Professional Documents

Culture Documents

New Microsoft Word Document (489

Uploaded by

abdulmatinhublikarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Microsoft Word Document (489

Uploaded by

abdulmatinhublikarCopyright:

Available Formats

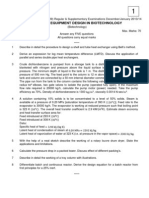

Department of Mechanical engineering Ist internal assessment Subject: Design of heat transfer equipments Subject code: Semester: IIIrd

SEM M.Tech Note: Answer any one question. Q1) 6900 lb/hr of 260 API lubricating oil must be cooled from 4500-3500F by 72500 lb/hr of 340 API midcontinent crude oil. The crude will be heated from 3000-3100 F. A fouling factor of 0.003 should be provided for each stream and allowable pressure drop on each stream will be 10 psi. A number of 20 ft hair fins of 3/2 IPS are available how many must be used and how shall they be arranged the viscosities are 1.4 centipoises at 500 F for lubricating oil 3.08 4000 F and 7.7 at 3000 F. (25 Marks) OR 1,75,000 lb/hr of distilled water enters an exchanger at 930 F and leaves at 850 F. The heat will be transferred to 2,80,000 lb/hr of raw water supplied at 750 F and leave the exchanger at 800 F at 10 psi pressure drop may be expected on both the streams while Rd= 0.0005 for the distilled water and 0.0015 for raw water. When the tube velocity exceeds 6FPS available for this service is a 15.25 ID exchanger having 160 3.25 OD 18BWG 16 ft long tubes laid out on 15/16 triangular pitch. The bundle is arranged for 2 passes and baffles are spaced 12 apart will the exchanger be suitable? (25 Marks) Q2) It is desired to heat 9820lb/hr of cold benzene from 80 to 120 F using toluene cool from 160 to 100 F. A fouling factor and pressure drop of 0.001 and 10 psi should be provided on each stream. A number of 20 feet hair pins of 2 by 1 in IPS available how many hair pin is required. (25 marks) OR 43800 lb/hr of 42 API kerosene leaves distilling column at 390 F and cooled to 200 F by 149000 lb/hr of 34 API midcontinent crude coming from a storage at 100 F and heated to 170 F. A fouling factor and pressure drop of 0.003 and 10 psi should be provided on each stream. Available for this service is 21 inch inner diameter exchanger having 158 1 inch OD, 13 BWG tubes 16 inch long and laid out on 1 inch sq pitch. The bundle is arranged for 4 passes and baffles are spaced 5 inch apart, will the exchanger suitable. (25 marks) Date: Time: 1 hour

Department of Mechanical engineering

III rd internal assessment Subject: Design of heat transfer equipments Subject code: Semester: IIIrd SEM M.Tech Note: Answer any one question. Date: Time: 1 hour

Q1) a)A cooling operation consist of passing 50,000 lb/hr of bone dry gas over trays of hot material from whose surface oxygen must be excluded. The gas is heated from 200 to 300 F and emerges with a dew point of 120 F. It then goes to cooler where it is cooled back to 200 F and heated from 85 to 120 F. A pressure drop of 2 inch of water is permissible. How many diffusion units must the tower be capable of performing to fulfill process requirement. (35 marks) b) What is cooling tower explain any two types of cooling towers with detail classifications. (15 marks)

Q1) A plant is being laid out in a restricted water locality. The total heat to be removed by the cooling tower is 26000,000 BTU/ hr. The locality has 5% WBT of 75o F The water will leave tower with 10 approach to WBT. Being water of ordinary mineral content it will emerge from equipment at 120 F. A tower 24X 24 Feet has been erected with a fan capacity of 187,000 CFM. How many diffusion units must the tower be capable of performing to fulfill process requirement. (50 marks)

OR

You might also like

- Department of Mechanical EngineeringDocument2 pagesDepartment of Mechanical EngineeringAbdul Razak KaladgiNo ratings yet

- COMSATS Institute of Information Technology, Lahore: HTO Lab AssignmentDocument1 pageCOMSATS Institute of Information Technology, Lahore: HTO Lab AssignmentUmair farooqNo ratings yet

- QUESTION BANK BASED ON PREVIOUS YEAR HEAT EXCHANGER QUESTIONSDocument11 pagesQUESTION BANK BASED ON PREVIOUS YEAR HEAT EXCHANGER QUESTIONSVenkadeshwaran KuthalingamNo ratings yet

- Department of Mechanical EngineeringDocument2 pagesDepartment of Mechanical EngineeringabdulmatinhublikarNo ratings yet

- New Microsoft Word Document1 211111786Document2 pagesNew Microsoft Word Document1 211111786Abdul Razak KaladgiNo ratings yet

- Heat Exchanger Design and Operation CalculationsDocument3 pagesHeat Exchanger Design and Operation CalculationsFernando MiyazakiNo ratings yet

- Assignment 2Document2 pagesAssignment 2EZA Solution67% (3)

- NED University Advanced Heat Transfer Exam QuestionsDocument1 pageNED University Advanced Heat Transfer Exam QuestionsHassan FaheemNo ratings yet

- Heat TransferDocument1 pageHeat TransferjacksonNo ratings yet

- Heat Transfer PROBLEMSDocument5 pagesHeat Transfer PROBLEMSEcel Pablo PromentillaNo ratings yet

- New Microsoft Word Document1 1Document2 pagesNew Microsoft Word Document1 1Abdul Razak KaladgiNo ratings yet

- Tutorial 5 TFP260S PDFDocument2 pagesTutorial 5 TFP260S PDFHundzukani Ngobeni100% (1)

- PS Compilation For 2019Document10 pagesPS Compilation For 2019Nicole RamirezNo ratings yet

- Numerical Problems LMTDDocument4 pagesNumerical Problems LMTDKhalidNo ratings yet

- Serth ProblemsDocument7 pagesSerth ProblemsRuel CedeñoNo ratings yet

- SL NoDocument3 pagesSL NoAbdul Razak KaladgiNo ratings yet

- Heat Transfer and Pressure Drop Calculations in Shell and Tube Heat ExchangersDocument5 pagesHeat Transfer and Pressure Drop Calculations in Shell and Tube Heat ExchangersvikirhythmNo ratings yet

- Sheet (3.1) Heat Exchangers Analysis Using LMTD MethodDocument2 pagesSheet (3.1) Heat Exchangers Analysis Using LMTD MethodAya Bekhet 1253No ratings yet

- Ejercicios PDFDocument4 pagesEjercicios PDFserepoesia10No ratings yet

- Cryopump For Beam Tube Bakeout: Component SpecificationDocument1 pageCryopump For Beam Tube Bakeout: Component SpecificationNipun RavalNo ratings yet

- Assignment 1 & 2 PED&DDocument1 pageAssignment 1 & 2 PED&DA KhapreNo ratings yet

- Heat Transfer Assignment QuestionsDocument2 pagesHeat Transfer Assignment QuestionsMurali KrishnaNo ratings yet

- Heat Transfer Jan2003 or 220852Document2 pagesHeat Transfer Jan2003 or 220852Nizam Institute of Engineering and Technology LibraryNo ratings yet

- PEHC ZC 341 Heat Transfer Assignments IIDocument2 pagesPEHC ZC 341 Heat Transfer Assignments IIUjjval PatelNo ratings yet

- Heat Exchanger Tutorial Sheet 5Document4 pagesHeat Exchanger Tutorial Sheet 5Charlotte BNo ratings yet

- Heat Exchanger Tutorial Sheet 5Document4 pagesHeat Exchanger Tutorial Sheet 5Charlotte BNo ratings yet

- New Microsoft Word Document1 24444Document3 pagesNew Microsoft Word Document1 24444Abdul Razak KaladgiNo ratings yet

- Saint Louis University: Chemical Engineering PrinciplesDocument6 pagesSaint Louis University: Chemical Engineering PrinciplesAileen MayaNo ratings yet

- Flow Through OrificeDocument3 pagesFlow Through OrificeAbdul Razak KaladgiNo ratings yet

- Department of Mechanical Engineering: B. V. Raju Institute of Technology (Autonomous)Document2 pagesDepartment of Mechanical Engineering: B. V. Raju Institute of Technology (Autonomous)Murali KrishnaNo ratings yet

- Heat Exchanger Design Problems and CalculationsDocument2 pagesHeat Exchanger Design Problems and CalculationsDenisse M. ZamoraNo ratings yet

- 15P403 May18Document3 pages15P403 May18Aakhil FizanNo ratings yet

- Assignment - IVDocument4 pagesAssignment - IVdivyanshu.221ch018No ratings yet

- A Centrifugal Pump Is Drawing Water From An Overhead Tank - Autosaved - AutosavedDocument16 pagesA Centrifugal Pump Is Drawing Water From An Overhead Tank - Autosaved - AutosavedAkshat KhandelwalNo ratings yet

- Prob Set Heat and MassDocument15 pagesProb Set Heat and MassCheng PasionNo ratings yet

- ExamDocument3 pagesExamBiyadgie AlebelNo ratings yet

- Problemario Entropía y ExergíaDocument2 pagesProblemario Entropía y ExergíaDIEGO ALFREDO ROSALES TORRESNo ratings yet

- Ped QuestionsDocument11 pagesPed QuestionsYashPatel100% (1)

- Heat Exchanger Design and Refrigeration Cycle CalculationsDocument2 pagesHeat Exchanger Design and Refrigeration Cycle CalculationsgodadNo ratings yet

- Registration Number Heat Exchanger DesignDocument5 pagesRegistration Number Heat Exchanger DesignAbhishekRajeshDhobeNo ratings yet

- Tripoli University Chemical Engineering Department: Homework #4Document2 pagesTripoli University Chemical Engineering Department: Homework #4Good BadNo ratings yet

- Ihte Que BankDocument2 pagesIhte Que BankNikunj PatelNo ratings yet

- Step 1: Calculate The LMTD: HOT ColdDocument34 pagesStep 1: Calculate The LMTD: HOT ColdFrancisca Hanna0% (2)

- 619PT304Document4 pages619PT304arpit gargNo ratings yet

- Tut 4 Heat ExchangersDocument2 pagesTut 4 Heat ExchangersGomolemo BaarxxNo ratings yet

- Termo 6-31Document6 pagesTermo 6-31geki91No ratings yet

- Heat Transfer Problem StatemntDocument5 pagesHeat Transfer Problem StatemntKareem TarekNo ratings yet

- Raw Board Battle Round 1Document13 pagesRaw Board Battle Round 1Maridil Joy IsidroNo ratings yet

- Me8595 Iq R17Document2 pagesMe8595 Iq R17Narayanan SubramanianNo ratings yet

- Heat Exchangers Design: Effectiveness - NTU MethodDocument35 pagesHeat Exchangers Design: Effectiveness - NTU MethodSaurabh SengarNo ratings yet

- MEHB323 Tutorial Assignment Ch11Document2 pagesMEHB323 Tutorial Assignment Ch11Lufy HahaNo ratings yet

- PEDD Question Bank For STHEDocument6 pagesPEDD Question Bank For STHERajat SrivastavaNo ratings yet

- 9A23702 Process Equipment Design in BiotechnologyDocument4 pages9A23702 Process Equipment Design in BiotechnologysivabharathamurthyNo ratings yet

- HEAT TRANSFER 2011 JNTUH Question PaperDocument8 pagesHEAT TRANSFER 2011 JNTUH Question PaperAnil Frivolous AbstemiousNo ratings yet

- Design III HX Design Tutorial 3 Solutions PDFDocument4 pagesDesign III HX Design Tutorial 3 Solutions PDFMziyanda Boet-Bhayi Shumî100% (2)

- Heat Transfer Practice ExerciseDocument1 pageHeat Transfer Practice ExerciseRugi Vicente RubiNo ratings yet

- Practice Problems For Heat ExchangerDocument2 pagesPractice Problems For Heat ExchangerFour AyesNo ratings yet

- Ia 2 Nces QPDocument1 pageIa 2 Nces QPabdulmatinhublikarNo ratings yet

- External Fac Application Form IIT GoaDocument6 pagesExternal Fac Application Form IIT GoahameedhaaNo ratings yet

- External Fac Application Form IIT DharwadDocument5 pagesExternal Fac Application Form IIT DharwadhameedhaaNo ratings yet

- Fluid Mechanics Unit Test ProblemsDocument1 pageFluid Mechanics Unit Test ProblemsabdulmatinhublikarNo ratings yet

- 2Document3 pages2abdulmatinhublikarNo ratings yet

- 1ba697dd-98c1-4844-a8a9-d89b3051469eDocument305 pages1ba697dd-98c1-4844-a8a9-d89b3051469eabdulmatinhublikarNo ratings yet

- VTU Belgaum M.Tech Thermal Engineering Scheme of Teaching and ExamsDocument20 pagesVTU Belgaum M.Tech Thermal Engineering Scheme of Teaching and ExamsabdulmatinhublikarNo ratings yet

- 1st IA EnergyDocument1 page1st IA EnergyabdulmatinhublikarNo ratings yet

- Journals To ApplyDocument1 pageJournals To ApplyabdulmatinhublikarNo ratings yet

- Energy Question Paper Ist InternalDocument2 pagesEnergy Question Paper Ist InternalabdulmatinhublikarNo ratings yet

- India Agriculture Is Said To Be Gamble With MonsoonDocument1 pageIndia Agriculture Is Said To Be Gamble With MonsoonabdulmatinhublikarNo ratings yet

- There Are Two Types of Air Preheahers: Course OutcomesDocument2 pagesThere Are Two Types of Air Preheahers: Course OutcomesabdulmatinhublikarNo ratings yet

- New Microsoft Word Document2333Document5 pagesNew Microsoft Word Document2333abdulmatinhublikarNo ratings yet

- Department of Mechanical Engineering Sub: Books For Department LibraryDocument4 pagesDepartment of Mechanical Engineering Sub: Books For Department LibraryabdulmatinhublikarNo ratings yet

- 1Document2 pages1abdulmatinhublikarNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentabdulmatinhublikarNo ratings yet

- 1Document1 page1abdulmatinhublikarNo ratings yet

- P.A. College of Engineering Mangalore Department of Mechanical Engineering Sub: Books For Department LibraryDocument4 pagesP.A. College of Engineering Mangalore Department of Mechanical Engineering Sub: Books For Department LibraryabdulmatinhublikarNo ratings yet

- New Microsoft Word Document (26Document1 pageNew Microsoft Word Document (26abdulmatinhublikarNo ratings yet

- New Microsoft Word Document2221Document2 pagesNew Microsoft Word Document2221abdulmatinhublikarNo ratings yet

- New Microsoft Word Document2221Document2 pagesNew Microsoft Word Document2221abdulmatinhublikarNo ratings yet

- New Microsoft Word Document2221Document2 pagesNew Microsoft Word Document2221abdulmatinhublikarNo ratings yet

- New Microsoft Word Document2221Document2 pagesNew Microsoft Word Document2221abdulmatinhublikarNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentabdulmatinhublikarNo ratings yet

- New Microsoft Word Document (200Document3 pagesNew Microsoft Word Document (200abdulmatinhublikarNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentabdulmatinhublikarNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentabdulmatinhublikarNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentabdulmatinhublikarNo ratings yet

- Piling Workshop Rev.a SingaporeDocument122 pagesPiling Workshop Rev.a SingaporeBalanNo ratings yet

- Fatigue Curve For SCM440Document6 pagesFatigue Curve For SCM440Nagaraj RaoNo ratings yet

- Concrete BUildings Scheme Design Manual PDFDocument142 pagesConcrete BUildings Scheme Design Manual PDFAnilMohanK67% (3)

- Practice Questions METL 1313 - Final ExamDocument15 pagesPractice Questions METL 1313 - Final Examفراس فراسNo ratings yet

- Advance Welding PDFDocument2 pagesAdvance Welding PDFRajeevNo ratings yet

- Webforge Access WebDocument32 pagesWebforge Access WebWajeeh Ul HassanNo ratings yet

- NE1130BZ: Compressor Technical SpecificationDocument9 pagesNE1130BZ: Compressor Technical SpecificationIsidro MendozaNo ratings yet

- Sizing Gutter DesignDocument8 pagesSizing Gutter DesignNelson VargasNo ratings yet

- Fresh Air Handling Unit Control with Lonix ModulesDocument6 pagesFresh Air Handling Unit Control with Lonix ModuleswalsarisNo ratings yet

- Convair CP15HS ManualDocument16 pagesConvair CP15HS Manualkoza_gNo ratings yet

- Demolish and Extension BoQ - Supply and Installation - 141019Document3 pagesDemolish and Extension BoQ - Supply and Installation - 141019Patrick SipatelaNo ratings yet

- Compression Test On Concrete PDFDocument13 pagesCompression Test On Concrete PDFAudia SavitriNo ratings yet

- Fallas Por Fatiga Criterios y ProblemasDocument27 pagesFallas Por Fatiga Criterios y ProblemasTeio EstNo ratings yet

- Notes Earthing 23 03 20 PDFDocument11 pagesNotes Earthing 23 03 20 PDFAkhilesh MendonNo ratings yet

- 17th Edition WiringDocument12 pages17th Edition WiringCesar Bl100% (2)

- Laser Welding Steel Wheel RimsDocument5 pagesLaser Welding Steel Wheel RimsSamanthaPereraNo ratings yet

- Aashto T 119Document6 pagesAashto T 119Regen BasiñoNo ratings yet

- Stiffened Plates PDFDocument16 pagesStiffened Plates PDFfarhadmrt6923No ratings yet

- ASHRAEJournal SolarRefrigeration KleinReindl2005Document6 pagesASHRAEJournal SolarRefrigeration KleinReindl2005RutujaNo ratings yet

- AravindDocument6 pagesAravindyuvi7003No ratings yet

- 316 316L Technical Information SheetDocument5 pages316 316L Technical Information SheetfejlongNo ratings yet

- Home Pod-Soundbox 斜顶 1115Document10 pagesHome Pod-Soundbox 斜顶 1115afigueira10No ratings yet

- BT 4 WallDocument5 pagesBT 4 WallJuvelle CambiaNo ratings yet

- LECTURE No. 7. LOW MELTING CRYOGENIC ALLOYS-MARAGING-SUPERALLOYSDocument8 pagesLECTURE No. 7. LOW MELTING CRYOGENIC ALLOYS-MARAGING-SUPERALLOYSBizuayehu Tadesse AzeneNo ratings yet

- Elastisitas MaterialDocument4 pagesElastisitas MaterialRantih FebriNo ratings yet

- Fire Exit Railing DetailsDocument1 pageFire Exit Railing DetailsRenz ChuaNo ratings yet

- Asce 41Document102 pagesAsce 41Ahmed AlyNo ratings yet

- RJ Testing & InspectionDocument25 pagesRJ Testing & Inspectionmuhamadrafie1975No ratings yet

- Saudi Arabian Oil Company: N W o DDocument1 pageSaudi Arabian Oil Company: N W o DNadia BahloulNo ratings yet

- GfrsDocument9 pagesGfrsnamanNo ratings yet