Professional Documents

Culture Documents

Design Feature - Steppermotor

Uploaded by

Amarnath M DamodaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Feature - Steppermotor

Uploaded by

Amarnath M DamodaranCopyright:

Available Formats

DESIGNfeature

TOM HOPKINS, Director of Engineering

STMicroelectronics

Stepper pp p Motor Controller/Driver Simplifies Stepper Motor System

A stepper motor controller/ driver IC integrates a digital control core which enables a single microcontroller to easily manage several motors, because it only has to issue high-level movement commands to the IC.

A

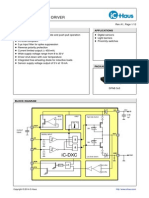

Driver

OSC1 OSC2

VREG

ADCIN

new controller IC, the L6470 for stepper motors, integrates the power stage along with a digital control core on a monolithic IC. The device can receive motion profile commands across the SPI interface and autonomously execute the complete movement using the programmed acceleration and speed profile. It can also autonomously accelerate the motor up and keep it running at a programmed speed. Fig. 1 shows a block diagram of the device. The Control Logic is a programmable state machine that can receive and store parameters for the acceleration rate, deceleration rate, start speed, run speed, phase current control (PWM) parameters and step mode. Eight step modes, from full step to 1/128 microstepping are supported by the controller. For any selected step mode, the internal absolute position counter counts the number of steps, or microsteps, to continually track the motor position with a resolution equal to the step mode. Rotating a 1.8 degree per step motor one full rotation in 1/128 microstepping would increment (or decrement) the position counter by 25600 counts (128 200 steps). An SPI interface receives all the motion parameters and the movement commands. The commands, like move forward a number of steps, are interpreted by the control logic that controls the output step time and number of steps to accelerate the motor from the starting speed to the running speed and back down to stop while moving the total number of steps commanded. Complex movements can be made by programming queuing up and sending a set of movement commands to be sent across the SPI to the device. CP V

BOOT

Charge pump Clock generator Internal 3V regulator ADC UVLO OUT_A1 VDD A1 A2 Driver OUT_A2 PGNDA VSB OUT_B1 Driver B2 Driver OUT_B2 PGND B Thermal sensing DGND DACs and comparators Current sensing AGND VSA

MOVEMENT AND POSITION COMMANDS

The Digital Core can execute five movement commands and four stop commands included in Table 1. Before any movement is made the operating parameters, Minimum Speed, Maximum Speed, Acceleration Rate, Deceleration Rate, and other operating values are set using the SetParam command across the SPI interface. To insure motion integrity, many of the motion profile settings are locked during a movement

Interface

dSPIN core

Fig. 1. The L6470 is a programmable state machine that can receive and store motion parameters.

24

Power Electronics Technology y | August 2010

www.powerelectronics.com

STEPPERMOTORcontroller

and can only be updated when the motor is stopped. Fig. 2 shows a typical movement profile for the Move command. When the device receives a Move command, it calculates the required profile and executes the profile to accelerate from the minimum speed to the maximum speed and back down to end at a position N steps from the starting

Maximum speed From 15.25 to 15610 steps/s (15.25 steps/s resolution)

Speed

Time Minimum speed From 0 to 976 steps/s (0.24 step/s resolution) Acceleration & Deceleration From 14.55 to 59590 step/s2 (14.55 step/s2 resolution)

Fig. 2. Typical movement profile for the Move command.

Speed (step frequency) SPD3

SPD1 SPD2 Run (SPD2, FW) Minimum speed Maximum speed Run (SPD1, FW) SPD4 Run (SPD3, FW)

position, all under control of the digital core hardware. The GoTo command tells the driver to move the motor to a specific position based on the internal 22-bit absolute position counter. There are two GoTo commands, one that will move in the specified direction and the other that will move in most direct path, determining the direction to move that moves the least number of steps to reach the desired position. For a 1.8 degree per step motor operation at 1/128 microstepping, the resolution of the 22-bit position counter is equivalent to about 164 revolutions of the motor. Even with a significant gear reduction, the usable resolution is still well within the range of the position counter. The movement profile for the GoTo command looks the same as a Move command, but the number of steps is automatically calculated to reach the commanded absolute position. The Run and GoUntil commands are used to run the motor at a constant speed until a stop command (Run) is received or an external event (GoUntil) occurs. When a stop command is received the device either hard stops or decelerates down to a stop, depending on the command. The device can also be commanded to stop, hard or soft, and then tri-state the outputs. Complex movements can be performed using a series of run commands, as shown in Fig. 3. Each time a new run command is received the device will accelerate, or decelerate, the motor to Run (SPD4, BW) the new commanded speed and continue to run at that speed until the next run command or a stop command is received. When a command is received to reverse the direction of movement, the motor is decelerated down to the Time minimum speed and then accelerated up to speed in the opposite direction.

VOLTAGE MODE MICROSTEPPING

Typically, stepper motor drives have been designed to operate in current mode with the current controller sensing and controlling the winding current. This allows designers to maintain the desired torque over a wide range of speed and power supply voltage fluctuations. This works very well for full step and half step drives and is pretty simple to implement. Most designers have avoided doing microstepping drives with voltage mode since the peak current could vary widely due to variations the power supply voltage and the increasing back EMF from the motor as the speed increases.

Fig. 3. Multiple run commands can implement complex movements using a series of run commands.

TABLE 1. MOVEMENT AND STOP COMMANDS

TYPE Move Move Move Move Move Stop Stop Stop Stop COMMAND Run (Direction, Speed) Move (Direction, N_Steps) GoTo (Position) GoTo (Direction, Position) GoUntil (Act, Direction, Speed) SoftStop Hard Stop SoftHiZ HardHiZ OPERATION Accelerates up and runs at speed until stopped. Move in N steps in the defined direction. Moves to the absolute position in most direct path Moves to the absolute position in the defined direction. Accelerate up and run until an external event occurs. Decelerate down to a stop. Stop without decelerating Decelerate down to a stop then turn the bridge off. Stop and turn bridge off

www.powerelectronics.com

August 2010 | Power Electronics Technology

25

STEPPERMOTORcontroller

Without Compensation KVal Speed

With BEMF Compensation KVal Speed

Compensation value FN_SLP_ACC FN_SLP_DEC

ST_SLP Applied Voltage Applied Voltage

INT_SPEED

Speed

Fig. 5. With BEMF compensation, peak current is constant over the entire operation speed range of the deview.

BEMF BEMF

BEMF COMPENSATION

If the same peak voltage is supplied to the motor over the entire speed range, the current would go down as the speed increases since the BEMF of the motor effectively reduces the voltage applied to the coil. The waveforms on the left of Fig. 4 show the operation of the motor without BEMF compensation. As the speed increased, the BEM increases linearly and, since the voltage across the coil is effectively the applied phase voltage minus the BEMF voltage, the current decreases. To compensate for the increase in BEMF, the device includes an additional factor to the KVAL that compensates for the BEMF. Essentially this is a compensation that is added to the initial KVAL setting to offset the BEMF. Since the BEMF is directly proportional to the speed, this compensation factor is given as a slope so that the real time compensation can be calculated from the slope and the current speed. The device has different values for the compensation. The first is the standard value that is applied to the motor starting at zero speed up until the speed reaches a threshold set by the intersect speed parameter, INT_SPEED. Above the intersect speed, the slope can be adjusted by two additional slope terms, one used during constant speed operation and acceleration, and one used during deceleration. When the BEMF compensation is properly set, the peak current will be essentially constant over the entire operation speed range. Fig. 6 shows the actual current waveform for a motor as it accelerates.

Phase Current

Phase Current

Fig. 4. Phase current without BEMF compensation.

However, both of these factors can be compensated for with a digital control. To implement the voltage mode drive, the output pulse width is controlled by a PWM counter/timer circuit that digitally sets the output duty cycle. The L6470 controls the phase current by applying a voltage to motor windings. The phase current amplitude is not directly controlled, but depends on phase voltage amplitude, load torque, motor electrical characteristics and rotation speed. The effective output voltage is proportional to the motor supply voltage multiplied by a coefficient (KVAL). KVAL ranges from 0 to 100% of the supply voltage. In microstepping, this peak value is then multiplied by the modulation index to generate a sine wave with the selected number of steps. The peak voltage value is given by the equation: VOUT = VS KVAL The value for KVAL can be calculated from the formula: KVAL = (Ipk k R)/Vs Where: Ipk k = Desired Peak Current Vs = Typical Power supply Voltage R = Motor winding resistance

POWER SUPPLY AND PHASE RESISTANCE COMPENSATION

Two other major factors that affect the phase current are the motor supply voltage and phase resistance. Since the device operates in voltage mode, controlling the output duty cycle, variations in either will directly affect the

The device includes registers that allow setting different KVAL settings for acceleration, deceleration, running at constant speed and holding position to easily allow different torque settings Fig. 6. With BEMF compensation, the actual current in each part of the motion profile. waveform variation for a motor as it accelerates.

26

Power Electronics Technology y | August 2010

www.powerelectronics.com

STEPPERMOTORcontroller

Compensation algorithm calculates correction coefcient L6470

VS + n(t)

ADC

COMP

PWM + H-Bridge

VOUT

Sinewave Amplitude 5-bit ADC measures actual motor supply voltage Compensation coefcient applies to sinewave amplitude

Fig. 7. The IC includes compensation for power supply variation, which might cause the motor to stall.

phase current. When operating on an unregulated power supply, there may be a significant amount of ripple on the supply voltage to the motor driver circuitry. As the supply voltage varies, the motor current will also vary. If the ripple on the supply voltage is significant, then there is a risk of stalling the

motor if the motor current falls too low. The device compensates for the power supply variation, as shown in Fig. 7. In this circuit, an internal A/D converter measures the power supply voltage, and then the algorithm in the digital core calculates an appropriate compensation factor that is applied to the PWM duty cycle to maintain a constant output voltage over the variations in supply voltage. Variations in the phase resistance as the motor heats also directly affect the phase current. The KTHERM setting is used to compensate for the variation in phase resistance due to the internal heating of the motor. Software in the driving microcontroller can monitor or estimate the motor temperature rise and set the KTHERM value to compensate for the increase in motor resistance due to the temperature increases. The L6470s features allow the designer to implement a voltage mode microstepping drive and compensate for the typical system variations that, in the past, have been overcome using current mode drives. Using the digital based voltage mode PWM, microstepping drives up to 128 microsteps per step can easily be implanted. The sine-wave profile is more accurate and allows higher position resolution than with current mode implementations.

24th International Trade Fair New Munich Trade Fair Centre 0912 November 2010

Register online and enjoy the benets: www.electronica.de/en/tickets

erolpxe

the possibilities of tomorrow.

Automotive e-Mobility Displays / e-Signage Embedded systems / software Medical / MEMS Photovoltaics Time for electronics. Time for the future. Key topics, trends and technologies. The latest components, systems and applications. Visit electronica 2010, the international trade fair that will show you today what is important tomorrow and generate momentum for real growth. Parallel event: hybridica. Trade fair for hybrid-component production. www.hybridica.de

electronica 2010

components | systems | applications

www.electronica.de/en

get the whole picture

www.powerelectronics.com

August 2010 | Power Electronics Technology

27

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Questions & Answers On Capacitance and CapacitorsDocument113 pagesQuestions & Answers On Capacitance and Capacitorskibrom atsbha71% (14)

- Electricity From WalkingDocument8 pagesElectricity From WalkingSanthosh100% (6)

- ECG Peak DetectionDocument7 pagesECG Peak DetectionAmarnath M DamodaranNo ratings yet

- Digital Sensor I/O DriverDocument12 pagesDigital Sensor I/O DriverAmarnath M DamodaranNo ratings yet

- CAN Bus ESD Protection Diode (PESD2CAN)Document13 pagesCAN Bus ESD Protection Diode (PESD2CAN)Amarnath M Damodaran100% (1)

- System Level ESD Protection FAQDocument7 pagesSystem Level ESD Protection FAQAmarnath M DamodaranNo ratings yet

- AVR415: RC5 IR Remote Control Transmitter: 8-Bit Microcontroller Application NoteDocument8 pagesAVR415: RC5 IR Remote Control Transmitter: 8-Bit Microcontroller Application NoteØrova RaihanNo ratings yet

- CPR (Cardio Pulmonary Resuscitation)Document3 pagesCPR (Cardio Pulmonary Resuscitation)Amarnath M DamodaranNo ratings yet

- Unidirectional and Bidirectional TVS DevicesDocument2 pagesUnidirectional and Bidirectional TVS DevicesAmarnath M Damodaran100% (2)

- AVR Hardware Design ConsiderationsDocument14 pagesAVR Hardware Design ConsiderationsAmarnath M Damodaran100% (1)

- Decap PaperDocument4 pagesDecap PaperTanmoy RoyNo ratings yet

- Interfacing DDR SDRAM With Cyclone DevicesDocument42 pagesInterfacing DDR SDRAM With Cyclone DevicesAmarnath M DamodaranNo ratings yet

- Technical Note: TN-46-07 Ddr333 Design Guide For Two-Dimm SystemsDocument21 pagesTechnical Note: TN-46-07 Ddr333 Design Guide For Two-Dimm SystemsAmarnath M DamodaranNo ratings yet

- Uc 3909Document14 pagesUc 3909Amarnath M DamodaranNo ratings yet

- Photoelectric SensorDocument3 pagesPhotoelectric SensorAmarnath M DamodaranNo ratings yet

- Phantom GravityDocument41 pagesPhantom GravityAmarnath M DamodaranNo ratings yet

- Phantom GravityDocument41 pagesPhantom GravityAmarnath M DamodaranNo ratings yet

- Red GuideDocument33 pagesRed GuideAmarnath M DamodaranNo ratings yet

- Shark2 Operators Manual GenDocument88 pagesShark2 Operators Manual GenAmarnath M DamodaranNo ratings yet

- Manual Sharkv3.94Document86 pagesManual Sharkv3.94Amarnath M DamodaranNo ratings yet

- Chapter 2, Traffic Detector Handbook - Third Edition-Volume I - FHWA-HRT-06-108Document45 pagesChapter 2, Traffic Detector Handbook - Third Edition-Volume I - FHWA-HRT-06-108Amarnath M Damodaran100% (1)

- VFD Fundamentals & TroubleshootingDocument28 pagesVFD Fundamentals & TroubleshootingPrashanthi Balamurugan67% (3)

- MT 222Document3 pagesMT 222Amarnath M DamodaranNo ratings yet

- 17 99 1 PBDocument5 pages17 99 1 PBAmarnath M DamodaranNo ratings yet

- LMH 6611Document42 pagesLMH 6611Amarnath M DamodaranNo ratings yet

- Ilb Ilbb EnoteDocument5 pagesIlb Ilbb EnoteAmarnath M DamodaranNo ratings yet

- PanavisionSVI ELIS 1024A Datasheet PDS0004RevJDocument13 pagesPanavisionSVI ELIS 1024A Datasheet PDS0004RevJAmarnath M DamodaranNo ratings yet

- 185Document4 pages185Amarnath M DamodaranNo ratings yet

- MSP 430 F 2011Document93 pagesMSP 430 F 2011Amarnath M DamodaranNo ratings yet

- ADP1614Document20 pagesADP1614Amarnath M DamodaranNo ratings yet

- Single Ended Primary Inductor ConverterDocument4 pagesSingle Ended Primary Inductor ConverterAmarnath M DamodaranNo ratings yet

- Subsection 15 6 5 PDFDocument4 pagesSubsection 15 6 5 PDFAmarnath M DamodaranNo ratings yet

- PLL 565Document6 pagesPLL 565Dinesh Kumar MehraNo ratings yet

- SEMIKRONPowerSemiconductors PDFDocument466 pagesSEMIKRONPowerSemiconductors PDFasccorreaNo ratings yet

- TL 072 PDFDocument9 pagesTL 072 PDFJose M PeresNo ratings yet

- Chapter 3 - Semiconductor PN Junction Diode: Series Diode Configuration With DC InputsDocument4 pagesChapter 3 - Semiconductor PN Junction Diode: Series Diode Configuration With DC InputsVince Lester DP. De CastroNo ratings yet

- Rif 1 PDFDocument17 pagesRif 1 PDFNelson Naval CabingasNo ratings yet

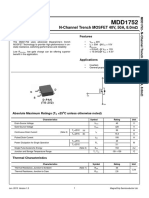

- MDD1752Document7 pagesMDD1752Homer Sadych Henao MarinNo ratings yet

- Capacitor Tantalio SMT 1206KEM T2005 T491Document24 pagesCapacitor Tantalio SMT 1206KEM T2005 T491Jeziel Vazquez NavaNo ratings yet

- Design and Implementation of A Discrete Controller For Soft Switching DC - DC ConverterDocument8 pagesDesign and Implementation of A Discrete Controller For Soft Switching DC - DC ConverterfoufouNo ratings yet

- 5101 Motor DriverDocument11 pages5101 Motor DriverMoise CristinaNo ratings yet

- TestDocument25 pagesTestsubha4studyNo ratings yet

- Operation Principles of Bi-Directional Full-Bridge DCDC Converter With Unified Soft-Switching Scheme and Soft-Starting CapabilityDocument8 pagesOperation Principles of Bi-Directional Full-Bridge DCDC Converter With Unified Soft-Switching Scheme and Soft-Starting CapabilityJie99No ratings yet

- VLSI C - V CharacteristicsDocument24 pagesVLSI C - V CharacteristicsMALATHI .LNo ratings yet

- Using TC74 Temp SensorDocument13 pagesUsing TC74 Temp SensorGaneshVenkatachalamNo ratings yet

- Irfz34, Sihfz34: Features Product SummaryDocument7 pagesIrfz34, Sihfz34: Features Product SummarySamia TouffaNo ratings yet

- Variable Frecuency Drives For Fans PDFDocument15 pagesVariable Frecuency Drives For Fans PDFReyes SanchezNo ratings yet

- DC SlidesDocument9 pagesDC SlidesMarlon BoucaudNo ratings yet

- XSTR Equivalentes PDFDocument62 pagesXSTR Equivalentes PDFReginaldoNo ratings yet

- Topics ElecDocument8 pagesTopics Elecmahum jamil100% (1)

- Reactive Power Compensation Using A Voltage Source GeneratorDocument10 pagesReactive Power Compensation Using A Voltage Source GeneratorkubikNo ratings yet

- Remote CodesDocument21 pagesRemote CodesBhavya .tNo ratings yet

- Decibels PDFDocument4 pagesDecibels PDFMarina CzuprynaNo ratings yet

- Samsung Mx-c630d Xer SMDocument62 pagesSamsung Mx-c630d Xer SMEdu Kees Morello100% (1)

- Test and MeasurementsDocument16 pagesTest and MeasurementsKimberly TaboraNo ratings yet

- WG B5.37 - Protection PDFDocument199 pagesWG B5.37 - Protection PDFnitinatp1978No ratings yet

- Report On Power SupplyDocument14 pagesReport On Power SupplyBhavesh MaheshwariNo ratings yet

- Unit 1 Notes TopperDocument33 pagesUnit 1 Notes TopperShashank BakshiNo ratings yet

- GKDocument48 pagesGKOmkar SheteNo ratings yet

- Soft-Error-Aware Read-Stability-Enhanced Low-Power 12T SRAM With Multi-Node Upset Recoverability For Aerospace ApplicationsDocument11 pagesSoft-Error-Aware Read-Stability-Enhanced Low-Power 12T SRAM With Multi-Node Upset Recoverability For Aerospace ApplicationsZhongpeng LiangNo ratings yet