Professional Documents

Culture Documents

Brace Connection

Uploaded by

rajedmaglinteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brace Connection

Uploaded by

rajedmaglinteCopyright:

Available Formats

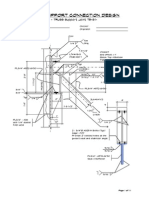

Design Calculation for Bracing Connection - Joint SWF-SF13

1.) LAYOUT

W36X232

See calcs attached

1'-1/4" 8 1/4"

3/16" 3/16"

6" 6" Typ

5 3/16"

PL 0.375 - A36 Gusset Offset = 1/2''

1'-3 3/4"

1'-1"

6.00

8 3/8"

HSS8X6X1/4 3/16"

4" 4" Typ

1

4.0 9 1/2" 5"

3/16"

HSS8X4X1/8

2.)

REQUIRED STRENGTHS: Member 1: Axial Load, Ta Axial Load, Ca

= =

5.0 5.0

kips (Tension) kips (Compression)

Member 2: (See below for details) Axial Load, Ta = 4.0 Axial Load, Ca = 4.0 6.0 Shear Load, Va =

kips (Tension) kips (Compression) kips

3.)

MATERIAL & GEOMETRIC PROPERTIES: Member 1: Size: Fy Fu B HT A

HSS8X4X1/8 = 46 = 58 4.00 = 8.00 = 2.70 =

ASTM A500 Gr. B ksi ksi in in in

Page 1 of 13

Design Calculation for Bracing Connection - Joint SWF-SF13

t Member 2: Size: Fy Fu B HT A t Member 3: Size: Fy Fu B HT A t = 0.116 in

HSS8X6X1/4 = 46 = 58 6.00 = 8.00 = 6.17 = 0.233 =

ASTM A500 Gr. B ksi ksi in in in in

HSS8X8X1/4 = 46 = 58 8.00 = 8.00 = 7.10 = 0.233 =

ASTM A500 Gr. B ksi ksi in in in in ASTM 36 ksi ksi in

Gusset Plate: Fy = Fu = tgusset = 4.) BRACE CONNECTION MEMBER 1: Brace to Gusset Plate Weld: Electrode Class Fu Fv = = = = = = = = = = = = = = = = =

36 58 3/8

E700XX

Nominal Tensile Strength of Weld 70.00 Ksi Allowable Weld Shear Strength 0.6 Fu / 2 21.00 Ksi Size of Weld 0.1875 in. (Use 0.1250 in. for calculation)

w Pw

Shear Capacity of 1/8" weld per Linear Inch 0.707 * Fv * w (0.707 * 21 * 0.125) 1.856 Kips/in Length of Weld 4.00 in. Weld Shear Capacity Pw * 4 L2 29.694 Kips

L1 Vw

Vw

>

5.00

Kips

(OK)

Tension Yielding of the Brace:

Page 2 of 13

Design Calculation for Bracing Connection - Joint SWF-SF13

Rn/ = = = Capacity from 'Limit State of Tension Yielding of Brace' Fyb * Ag1 1.67 74.37 kips > 5.00 kips (OK)

Tension Rupture of the Brace: Rn/ Capacity from 'Limit State of Tension Rupture of Brace' Fub * Ae = 2.00 where: 4.00 in = (Length of Weld in HSS) L B H x U An Ae = = = = = = = = = = 8.00 4.00 in in (Width of HSS Section) (Height of HSS Section) =

2 (B + 2 * B * H) / (4 * (B + H)) 2.667 in

1 - (x / L) 0.333 Ag1 - 2 * (tp + 0.0625) * t1 2.599 in U * An 0.866 25.12 kips in > 5.00 kips (OK)

Rn/

Whtimore Section L= L= 2 lw tan 30 + B 8.619 in 0.000 0.600 in in = 1.67 B= 4.00 in

Whitmore width in Vertical Edge = Whitmore width in Horizontal Edge =

Check tension yielding on the Whitmore section Rn = Fy Aw Rn = 36 x [ ( 8.619 - 0 - 0.6 ) x 0.375 ] Rn = Rn/ 108.25 = kips kips > 5.00

64.82

kips

(OK)

Check block shear rupture of the gusset Rn = = Nominal Block Shear Strength of Gusset ( =2)

2 x Min[ (0.6 x Fu x Anv + Ubs x Fu x Ant);

Page 3 of 13

Design Calculation for Bracing Connection - Joint SWF-SF13

(0.6 x Fy x Agv + Ubs x Fu x Ant) ] Where: Ubs = 1.0 Ant = Net Area with Tension Resistance = Bbrace x tgusset = 1.50 in

2

Agv = Gross Area with Shear Resistance = 2 x lw x tgusset = 3.00 in

2

Anv = Net Area with Shear Resistance = Rn/ = 3.00 75.90 in

2

kips

>

5.00

kips

(OK)

Plate Buckling of Connection Plate Ap = = = = = = = = = = = Effective Plate Cross-sectional Area L*t 3.232 in Plate Unbraced Length of Whitmore Section 4.63 in. Effective Length Factor 1.200 Radius of Gyration t / 3.464 0.108 in. 51.323 > 25

Lcr

K Lcr/r

From Specification E3 Fe = = Fcr = (!)*E/(KL/r) 108.66 ksi

>

0.44*Fy = 15.84 ksi

[0.658^(Fy/Fe)]*Fy 31.34 ksi Allowable Strength in Compression Ap * Fcr 1.67 60.65 kips > 5.00 kips (OK)

Rn/

= =

MEMBER 2: Brace to Gusset Plate Weld:

Page 4 of 13

Design Calculation for Bracing Connection - Joint SWF-SF13

Electrode Class Fu = = = = = w = = = = = = = = = = = = = = = E700XX

Nominal Tensile Strength of Weld Ksi 70.00 tan-1( 6.00 4.03 rad 0.97883 deg 56.0827 Size of Weld in. 0.1875

(Use

0.1250 in. for calculation)

Fv

Allowable Weld Shear Strength 0.6 Fu / 2 Ksi 21.00 Shear Capacity of 1/8" weld per Linear Inch 0.707 * Fv * w (0.707 * 21 * 0.125) 1.856 Kips/in " ( 6 + 4.03 ) 7.23028 kips Length of Weld in. 6.00 3.61514 kips (See attached Calcs)

Pw

P/2

Tension Yielding of the Brace: Rn/ = = = Capacity from 'Limit State of Tension Yielding of Brace' Fyb * Ag2 1.67 169.95 kips > 4.03 kips (OK)

Tension Rupture of the Brace: Rn/ Capacity from 'Limit State of Tension Rupture of Brace' Fub * Ae = 2.00 where: L = (Length of Weld in HSS) 6.00 in B H x = = = =

2

6.00 8.00

in in

(Width of HSS Section) (Height of HSS Section)

(B + 2 * B * H) / (4 * (B + H)) 2.357 in

Page 5 of 13

Design Calculation for Bracing Connection - Joint SWF-SF13

U = = = = = = 1 - (x / L) 0.607 Ag3 - 2 * (tp + 0.0625) * t3 5.966 in U * An 3.622 kips

An

Ae

in > 4.03 kips (OK)

Rn/

105.05

Whtimore Section L= L= 2 lw tan 30 + B 14.928 in 0.000 2.600 in in = 1.67 B= 8.00 in

Whitmore width in Vertical Edge = Whitmore width in Horizontal Edge =

Check tension yielding on the Whitmore section Rn = Fy Aw Rn = 36 x [ ( 14.928 - 0 - 2.6 ) x 0.375 ] Rn = Rn/ 166.43 = kips 99.66 kips > 4.03

kips

(OK)

Check block shear rupture of the gusset Rn = = Nominal Block Shear Strength of Gusset ( =2)

2 x Min[ (0.6 x Fu x Anv + Ubs x Fu x Ant); (0.6 x Fy x Agv + Ubs x Fu x Ant) ] Where: Ubs = 1.0 Ant = Net Area with Tension Resistance = Bbrace x tgusset = 3.00 in

2

Agv = Gross Area with Shear Resistance = 2 x lw x tgusset = 4.50 in

2

Anv = Net Area with Shear Resistance = Rn/ = 4.50 135.60 in

2

kips

>

4.03

kips

(OK)

Page 6 of 13

Design Calculation for Bracing Connection - Joint SWF-SF13

Plate Buckling of Gusset Plate Ap = = = = = = = = = = = Effective Plate Cross-sectional Area L*t 5.598 in Plate Unbraced Length of Whitmore Section 1.00 in. Effective Length Factor 1.200 Radius of Gyration t / 3.464 0.108 in. 11.085 < 36 25 ksi

Lcr

K Lcr/r

Thus Fcr = Fy = Rn/ = =

Allowable Strength in Compression Ap * Fcr 1.67 120.68 kips > 4.03 kips (OK)

Gusset Plate to Colum:

Face of support

Px

Py P (Tension or compression)

Solving for component forces: Px = = Py = 5 (1.366) " [ (1) + (1.366) ] 4.0 kips

5 (1) " [ (1) + (1.366) ]

Page 7 of 13

Design Calculation for Bracing Connection - Joint SWF-SF13

= 3.0 kips

It can be shown that Px is balanced by the force from the horizontal HSS member. Thus, the web is relieved from this force. Designed gusset connection for pure shear (Py + V) only. (See attached.)

Page 8 of 13

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Astm C78Document3 pagesAstm C78avrajan100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Design of Slabs-on-Ground (ACI 360R-06Document7 pagesDesign of Slabs-on-Ground (ACI 360R-06Ivan Pacompia Calcina50% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Alcohol, Phenol and Ethers Digital Notes by Bharat PanchalDocument24 pagesAlcohol, Phenol and Ethers Digital Notes by Bharat Panchalzaid ansari86% (7)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Bracing ConnectionDocument15 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Corrosion Protection of Steel BridgesDocument0 pagesCorrosion Protection of Steel Bridgesrajedmaglinte100% (1)

- Wood and Armer Slab Design Method for Twisting MomentsDocument2 pagesWood and Armer Slab Design Method for Twisting MomentsBalaji VenkateswaranNo ratings yet

- Bracing Connection Design CalculationDocument10 pagesBracing Connection Design CalculationrajedmaglinteNo ratings yet

- Piling RequirementsDocument80 pagesPiling Requirementsthusi67% (3)

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- Twisting Momentsin Two-Way SlabsDocument6 pagesTwisting Momentsin Two-Way SlabsProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- Arkema - Polymer Selection Guide For Liquid ResinsDocument28 pagesArkema - Polymer Selection Guide For Liquid ResinsYoNo ratings yet

- PCA Rectangular - Tank Design ExampleDocument15 pagesPCA Rectangular - Tank Design ExampleConrad Otieno100% (4)

- Calculation Note Project: Appartment: Required StrengthDocument8 pagesCalculation Note Project: Appartment: Required StrengthChanthy RathedNo ratings yet

- A325 and Class 8.8Document3 pagesA325 and Class 8.8rajedmaglinte100% (1)

- BS EN 10164 (2018) - CurrentDocument18 pagesBS EN 10164 (2018) - Currentramalingam100% (7)

- Hot Dip Galvanizing Process ExplainedDocument13 pagesHot Dip Galvanizing Process ExplainedaselabollegalaNo ratings yet

- Rule of Thumb Concrete DesignDocument54 pagesRule of Thumb Concrete DesignrunkirNo ratings yet

- Plastic Roads: A Sustainable Solution to Plastic WasteDocument8 pagesPlastic Roads: A Sustainable Solution to Plastic WasteShahid Bhat0% (1)

- Exp 6 Phase Equilibrium Eutectic SystemDocument6 pagesExp 6 Phase Equilibrium Eutectic SystemNur Fadhilah33% (3)

- Quick, easy posthole sleevesDocument2 pagesQuick, easy posthole sleevesrajedmaglinteNo ratings yet

- SP Slab PresentationDocument19 pagesSP Slab PresentationrajedmaglinteNo ratings yet

- WireRopeRailingEngSection ADocument16 pagesWireRopeRailingEngSection ArajedmaglinteNo ratings yet

- Haydon TC Wrench InfoDocument11 pagesHaydon TC Wrench InforajedmaglinteNo ratings yet

- Structural Engineer 2009 Top Performers ListDocument3 pagesStructural Engineer 2009 Top Performers ListrajedmaglinteNo ratings yet

- Spslab Manual PDFDocument251 pagesSpslab Manual PDFrajedmaglinteNo ratings yet

- Chap 3-Structural Bolts PDFDocument45 pagesChap 3-Structural Bolts PDFAndang85No ratings yet

- Hilti HIT-200 System Replaces HIT-HY 150Document3 pagesHilti HIT-200 System Replaces HIT-HY 150rajedmaglinte100% (1)

- Hilti Screw Anchor KC II+ 1/4" x 1-3/4Document2 pagesHilti Screw Anchor KC II+ 1/4" x 1-3/4rajedmaglinteNo ratings yet

- Hilti HIT-200 System Replaces HIT-HY 150Document3 pagesHilti HIT-200 System Replaces HIT-HY 150rajedmaglinte100% (1)

- 3in DeckDocument1 page3in DeckrajedmaglinteNo ratings yet

- Beam Design Constants and Reinforcement Details for Two BeamsDocument1 pageBeam Design Constants and Reinforcement Details for Two BeamsrajedmaglinteNo ratings yet

- Forged Steel Clevis: Caution: Never Exceed The Working Load LimitDocument1 pageForged Steel Clevis: Caution: Never Exceed The Working Load LimitrajedmaglinteNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Steel Connection Formulas - Tension CheckDocument1 pageSteel Connection Formulas - Tension CheckrajedmaglinteNo ratings yet

- Column TiesDocument1 pageColumn TiesrajedmaglinteNo ratings yet

- FootingsDocument2 pagesFootingsrajedmaglinteNo ratings yet

- FootingsDocument2 pagesFootingsrajedmaglinteNo ratings yet

- Plastics AssignmentDocument2 pagesPlastics AssignmentKatharine MorrisonNo ratings yet

- Van Der WaalsDocument2 pagesVan Der WaalsDwi Esti KusumandariNo ratings yet

- CF31 Sort110 EU Data Sheetchainflex CF31Document6 pagesCF31 Sort110 EU Data Sheetchainflex CF31Luiz Felipe OliveiraNo ratings yet

- Technical Data Sheet Magnetic Flowmeter Material Selection Guide Data PDFDocument28 pagesTechnical Data Sheet Magnetic Flowmeter Material Selection Guide Data PDFThiagarajNo ratings yet

- Firekab Je H ST H BD Fe180 ph120Document2 pagesFirekab Je H ST H BD Fe180 ph120Azzeddine ZerroukNo ratings yet

- Fiche Tech - Freyssibar HSA en - v02Document2 pagesFiche Tech - Freyssibar HSA en - v02Triệu Duy AnhNo ratings yet

- Polymer Processing Assignment-2 (11,20,25,45,51)Document2 pagesPolymer Processing Assignment-2 (11,20,25,45,51)Eshan BhatNo ratings yet

- Preliminary Technical Program HMnS2016Document33 pagesPreliminary Technical Program HMnS2016manjumv27No ratings yet

- Awareness of Domestic Solid Waste ManagementDocument6 pagesAwareness of Domestic Solid Waste ManagementJenemarNo ratings yet

- PT MineralDocument2 pagesPT MineralFajar Premana PutraNo ratings yet

- Leaflet SPM and SOPDocument4 pagesLeaflet SPM and SOPAbdullah Al-ZahraniNo ratings yet

- 1singly-Reinforced Beams1Document29 pages1singly-Reinforced Beams1Jayson MariNo ratings yet

- Evaluating the Structural Strength of Shipping Containers for Building ApplicationsDocument10 pagesEvaluating the Structural Strength of Shipping Containers for Building ApplicationsSergio OrozcoNo ratings yet

- Chemical Bonding TestDocument2 pagesChemical Bonding TestChhavindra TripathiNo ratings yet

- Machined Seals: Product RangeDocument43 pagesMachined Seals: Product RangeAnonymous r3MoX2ZMTNo ratings yet

- What Are The Advantages of Water As A Solvent?: Weathering of Rocks MedicinesDocument1 pageWhat Are The Advantages of Water As A Solvent?: Weathering of Rocks MedicinesBernardo Milleniu De VeraNo ratings yet

- Synthetic Oils: E-Books Download Weblog: Water Engineering WeblogDocument11 pagesSynthetic Oils: E-Books Download Weblog: Water Engineering WeblogalbertofgvNo ratings yet

- Ash Fusion MANUAL-IF2000201209Document118 pagesAsh Fusion MANUAL-IF2000201209Ch Rajeswara RaoNo ratings yet

- Gas CuttingDocument8 pagesGas CuttingringboltNo ratings yet

- ASTM standards for concrete specificationsDocument2 pagesASTM standards for concrete specificationsAlaaFaragAllahNo ratings yet

- Chemsheets A2 1029 (Catalysis)Document17 pagesChemsheets A2 1029 (Catalysis)Jon HadleyNo ratings yet

- Bioplastic: Sustainable Green Plastic: December 2015Document3 pagesBioplastic: Sustainable Green Plastic: December 2015Lakshmipriya GopinathNo ratings yet