs CRT - Generaljaiqc100% (1)

- 200150, 200155 & 200157 Accelerometers: DescriptionDocument16 pages200150, 200155 & 200157 Accelerometers: DescriptionJOSE MARIA DANIEL CANALESNo ratings yet

- TrellisDocument1 pageTrellisCayenne LightenNo ratings yet

- BECIL Registration Portal: How To ApplyDocument2 pagesBECIL Registration Portal: How To ApplySoul BeatsNo ratings yet

- Timetable - Alton - London Timetable May 2019 PDFDocument35 pagesTimetable - Alton - London Timetable May 2019 PDFNicholas TuanNo ratings yet

- Using The Monopoly Board GameDocument6 pagesUsing The Monopoly Board Gamefrieda20093835No ratings yet

- Feds Subpoena W-B Area Info: He Imes EaderDocument42 pagesFeds Subpoena W-B Area Info: He Imes EaderThe Times LeaderNo ratings yet

- Resume NetezaDocument5 pagesResume Netezahi4149No ratings yet

- Antibiotics MCQsDocument4 pagesAntibiotics MCQsPh Israa KadhimNo ratings yet

- Invoices For UEG IstanbulDocument7 pagesInvoices For UEG IstanbulIesaw IesawNo ratings yet

- PCI Bridge ManualDocument34 pagesPCI Bridge ManualEm MarNo ratings yet

- Specialty Coffee Association of Indonesia Cupping Form (ARABICA)Document1 pageSpecialty Coffee Association of Indonesia Cupping Form (ARABICA)Saiffullah RaisNo ratings yet

- Usm 1Document47 pagesUsm 1Abhishek KumarNo ratings yet

- WinCC Control CenterDocument300 pagesWinCC Control Centerwww.otomasyonegitimi.comNo ratings yet

- Power System Planning and OperationDocument2 pagesPower System Planning and OperationDrGopikrishna Pasam100% (4)

- Model TB-16Document20 pagesModel TB-16xuanphuong2710No ratings yet

- Ds-Module 5 Lecture NotesDocument12 pagesDs-Module 5 Lecture NotesLeela Krishna MNo ratings yet