Professional Documents

Culture Documents

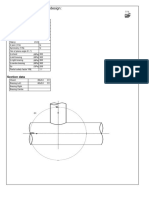

Jack-In-Piles Specification

Uploaded by

Nyu1234560 ratings0% found this document useful (0 votes)

116 views4 pagesJack-in pile specification

Original Title

Jack in Pile

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJack-in pile specification

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

116 views4 pagesJack-In-Piles Specification

Uploaded by

Nyu123456Jack-in pile specification

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

G&P GEOTECHNICS SDN BHD

Specification for J ack-In-Piles

7 October 1999

SPECIFICATION FOR JACK-IN-PILES

1.0 GENERAL

This work shall consist of the supply, installation and testing of piles in accordance with this

Specification and the lines, levels, grades and cross-sections shown on the Drawings and as

directed by the Engineer.

2.0 GROUND CONDITION

The Contractor shall check the existing site condition including levels, slopes, drainage,

presence of obstacles such as foundation, tree stumps, etc and shall allow in his rate for

completing the work as intended, no claims whatsoever in respect of any discrepancies shall

be entertained.

2.1 Obstruction

The rates in the Bills of Quantities for piling work shall include for excavation of any material

to remove obstruction below existing ground level which may prove to be sufficient to prevent

installing or which interfere with the proper alignment of the piles, timbering, backfilling, the

restoration of the ground around the piles and any other works which may require to complete

the operation to the satisfaction of the Engineer. Obstructions below the level which occur

during the course of work (e.g. broken sea wall shoes or piles, etc) shall likewise be removed

by the Contractor at his own expense. Provision of preboring has been provided in the Bills of

Quantities for overcoming the piling obstruction at deep level. No standing time for rigs or

extension of time will be allowed in consequence of obstructions of any kind.

All materials shall be new. Materials, workmanship and conditions for the manufacture and

installation of piles foundations shall be strictly in accordance with the relevant clauses of the

specification. Where certain items of pile foundation are not covered by the specification,

they shall comply with the latest British Standard specification, Code of Practice etc, with

regard to design, workmanship, material, etc.

3.0 REQUIREMENTS FOR TOLERANCES

3.1 Setting Out

Setting out shall be carried out using the data and reference points as shown on the

Drawings. Immediately before installation of the pile, the pile position shall be marked with

suitable identifiable pins, pegs or markers.

3.2 Position

For a pile cut off at or above ground level, the maximum permitted deviation of the pile centre

from the centre points shown on the Drawings shall not exceed 50mm for single and two pile

groups (may limited the deviation to 25mm if small size reinforced concrete piles are used),

75mm for three pile groups and more in any direction unless otherwise directed by the

Engineer.

3.3 Verticality

The maximum permitted deviation of the finished pile from the vertical is 1 in 75.

3.4 Rake

The piling rig shall be set and maintained to attain the required rake where is specifically

mentioned in the drawings. The maximum permitted deviation of the finished pile from the

specified rake or the rake shown on the Drawings is 1 in 25.

J IP1

G&P GEOTECHNICS SDN BHD

Specification for J ack-In-Piles

7 October 1999

3.5 Forcible Corrections

Forcible corrections to concrete piles shall not be permitted. Forcible corrections may be

permitted to other types of piles if approved by the Engineer. However, no forcible

corrections shall be made to piles which have deviated beyond the permissible limits specified

in Sections above.

3.6 Piles Out of Alignment or Position

The Contractor shall, if ordered by the Engineer, extract and reinstall any pile which has

deviated out of the position or alignment by more than the specified limit, or alternatively the

substructure shall be modified to the approval of the Engineer. This shall only be relaxed if

directed by the Engineer. The cost of such extraction and reinstallation or any extra cost in

the design and construction of a modified foundation shall be borne by the Contractor if, in the

opinion of the Engineer, such extra works have been made necessary due to the error and/or

negligence of the Contractor.

3.7 Records

The Contractor shall keep record of the installation of each pile as required by the Engineer

and shall submit two signed copies of these records to the Engineer not later than at noon of

the next working day after the pile has been installed. The signed records shall form part of

the records for the Works. Any unexpected installation conditions shall be reported in the

records.

4.0 PRECAST JACK-IN-PILES

This work shall comprise the supply and installation of the precast reinforced concrete piles or

precast prestressed piles, inclusive of pitching and driving, lengthening and cutting and

preparation of pile heads, all in accordance with this Specification and to the details shown on

the Drawings.

4.1 Materials

4.1.1 Concrete

The concrete to be used shall be of grade in accordance to the Drawings unless

otherwise directed by the Engineer. Special care shall be taken during compaction to

prevent segregation of the constituents of concrete and the displacement

reinforcements.

4.1.2 Reinforcement

For precast prestressed piles, the Contractor shall show by calculations that sufficient

prestressing steel in the form of high tensile wire, strand or bar are used so that the

effective prestress after losses is sufficient to resist the handling, jacking and service

load. Longitudinal prestressing shall not be considered as load bearing

reinforcement.

4.2 Pile Shoe

Depending on the nature of the soil condition, pile shoes may be used. For piles sitting on the

bedrock, rock shoes shall be placed. The Contractor has to propose the type of pile shoe to

be used and approved by the Engineer prior to installation of the piles.

4.3 Handling and Storage

J IP2

G&P GEOTECHNICS SDN BHD

Specification for J ack-In-Piles

7 October 1999

The method and sequence of lifting, handling, transporting and storing piles shall be such that

piles are not damaged. Only the designed lifting and support points shall be placed on

adequate supports located under the lifting points of the piles.

5.0 INSTALLATION

5.1 Pitching of Piles

Piles shall be pitched accurately in the positions as shown on the Drawings. At all stages

during installation and until the pile has set, all exposed piles shall be cut off to the ground

level (provided is minimum 2m above cut off level) by means of hydraulic breaker. All cutting

of pile to the cut off level shall be by diamond cutter. All cut off piles shall be prevented from

damage and deviated out of position. For all piles to specified lengths, pile head cut off shall

be avoided by using suitable combination of pile lengths.

5.2 Installation of Piles

Each pile shall be hydraulically injected continuously until the specified pressure gauge

reading and/or depth has been reached. A follower (long dolly) is not permitted unless

approval has been obtained from the Engineer. The Contractor shall inform the Engineer

without delay if an unexpected change in driving characteristic is encountered.

A detailed record of the driving resistance over the full length of each pile shall be kept. The

log shall record loading resistance for every 300mm of pile penetration.

The pile other than frictional pile, will be considered SET when the pile has ceased to settle at

the recorded pressure which gives a resultant load of 2.5 times the design load, unless

otherwise agreed by the Engineer.

Unless otherwise specified in the Drawing, all friction piles shall be driven to the specified

depth.

Piles shall be driven in an approved sequence to minimize the detrimental effects of heave

and lateral displacement of the ground. When required, levels and measurements shall be

taken to determine the movement of the ground or any pile resulting from the installation

process. If any pile rise occurs as a result of adjacent piles being installed, the Contractor

shall submit to the Engineer his method for correcting this and to avoid similar occurrences in

subsequent work.

Piles can be jointed by means of mild steel sleeve. When the pile has been driven to the

required set or depth, the head of the pile shall be cut off to the level specified or shown in the

Drawings.

The jacking force has to be applied axially to avoid damaging the pile. If the system is

applying the forced through gripping the body of the pile, the gripping mechanism shall not

cause any defect on pile.

Dolly shall not be allowed in the pile installation.

5.3 Termination Criteria

The termination criterion is to jack the pile to 2.5 times of the design load for a minimum of

two cycles or other safety factor as instructed by the Engineer. The corresponding pressure

has to be held for minimum 30 seconds without settlement or unless otherwise specified by

the Engineer. The process shall be repeated if instructed by the Engineer.

6.0 PILE TESTING

Pile testing shall be carried out in accordance to Specification for Pile Testing.

J IP3

G&P GEOTECHNICS SDN BHD

Specification for J ack-In-Piles

7 October 1999

TABLE OF CONTENTS

Description Page

1.0 GENERAL...................................................................................................................................J IP1

2.0 REQUIREMENTS FOR TOLERANCES.....................................................................................J IP1

2.1 Setting Out ....................................................................................................................J IP1

2.2 Position .........................................................................................................................J IP1

2.3 Verticality .......................................................................................................................J IP1

2.4 Rake ..............................................................................................................................J IP1

2.5 Forcible Corrections ......................................................................................................J IP1

2.6 Piles Out of Alignment or Position ................................................................................J IP1

2.7 Records .........................................................................................................................J IP1

3.0 PRECAST J ACK-IN-PILES.........................................................................................................J IP2

3.1 Materials.........................................................................................................................J IP2

3.1.1 Concrete ...........................................................................................................J IP2

3.1.2 Reinforcement ..................................................................................................J IP2

3.2 Pile Shoe .......................................................................................................................J IP2

3.3 Casting ..........................................................................................................................J IP2

3.4 Handling and Storage ...................................................................................................J IP2

4.0 INSTALLATION...........................................................................................................................J IP2

4.1 Pitching of Piles .............................................................................................................J IP2

4.2 Installation of Piles .........................................................................................................J IP2

4.3 Termination Criteria........................................................................................................J IP3

5.0 PILE TESTING ...........................................................................................................................J IP3

J IP4

You might also like

- Waffle Box Building Technology PhilippinesDocument20 pagesWaffle Box Building Technology PhilippinesRalphGeraldF.LopezNo ratings yet

- 01) Jack-In Pile SubmissionDocument47 pages01) Jack-In Pile Submissionalfredo100% (2)

- HCM001 Hollow-Core Design Manual - Complete - 03.23.15Document38 pagesHCM001 Hollow-Core Design Manual - Complete - 03.23.15lbhnsw5930100% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Complete Project ReportDocument85 pagesComplete Project ReportPrashant VyasNo ratings yet

- Concrete Forms Product CatalogDocument86 pagesConcrete Forms Product CatalogLucas Michael LuzziNo ratings yet

- HOARDINGS - A GUIDE TO GOOD PRACTICEDocument42 pagesHOARDINGS - A GUIDE TO GOOD PRACTICEsamirbendre1No ratings yet

- Secant Pile Wall SpecificationDocument16 pagesSecant Pile Wall SpecificationZein FarahNo ratings yet

- Example Method Statement Jack in-PPCDocument4 pagesExample Method Statement Jack in-PPCLatifi AmirNo ratings yet

- DOE Condition Assessment Work Breakdown StructureDocument1 pageDOE Condition Assessment Work Breakdown Structurescribd_spiceNo ratings yet

- Terrace House and Surau IBS Scores ComparisonDocument5 pagesTerrace House and Surau IBS Scores ComparisonSiongyung KongNo ratings yet

- Pile Design To BS EN 1997-1:2004 (EC7) and The National AnnexDocument68 pagesPile Design To BS EN 1997-1:2004 (EC7) and The National AnnexSewGuanNo ratings yet

- ES2 HoardingDocument1 pageES2 Hoardingerikaren85No ratings yet

- Load Testing SetupDocument23 pagesLoad Testing SetupWalid TahhanNo ratings yet

- Guidelines for safe Kentledge pile load testingDocument10 pagesGuidelines for safe Kentledge pile load testingPeter KyawNo ratings yet

- Technical Specifications of Boundary WallDocument5 pagesTechnical Specifications of Boundary WallAndy100% (1)

- Finger 1 Project - ERSS Report For Temporary Drain Diversion - 24 Sep 2014Document67 pagesFinger 1 Project - ERSS Report For Temporary Drain Diversion - 24 Sep 2014mypenta2008No ratings yet

- Comparison of Malaysian and EC7 Design Methods for Pile FoundationsDocument83 pagesComparison of Malaysian and EC7 Design Methods for Pile FoundationsAdam LimNo ratings yet

- Jack in PileDocument56 pagesJack in PileArif Azizan0% (1)

- European Practice On Design&Construction of Concrete PavementsDocument103 pagesEuropean Practice On Design&Construction of Concrete Pavementsshakirhamid6687No ratings yet

- Lecture 4 - Jack-In PileDocument52 pagesLecture 4 - Jack-In PileAyingaran Thevathasan100% (3)

- Pile Set CriteriaDocument3 pagesPile Set CriteriaAnonymous O404LiV4CNo ratings yet

- 1.3 - Er. Chandrasegaran Sundararaju - Quality Control Measures in The Construction of DwallDocument94 pages1.3 - Er. Chandrasegaran Sundararaju - Quality Control Measures in The Construction of Dwallsusan87No ratings yet

- Skin Friction and Pile DesignDocument7 pagesSkin Friction and Pile DesignNaveen RNo ratings yet

- 02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporeDocument39 pages02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporefreezefreezeNo ratings yet

- RC Pile Singapore Spec (Grade 40 or 50)Document4 pagesRC Pile Singapore Spec (Grade 40 or 50)Aristya DhaneswaraNo ratings yet

- Technical Guidance Note: Omnia Wideslab Permanent FormworkDocument2 pagesTechnical Guidance Note: Omnia Wideslab Permanent FormworkBogdanBNo ratings yet

- Installation of Steel Sheet PilesDocument2 pagesInstallation of Steel Sheet PilesAdam Lim100% (1)

- Advisory Note 1-09 On Earth Retaining or Stabilising Structures (Erss)Document23 pagesAdvisory Note 1-09 On Earth Retaining or Stabilising Structures (Erss)Difa Liu100% (2)

- Micropile Specification G&P GeotechnicsDocument9 pagesMicropile Specification G&P GeotechnicsChristian SchembriNo ratings yet

- Section 10 Piling Works PDFDocument31 pagesSection 10 Piling Works PDFLeanna Abdul Wahab75% (4)

- BORED PILES DESIGN & TESTING FOR MRT STRUCTURESDocument21 pagesBORED PILES DESIGN & TESTING FOR MRT STRUCTURESfreezefreezeNo ratings yet

- JKR Guideline For Slope Design (Malaysia)Document37 pagesJKR Guideline For Slope Design (Malaysia)TUN SHEIKH HAMBALEE SHAMSULNo ratings yet

- Goh EC7 Pile CPG July2013 PDFDocument58 pagesGoh EC7 Pile CPG July2013 PDFHT Binh75% (4)

- Guidlines For Pile Load Testing Using Kentledge Method PDFDocument10 pagesGuidlines For Pile Load Testing Using Kentledge Method PDFImran FarooqNo ratings yet

- Bored PileDocument9 pagesBored PileMichael RootNo ratings yet

- Sunway Spun Pile PDFDocument2 pagesSunway Spun Pile PDFLim Cheng Zhou100% (1)

- Concretec Catalog Sample PDFDocument24 pagesConcretec Catalog Sample PDFseagull70No ratings yet

- EC7 Briefing on Ground InvestigationDocument32 pagesEC7 Briefing on Ground Investigationjohnkoh99100% (1)

- 04-NSF Design and EC7 (Prof Harry Tan)Document66 pages04-NSF Design and EC7 (Prof Harry Tan)thusiyanthanp100% (2)

- Injection Precast Concrete PileDocument18 pagesInjection Precast Concrete PileLee CwNo ratings yet

- 1 Shear Strength & Slope Stability-IEM Lecture (22feb19) V2notes PDFDocument152 pages1 Shear Strength & Slope Stability-IEM Lecture (22feb19) V2notes PDFJensen Tan100% (1)

- JACK in Foundation PIlesDocument112 pagesJACK in Foundation PIlesVincent ChinNo ratings yet

- 01-Load Test Using Kentledge (Er Foo HK) PDFDocument90 pages01-Load Test Using Kentledge (Er Foo HK) PDFtun20000100% (2)

- Segmenal BridgesDocument5 pagesSegmenal BridgesManikanta SharmaNo ratings yet

- Sub BaseDocument4 pagesSub BaseAnonymous Dk3ItoC8MFNo ratings yet

- Precast Wall Production and Installation MethodologyDocument18 pagesPrecast Wall Production and Installation MethodologyPavan PatchigollaNo ratings yet

- Technical Note: Safe But Economical Working Platform DesignDocument3 pagesTechnical Note: Safe But Economical Working Platform DesignSalvatore MirandaNo ratings yet

- Termination Criteria of Piles Subjected To Axial Loading To Is StandardsDocument15 pagesTermination Criteria of Piles Subjected To Axial Loading To Is Standardssongkk100% (1)

- Jacked Foundation Piles SeminarDocument112 pagesJacked Foundation Piles SeminarfreezefreezeNo ratings yet

- Typical Horizontal Formwork: Plywood 18mm THKDocument9 pagesTypical Horizontal Formwork: Plywood 18mm THKJinxian XuNo ratings yet

- Specification For Jack in PileDocument4 pagesSpecification For Jack in Pilekhuanoz100% (1)

- Micropile and Soil Nailing Design ConceptDocument135 pagesMicropile and Soil Nailing Design ConceptwongtianhuiNo ratings yet

- Piling Specification To BS5400Document25 pagesPiling Specification To BS5400Atiq ZakariaNo ratings yet

- 2500 Companies DetailsDocument282 pages2500 Companies DetailsMargreat Puspanathan100% (7)

- South Beach Development-IstructE Conference Singapore 2012Document20 pagesSouth Beach Development-IstructE Conference Singapore 2012blithevincentNo ratings yet

- 5 Tips On Designing To Ec 7 and Guidelines On Pre Construction Survey DR PohDocument57 pages5 Tips On Designing To Ec 7 and Guidelines On Pre Construction Survey DR Pohmichlsy110% (1)

- Continental Steel - Structural SteelDocument191 pagesContinental Steel - Structural SteelDesmond TongNo ratings yet

- TR 26-2010 (2013) - PreviewDocument9 pagesTR 26-2010 (2013) - Previewgodzillafood0% (1)

- Plate Bearing Test - Jurutera AddaDocument12 pagesPlate Bearing Test - Jurutera Addactlim88No ratings yet

- Boiling or Heaving in CofferdamsDocument2 pagesBoiling or Heaving in Cofferdamsslawek780303No ratings yet

- Soil Nail BrochureDocument44 pagesSoil Nail BrochureElancheliyanNo ratings yet

- En 14490 After CEN Enquiry (Soil Nailing)Document59 pagesEn 14490 After CEN Enquiry (Soil Nailing)Abraham FIgueroa ARevaloNo ratings yet

- MOS For Pull Out TestDocument5 pagesMOS For Pull Out TestHasbullah HamzahNo ratings yet

- Mi TSDocument37 pagesMi TSwhoammeNo ratings yet

- NPQS Chapter4 PDFDocument17 pagesNPQS Chapter4 PDFbryan94No ratings yet

- Jack in Pile PDFDocument4 pagesJack in Pile PDFlattmdyNo ratings yet

- Specification For Jack-In-Piles: 1.0 GeneralDocument4 pagesSpecification For Jack-In-Piles: 1.0 Generalmhamed1No ratings yet

- Specification - High Performance Pretensioned Spun High Strength Concrete Pile Works - Bidder To Sign Stamp Last Page N Submit With TenderDocument15 pagesSpecification - High Performance Pretensioned Spun High Strength Concrete Pile Works - Bidder To Sign Stamp Last Page N Submit With TendertanminweeNo ratings yet

- Singapore Cruise Terminal Project Pile Spec.Document22 pagesSingapore Cruise Terminal Project Pile Spec.kim y hNo ratings yet

- Section B - Piling Works 1. GeneralDocument18 pagesSection B - Piling Works 1. GeneralMuhammad GhazaliNo ratings yet

- Deflections For Load Case C1: Proposed 2 Storey MS PlatformDocument96 pagesDeflections For Load Case C1: Proposed 2 Storey MS PlatformNyu123456No ratings yet

- Column Base Design: Type P1Document5 pagesColumn Base Design: Type P1Nyu123456No ratings yet

- Column Base Design: Type P1Document5 pagesColumn Base Design: Type P1Nyu123456No ratings yet

- L Ten Sang Industetterto EXISDocument1 pageL Ten Sang Industetterto EXISNyu123456No ratings yet

- Column Base Design: Type P1Document5 pagesColumn Base Design: Type P1Nyu123456No ratings yet

- Report 1bDocument1 pageReport 1bNyu123456No ratings yet

- 0 2Document37 pages0 2Nyu123456No ratings yet

- Combined stresses require member design optimizationDocument8 pagesCombined stresses require member design optimizationNyu123456No ratings yet

- Member Design For Axial ForceDocument5 pagesMember Design For Axial ForceNyu123456No ratings yet

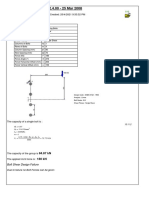

- Bolt Group Design Ver W2.4.00 - 25 Mar 2008: Title: Default ConnectionDocument1 pageBolt Group Design Ver W2.4.00 - 25 Mar 2008: Title: Default ConnectionNyu123456No ratings yet

- Proposed Two (2) Level Ms Platform at Existing Factory Senawang Industrial Park, Seremban. NSDK 1.0 General InformationDocument1 pageProposed Two (2) Level Ms Platform at Existing Factory Senawang Industrial Park, Seremban. NSDK 1.0 General InformationNyu123456No ratings yet

- Report 1Document1 pageReport 1Nyu123456No ratings yet

- Member Design for Combined Stresses Element 122-403 and 50-123Document7 pagesMember Design for Combined Stresses Element 122-403 and 50-123Nyu123456No ratings yet

- Member Design For Combined StressesDocument7 pagesMember Design For Combined StressesNyu123456100% (1)

- Member Design For Axial ForceDocument2 pagesMember Design For Axial ForceNyu123456No ratings yet

- Member Design For Axial ForceDocument2 pagesMember Design For Axial ForceNyu123456No ratings yet

- Beam - Column Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsDocument2 pagesBeam - Column Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsNyu123456No ratings yet

- 40 X 80 RECTDocument1 page40 X 80 RECTNyu123456No ratings yet

- Section Properties: Rectangular Hollow Section: Input Tables SettingsDocument2 pagesSection Properties: Rectangular Hollow Section: Input Tables SettingsNyu123456No ratings yet

- Single Bolt WeldDocument1 pageSingle Bolt WeldNyu123456No ratings yet

- Apex Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsDocument2 pagesApex Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsNyu123456No ratings yet

- Section Properties:: Input Tables SettingsDocument2 pagesSection Properties:: Input Tables SettingsNyu123456No ratings yet

- Bolted Double Angle Cleat Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsDocument11 pagesBolted Double Angle Cleat Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsNyu123456No ratings yet

- Bolt Group WeldDocument1 pageBolt Group WeldNyu123456No ratings yet

- Bolted Double Angle Cleat Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsDocument2 pagesBolted Double Angle Cleat Connection - Ver W2.4.00 - 25 Mar 2008 Title: Code of Practice: Created: Notes and AssumptionsNyu123456No ratings yet

- BWall 1Document1 pageBWall 1Nyu123456No ratings yet

- Hollow Section Connection design for chord force of 112 kNDocument3 pagesHollow Section Connection design for chord force of 112 kNNyu123456No ratings yet

- GutterDocument1 pageGutterNyu123456No ratings yet

- Single Span Beam Design On GroundDocument1 pageSingle Span Beam Design On GroundNyu123456No ratings yet

- Wind Design To CP3 - 1972: General Wind Input TablesDocument2 pagesWind Design To CP3 - 1972: General Wind Input TablesNyu123456No ratings yet

- Conquas 2012Document68 pagesConquas 2012Anonymous p2cFoXbjDNo ratings yet

- Corrected Nov.21 CVDocument5 pagesCorrected Nov.21 CVapoorva shrivastavaNo ratings yet

- GroutecDocument82 pagesGroutecThompson LaiNo ratings yet

- Tutorial IBS Jointing Week 7 - Nizamuddin AbdullahDocument10 pagesTutorial IBS Jointing Week 7 - Nizamuddin AbdullahNizamuddin AbdullahNo ratings yet

- 18-0022 Elliot JA22Document33 pages18-0022 Elliot JA22basemNo ratings yet

- Precast concrete girder brochureDocument9 pagesPrecast concrete girder brochureA Akbar HawardiNo ratings yet

- Types of Vibrators and Curing Methods for Concrete CompactionDocument16 pagesTypes of Vibrators and Curing Methods for Concrete CompactionSasanka SekharNo ratings yet

- Guide Specifications (Pci Hcs Manual)Document3 pagesGuide Specifications (Pci Hcs Manual)KhaleelNo ratings yet

- Adeyele Siwes Q.SDocument19 pagesAdeyele Siwes Q.SOlajuwon OdumosuNo ratings yet

- Specification For Industrialised Building SystemDocument6 pagesSpecification For Industrialised Building SystemNorazmiMohdNorNo ratings yet

- Extruder E9-1200e Brochure en LRDocument4 pagesExtruder E9-1200e Brochure en LRspnasurde2013No ratings yet

- BTW Sor (Fy10)Document236 pagesBTW Sor (Fy10)Tan AnthonyNo ratings yet

- 4.15.MP75 CVL 015 STRL Des CriteriaDocument27 pages4.15.MP75 CVL 015 STRL Des CriteriaLandon MitchellNo ratings yet

- PT Mimpi Design: Company ProfileDocument5 pagesPT Mimpi Design: Company ProfileSyamNo ratings yet

- W3 Concrete and IBS ConstructionDocument86 pagesW3 Concrete and IBS ConstructionSyazwani ArifahNo ratings yet

- Precast Concrete Girder BridgesDocument30 pagesPrecast Concrete Girder BridgesPacha Khan KhogyaniNo ratings yet

- Precast Concrete Approved SuppliersDocument4 pagesPrecast Concrete Approved SuppliersenggmohanNo ratings yet

- PFS QBDocument7 pagesPFS QBnikhil johnNo ratings yet

- Seismic Behavior of Grouted Sleeve Connections Between Foundations and Precast ColumnsDocument11 pagesSeismic Behavior of Grouted Sleeve Connections Between Foundations and Precast ColumnsJett AglipayNo ratings yet