Professional Documents

Culture Documents

Comparison Between Vacuum and SF6 Circuit Breaker PDF

Uploaded by

Robert GalarzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison Between Vacuum and SF6 Circuit Breaker PDF

Uploaded by

Robert GalarzaCopyright:

Available Formats

e le ct rical-e ngine e ring-po rt al.co m http://electrical-engineering-po rtal.

co m/co mpariso n-between-vacuum-and-sf6-circuit-breaker

Comparison Between Vacuum and SF6 Circuit Breaker

Edvard

Until recently oil circuit breakers were used in large numbers f or Medium voltage Distribution system in many medium voltage switchgears. T here are number of disadvantages of using oil as quenching media in circuit breakers. Flammability and high maintenance cost are two such disadvantages! Manuf acturers and users were f orced to search f or dif f erent medium of quenching. Air blast and Magnetic air circuit breakers were developed but could not sustain in the market due to other disadvantages associated with such circuit breakers. T hese new types of breakers are bulky and cumbersome. Further research were done and simultaneously two types of breakers were developed with SF6 as quenching media in one type and Vacuum as quenching media in the other.

What CB to us e ? Vac uum o r SF6 c irc uit b re ake r?

T hese two new types of breakgasers will ultimately replace the other previous types completely shortly. T here are a f ew disadvantages in this type of breakers also. One major problem is that the user of the breakers are biased in f avour of old f ashioned oil circuit breakers and many of the users always have a step motherly attitude to the new generations of the breakers. However in due course of time this attitude will disappear and the new type of breakers will get its acceptance among the users and ultimately they will completely replace the oil circuit breakers. An attempt is made to make a comparison between the SF6 type and vacuum type circuit breakers with a view to f ind out as to which of the two types is superior to the other. We will now study in detail each type separately bef ore we compare them directly. Top

Vacuum Circuit Breaker

In a Vacuum circuit breaker , vacuum interrupters are used f or breaking and making load and f ault currents. When the contacts in vacuum interrupter separate, the current to be interrupted initiates a metal vapour arc discharge and f lows through the plasma until the next current zero. T he arc is then extinguished and the conductive metal vapour condenses on the metal surf aces within a matter of micro seconds. As a result the dielectric strength in the breaker builds up very rapidly. T he properties of a vacuum interrupter depend largely on the material and f orm of the contacts. Over the period of their development, various types of contact material have been used. At the moment it is accepted that an oxygen f ree copper chromium alloy is the best material f or High voltage circuit breaker. In this alloy , chromium is distributed through copper in the f orm of f ine grains. Evo lis MV Circ uit Bre ake r T his material combines good arc extinguishing characteristic with a reduced tendency to contact welding and low chopping current when switching inductive current. T he use of this special material is that the current chopping is limited to 4 to 5 Amps. At current under 10KA, the Vacuum arc burns as a dif f use discharge. At high values of current the arc changes to a constricted f orm with an anode spot. A constricted arc that remain on one spot f or too long can thermically over stress the contacts to such a degree that the deionization of the contact zone at current zero can no longer be guaranteed . To overcome this problem the arc root must be made to move over the contact surf ace. In order to achieve this, contacts are so shaped that the current f low through them results in a magnetic f ield being established which is at right angles to the arc axis. T his radial f ield causes the arc root to rotate rapidly around the contact resulting in a unif orm distribution of the heat over its surf ace. Contacts of this type are called radial magnetic f ield electrodes and they are used in the majority of circuit breakers f or medium voltage application. A new design has come in Vacuum interrupter, in which switching over the arc f rom dif f usion to constricted state by subjecting the arc to an axial magnetic f ield. Such a f ield can be provided by leading the arc current through a coil suitably arranged outside the vacuum chamber. Alternatively the f ield can be provided by designing the contact to give the required contact path. Such contacts are called axial magnetic f ield electrodes. T his principle has advantages when the short circuit current is in excess of 31.5 KA. Top

SF6 Gas Circuit Breaker

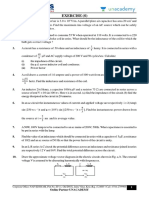

T he direction of the gas f low, i.e., whether it is parallel to or across the axis of the arc, has a decisive inf luence on the ef f iciency of the arc interruption process. Research has shown that an axial f low of gas creates a turbulence which causes an intensive and continuous interaction between the gas and the SF6 c irc uit b re ake rs plasma as the current approaches zero. Cross-gas-f low cooling of the arc is generally achieved in practice by making the arc move in the stationary gas. T his interruption process can however, lead to arc instability and resulting great f luctuations in the interrupting capability of the circuit breaker. In order to achieve a f low of gas axially to the arc a pressure dif f erential must be created along the arc. T he f irst generation of the SF6 circuit breakers used the two-pressure principle of the air-blast circuit-breaker. Here a certain quantity of gas was kept stored at a high pressure and released into the arcing chamber. At the moment high pressure gas and the associated compressor was eliminated by the second generation design. Here the pressure dif f erential was created by a piston attached to the moving contacts which compresses the gas in a small cylinder as the contact opens. A disadvantage is that this puf f er system requires a relatively powerf ul operating mechanism. Neither of the two types of circuit breakers described was able to compete with the oil circuit breakers price wise. A major cost component of the puf f er circuit-breaker is the operating mechanism; consequently developments f ollowed which were aimed at reducing or eliminating this additional cost f actor. T hese developments concentrated on employing the arc energy itself to create directly the pressure-dif f erential needed. T his research led to the development of the self -pressuring circuit-breaker in which the over pressure is created by using the arc energy to heat the gas under controlled conditions. During the initial stages of development, an auxiliary piston was included in the interrupting mechanism, in order to ensure the satisf actory breaking of small currents. Subsequent improvements in this technology have eliminated this requirement and in the latest designs the operating mechanism must only provide the energy needed to move the contacts. Parallel to the development of the self -pressuring design, other work resulted in the rotating arc SF6 gas circuit breaker. In this design the arc is caused to move through, in ef f ect the stationery gas. T he relative movement between the arc and the gas is no longer axial but radial, i.e., it is a cross-f low mechanism. T he operating energy required by circuit breakers of this design is also minimal. Table 1. Characteristics of the SF6 and vacuum current interrupting technologies. SF6 Circuit Breakers Criteria Operating energy requirements Puf f er Circuit Breaker Operating Energy requirements are high, because the mechanism must supply the energy needed to compress the gas. Self -pressuring circuitbreaker Operating Energy requirements are low, because the mechanism must move only relatively small masses at moderate speed, over short distances. T he mechanism does not have to provide the energy to create the gas f low Vacuum Circuit Breakers Contact material-ChromeCopper Operating energy requirements are low, because the mechanism must move only relatively small masses at moderate speed, over very short distances.

Arc Energy

Because of the high conductivity of the arc in the SF6 gas, the arc energy is low. (arc voltage is between 150 and 200V.)

Because of the very low voltage across the metal

vapour arc, energy is very low. (Arc voltage is between 50 and 100V.) Contact Erosion Due to the low energy the contact erosion is small. Due to the very low arc energy, the rapid movement of the arc root over the contact and to the f act that most of the metal vapour recondenses on the contact, contact erosion is extremely small. No additional extinguishing medium is required. A vacuum at a pressure of 10-7 bar or less is an almost ideal extinguishing medium. T he interrupters are sealed f or lif e so that supervision of the vacuum is not required. No f low of an extinguishing medium needed to extinguish the vacuum arc. An extremely rapid de-ionization of the contact gap, ensures the interruption of all currents whether large or small. High f requency transient currents can be interrupted. T he value of the chopped current is determined by the type of contact material used. T he presence of chrome in the contact alloy with vacuum also. 30100

Arc extinguishing media

T he gaseous medium SF6 possesses excellent dielectric and arc quenching properties. Af ter arc extinction, the dissociated gas molecules recombine almost completely to ref orm SF6. T his means that practically no loss/consumption of the quenching medium occurs. T he gas pressure can be very simply and permanently supervised. T his f unction is not needed where the interrupters are sealed f or lif e. T he pressure build-up and theref ore the f low of gas is independent of the value of the current. Large or small currents are cooled with the same intensity. Only small values of high f requency, transient currents, if any, will be interrupted. T he deionization of the contact gap proceeds very rapidly, due to the electro-negative characteristic of the SF6 gas and the arc products. 1050 T he pressure build-up and theref ore the f low of gas is dependent upon the value of the current to be interrupted. Large currents are cooled intensely, small currents gently. High f requency transient currents will not, in general, be interrupted. T he de-ionization of the contact gap proceeds very rapidly due to the electro-negative characteristic of the SF6 gas and the products. 1050

Switching behavior in relation to current chopping

No. of short-circuit operation No. f ull load operation No. of mechanical operation

500010000 500020000

500010000 500020000

1000020000 1000030000

Comparison of the SF6 And Vacuum Technologies

T he most important characteristics of the SF6 gas and vacuum-circuit breakers, i.e., of SF6 gas and vacuum as arc-extinguishing media are summarized in Table-1.

In the case of the SF6 circuit-breaker, interrupters which have reached the limiting number of operations can be overhauled and restored to as new condition. However, practical experience has shown that under normal service conditions the SF6 interrupter never requires servicing throughout its lif etime. For this reason, some manuf acturers no longer provide f acilities f or the user to overhaul the circuit-breaker, but have adopted a sealed f or lif e design as f or the vacuum-circuit breaker. T he operating mechanisms of all types of circuit-breakers require servicing, some more f requently than others depending mainly on the amount of energy they have to provide. For the vacuum-circuit breaker the service interval lies between 10,000 and 20,000 operations. For the SF6 designs the value varies between 5,000 and 20,000 whereby, the lower value applies to the puf f er circuit-breaker f or whose operation, the mechanism must deliver much more energy. T he actual maintenance requirements of the circuit-breaker depend upon its service duty, i.e. on the number of operations over a given period of time and the value of current interrupted. Based on the number of operations given in the previous section, it is obvious that SF6 and vacuum circuit-breakers used in public supply and /or industrial distribution systems will, under normal circumstances, never reach the limits of their summated breaking current value. T heref ore, the need f or the repair or replacement of an interrupter will be a rare exception and in this sense these circuit-breakers can be considered maintenance-f ree. Service or maintenance requirements are theref ore restricted to routine cleaning of external surf aces and the checking and lubrication of the mechanism, including the trip-linkages and auxiliary switches. In applications which require a very high number of circuit-breaker operations e.g. f or arc f urnace duty or f requently over the SF6 design, due to its higher summated-breaking current capability. In such cases it is to be recommended that the estimation of circuit-breaker maintenance costs be given some consideration and that these be included in the evaluation along with the initial, capital costs. Top

Reliability

In practice, an aspect of the utmost importance in the choice of a circuit-breaker is reliability. T he reliability of a piece of equipment is def ined by its mean time to f ailure (MT F), i.e. the average interval of time between f ailures. Today, the SF6 and vacuum circuit-breakers made use of the same operating mechanisms, so in this regard they can be considered identical. However, in relation to their interrupters the two circuit breakers exhibit a marked dif f erence. T he number of moving parts is higher f or the SF6 circuit-breaker than that f or the vacuum unit. However, a reliability comparison of the two technologies on the basis of an analysis of the number of components are completely dif f erent in regards design, material and f unction due to the dif f erent media. Reliability is dependent upon f ar too many f actors, amongst others, dimensioning, design, base material, manuf acturing methods, testing and quality control procedures, that it can be so simply analyzed. In the meantime, suf f icient service experience is available f or both types of circuit-breakers to allow a valid practical comparison to be made. A review of the available data on f ailure rates conf irms that there is no discernible dif f erence in reliability between the two circuit-breaker types. More over, the data shows that both technologies exhibit a very high degree of reliability under normal and abnormal conditions. Top

Switching of f ault currents

Today, all circuit-breakers f rom reputable manuf acturers are designed and type-tested in conf ormance with recognized national or international standards (IEC56). T his provides the assurance that these circuit-breakers will reliably interrupt all f ault currents up to their maximum rating. Further, both types of circuit-breakers are basically capable of interrupting currents with high DC components; such currents can arise when short circuits occur close to a generator. Corresponding tests have indeed shown that individual circuit-breakers of both types are in f act, capable of interrupting f ault currents with missing current zeros i.e. having a DC component greater than 100 per cent. Where such application is envisaged, it is always to be recommended that the manuf acturer be contacted and given the inf ormation needed f or a prof essional opinion. As regards the recovery voltage which appears af ter the interruption of a f ault current the vacuum-circuit breaker can, in general, handle voltages with RRV values of up to 5KV. SF6 circuit-breakers are more limited, the values being in the range f rom 1 to 2 KV. In individual applications, e.g. in installations with current limiting chokes or reactors, etc., With SF6 circuit-breakers it may be advisable or necessary to take steps to reduce that rate of rise of the transient recovery voltage. Top

Switching small inductive currents

T he term, small inductive currents is here def ined as those small values of almost pure inductive currents, such as occur with unloaded transf ormers, motor during the starting phase or running unloaded and reactor coils. When considering the behavior of a circuit-breaker interrupting such currents, it is necessary to distinguish between high f requency and medium f requency transient phenomena. Medium f requency transients arise f rom, amongst other causes, the interruption of a current bef ore it reaches its natural zero. All circuit-breakers can, when switching currents of the order of a f ew hundred amperes and, due to instability in the arc, chop the current immediately prior to a current zero. T his phenomenon is termed real current chopping. When it occurs, the energy stored in the load side inductances oscillates through the system line to earth capacitances (winding and cable capacitances) and causes an increase in the voltage. T his amplitude of the resulting over voltage is a f unction of the value of the current chopped. T he smaller the chopped current, the lower the value of the over voltage. In addition to the type of circuit breaker, the system parameters at the point of installation are f actors which determine the height of the chopping current, in particular the system capacitance parallel to the circuit breaker is of importance. T he chopping current of SF6 circuit-breakers is essentially determined by the type of circuitbreaker. T he value of chopping current varies f rom 0.5A to 15A, whereby the behavior of the self pressuring circuit-breaker is particularly good, its chopping current being less than 3A.T his sof t switching f eature is attributable to the particular characteristics of the interrupting mechanism of the self -pressuring design and to the properties of the SF6 gas itself . In the early years of the development of the vacuum circuit-breaker the switching of small inductive currents posed a major problem, largely due to the contact material in use at that time. T he introduction of the chrome copper contacts brought a reduction of the chopping current to between 2 to 5A.T he possibility of impermissible over voltages arising due to current chopping has been reduced to a negligible level. High f requency transients arise due to pre- or re-striking of the arc across the open contact gap. If , during an opening operation, the rising voltage across the opening contacts, exceed the dielectric strength of the contact gap , a re-strike occurs. T he high-f requency transient current arising f rom such a re-strike can create high f requency current zeros causing the circuit-breaker to, interrupt again. T his process can cause a f urther rise in voltage and f urther re-strikes. Such an occurrence is termed as multiple restriking.

With circuit- breakers that can interrupt high f requency transient currents, re-striking can give rise to the phenomenon of virtual current chopping. Such an occurrence is possible when a re-strike in the f irst-phase-toclear, induces high f requency transients in the other two phases, which are still carrying service f requency currents. T he superimposition of this high f requency oscillation on the load current can cause an apparent current zero and an interruption by the circuit-breaker, although the value of load current may be quite high. T his phenomenon is called virtual current chopping and can result in a circuit breaker chopping very much higher values of current than it would under normal conditions. T he results of virtual current chopping are over-voltages of very high values. T his phenomenon is termed real current chopping. When it occurs, the energy Stored in the load side inductances oscillates through the system line to earth capacitances (winding and cable capacitances) and causes an increase in the voltage. T his amplitude of the resulting over voltage is a f unction of the value of the current chopped. T he smaller the chopped current, the lower the value of the over voltage. In addition to the type of circuit breaker, the system parameters at the point of installation are f actors which determine the height of the chopping current, in particular the system capacitance parallel to the circuit breaker is of importance. T he chopping current of SF6 circuit-breakers is essentially determined by the type of circuitbreaker. T he value of chopping current varies f rom 0.5A to 15A, whereby the behaviour of the self pressuring circuit-breaker is particularly good, its chopping current being less than 3A.T his sof t Switching f eature is attributable to the particular characteristics of the interrupting mechanism of the self -pressuring design and to the properties of the SF6 gas itself . In the early years of the development of the vacuum circuit-breaker the switching of small inductive currents posed a major problem, largely due to the contact material in use at that time. T he introduction of the chrome copper contacts brought a reduction of the chopping current to between 2 to 5A.T he possibility of impermissible over voltages arising due to current chopping has been reduced to a negligible level. High f requency transients arise due to pre- or re-striking of the arc across the open contact gap. If , during an opening operation, the rising voltage across the opening contacts exceeds the dielectric strength of the contact gap, a re-strike occurs. T he high-f requency transient current arising f rom such a re-strike can create high f requency current zeros causing the circuit-breaker to, interrupt again. T his process can cause a f urther rise in voltage and f urther re-strikes. Such an occurrence is termed as multiple re-striking. With circuit- breakers that can interrupt high f requency transient currents, re-striking can give rise to the phenomenon of virtual current chopping. Such an occurrence is possible when a re-strike in the f irst-phase-toclear, induces high f requency transients in the other two phases, which are still carrying service f requency currents. T he superimposition of this high f requency oscillation on the load current can cause an apparent current zero and an interruption by the circuit-breaker, although the value of load current may be quite high. T his phenomenon is called virtual current chopping and can result in a circuit breaker chopping very much higher values of current than it would under normal conditions. T he results of virtual current chopping are over-voltages of very high values Table2. Comparison of the SF6 And Vacuum Technologies In Relation To Operational Aspects Criteria Summated current cumulative Breaking current capacity of interrupter SF6 Breaker 10-50 times rated short circuit current 5000-10000 times Vacuum Circuit Breaker 30-100 times rated short circuit current 10000-20000 times

Mechanical operating lif e No operation bef ore maintenance Time interval between servicing Mechanism Outlay f or maintenance Reliability Dielectric withstand strength of the contact gap

5000-20000 C-O operations 5000-20000 C-O operations 5-10 years Labour cost High, Material cost Low High High

10000-30000 C-O operations 10000-30000 C-O operations 5-10 years Labour cost Low, Material cost High High Very high

Very extensive testing has shown that, because of its special characteristics the SF6 self -pressuring circuitbreaker possesses considerable advantages in handling high f requency transient phenomena, in comparison with both the puf f er type SF6 and the vacuum circuit breakers. T he past f ew years have seen a thorough investigation of the characteristics of vacuum circuit breakers in relation to phenomena such as multiple restriking and virtual current chopping. T hese investigations have shown that the vacuum circuit-breaker can indeed cause more intense re-striking and hence more acute over voltages than other types. However, these arise only in quite special switching duties such as the tripping of motors during starting and even then only with a very low statistical probability. T he over-voltages which are created in such cases can be reduced to saf e levels by the use of metal oxide surge diverters. Table3. Comparison of the SF6 And Vacuum Switching Technologies In Relation To Switching Applications Criteria Switching of Short circuit current with High DC component Switching of Short circuit current with High RRV Switching of transf ormers Switching of reactors SF6 Circuit Breaker Well suited Vacuum Circuit Breaker Well suited

Well suited under certain conditions (RRV>1-2 kV per Milli seconds Well suited. Well suited

Very well suited

Well suited Well suited. Steps to be taken when current <600A. to avoid over voltage due to current chopping Well suited. Re-strike f ree Suited. In some cases current limiting reactors required to limit inrush current Well suited. Steps to be taken to limit over voltage.

Switching of capacitors Switching of capacitors back to back Switching of arc f urnace

Well suited. Re-strike f ree Suited. In some cases current limiting reactors required to limit inrush current Suitable f or limited operation

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 8 Substation Equipment Needed To Power Up Data Center - EEPDocument17 pages8 Substation Equipment Needed To Power Up Data Center - EEPRobert GalarzaNo ratings yet

- 3 Lighting Essentials You Cant Deny PDFDocument6 pages3 Lighting Essentials You Cant Deny PDFRobert GalarzaNo ratings yet

- 3 Conditions That Can Damage Your PLCDocument4 pages3 Conditions That Can Damage Your PLCRobert GalarzaNo ratings yet

- 3 Common Transformer Phenomena That Should Worry Substation Engineers - EEPDocument7 pages3 Common Transformer Phenomena That Should Worry Substation Engineers - EEPRobert GalarzaNo ratings yet

- This Bus Is Ready To Electrify Public TransitDocument10 pagesThis Bus Is Ready To Electrify Public TransitRobert GalarzaNo ratings yet

- 3 Conditions That Can Damage Your PLCDocument7 pages3 Conditions That Can Damage Your PLCRobert GalarzaNo ratings yet

- 3 Designs of DC Distribution Systems in Power Substations PDFDocument8 pages3 Designs of DC Distribution Systems in Power Substations PDFRobert GalarzaNo ratings yet

- Planning and Installing Raceway SystemsDocument4 pagesPlanning and Installing Raceway SystemsRobert GalarzaNo ratings yet

- How Sensors and Actuators Work Behind RTUs and SCADA SystemsDocument10 pagesHow Sensors and Actuators Work Behind RTUs and SCADA SystemsRobert GalarzaNo ratings yet

- 6 Different Types of Relaying Schemes T... e EHV and UHV Transmission Lines PDFDocument8 pages6 Different Types of Relaying Schemes T... e EHV and UHV Transmission Lines PDFRobert GalarzaNo ratings yet

- Checklist To Design AssembliesDocument1 pageChecklist To Design AssembliesRobert GalarzaNo ratings yet

- 10 Things To Consider When Selecting A High Quality Medium Voltage DriveDocument4 pages10 Things To Consider When Selecting A High Quality Medium Voltage DriveRobert GalarzaNo ratings yet

- Arc Flash Clothing Labeling RequirementsDocument2 pagesArc Flash Clothing Labeling RequirementsRobert GalarzaNo ratings yet

- Protecting Motors Fron External Network Disturbing - EEPDocument5 pagesProtecting Motors Fron External Network Disturbing - EEPRobert GalarzaNo ratings yet

- How To Control and Protect Capacitor Banks Before Something Goes Wrong - EEPDocument7 pagesHow To Control and Protect Capacitor Banks Before Something Goes Wrong - EEPRobert GalarzaNo ratings yet

- Wiring Tips For Connections and Routing Inside Industrial Control Panel - EEPDocument7 pagesWiring Tips For Connections and Routing Inside Industrial Control Panel - EEPRobert GalarzaNo ratings yet

- How To Save Your Battery System Before It FailsDocument10 pagesHow To Save Your Battery System Before It FailsRobert GalarzaNo ratings yet

- 3 Conditions That Can Damage Your PLCDocument7 pages3 Conditions That Can Damage Your PLCRobert GalarzaNo ratings yet

- What Are Triplen Harmonics and Where Do They Happen - EEPDocument5 pagesWhat Are Triplen Harmonics and Where Do They Happen - EEPRobert GalarzaNo ratings yet

- 3 Good Ways To Improve Earth Electrode Resistance - EEPDocument9 pages3 Good Ways To Improve Earth Electrode Resistance - EEPRobert GalarzaNo ratings yet

- Current Systems (AC - DC) and Voltage Levels Basics You Must Never Forget - EEPDocument11 pagesCurrent Systems (AC - DC) and Voltage Levels Basics You Must Never Forget - EEPRobert GalarzaNo ratings yet

- 3 Easy Measures For Good PLC System Maintenance - EEPDocument3 pages3 Easy Measures For Good PLC System Maintenance - EEPRobert GalarzaNo ratings yet

- 3 Greatest Enemies To The Transformer Operation (And How To Prevent Them) - EEPDocument17 pages3 Greatest Enemies To The Transformer Operation (And How To Prevent Them) - EEPRobert GalarzaNo ratings yet

- Working Principle of Thermal Motor Protection RelayDocument3 pagesWorking Principle of Thermal Motor Protection RelayRobert GalarzaNo ratings yet

- 2 Most Common Contributing Factors in Insulation FailureDocument5 pages2 Most Common Contributing Factors in Insulation FailureRobert Galarza0% (1)

- Wiring Practices To Provide Future Load Growth in BuildingsDocument6 pagesWiring Practices To Provide Future Load Growth in BuildingsRobert GalarzaNo ratings yet

- Automation Control System Specification Design and Installation Guide PDFDocument93 pagesAutomation Control System Specification Design and Installation Guide PDFsabeerNo ratings yet

- Lean ManufacturingDocument36 pagesLean ManufacturingRobert GalarzaNo ratings yet

- An Example of Transformer Tap-Changer Correct Adjustment - EEPDocument2 pagesAn Example of Transformer Tap-Changer Correct Adjustment - EEPRobert GalarzaNo ratings yet

- Wiring Practices To Provide Future Load Growth in BuildingsDocument6 pagesWiring Practices To Provide Future Load Growth in BuildingsRobert GalarzaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Transmission Line ParameterDocument75 pagesTransmission Line Parameteraregawi weleabezgi100% (1)

- 3elec CircuitDocument37 pages3elec Circuiteuge sylNo ratings yet

- Medical Physics PresentationDocument18 pagesMedical Physics Presentationsamavia sohailNo ratings yet

- Exercise (S) : R L, R C L, RDocument19 pagesExercise (S) : R L, R C L, RTausif RazaNo ratings yet

- Application Note An-45 Linkswitch-Cv Family: Design GuideDocument18 pagesApplication Note An-45 Linkswitch-Cv Family: Design Guidebharath prabhuNo ratings yet

- 2018 - Laboratory Scale Long Transmission Line SCADADocument5 pages2018 - Laboratory Scale Long Transmission Line SCADAjulioNo ratings yet

- MATLAB/Simulink Model of PV Integrated DC-DC Converter: Divya Dileepkumar, Maheswaran. KDocument6 pagesMATLAB/Simulink Model of PV Integrated DC-DC Converter: Divya Dileepkumar, Maheswaran. Khabte gebreial shrashrNo ratings yet

- mc9 BrochureDocument8 pagesmc9 BrochureturricanNo ratings yet

- Edc - Lab Manual by MadhuDocument101 pagesEdc - Lab Manual by Madhu224g1a0405No ratings yet

- JEE Mains-Print PDFDocument198 pagesJEE Mains-Print PDFtech yuvyashNo ratings yet

- Subjective Questions B2Document2 pagesSubjective Questions B2Vikash PalNo ratings yet

- Edwin Gray Electronic Circuit PDFDocument6 pagesEdwin Gray Electronic Circuit PDFAvram StefanNo ratings yet

- Leakage Reactance - PaperDocument24 pagesLeakage Reactance - PaperRodrigo Javier RomayNo ratings yet

- Lecture Notes EMIDocument92 pagesLecture Notes EMIISL EEE HODNo ratings yet

- (MWJ0306) RF Test Fixture BasicsDocument6 pages(MWJ0306) RF Test Fixture BasicsGhulam MehdiNo ratings yet

- LAB Manual ECTE423 923 22 03 2019-FINAL 1Document27 pagesLAB Manual ECTE423 923 22 03 2019-FINAL 1bxox0000No ratings yet

- L Umanad Powertrans DesignDocument48 pagesL Umanad Powertrans Designdeshraj100% (2)

- P1870Document2 pagesP1870NataGBNo ratings yet

- Electrical Q&A Part-1 - Electrical Notes & ArticlesDocument46 pagesElectrical Q&A Part-1 - Electrical Notes & ArticlesAbdelrahman shokryNo ratings yet

- Design Modification of Rogowski Coil For Current MDocument7 pagesDesign Modification of Rogowski Coil For Current MLeandro AriasNo ratings yet

- Lecture5 SuperconductivityDocument10 pagesLecture5 Superconductivityairtel3gNo ratings yet

- 2910 Enthusiast Phase-TEAS (Pre-Score) Paper-2 (E) JADocument24 pages2910 Enthusiast Phase-TEAS (Pre-Score) Paper-2 (E) JAarushrigangjiNo ratings yet

- Sencore Tech Tip #101Document4 pagesSencore Tech Tip #101rich_golfNo ratings yet

- A2 Electrical Circuits and Power Jan 2021Document34 pagesA2 Electrical Circuits and Power Jan 2021narenmaniam0% (1)

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument12 pages3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesGiovanni Carrillo VillegasNo ratings yet

- L5 ATPDraw Long PDFDocument51 pagesL5 ATPDraw Long PDFJosNo ratings yet

- Power Systems: KPSC Objective MCQ Series (Topic Wise With Solution)Document30 pagesPower Systems: KPSC Objective MCQ Series (Topic Wise With Solution)Grigesh K MadhavNo ratings yet

- 3rd Sem Electric CircuitDocument57 pages3rd Sem Electric CircuitRajkumarJhapteNo ratings yet

- Ee6201 Circuit Question BankDocument33 pagesEe6201 Circuit Question BankBanu ChandarNo ratings yet

- Syllabus (2015 - 2016batch) Third YearDocument167 pagesSyllabus (2015 - 2016batch) Third Yearkandavel71No ratings yet