Professional Documents

Culture Documents

RTD Spec for Platinum Elements

Uploaded by

Silo MiyanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RTD Spec for Platinum Elements

Uploaded by

Silo MiyanCopyright:

Available Formats

MESC SPECIFICATION SPE 60.44.

04/001

Revision: Page 1 of 3

RESISTANCE THERMOMETER ELEMENTS: Specification for platinum resistance thermometer (RTD) elements. GENERAL: This specification covers sheathed platinum resistance thermometer elements for temperature measurement in the range of -200 to +650C. 1. 2. Generally applied as temperature sensors in protective thermowell assemblies; standard dwg.S35.409.current revision refers. (Figure.1) In applications where heat transfer from process to RTD is slow and sheath is to be installed in direct contact with the process; standard dwg.S35.406.current revision refers. When use of protective thermowells are not practical, such as elements used for pipe surface temperature sensing; standard dwg.S35.411.current revision refers. (Figure.2)

3.

ENVIRONMENT: Environmental conditions as specified by IEC 654-1 for outdoor conditions class D2 shall apply, unless specified otherwise by the principal. DESCRIPTION. Resistance thermometer elements shall consist of an outer metal sheath, containing a sensing element of annealed platinum resistance wire. The resistance and connecting wires shall be electrically insulated from the outer sheath by compacted ceramic material, or suitable alternative compatible with the RTD operating temperature. The sheath end closure by seal welding shall be impervious to gases and liquids. Cracks, holes or defects penetrating the wall shall not be permitted. The tip shape is optional, rounded, flat or conical, the other end shall be hermetically sealed, suitable for an operating temperature of minimum 70C, to prevent the ingress of moisture. The sealed end of the element shall be provided with a flange in accordance with DIN.43734, for terminal block or converter/ transmitter mounting, and spring loaded screws for adjustment. A positive means of preventing strain on the connecting wires emerging from the sheath material shall be provided. Terminals shall be suitable for solid wires or wire pins of maximum 1.2mm diameter. For: 3 wire configuration the lead wire terminals shall be colour coded red;red;white. 4 wire configuration the lead wire terminals shall be colour coded red;red;white;white.

In accordance with IEC 751. The option of 3 or 4 wire configuration shall be specified in the purchase order. Normally simplex sensors shall be used, where duplex sensors are required it shall be specified in the purchase order.

MESC SPECIFICATION SPE 60.44.04/001

Revision: Page 2 of 3

DIMENSIONS: The sheath shall have a nominal outside diameter of 6.0mm ? 0.1mm. Length of element measured from the sheath tip to the flange shall be specified in the purchase order. Standard dwg.S35.409.current revision refers. MATERIALS: Sensing element shall be annealed platinum. Sheath shall be austenitic stainless steel or high-nickel alloy tubing, grade determined subject to the limit of the operating temperatures. Insulating material within the sheath shall be compatible with the platinum resistance thermometer operating temperature. Hermetically sealing compound shall be compatible with the environmental conditions specified in the purchase order. Connecting wire joining materials shall withstand the RTD maximum operating temperature. PERFORMANCE: The platinum resistance thermometer performance shall be in accordance with the requirements of IEC 751.PT.100 elements. Having a resistane of 100e at 0C with a fundamental interval of 38.5e to 100C. The resistance tolerances shall comply with class A or B according to IEC 751 as specified in the purchase order. Class A tolerance (C) 0.15 +0.002[t] Class B tolerance (C) 0.3 +0.005[t] [t] = modulus of temperature in degrees celsius without regard to sign. If tolerance is not specified class B tolerance shall apply. The insulation resistance of the compacted ceramic material shall have a minimum resistance of 100Me at ambient temperature (15-35C ?5) and a relative humidity of minimum 80%, with an applied 10 to 100 V. DC voltage in accordance with IEC 751. Any decrease in insulation resistance at elevated temperatures shall be in accordance with IEC 751. IDENTIFICATION: The element flange shall bear the following information: - manufacturers name or trade mark. - manufacturers model or serial number. - pt 100 element. - tolerance class/grade. - sheath material. FACTORY TESTING: Manufacturers inspection/test procedures shall be submitted for purchaser approval if requested. Unless otherwise specified in the purchase order, manufacturers standard test procedures are acceptable (IEC 751 refers). Minimum standard tests are as follows: - visual and dimensional inspection. - insulation resistance measurement. - calibration test.

MESC SPECIFICATION SPE 60.44.04/001

Revision: Page 3 of 3

- minimum immersion length test. - pressure test. WITNESS INSPECTION: When specified in the purchase order, thermometer assemblies shall be inspected by the authorised inspector. Unless otherwise specified, the inspection will be confined to visual and dimensional checks and verification of satisfactory factory testing. CERTIFICATION: The manufacturer shall provide a certificate of compliance with specification and purchase order. Additional required certification shall be specified in the purchase order. PACKING AND TRANSIT: All items shall be clean and free from all foreign matter prior to packing. REFERENCES: Latest issue references shall apply. American Standards. Industrial platinum resistance thermometers. German Standards. Stop flanges for TC and RTD thermometers. sensor units for resistance thermometers. International Standards. Temperature, humidity and barometric pressure. industrial platinum resistance thermometer sensors. Standard Drawings. Thermocouple assembly for stirring kettle. thermometer assemblies in thermowells. thermometer assembly surface mounting. ASTM E1137 DIN 43734 DIN 43762 IEC 654-1 IEC 751 S35-406 S35-409 S35-411

You might also like

- Best Blackpowder2013Document24 pagesBest Blackpowder2013sohail1985No ratings yet

- 10 Ways To Avoid Losing Money in Forex: LeverageDocument22 pages10 Ways To Avoid Losing Money in Forex: LeverageLathika Lanka AbeyrathnaNo ratings yet

- Insulation Stiffness Test Report for 600mm Diameter PipeDocument2 pagesInsulation Stiffness Test Report for 600mm Diameter PipekasvikrajNo ratings yet

- Candlesticks Technical AnalysisDocument17 pagesCandlesticks Technical Analysiswhy_1234_5678No ratings yet

- Qamar Hassan Iqbal CVDocument2 pagesQamar Hassan Iqbal CVQamar Hassan IqbalNo ratings yet

- Referral Compensation ProgramDocument6 pagesReferral Compensation ProgramFelipe NadalNo ratings yet

- FX Floor Trader StrategyDocument14 pagesFX Floor Trader StrategyAlvin CardonaNo ratings yet

- QCD Compliance Fire Safety WorksDocument17 pagesQCD Compliance Fire Safety WorksJeffersonDeGuiaNo ratings yet

- Technical and Fundamental AnalysisDocument10 pagesTechnical and Fundamental AnalysisRakesh BhardwajNo ratings yet

- Steam O&MDocument28 pagesSteam O&MmadiNo ratings yet

- Optimize Energy Usage with Time of Day MeteringDocument6 pagesOptimize Energy Usage with Time of Day MeteringSreepadam Padam100% (1)

- 06 User Manual, 48 V, 40 Amp, NetSure 503 IA4Document44 pages06 User Manual, 48 V, 40 Amp, NetSure 503 IA4Vivek Kumar RaiNo ratings yet

- Valves SpecsDocument3 pagesValves SpecsTareq AlsadiNo ratings yet

- RSI Divergence Types & Strategies ExplainedDocument11 pagesRSI Divergence Types & Strategies ExplainedGoogleuser googleNo ratings yet

- Black Powder in Sales Gas Pipelines: Sources and Technical RecommendationsDocument15 pagesBlack Powder in Sales Gas Pipelines: Sources and Technical RecommendationsQueenNo ratings yet

- PheDocument32 pagesPhesalamrefighNo ratings yet

- SABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingDocument15 pagesSABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingAbdelaziz EldeebNo ratings yet

- Trading and Profit Loss AccountDocument8 pagesTrading and Profit Loss AccountOrange Noida100% (1)

- Site Clearance Inspection ChecklistDocument2 pagesSite Clearance Inspection ChecklistSuresh Praba PNo ratings yet

- VAV Box SpecificationDocument1 pageVAV Box SpecificationSithuNo ratings yet

- Installing Seismic Restraints For Mechanical EquipmentDocument158 pagesInstalling Seismic Restraints For Mechanical EquipmentinitbashNo ratings yet

- Thermo Ramsey EngDocument13 pagesThermo Ramsey EngSebastian NarvaezNo ratings yet

- PCR TouchdownDocument3 pagesPCR TouchdownDeepak Ranjan SahooNo ratings yet

- Energy Masters Prospectus PDFDocument66 pagesEnergy Masters Prospectus PDFjoNo ratings yet

- DMRC Rs6 Ci Main Line Test Procedure 8 Car Meirs6mltpci-002Document34 pagesDMRC Rs6 Ci Main Line Test Procedure 8 Car Meirs6mltpci-002Chaitanya Bhargav KotikeNo ratings yet

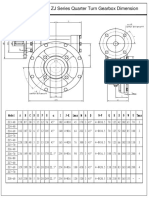

- ZJ Series Quarter Turn Gearbox Dimensions TableDocument3 pagesZJ Series Quarter Turn Gearbox Dimensions TableCan PoonsawatNo ratings yet

- Condition-Based Monitoring ShiftDocument3 pagesCondition-Based Monitoring ShiftCyrix.One100% (1)

- MAE 570 Aircraft Inlets, A - SDocument84 pagesMAE 570 Aircraft Inlets, A - SLuiz Felipe Disconzi Lopes100% (1)

- Hex Bolt Identification GuideDocument4 pagesHex Bolt Identification GuideSyed ZakiuddinNo ratings yet

- Big Blaster® Hurricane Air Blaster PDFDocument52 pagesBig Blaster® Hurricane Air Blaster PDFZahir KhiraNo ratings yet

- Stock Market Course ContentDocument12 pagesStock Market Course ContentSrikanth SanipiniNo ratings yet

- FX Trading Strategy Guide - Follow Trends & Use IndicatorsDocument2 pagesFX Trading Strategy Guide - Follow Trends & Use IndicatorsTakudzwaNo ratings yet

- The Million TeamDocument118 pagesThe Million TeamDrevo Wil'zNo ratings yet

- CV of GTDocument5 pagesCV of GTMD ASIF ALINo ratings yet

- Flex Tube Boiler BookDocument38 pagesFlex Tube Boiler BookrasheedillikkalNo ratings yet

- Industrial Washing MachineDocument10 pagesIndustrial Washing MachineDiêm Công ViệtNo ratings yet

- 2019-10 Global KOSO PresentationDocument51 pages2019-10 Global KOSO Presentationreyhan mNo ratings yet

- Mass Flow Meter CoriolisisDocument5 pagesMass Flow Meter CoriolisisSHINo ratings yet

- Technical Analysis For Beginners Episode - 1Document24 pagesTechnical Analysis For Beginners Episode - 1Googleuser googleNo ratings yet

- Safety and Standard Protection Code QuestionsDocument3 pagesSafety and Standard Protection Code QuestionsEgbodor Peter100% (1)

- TCVN 5307-2009Document44 pagesTCVN 5307-2009sooner123456100% (3)

- Megger Test Procedure Explained With Transformer ExampleDocument4 pagesMegger Test Procedure Explained With Transformer ExamplesamsungloverNo ratings yet

- IIT Piping EnggDocument7 pagesIIT Piping EnggSikander GirgoukarNo ratings yet

- Online Leak Sealing TenderDocument10 pagesOnline Leak Sealing TenderchennaiNo ratings yet

- Introduction to Process SimulationDocument12 pagesIntroduction to Process SimulationSamriddha Das GuptaNo ratings yet

- Time Study Techniques and MethodsDocument16 pagesTime Study Techniques and MethodsMubasher RajputNo ratings yet

- Drag & Drop Volume Profile Indicator Installation GuideDocument7 pagesDrag & Drop Volume Profile Indicator Installation GuidecaicocnhoNo ratings yet

- How To Trade Using Long and Short Information - MoneyPatiDocument10 pagesHow To Trade Using Long and Short Information - MoneyPatiFaker FockerNo ratings yet

- One-Click Trade Pro MT4 EADocument13 pagesOne-Click Trade Pro MT4 EAMichael MarioNo ratings yet

- Bollinger BandsDocument10 pagesBollinger Bandsarvindk.online6095No ratings yet

- Compressor ChecklistDocument1 pageCompressor ChecklistRolando DaclanNo ratings yet

- Sectional Weight PDFDocument3 pagesSectional Weight PDFsivaNo ratings yet

- Expension Joints Engineering AppliancesDocument30 pagesExpension Joints Engineering AppliancesAcid BurnsNo ratings yet

- Al Brooks Trading Price Action ReversalsDocument2 pagesAl Brooks Trading Price Action ReversalsZenpowermanNo ratings yet

- Speed up MT4 Platform by Reducing Price Bars, Deleting Logs & History FilesDocument4 pagesSpeed up MT4 Platform by Reducing Price Bars, Deleting Logs & History FilesDragan BabicNo ratings yet

- Computer Aided Pipe Stress AnalysisDocument1 pageComputer Aided Pipe Stress AnalysisSandeep BhatiaNo ratings yet

- MESC specification for platinum resistance thermometer elementsDocument3 pagesMESC specification for platinum resistance thermometer elementsharshkumar patelNo ratings yet

- Winding Temperature IndicatorDocument9 pagesWinding Temperature IndicatorTruong Van Quang100% (2)

- Armaflex Insulation + Fire Rated DuctworkDocument7 pagesArmaflex Insulation + Fire Rated DuctworkGiải Pháp Cơ ĐiệnNo ratings yet

- RTD Gen Specs RefDocument4 pagesRTD Gen Specs RefRamesh SubramanianNo ratings yet

- Control ValveDocument25 pagesControl ValveAsad RazaNo ratings yet

- PTCLDocument1 pagePTCLYasir JatoiNo ratings yet

- Paper 1 - Stevens (Instrumentation Q&A)Document29 pagesPaper 1 - Stevens (Instrumentation Q&A)Silo MiyanNo ratings yet

- Industrial Instrumentation & Control BasicsDocument70 pagesIndustrial Instrumentation & Control BasicsSilo MiyanNo ratings yet

- Paper 1 - Stevens (Instrumentation Q&A)Document29 pagesPaper 1 - Stevens (Instrumentation Q&A)Silo MiyanNo ratings yet

- WinRAR User ManualDocument29 pagesWinRAR User ManualMcSwitch01No ratings yet

- Verified Email Ids From IndoreDocument3 pagesVerified Email Ids From IndoreAnuraag GuptaaNo ratings yet

- Verified Email Ids From IndoreDocument3 pagesVerified Email Ids From IndoreAnuraag GuptaaNo ratings yet

- RealTemp ChangelogDocument2 pagesRealTemp ChangelogMihai DimoiuNo ratings yet

- WinRAR User ManualDocument29 pagesWinRAR User ManualMcSwitch01No ratings yet

- Whats NewDocument7 pagesWhats NewBruno RafaelNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Ariston Lbe 8 X 80269690000Document80 pagesAriston Lbe 8 X 80269690000frNo ratings yet

- Thongwik 2008Document5 pagesThongwik 2008João Paulo VissottoNo ratings yet

- Engine 310G 310SGDocument7 pagesEngine 310G 310SGANDRES BAZURTONo ratings yet

- 5550/5550G Mechanical Vibration Switches DatasheetDocument8 pages5550/5550G Mechanical Vibration Switches DatasheetJadid AbdullahNo ratings yet

- Examples: 238 17 PsychrometricsDocument12 pagesExamples: 238 17 PsychrometricsJunior Ferrel AlvarezNo ratings yet

- DTS - Ship Const & StabDocument12 pagesDTS - Ship Const & StabYASHKAR VERMA100% (2)

- Installation Instructions: CautionDocument4 pagesInstallation Instructions: CautionVMNo ratings yet

- Compile of Lab Thin CylinderDocument13 pagesCompile of Lab Thin CylinderKhairi Azri100% (4)

- Ibc Mixer - Brochure EnglishDocument4 pagesIbc Mixer - Brochure EnglishJonathan HensleyNo ratings yet

- 21UTSR HeldDocument52 pages21UTSR HelddavidNo ratings yet

- Compression Member FailureDocument8 pagesCompression Member FailureEarl LomotanNo ratings yet

- Engineering MCQs and D.C. Generators QuestionsDocument31 pagesEngineering MCQs and D.C. Generators QuestionsNitin MauryaNo ratings yet

- Sand Control in Well Construction and OperationDocument205 pagesSand Control in Well Construction and OperationPisethNo ratings yet

- Guidelines For Specification of Turbulence at Inflow BoundariesDocument3 pagesGuidelines For Specification of Turbulence at Inflow BoundariesAmbrish Singh100% (2)

- Hattat HEMA Hydraulic Pump CatalogDocument171 pagesHattat HEMA Hydraulic Pump CatalogTehpartsNo ratings yet

- Guideline On Submission of Amendment and Record Piling Plans PDFDocument9 pagesGuideline On Submission of Amendment and Record Piling Plans PDFBlu SmileyNo ratings yet

- CMC Ready ReckonerxlsxDocument3 pagesCMC Ready ReckonerxlsxShalaniNo ratings yet

- Thermodynamics 1 MEP 261: Dr. M. Ehtisham SiddiquiDocument64 pagesThermodynamics 1 MEP 261: Dr. M. Ehtisham Siddiquiانس الحربيNo ratings yet

- DrillchartDocument5 pagesDrillchartcc6689No ratings yet

- A Two Phase Model CavitationDocument11 pagesA Two Phase Model CavitationThePrius0% (1)

- PPV PresentationDocument66 pagesPPV PresentationIvan BogdanNo ratings yet

- Airconditioning - HTML: Solar "Commercial Air-Conditioning" Systems Our Achievements and Our GoalsDocument9 pagesAirconditioning - HTML: Solar "Commercial Air-Conditioning" Systems Our Achievements and Our GoalsWeyuma ToleraNo ratings yet

- Sulzer RTA air start valve operating principleDocument5 pagesSulzer RTA air start valve operating principleHrishikesh More100% (1)

- Gas Welding Equipment - Hose Connections For Welding, Cutting and Allied ProcessesDocument12 pagesGas Welding Equipment - Hose Connections For Welding, Cutting and Allied ProcessesMustafa Ersin EkremNo ratings yet

- 5 Port Solenoid Valve: Reduced Power ConsumptionDocument60 pages5 Port Solenoid Valve: Reduced Power ConsumptionkrisornNo ratings yet

- Ashok Leyland In-Plant Training ReportDocument12 pagesAshok Leyland In-Plant Training Reportbalakvit100% (2)

- Defects and Discontinuities: Tim Turner Elizabethtown Technical CollegeDocument78 pagesDefects and Discontinuities: Tim Turner Elizabethtown Technical Collegepurav_patel20079232No ratings yet

- TURNING FIX (04-005) - Sheet - 1Document1 pageTURNING FIX (04-005) - Sheet - 1daryosh hassanyNo ratings yet

- History of MechatronicsDocument20 pagesHistory of MechatronicsManoj DhageNo ratings yet

- Tutorial Letter MOMDocument12 pagesTutorial Letter MOMTshepo MolotoNo ratings yet