Professional Documents

Culture Documents

Ductile Concrete

Uploaded by

Salmaan RaafiQqOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ductile Concrete

Uploaded by

Salmaan RaafiQqCopyright:

Available Formats

December 2013

30

new trends, new techniques

and current industry issues

INSIGHTS

STRUCTURE magazine

Victor Li, Ph.D., FASCE,

FASME, FWIF, FACI, is the

E. Benjamin Wylie Collegiate

Professor at the University of

Michigan, Ann Arbor. He may

be reached at vcli@umich.edu.

Victor C. Li, Ph.D., FASCE,

FASME, FWIF, FACI

What if Concrete Can Be

Made Ductile?

T

he most important concrete prop-

erty in the ACI 318 Building Code is

compressive strength. Tis refects the

notion of using concrete as a strong

material against compressive stress in structural

members. Tensile forces are expected to be car-

ried by prestressing or reinforcing steel. Tese

fundamental structural design concepts of putting

concrete in compression and steel in tension have

largely worked very well.

In recent years, the increasing attention to

the need for structural resiliency and environ-

mental sustainability has shed new light on

the limitations of concrete material. Tere are

plenty of visual examples of fracture failure

of reinforced concrete members during major

earthquakes, for example. It is also known

that the durability of concrete structures is

often compromised by the presence of cracks

while exposed to an aggressive environment.

Te high carbon and energy footprints of civil

infrastructure are closely

linked to the need for

repeated repairs during

its service life.

What if concrete can be

made ductile?

A ductile concrete can

result in high structural load capacity, even

though high structural strength is more com-

monly associated with high material strength.

For structural members whose capacity is lim-

ited by brittle fracture failure of concrete, the

governing parameter is tensile ductility, not

the compressive strength. As an example, S.

Billington at Stanford University conducted a

comparative test of a shear panel using a normal

concrete of 7,250 psi compressive strength and

a ductile concrete of 5,950 psi compressive

strength. Te ductile concrete panel yielded a

higher structural shear capacity of 12,590 lbf

compared to 8,540 lbf for the normal concrete

panel. Tis illustrates that structural capacity

does not always correlate with material com-

pressive strength. Apart from enhancing load

capacity, ductility of concrete also embeds

damage tolerance, and therefore resiliency,

into structures.

While concrete structural durability is often

associated with concrete impermeability, there

is evidence that a densely packed concrete does

not always translate into structural durability.

As example, P.K. Mehta of UC Berkeley exam-

ined the durability of concrete bridge decks and

concluded that those built with high strength,

densely packed concrete have, in recent years,

demonstrated a lower service life than their

predecessors using lower strength concrete. Te

underlying cause of the discrepancy in durabil-

ity expectations is that the lower permeability

concrete is measured in the laboratory without

load application, whereas the feld permeability

of concrete structures under load is dominated

by the presence of cracks. Hence, material

durability (impermeability) does not always

translate into structural durability. Instead,

a ductile concrete can suppress cracking with

wide crack width and lend itself to supporting

structural durability.

A ductile concrete, with substantially higher

tensile ductility compared to normal concrete,

can contribute to higher structural resiliency

and environmental sustainability, the latter

by virtue of the need for less frequent repairs.

Te technology to making concrete duc-

tile, with tensile strain capacity several orders

of magnitude higher than normal concrete,

has been realized in recent years. Tis class

of concrete, often known as strain-hardening

cementitious composites (SHCC), exhib-

its a tensile stress-strain curve with a shape

that resembles that of a ductile metal, while

maintaining a compressive strength of that

of a normal to high strength concrete. While

still expensive, the material has found its way

into full-scale structural applications in sev-

eral countries and especially in Japan. Te

Japan Society of Civil Engineers has published

a design recommendation on SHCC to fll

the gap left by standard concrete structural

design codes that emphasize mainly the com-

pressive strength of concrete. In the popular

press, SHCC has often been called Bendable

Concrete due to its ability to undergo large

Figure 1: Ductile SHCC under bending.

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

rig

h

t

STRUCTURE magazine December 2013

31

A

D

V

E

R

T

I

S

E

M

E

N

T

-

F

o

r

A

d

v

e

r

t

i

s

e

r

I

n

f

o

r

m

a

t

i

o

n

,

v

i

s

i

t

w

w

w

.

S

T

R

U

C

T

U

R

E

m

a

g

.

o

r

g

IES, Inc. | 519 E Babcock St. Bozeman MT 59715

800-707-0816 | info@iesweb.com

www.iesweb.com

Free 30-Day Trial

Structural Sofware Designed for Your Success

* Easy to Learn

* Analyze Anything

* Design for:

+ Steel

+ Wood

+ Concrete

+ Aluminum

+ Cold-Formed

* Friendly Support

fexural deformation even without steel

reinforcement (Figure 1).

Figure 2 illustrates the change in building

design with the introduction of this new

SHCC technology, utilized in high-rise con-

struction project in Japan. In the design

without SHCC (Figure 2a), the building

self-centers under seismic loading by means

of two pairs of super-frames that bracket

the whole building in two perpendicular

directions. Each super-frame is constructed

of two huge columns that rise from the

building foundation to the top of the build-

ing, and connected through dampers at the

ends of an enormous sky beam. Te 9-foot-

deep beam is difcult to hoist to the top of

the building, requiring fabrication at the

building top. In the SHCC design (Figure

2b), the super-frames were eliminated and

replaced with four SHCC precast coupling

beams to connect the core walls on each

foor. Te damage tolerant SHCC coupling

beams are expected to undergo large shear

deformation in a ductile mode with high

energy-absorption capability.

In 2005, the Michigan Department of

Transportation conducted a demonstra-

tion project on a new type of jointless

bridge deck. Te conventional expan-

sion joint was replaced by a 9 inch thick

SHCC link-slab, measuring 16.5 feet

x 60.75 feet. Te link-slab connects

the adjacent normal concrete bridge

deck and accommodates temperature-

induced expansion and contraction of

the underlying steel girders, acting as

an invisible joint. Te design require-

ments called for a tensile strain capacity

of 2% in the link-slab material, a value

not achievable with standard concrete

of any compressive strength.

Other recent use of SHCC includes

repair applications, such as the rehabili-

tation of the Mitaka Dam and the repair

of the Hida tunnel lining in Japan.

While the applications in transportation,

building, water and energy infrastructures

appear widely diferent, the primary fea-

ture of SHCC is its ability to meet tensile

deformation and durability demands.

Ductile concrete can serve as a new

material technology that contributes to

enhancing civil infrastructure resiliency

and sustainability. Although current

application of the material remains lim-

ited, the advantages of ductile concrete

will likely broaden its adoption in coming

years when a supply chain of this new

class of concrete is established globally.

Figure 2: (a) Previous design with super-frame; (b) New design with SHCC coupling beams.

Courtesy of T. Kanda, Kajima Corporation, Japan.

(a) (b)

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

rig

h

t

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Dragon Drop Adventures Vol. 1 v1.3Document57 pagesDragon Drop Adventures Vol. 1 v1.3Erik.VBNo ratings yet

- Seismic Code RequirementsDocument34 pagesSeismic Code Requirementsronison78No ratings yet

- ADU Construction SetDocument9 pagesADU Construction SetNasir UllahNo ratings yet

- TxDot Bridge Design Manual (2013)Document81 pagesTxDot Bridge Design Manual (2013)AMNo ratings yet

- Light Weight ConcreteDocument17 pagesLight Weight ConcreteSUSANNo ratings yet

- Ebook PDF Steel Design 6th Edition by William T Segui PDFDocument27 pagesEbook PDF Steel Design 6th Edition by William T Segui PDFlinda.cadogan684100% (41)

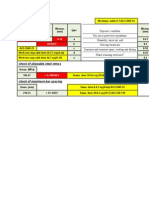

- Estimate For The Construction of 45 MTR Span SFB Over Raffu Khola in Between Rackiding and Tukdang in South SikkimDocument22 pagesEstimate For The Construction of 45 MTR Span SFB Over Raffu Khola in Between Rackiding and Tukdang in South SikkimNiraj Rai100% (6)

- Units Conversion TableDocument1 pageUnits Conversion Tabler4raj007No ratings yet

- Units Conversion TableDocument1 pageUnits Conversion Tabler4raj007No ratings yet

- Chequer Plate DesignDocument1 pageChequer Plate Designmanish_chhuganiNo ratings yet

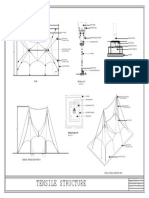

- Tensile StructureDocument1 pageTensile StructureChndrashekhar DombNo ratings yet

- Capitol Complex, ChandigarhDocument19 pagesCapitol Complex, Chandigarhkhushi bansalNo ratings yet

- AASHTO Section 11 Manual PDFDocument156 pagesAASHTO Section 11 Manual PDFChristine Hermawan100% (1)

- Architectural SpecificationsDocument12 pagesArchitectural SpecificationsRaymundo DelfinNo ratings yet

- Case StudyDocument6 pagesCase StudyPragathi P100% (1)

- Purdue Owl-Apa Sample PaperDocument11 pagesPurdue Owl-Apa Sample PaperCalvin WirawanNo ratings yet

- PipeDocument18 pagesPipeSalmaan RaafiQqNo ratings yet

- Cable ElongationDocument8 pagesCable ElongationSalmaan RaafiQqNo ratings yet

- Job Application Form: Page 2 of 2Document2 pagesJob Application Form: Page 2 of 2Salmaan RaafiQqNo ratings yet

- Healthy Food For Your Mental Health: Get Over DepressionDocument2 pagesHealthy Food For Your Mental Health: Get Over DepressionSalmaan RaafiQqNo ratings yet

- Order No. SO (WMO) 22-54 CR 2009, Dr. Qamar Sultana Bhatti, SWMO BS-18, 17-5-17Document2 pagesOrder No. SO (WMO) 22-54 CR 2009, Dr. Qamar Sultana Bhatti, SWMO BS-18, 17-5-17Salmaan RaafiQqNo ratings yet

- KALA BAGH DAM Presentation by WAPDA PDFDocument13 pagesKALA BAGH DAM Presentation by WAPDA PDFSalmaan RaafiQqNo ratings yet

- Properties of Frame Element For Grillage To Be Used in BridgeDocument1 pageProperties of Frame Element For Grillage To Be Used in BridgeSalmaan RaafiQqNo ratings yet

- PlanDocument1 pagePlanSalmaan RaafiQqNo ratings yet

- Deflection FigDocument1 pageDeflection FigSalmaan RaafiQqNo ratings yet

- Use of Limit State Design in Foundation EngineeringDocument60 pagesUse of Limit State Design in Foundation EngineeringKuber BogatiNo ratings yet

- Check of Crack WidthDocument1 pageCheck of Crack WidthSalmaan RaafiQqNo ratings yet

- CaltransDocument1 pageCaltransSalmaan RaafiQqNo ratings yet

- CaltransDocument1 pageCaltransSalmaan RaafiQqNo ratings yet

- Etd 3137Document290 pagesEtd 3137Salmaan RaafiQqNo ratings yet

- Degree of Curvature Is Used. This Is Indeed ADocument2 pagesDegree of Curvature Is Used. This Is Indeed ASalmaan RaafiQqNo ratings yet

- Etd 3137Document290 pagesEtd 3137Salmaan RaafiQqNo ratings yet

- L N 28Document7 pagesL N 28Salmaan RaafiQqNo ratings yet

- This Guide Is Provided Free of Charge and Is For Use Outside The UK OnlyDocument7 pagesThis Guide Is Provided Free of Charge and Is For Use Outside The UK OnlydwatilNo ratings yet

- Lda Act 1975 As Amended by 2013 PDFDocument28 pagesLda Act 1975 As Amended by 2013 PDFSalmaan RaafiQqNo ratings yet

- Ch5notes PDFDocument71 pagesCh5notes PDFPaul Chukwudi IkezueNo ratings yet

- Paper Formating InstructionsDocument4 pagesPaper Formating InstructionsSalmaan RaafiQqNo ratings yet

- Ch5notes PDFDocument71 pagesCh5notes PDFPaul Chukwudi IkezueNo ratings yet

- Building Estimate NewDocument40 pagesBuilding Estimate Newgolu23_1988No ratings yet

- StonemasonryDocument46 pagesStonemasonryWawaChumelNo ratings yet

- 1.3 Copy How To Unlock D-WPS OfficeDocument2 pages1.3 Copy How To Unlock D-WPS OfficeJovan DagantaNo ratings yet

- Construction PaintingDocument8 pagesConstruction PaintingSusan Mabitad100% (1)

- Architectural Vernacular TermsDocument43 pagesArchitectural Vernacular TermsNyak nyak100% (1)

- Training Plan Carpentry NC IiDocument14 pagesTraining Plan Carpentry NC IiRodel P. PilloNo ratings yet

- DDRS SyllabusDocument2 pagesDDRS SyllabusmailjoelsamuelNo ratings yet

- 5 - Structural Elements and LoadingDocument84 pages5 - Structural Elements and LoadingCt Kamariah Md SaatNo ratings yet

- Average House Construction Cost Philippines - PHILCON PRICESDocument4 pagesAverage House Construction Cost Philippines - PHILCON PRICESJohn AlcantaraNo ratings yet

- Liveable Cities Lab - Circular EconomyDocument38 pagesLiveable Cities Lab - Circular EconomyarmagnetoNo ratings yet

- Central Market, Kuala Lumpur 1.1 Central MarketDocument14 pagesCentral Market, Kuala Lumpur 1.1 Central MarketHanaAnuarNo ratings yet

- Concrete Structures For Retaining Aqueous Liquids - Code of PracticeDocument28 pagesConcrete Structures For Retaining Aqueous Liquids - Code of PracticeProject ManagerStructuresNo ratings yet

- Interiors201601 14768150050008e82fc43db PPDocument142 pagesInteriors201601 14768150050008e82fc43db PPWahid Ullah AhmedNo ratings yet

- What Is Punching Shear Punching Shear in Slabs and FoundationsDocument5 pagesWhat Is Punching Shear Punching Shear in Slabs and FoundationsUsman ShahidNo ratings yet

- Installation Instructions For Universal Lightning ArrestorDocument4 pagesInstallation Instructions For Universal Lightning ArrestorKevin_INo ratings yet

- S-000-13a0-001 - 2a General Spesifikation For Painting and CoatingDocument57 pagesS-000-13a0-001 - 2a General Spesifikation For Painting and Coatingderi yuliantoNo ratings yet

- Protects Concrete, Mortar, Block & Brick - Waterproofs and Seals - Excellent AdhesionDocument2 pagesProtects Concrete, Mortar, Block & Brick - Waterproofs and Seals - Excellent AdhesionAlfred GomoeliaNo ratings yet

- GSPO-HSE-PRO-17-F-45 Dropped Objects Derrick Inspection - Zone 4 - RIGSDocument6 pagesGSPO-HSE-PRO-17-F-45 Dropped Objects Derrick Inspection - Zone 4 - RIGSalexandru popescuNo ratings yet

- AITECH Manual As of November 2022Document36 pagesAITECH Manual As of November 2022Eric LansangNo ratings yet