Professional Documents

Culture Documents

Hydraulic Calculations For Small Rooms

Uploaded by

Anonymous qrSsYuxyoYOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Calculations For Small Rooms

Uploaded by

Anonymous qrSsYuxyoYCopyright:

Available Formats

TECHNICALLY SPEAKING

SQ

Hydraulic Calculations for Small Rooms

By Kenneth E. Isman, P.E.

eve all used the Small Room Rule in NFPA 13 to gain some exibility in spacing sprinklers. But how are the hydraulics in small rooms different from the hydraulics in large open spaces? The answer is that there are pitfalls to the hydraulic calculation procedures in small rooms. People that just plug numbers into computer programs and dont understand what to look for in the output can get caught with insufcient ow or pressure for their sprinkler systems. Likewise, plan reviewers need to understand what to look for in the calculation of small rooms so that they only approve hydraulic calculations that have been performed correctly. This article will address some of the potential pitfalls and show how to nd them on computer program outputs. This article will reference sections from the 2010 edition of NFPA 13. But the concepts and requirements are the same in all recent previous editions (going back before the 1990s). The section numbers in previous editions may be different depending on the edition.

What is the Small Room Rule?

The Small Room Rule is actually a combination of three different sections of NFPA 13. When used together, these sections allow the user to select one wall in a room and place sprinklers up to 9 ft from that single wall. In addition, the Small Room Rule allows the user to average the area of the room using the number of sprinklers in the room to determine the area of

coverage per sprinkler rather than using the S x L rules of section 8.5.2. The rst section in the Small Room Rule is section 3.3.17, which denes a Small Room as one not greater than 800 sq ft with unobstructed ceiling construction in a light hazard occupancy. This last limitation is important in that the Small Room Rule cannot be used in ordinary hazard, extra hazard, or high piled storage. Limited openings are allowed in the walls leading to other rooms. The second section in the Small Room Rule is section 8.6.3.2.4, which permits upright and pendent standard spray sprinklers to be installed up to 9 ft from a single wall. Note that this only allows the sprinklers to be 9 ft from one wall in the room, not from two or more walls. Also note that this only applies to upright and pendent standard spray sprinklers. This rule does not apply to residential sprinklers, extended coverage sprinklers, or any kind of sidewall sprinkler. The third section in the Small Room Rule is section 8.6.2.1.2, which permits to user to ignore the S x L Rule of 8.5.2 and average out the size of the room by the number of sprinklers to determine the area of coverage per sprinkler. In order to use this portion of the rule, it is not necessary to have any sprinklers up to 9 ft from a wall. This section of NFPA 13 is independent of the portion of the rule that allows sprinklers to be more than 7.5 ft from a wall. Note that the averaging is only in the section for upright and pendent standard spray sprinklers, so it does not apply to

extended coverage sprinklers or sidewall spray sprinklers. However, section 11.3.1.3, which covers the minimum density of 0.1 gpm per sq ft being applied to residential sprinklers when such sprinklers are used in an NFPA 13 system references this section for calculating the area of coverage for residential sprinklers in small rooms. Therefore, in this one limited circumstance, residential sprinklers can use the Small Room Rule to determine the minimum required discharge from the sprinkler. See the article, The Small Room Rule in the Spring 2000 issue of Sprinkler Quarterly for more information on how to use the Small Room Rule for spacing of standard spray sprinklers.

Design Area

The rst step in hydraulics is to determine the design area (the reasonable worse-case sprinklers that would be open if there was a re in the building). As with all sprinkler systems, this is determined using the Room Design Method or the Density/Area Method.

> > continUed on page 20

Kenneth E. Isman, P.E.

19

www.nfsa.org

Vice President, Engineering for NFSA. Ken represents NFSA on the NFPA Technical Committee on Sprinkler System Discharge Criteria

> > continUed FROM page 19

In a building with many small compartments, it might be tempting to use the Room Design Method. But the most demanding room can be difcult to nd, and if there is one larger room in the building, this may not be practical. This article will focus on the use of the Density/Area Method. When using the Density/Area Method, the location of walls is ignored when making the initial decision about which sprinklers are the hydraulically most demanding. However, before nishing with the determination of which sprinklers are in the design area, you do need to make sure that the actual area protected by the sprinklers meets the minimum design area. In other words, you cant count on sprinklers spraying past a wall to cover area on the other side of a wall, even if the area on the other side of the wall is mathematically less than one-half of the allowable distance between sprinklers. In a situation like this, it is often advantageous to consider an example. For this article, we will use the sprinkler system shown in Figure 1 as an example of some of the pitfalls we might encounter in con-

ducting hydraulic calculations in buildings with small rooms. The building in this case has three rooms. Room A is 245 sq ft in the northwest corner. Room B is 637 sq ft next to Room A. The third room is the large space that is the rest of the building. The ceiling is 15 ft high (unobstructed construction) in this building and the occupancy is considered light hazard. The sprinklers are all standard spray quick response sprinklers (k-5.6), none of which is covering more than 225 sq ft (but many of which cover much less). (see gure 1) For a light hazard occupancy with a 15 ft ceiling and quick response sprinklers, the design point of 0.1 gpm per sq ft over 1500 sq ft can be selected from the density/ area curves. From there, the density can be adjusted by 32.5% (see 11.2.3.2.3) so that the nal density/area requirements are 0.1 gpm per sq ft over 1013 sq ft. Section 22.4.4.1.1.1 of NFPA 13 requires that the design area have a dimension of at least 1.2 times the square root of the design area. In this case, 1.2 times the square root of 1013 is 38.2 ft. If you start at the northwest corner and count 38.2 ft parallel to the branch lines, you get to a

point 2.2 ft to the east of the wall between sprinklers 3 and 4. This means that sprinkler 4 needs to be included in the design area, as well as sprinklers 1, 2 and 3. Next, sprinklers 5, 6, 7, and 8 need to be considered to be added to the design area. With these 8 sprinklers, the design area would be 1250 sq ft, which exceeds the 1013 sq ft required. If sprinkler 5, covering 122.5 sq ft at the end of the second branch line is dropped, the design area becomes 1127.5 sq ft, which still exceeds the required 1013 sq ft. If sprinkler 6 is dropped, the design area falls below the required 1013 sq ft, so the design area must be sprinklers 1, 2, 3, 4, 6, 7, and 8 as shown in Figure 2. (see gure 2)

Discharge from First Sprinkler

The next step is to determine the discharge from the most remote sprinkler, which in this case is sprinkler 1. According to the Small Room Rule, Room A is 245 sq ft and is protected by 2 sprinklers. This means that each sprinkler in Room A cov> > continUed on page 21

Figure 1 Sprinkler System Example

Figure 2 Design Area for Example

20

SQ july - august 2011

> > continUed FROM page 20

Table 1 Discharge from Sprinklers in Example

Table 2 Sprinkler Discharge and Density for Example

ers 122.5 sq ft (245/2 = 122.5). In order to achieve a 0.1 gpm per sq ft density out of sprinkler 1, the sprinkler would need to discharge 12.3 gpm (122.5 x 0.1 = 12.25 rounded up to 12.3). For a sprinkler with a k-factor of 5.6 to discharge 12.3 gpm, the pressure at the sprinkler needs to be at least 4.8 psi [(12.3/5.6)2 = 4.8]. Of course, a sprinkler is not allowed to discharge at so low a pressure. To meet the rules of NFPA 13, the pressure at the sprinkler needs to be increased to 7 psi. Some people will stop there and consider the discharge from sprinkler 1 as 12.3 gpm at 7 psi. But thats not how the laws of physics work. Once the pressure at the sprinkler is increased to 7 psi, the ow coming from the sprinkler increases as well. At a pressure of 7 psi, a sprinkler with a k-factor of 5.6 will discharge 14.8 gpm (5.6 times the square root of 7 is 14.8). So, that is where the hydraulic calculations must start (14.8 gpm at 7 psi).

Discharge from the Other Sprinklers

Whether you perform the hydraulic calculations by hand or use a computer program, youll need to gure out how much ow is going to discharge from each sprinkler. In order to do that, youll need to know what the water pressure is at each sprinkler. Hydraulic calculations show that when you start with 14.8 gpm at 7 psi at sprinkler 1, the total demand for the sprinklers on the two branch lines is 118.2 gpm at 17.6 psi (assuming 1.38 inch

branch lines and 3.068 inch main). Table 1 shows a printout that is typical to the one generated by hydraulic calculation computer programs, which lists the ow and pressure from each of the sprinklers in this example. (see table 1) As Table 1 shows, sprinkler 1 appears to be the most demanding and each sprinkler after it discharges more water at a higher water pressure than sprinkler 1. A person might be tempted to stop the hydraulic calculations there. But they would be wrong. After the hydraulic calculations have been performed (by hand or by computer), a check needs to be made of the density being provided to the oor surface being protected by each sprinkler. Table 2 shows the area of coverage for each sprinkler and the density it is putting into this coverage area (ow divided by coverage area). In this case, due to the conguration of the small rooms, there are three sprinklers that are not discharging enough water to sufciently cover the oor beneath them (sprinklers 2, 4 and 8). This is not an unusual occurrence when the Small Room Rule gets used. (see table 2) Sprinkler 2 covers 159.25 sq ft (the area of Room B divided by the four sprinklers in the room). This sprinkler would need to discharge a minimum of 15.9 gpm in order to create a density of 0.1 gpm per sq ft. Since the sprinkler is only discharging 15 gpm, it is falling short of the requirement. Likewise, sprinklers 4 and 8 are not in small rooms. Using the S x L rules, these

two sprinklers cover 225 sq ft. This means that they need to discharge 22.5 gpm at a minimum in order to achieve a density of 0.1 gpm per sq ft. But since they are only discharging 17.6 or 19.1 gpm, this calculation is not acceptable. In order to make sure that the calculations are acceptable, the discharge from the most remote sprinkler needs to be increased so that all of the discharges from all of the sprinklers increase to the point where all sprinklers meet their minimum discharge density requirement. Unfortunately, there is no direct way to calculate this increase. There are some computer programs that will perform this calculation for you, but not all programs do, so anyone doing hydraulic calculations should learn to try a few solutions until an acceptable one is found. Using a trial and correction method of starting at sprinkler 1 and trying a higher ow (and pressure) and seeing how that effects sprinklers further down the line (then trying again because the rst time through did not arrive at an acceptable answer), it can eventually be determined that a starting ow of 19 gpm at 11.5 psi yields an acceptable result. Doing this by hand took this author three tries and about 20 minutes to arrive at a solution. Use of a computer to change a few variables and try again would have saved some time. Table 3 shows the correct minimum ow and pressure requirements for the seven sprinklers on the two branch lines.

> > continUed on page 22

21

www.nfsa.org

> > continUed FROM page 21

The total ow demand for these seven sprinklers is 150.4 gpm at 28.1 psi. Note that each sprinkler is now discharging the minimum amount of ow to achieve the density of at least 0.1 gpm per sq ft. Also note that sprinkler 4 becomes the key sprinkler in the system since it is just barely able to achieve its minimum density. Any smaller pressure delivered to this system would cause sprinkler 4 to have less than its required minimum density. (see table 3)

Arent the Sprinklers in the Larger Room More Demanding?

At some point in time, someone reading this article has thought to themselves, Wait a minute! All of this is nice, but the sprinklers in the larger room are more demanding, so we should just calculate those! You should always be encouraged to consider the other spaces in a building, and you should even conduct some calculations to prove that you have selected the most demanding area in the building. In this case, this area containing the small rooms and sprinklers 1, 2, 3, 4, 6, 7 and 8 is

probably the most demanding. To prove it, calculations were performed for the 1035 sq ft represented by sprinklers 11, 12, 13, 14 and 15 in the northeast corner of the building as shown in Figure 3. (see gure 3) Sprinklers 11, 12 and 13 each cover 225 sq ft, making the total area that these three sprinklers cover 675 sq ft. Sprinklers 14 and 15 each cover 180 sq ft (due to the shorter distance between the second and third branch lines), bringing the total area covered by these ve sprinklers to 1035 sq ft. Since this exceeds the design area of 1013 sq ft and since this includes at least ve sprinklers, this is an appropriate design area to consider. Hydraulic calculations of these ve sprinklers, using the same size branch lines and main as the previous calculations for this example show that the demand would be 121.1 gpm at 25 psi at the second branch line. This is signicantly less than the 150.4 gpm at 28.1 psi needed at the same location for the sprinklers in the small rooms as discussed above. This means that the sprinklers calculated in the small room were a reasonable worse case for this particular situation.

Depending on the exact spacing of the sprinklers in the large room south of the small rooms and to the west of the cross main, it is possible that these sprinklers will be more demanding than the previously calculated areas. We will assume for the sake of this example that the sprinklers have been spaced in this area such that they are not more demanding than the situations calculated above.

Conclusion

When using the Small Room Rule, there are certain advantages to the hydraulic calculations. But be careful in the situations where the hydraulic calculations include sprinklers outside of the small rooms. Sprinklers closer to the riser might be more demanding, and might not be getting sufcient ow to achieve their required densities. In any situation, always check the print-out from the hydraulic calculations to make sure that every sprinkler is discharging the minimum necessary to achieve its density. Also, check multiple design areas to make sure that you have calculated the most demanding situation.

Table 3 Correct Minimum Flow and Pressure at Each Sprinkler in Example

Figure 3 Alternate Design Area for Example

22

SQ july - august 2011

You might also like

- George Orwell's handwritten notes and letters on culture, democracy and his famous work 1984Document6 pagesGeorge Orwell's handwritten notes and letters on culture, democracy and his famous work 1984Anonymous qrSsYuxyoYNo ratings yet

- Pet Word List PDFDocument51 pagesPet Word List PDFLore JimenezNo ratings yet

- Pet Word List PDFDocument51 pagesPet Word List PDFLore JimenezNo ratings yet

- Pet Word List PDFDocument51 pagesPet Word List PDFLore JimenezNo ratings yet

- Inspection, Testing and Maintenance of Fire Protection SystemsDocument126 pagesInspection, Testing and Maintenance of Fire Protection SystemsGee MacawileNo ratings yet

- Water Mist Nozzle GW M5 PDFDocument6 pagesWater Mist Nozzle GW M5 PDFZulfi Andrie ZulkiarNo ratings yet

- Water Base ProtectionDocument42 pagesWater Base ProtectionandreasbudiNo ratings yet

- Credit Management in Sap SDDocument17 pagesCredit Management in Sap SD0300123456100% (2)

- Orac TableDocument48 pagesOrac TableSteve SheldonNo ratings yet

- Fs2011 FullDocument242 pagesFs2011 FullryankckoNo ratings yet

- Redbook Vol1part1 LPCBDocument755 pagesRedbook Vol1part1 LPCBvbgiri0% (1)

- The Long Way of Fire Protection DesignDocument4 pagesThe Long Way of Fire Protection DesignPBDC MEPFS100% (1)

- NF Pa 13 Acceptance TestDocument4 pagesNF Pa 13 Acceptance Testaxl1No ratings yet

- Engineerweb PDFDocument35 pagesEngineerweb PDFyassine633No ratings yet

- Hydraulic Sprinkler CalculationsDocument1 pageHydraulic Sprinkler CalculationsZa YonNo ratings yet

- Handbook On Building Fire CodesDocument287 pagesHandbook On Building Fire Codesmz1234567100% (1)

- Rated Windows Atria Window Sprinklers - A Comparison ChartDocument4 pagesRated Windows Atria Window Sprinklers - A Comparison ChartArgile-assholeNo ratings yet

- Hydraulic Calculation Tutorial #1Document9 pagesHydraulic Calculation Tutorial #1Rahul DevaNo ratings yet

- Armover LengthDocument2 pagesArmover Lengthjo100% (1)

- Water Based Suppression SystemsDocument2 pagesWater Based Suppression SystemsdebasisdgNo ratings yet

- Bhagavan Ramana and Herbal Medicine - Dr. ManikkamDocument8 pagesBhagavan Ramana and Herbal Medicine - Dr. Manikkamdeepaksubsmani@yahoo.com100% (3)

- Staircase Pressurization System TestingDocument5 pagesStaircase Pressurization System TestingJavedNo ratings yet

- For 500 GPM CalDocument56 pagesFor 500 GPM CalNeal JohnsonNo ratings yet

- NFSA Handbook PDFDocument48 pagesNFSA Handbook PDFNeeraj Kumar100% (1)

- Alarm Check ValveDocument6 pagesAlarm Check ValveHellenHoaNo ratings yet

- Maximum Distance Between HangersDocument2 pagesMaximum Distance Between HangersAhmed Ali100% (1)

- Is 13039 External Fire HydrantDocument10 pagesIs 13039 External Fire HydrantNanu PatelNo ratings yet

- Wet Riser Stage 2 (Above)Document1 pageWet Riser Stage 2 (Above)ZamzuriNo ratings yet

- Victaulic G 105Document116 pagesVictaulic G 105lolochoNo ratings yet

- Sprinkler System Design CapacityDocument14 pagesSprinkler System Design Capacityisaacodi100% (1)

- Heat & Mass Transfer Term PaperDocument12 pagesHeat & Mass Transfer Term Paperamitammy19100% (1)

- CalcII IntegrationTechniques ProblemsDocument16 pagesCalcII IntegrationTechniques Problemsna zafira100% (1)

- Foam CalculationsDocument8 pagesFoam Calculationsahmed salemNo ratings yet

- Density/area Curves:: 8.2 System Protection Area LimitationsDocument3 pagesDensity/area Curves:: 8.2 System Protection Area Limitationsandam.abdulah100% (1)

- No Elevation K-Factor Flow Nominal Fitting Pressure CalculationsDocument4 pagesNo Elevation K-Factor Flow Nominal Fitting Pressure CalculationsRenzhel MamaclayNo ratings yet

- Sprinkler System DesignDocument19 pagesSprinkler System DesignRajahi Moahmed100% (1)

- Comparison of Various Codes of Fire On Structural DesignDocument17 pagesComparison of Various Codes of Fire On Structural DesignIJRASETPublicationsNo ratings yet

- Fire Protection Module 2020 PDFDocument60 pagesFire Protection Module 2020 PDFVELASCO JULIE-ANN G.100% (1)

- SprinklersDocument16 pagesSprinklersAdel Suker100% (1)

- System Design: Total Flooding Extinguishing SystemDocument45 pagesSystem Design: Total Flooding Extinguishing SystemsureshkanuboyinaNo ratings yet

- Fire SafetyDocument40 pagesFire SafetyPrantik Adhar SamantaNo ratings yet

- Manual de Plante MedicinaleDocument115 pagesManual de Plante Medicinalevrajitorul100% (3)

- Manual de Plante MedicinaleDocument115 pagesManual de Plante Medicinalevrajitorul100% (3)

- Hose Reel Friction Loss CalculationDocument2 pagesHose Reel Friction Loss CalculationNethajiNo ratings yet

- SQjanfeb 2012Document44 pagesSQjanfeb 2012Laptuca GabrielNo ratings yet

- NFPA 13 Sprinkler System Design Density Curves - Where Did They Come From - Sprinklers Content From Fire Protection Engineering PDFDocument7 pagesNFPA 13 Sprinkler System Design Density Curves - Where Did They Come From - Sprinklers Content From Fire Protection Engineering PDFBùi Trần Trung HậuNo ratings yet

- Sprinkler System FormulasDocument2 pagesSprinkler System Formulasturbosri_mech100% (1)

- Hyd Calcs Class 3Document30 pagesHyd Calcs Class 3Jerry Tom100% (1)

- Fire Sprinkler Pipe and Fittings NotesDocument6 pagesFire Sprinkler Pipe and Fittings Notesmary joy Panama100% (1)

- Viking Residential Sprinkler Installation GuideDocument18 pagesViking Residential Sprinkler Installation Guidesina_84No ratings yet

- Horizontal Sidewall Sprinklers Technical Data SheetDocument6 pagesHorizontal Sidewall Sprinklers Technical Data SheetAhrian BenaNo ratings yet

- Warehouse Regulatory RequirementsDocument15 pagesWarehouse Regulatory Requirementsliaw_zi_yang100% (2)

- NFPA 13 - 2016 Edition: - Specifically Permit Stainless Steel in Accordance With Schedule 10S or Schedule 40SDocument8 pagesNFPA 13 - 2016 Edition: - Specifically Permit Stainless Steel in Accordance With Schedule 10S or Schedule 40SAhmed NabilNo ratings yet

- Elite SoftwareDocument22 pagesElite SoftwareERIC SALGADONo ratings yet

- Hose stream demands for fire sprinkler systemsDocument4 pagesHose stream demands for fire sprinkler systemsHugo Mario Ariza PalacioNo ratings yet

- L Generation R2 Series Pipe and Charge CalculationDocument73 pagesL Generation R2 Series Pipe and Charge CalculationStefy CarrascoNo ratings yet

- Automated Hydrant Testing and Fire Flow AnalysisDocument2 pagesAutomated Hydrant Testing and Fire Flow AnalysisMuhammad Ehtsham0% (1)

- MECH3430: Fire Protection in BuildingsDocument38 pagesMECH3430: Fire Protection in Buildingstimho yuNo ratings yet

- Q and A For The 2011 Edition of NFPA 25 PDFDocument5 pagesQ and A For The 2011 Edition of NFPA 25 PDFbtjajadiNo ratings yet

- BAFSA Technical Guidance No 1, November 2012Document30 pagesBAFSA Technical Guidance No 1, November 2012flegheton100% (1)

- Specification For Sprinkler LPC - FSD Circular 2006 - 03Document46 pagesSpecification For Sprinkler LPC - FSD Circular 2006 - 03James Li100% (1)

- Fire ProtectionDocument25 pagesFire ProtectionNIBEDITA DEY100% (2)

- Relationships for Smoke Control CalculationsDocument148 pagesRelationships for Smoke Control CalculationsArgile-assholeNo ratings yet

- Extended Coverage Sprinkler SpacingDocument13 pagesExtended Coverage Sprinkler Spacingm.sofiqur rahmanNo ratings yet

- Non-Uniform Hydraulic Calculation Areas - Part 2Document2 pagesNon-Uniform Hydraulic Calculation Areas - Part 2wastedsunsetsNo ratings yet

- Hydraulic Calculation Procedures for Automatic Sprinkler SystemsDocument8 pagesHydraulic Calculation Procedures for Automatic Sprinkler Systemsahmad adnanNo ratings yet

- Fire Sprinkler System - Article ObstructionDocument5 pagesFire Sprinkler System - Article ObstructionKarthikeyan VeerasamyNo ratings yet

- Mixed HazardDocument4 pagesMixed Hazardapi_fabianNo ratings yet

- Manual Logitech X-230 SpeakersDocument9 pagesManual Logitech X-230 SpeakersAnonymous qrSsYuxyoYNo ratings yet

- AaaaaDocument4 pagesAaaaaAnonymous qrSsYuxyoYNo ratings yet

- StarCraft Manual PDFDocument7 pagesStarCraft Manual PDFNptn0No ratings yet

- Sadachar Discourse TipsDocument14 pagesSadachar Discourse TipsAnonymous qrSsYuxyoYNo ratings yet

- Moonsorrow - TyvenDocument2 pagesMoonsorrow - TyvenAnonymous qrSsYuxyoYNo ratings yet

- StarCraft Manual PDFDocument7 pagesStarCraft Manual PDFNptn0No ratings yet

- Sadachar Discourse TipsDocument14 pagesSadachar Discourse TipsAnonymous qrSsYuxyoYNo ratings yet

- StarWind Native SAN For Hyper-V Free Vs PaidDocument3 pagesStarWind Native SAN For Hyper-V Free Vs PaidAnonymous qrSsYuxyoYNo ratings yet

- StarCraft Manual PDFDocument7 pagesStarCraft Manual PDFNptn0No ratings yet

- PX5 Data Editor ManualDocument37 pagesPX5 Data Editor ManualMatt WinkworthNo ratings yet

- Quick Guide To Install Cryptocam 1.0.0Document10 pagesQuick Guide To Install Cryptocam 1.0.0Anonymous qrSsYuxyoYNo ratings yet

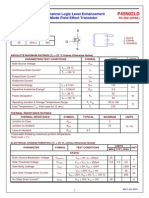

- P45N02LD Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorDocument3 pagesP45N02LD Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorAnonymous qrSsYuxyoYNo ratings yet

- Vocabulary ListDocument63 pagesVocabulary ListAnonymous qrSsYuxyoYNo ratings yet

- Bodhnath Stupa 01Document1 pageBodhnath Stupa 01Anonymous qrSsYuxyoYNo ratings yet

- B Dash Camp Pre-Event GuideDocument18 pagesB Dash Camp Pre-Event GuideAnonymous qrSsYuxyoYNo ratings yet

- Fashion VocabularyDocument2 pagesFashion VocabularySempredijous100% (2)

- Vocabulary ListDocument63 pagesVocabulary ListAnonymous qrSsYuxyoYNo ratings yet

- W83627THF InterfacciaDocument132 pagesW83627THF InterfacciaAnonymous qrSsYuxyoYNo ratings yet

- 2budda DesktopDocument1 page2budda DesktopAnonymous qrSsYuxyoYNo ratings yet

- P45N02LD Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorDocument3 pagesP45N02LD Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorAnonymous qrSsYuxyoYNo ratings yet

- Nokia N9 User GuideDocument116 pagesNokia N9 User GuideAnonymous qrSsYuxyoYNo ratings yet