Professional Documents

Culture Documents

Endorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPC

Uploaded by

Ezhil Vendhan PalanisamyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Endorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPC

Uploaded by

Ezhil Vendhan PalanisamyCopyright:

Available Formats

ENDORSEMENT SHEET FOR QP

REFERENCE / STANDARD / FIELD QUALITY PLAN (RQP / SQP/RFQP/SFQP) TO BE FILLED IN BY SUPPLIER AT TIME OF SUBMISSION

PROJECT NAME CONTRACT NO.: MAIN SUPPLIER MANUFACTURER WORKS & ADDRESS ITEM /EQUIPMENT / SYSTEM/ SUB-SYSTEM DETAILS i.e. MODEL TYPE / SIZE /RATING etc. APPROVED QP NO.: RQP/SQP/RFQP/SFQP DADRI CS-6130-108-2-FC-NOA-4722 BHEL M/S BHEL TRICHY BOILER STRUCTURE

To be filled in by NTPC

REVIEW & ENDORSEMENT BY NTPC PROJECT SPECIFIC QP NUMBER ALLOTTED QP NO.: 6130-108-QVM-G-003-01 REV 01 REV. NO.: DATE:

** The RQP/SQP/RFQP/SFQP once endorsed for a particular contract shall remain valid even though the original QP may have expired or revised, unless / otherwise mutually agreed with the supplier. �

(TICK APPLICABLE)

0000-999-QV M-T273

REV. NO.: 00

DATED**:29/07/2003

Confirmation by Main Supplier (TICK WHICHEVER APPLICABLE) I. That the item/ component is identical to that considered for QP approval. OR. II. That there are minor changes in the item/ component with respect to that considered for QP approval, however the same do not affect the contents of QP. OR III. That there are minor changes in the item/ component with respect to that considered for QP approval, however the same affect the QP slightly, as indicated BELOW. 1. Log-sheet no. 01 revised as per boiler layout plan drg. For Dadri 2. Log-sheet no. 02 revised as per boiler layout plan drg. For Dadri 3. Log-sheet no. 08 revised as per Trichy instruction of minimum structure required for Lifting boiler Drum .

Revised Log sheets noted. However, BHEL to ensure that the requirements of Erection manual and Erection drawings are completely converted into Log-sheets.

The QP is endorsed for this project without any change The QP is endorsed for this project with changes as indicated. DISTRIBUTION OF ENDORSEMENT OF A) RQP/SQP: 1. MAIN SUPPLIER (WITH A COPY OF QP) 2. MANUFACTURER 3. RIO 4. CQA-SPL 5. CQA-O/C B) RFQP/SFQP: 1. MAIN SUPPLIER (with a copy of QP) 2. MANUFACTURER 3. NTPC FQA (with a copy of QP) 4. NTPC Erection (with a copy of QP) 5. CQA-SPL 2007.05.2 6. CQA-O/C

( H.M.NAGDHAR ) DGM/Quality SIGN.: (Main Supplier) DATE BHEL/PSNR

3 14:25:42 +05'30'

SIGN.: (Manufacturer) DATE: NTPC (Reviewed /Approved by/ Date & Seal)

FORMAT NO.: QS-01-QAI-P-10/ F5-R1

1/1

ENGG. DIV./ QA&I

FIELD QUALITY PLAN

FOR

BOILER STRUCTURES

(Erection) FOR

DADRI TPP - 2 x 490 MW (M/s. National Thermal Power Corporation Ltd.)

BHARAT HEAVY ELECTRICALS LIMITED POWER SECTOR NORTHERN REGION NOIDA

QP NO. : PN-QPE-BR-100 REV.NO.: R00

FMT-QP-001 Rev.01

FIELD QUALITY PLAN FOR

BOILER STRUCTURES (Erection) DADRI TPP 2 x 490 MW (M/s. National Thermal Power Corporation Ltd.)

APPROVED BY QUALITY PLAN NO. ORIGINAL DATE OF ISSUE REVISION NO. & DATE COPY NO. ISSUED TO DATE OF ISSUE

AGM PSNR Q NOIDA

(S K DUTTA) PN-QPE-BR-100 24-04-2007 R00 Dt. 24-04-2007

CONTROLLED / INFORMATION COPY ISSUED BY (SIGNATURE & DESIGNATION)

( H.M.NAGDHAR ) DGM/Quality BHEL/PSNR

H M NAGDHAR/DGM/QUALITY

BHARAT HEAVY ELECTRICALS LIMITED POWER SECTOR NORTHERN REGION

FMT-QP-002 Rev. 01

QP NO. : PN-QPE-BR-100

CONTENTS

PSNR - Quality

REV.NO.: PAGE 1

R00 OF 1

Sl.No. 1.0 2.0 3.0

Description Status of amendments Authorisation for different categories of checks Field Quality Plan for BOILER STRUCTURES (Erection) For DADRI TPP 2 x 490 MW (M/s. National Thermal Power Corporation Ltd.)

No. of Pages 01 01

3.1 3.2 3.3

Statement of checks Documents referred in Quality Plan Log Sheets : L-00 to L-08

10 01 15

******

FMT-QP-003 Rev.00

QP NO. : PN-QPE-BR-100 STATUS OF AMENDMENTS

PSNR Quality

REV.No.: PAGE 1

R00 OF 1 Remarks

Sl.No.

Reference of Sheet(s) Amended

NIL

Amendment No. & Date

FMT-QP-016 Rev. 00

PSNR - Quality

AUTHORISATION FOR DIFFERENT CATEGORIES OF CHECK

Classification of Check Symbol Description BHEL A Critical NTPC BHEL B Major NTPC BHEL C Minor NTPC -----Erection / Commissioning Head of Section Quality Assurance Engineer Erection / Commissioning Inspection Agency Task performer & surveillance by QAE FQA Task performer Erection / Commissioning Task performer Clearing Agency HOS FQA HOS Erection / Commissioning Incharge Task performer Dispositioning Authority Engg. centre / Head Quality - Region CQA Engg. centre / Head Quality - Region FQA Engg. centre / Head Quality - Region

Legend

HOS QAE

NOTE : 1. Dispositioning Authority in A, B & C classes of checks shall be as under : Product non-conformities Process / system non-conformities 2. : Engineering Centre : Head / Quality - Region

QAE shall witness A Category checks. He is also authorised to carry out surveillance in any of theB and C category of checks at his discretion. In case of non-conformity, before accepting, clearing agency shall ensure dispositioning and the same shall be reflected in log sheets / protocols. Non-conformance Procedure, apart from above shall be in line with clause No. 4.7 of QA co-ordination procedure.

3.

4.

FMT QP 004 REV. 00

QP NO. : PN-QPE-BR-100 STATEMENT OF CHECKS

PSNR Quality

REV.No.: PAGE 1

R00 OF 10

Capacity / Type System Sub-System Area

*

: : : :

2 x 490 MW BOILER STRUCTURES ERECTION

For checks where log sheets are not called for, suitable records shall be maintained in the form of log book / protocols. As an evidence of having carried out the work satisfactorily, a general purpose log sheet L-00 shall be maintained for all the checks. The above sub-system covers Foundations, Boiler supporting structures including ceiling structures and welding. NTPC Technical specification and NTPC approved documents relevant to this product shall be binding and any Non-conformation to this shall be referred to NTPC for disposal as per NTPC-CQA non-conformance disposal procedure. Abbreviations used in the column Type of Check are : R M V : Record Verification

* *

: Measurement : Visual

FMT-QP-005 Rev. 00

FIELD QUALITY PLAN

MANUFACTURERS NAME & ADDRESS

PREPARED BY : PSNR-QUALITY, NOIDA

PROJECT : DADRI 2 x 490 MW

PACKAGE : SG CONTRACT NO. : CS-6130-108-2FC-NOA-4722 CONTRACTOR : BHEL, PS-NR

FORMAT OF RECORD REMARKS

BHEL, PS-NR,

Noida

PSNR - Quality

ITEM

: BOILER

SUB-SYSTEM : STRUCTURES

TYPE OF CHECK INSTRUMENT

QP NO. : PN-QPE-BR-100 REV. : R00 DATE : 24-04-2007 PAGE 2 OF 10

CLASS QUANTUM / FREQUENCY OF CHECK

SL. NO.

CHARACTERISTICS / ITEM

REFERENCE DOCUMENT/ ACCETANCE STANDARD

FOUNDATION : 1. Availability of identified & protected permanent bench mark. Elevation of top of foundation pedestals with reference to permanent bench mark. V B 100%

2.

Dumpy level / Water level / Tape Tape

100%

Drawing / Guidelines for erection

L - 01

3.

Disposition of foundation pedestals with reference to longitudinal axis of boiler and reference axis. Spacing between the foundation pedestals.

100%

-do-

L - 02

4.

Tape

100% -do-

L - 02

5. 6.

Diagonals of the main column foundation pedestals. Pitch distance of foundation pedestal bolts on both the axes and its diagonals.

M M

Tape Tape

B C

100% 100% -do-

L - 03 L - 04

FOR NTPC USE BHEL, PSNR-QUALITY BHEL, PS-NR MANUFACTURER / SUBCONTRACTOR CONTRACTOR SIGNATURE

DOC. NO.

ERECTION

AREA REVIEWED BY NAME & SIGNATURE, OF APPROVING AUTHORITY & SEAL

FMT-QP-015 REV.02

FIELD QUALITY PLAN

MANUFACTURERS NAME & ADDRESS

PREPARED BY : PSNR-QUALITY, NOIDA

PROJECT : DADRI 2 x 500 MW

BHEL, PS-NR,

Noida

PSNR - Quality

ITEM

: BOILER

SUB-SYSTEM : STRUCTURES

TYPE OF CHECK INSTRUMENT

: SG QP NO. : PN-QPE-BR-100 PACKAGE REV. : R00 CONTRACT NO. : CS-6130-108-2DATE : 24-04-2007 FC-NOA-4722 PAGE 3 OF 10 CONTRACTOR : BHEL, PS-NR

FORMAT OF RECORD CLASS QUANTUM / FREQUENCY OF CHECK REFERENCE DOCUMENT/ ACCETANCE STANDARD REMARKS

SL. NO.

CHARACTERISTICS / ITEM

STRUCTURES : 1. Preassembly of columns before erection, wherever applicable. V/M Tape / Piano wire / Water level - do C 100% Drawing

2.

Individual column piece camber and sweep (Tolerance : 1 mm / M ; 10 mm max.). Camber and sweep for assembled columns (Tolerance : 1 mm / M ; 18 mm max.). Total length of column before erection (Tolerance : 15 mm max.). Orientation of columns. Check for match mark, elevation mark, column No., splice size etc. Ensure matching of centre line of base plate with pedestal axes.

100%

Drawing / Guidelines for Erection - do -

3.

- do -

100%

4.

Tape

100%

- do -

5.

100%

- do -

6.

100%

- do -

FOR NTPC USE BHEL, PSNR-QUALITY BHEL, PS-NR MANUFACTURER / SUBCONTRACTOR CONTRACTOR SIGNATURE

DOC. NO.

ERECTION

AREA REVIEWED BY NAME & SIGNATURE, OF APPROVING AUTHORITY & SEAL

FMT-QP-015 REV.02

FIELD QUALITY PLAN

MANUFACTURERS NAME & ADDRESS

PREPARED BY : PSNR-QUALITY, NOIDA

PROJECT : DADRI 2 x 500 MW

BHEL, PS-NR,

Noida

PSNR - Quality

ITEM

: BOILER

SUB-SYSTEM : STRUCTURES

CHARACTERISTICS / ITEM TYPE OF CHECK INSTRUMENT

: SG QP NO. : PN-QPE-BR-100 PACKAGE REV. : R00 CONTRACT NO.: CS-6130-108-2-FC-NOA-4722 DATE : 24-04-2007 CONTRACTOR : BHEL, PS-NR PAGE 4 OF 10

CLASS QUANTUM / FREQUENCY OF CHECK REFERENCE DOCUMENT/ ACCETANCE STANDARD FORMAT OF RECORD REMARKS

SL. NO.

7.

Elevation of column at 1 metre level with reference to bench mark (Tolerance : 5 mm ). Alignment of first piece of column with horizontal beams and vertical bracings (Tolerance : Position w.r.t. reference axis : 5 mm ; elevation : 5 mm). Completion of boxes with main brace level members (MBL). Grouting gap below the column base (Min. 20 mm ; max. 70 mm ). Verification of test certificates and batch certificates of grout material.

Water level / Tape

100%

Drawing / Guidelines for Erection - do L 06

8.

Theodolite / Tape / Plumb bob

100%

9.

100%

- do -

10.

Tape

100%

- do -

11.

100%

Work Instruction for Grouting

12.

Grouting of column bases.

V/R

100%

Drawing / Grout Manufacturers Recommendation

L - 05

FOR NTPC USE BHEL, PSNR-QUALITY BHEL, PS-NR MANUFACTURER / SUBCONTRACTOR CONTRACTOR SIGNATURE FMT-QP-015 REV.02

DOC. NO.

ERECTION

AREA REVIEWED BY NAME & SIGNATURE, OF APPROVING AUTHORITY & SEAL

FIELD QUALITY PLAN

MANUFACTURERS NAME & ADDRESS

PREPARED BY : PSNR-QUALITY, NOIDA

PROJECT : DADRI 2 x 500 MW

BHEL, PS-NR,

Noida

PSNR - Quality

ITEM

: BOILER

SUB-SYSTEM : STRUCTURES

CHARACTERISTICS / ITEM TYPE OF CHECK INSTRUMENT

: SG QP NO. : PN-QPE-BR-100 PACKAGE REV. : R00 CONTRACT NO. : CS-6130-108-2-FC-NOA-4722 DATE : 24-04-2007 CONTRACTOR : BHEL, PS-NR PAGE 5 OF 10

CLASS QUANTUM / FREQUENCY OF CHECK REFERENCE DOCUMENT/ ACCETANCE STANDARD FORMAT OF RECORD REMARKS

SL. NO.

13.

Alignment of columns at every stage of erection.

Theodolite / Tape / Plumb bob Bolt Tension Calibrator / Torque wrench Piano wire / Tape / Water level - do -

100%

Drawing / Guidelines for Erection Drg. / Guidelines for Erection / HSFG Bolt Tightening Procedure Drawing / Guidelines for Erection

L - 06

14.

Tightening of HSFG bolts for column joints, horizontal beams and vertical bracings.

M/V

100%

15.

Camber and sweep of the individual ceiling girder pieces (Tolerance : 1 mm / M, max. 5 mm).

100%

16.

Camber, sweep, diagonal and overall length before and after welding (Tolerance : 1 mm / M, max. 15 mm). Alignment of ceiling girders.

100%

- do -

17.

Tape / Plumb bob / Water level Bolt Tension Calibrator / Torque wrench

100%

- do -

L - 07

18.

Tightening of HSFG bolts between ceiling girders and welded beams (WBs).

100%

Drawing / Guidelines for Erection / HSFG Bolt Tightening Procedure

FOR NTPC USE BHEL, PSNR-QUALITY BHEL, PS-NR MANUFACTURER / SUBCONTRACTOR CONTRACTOR SIGNATURE FMT-QP-015 REV.02

DOC. NO.

ERECTION

AREA REVIEWED BY NAME & SIGNATURE, OF APPROVING AUTHORITY & SEAL

FIELD QUALITY PLAN

MANUFACTURERS NAME & ADDRESS

PREPARED BY : PSNR-QUALITY, NOIDA

PROJECT : DADRI 2 x 500 MW

BHEL, PS-NR,

Noida

PSNR - Quality

ITEM

: BOILER

SUB-SYSTEM : STRUCTURES

CHARACTERISTICS / ITEM TYPE OF CHECK INSTRUMENT

: SG QP NO. : PN-QPE-BR-100 PACKAGE REV. : R00 CONTRACT NO : CS-6130-108-2-FC-NOA-4722 DATE : 24-04-2007 CONTRACTOR : BHEL, PS-NR PAGE 6 OF 10

CLASS QUANTUM / FREQUENCY OF CHECK REFERENCE DOCUMENT/ ACCETANCE STANDARD FORMAT OF RECORD REMARKS

SL. NO.

19.

Verticality of columns before and after ceiling girder erection, at every 5M and at column erection joints.

Theodolite / Plumb bob / Tape Theodolite / Tape

100 %

Drawing / Guidelines for Erection - do -

L-06

20.

Centre line of ceiling girders marked w.r.t. the longitudinal axis of boiler transferred from ground level to top. Readiness of structure for drum erection. Clearance of mile-stone activity. Verticality of all main columns (wherever possible) immediately after drum lifting and compare with previous values. Removal of temporary supports.

100%

L 07

21. 22. 23.

V V M Theodolite / Plumb bob / Tape

A A A

100% 100% 100%

- do -

L 08

Drawing / Guidelines for Erection

L 06

24.

100%

FOR NTPC USE BHEL, PSNR-QUALITY BHEL, PS-NR MANUFACTURER / SUBCONTRACTOR CONTRACTOR SIGNATURE FMT-QP-015 REV.02

DOC. NO.

ERECTION

AREA REVIEWED BY NAME & SIGNATURE, OF APPROVING AUTHORITY & SEAL

FIELD QUALITY PLAN

MANUFACTURERS NAME & ADDRESS

PREPARED BY : BHEL, PSNR -QUALITY, NOIDA

PROJECT : DADRI 2 x 500 MW

BHEL, PS-NR,

Noida

PSNR - Quality

ITEM

: BOILER

SUB-SYSTEM : STRUCTURES

CHARACTERISTICS / ITEM TYPE OF CHECK INSTRUMENT

: SG QP NO. : PN-QPE-BR-100 PACKAGE REV. : R00 CONTRACT NO.: CS-6130-108-2-FC-NOA-4722 DATE : 24-04-2007 CONTRACTOR : BHEL, PS-NR PAGE 7 OF 10

CLASS QUANTUM / FREQUENCY OF CHECK REFERENCE DOCUMENT/ ACCETANCE STANDARD FORMAT OF RECORD REMARKS

SL. NO.

WELDING & NDE : 1. 2. Qualification of welders. Availability of approved WPS, Heat Treatment Schedule, Erection Manual, Storage Manual, Calibration test certificates of instruments used. Adoption of correct procedure, approved electrodes and methods. V/R R A A 100% 100% Welding Manual

3.

V/R

100%

Drawing / Welding Manual / Heat Treatment Manual Drawing / Guidelines for Erection / Heat Treatment Manual

4.

Pre heating and Post Weld Heat Treatment of weld joints.

V/M

Time Temperature Recorder / Thermal Chalk

As per Reference Document

5.

NDE for welds of structural members : a) Edge Preparation : MPI / LPI for new edges prepared at site after flame cutting / trimming of respective member where t 32 mm. V C 100% NDE Manual

FOR NTPC USE BHEL, PS-NR BHEL, PS-QUALITY MANUFACTURER / SUBCONTRACTOR CONTRACTOR SIGNATURE FMT-QP-015 REV.02

DOC. NO.

ERECTION

AREA REVIEWED BY NAME & SIGNATURE, OF APPROVING AUTHORITY & SEAL

FIELD QUALITY PLAN

MANUFACTURERS NAME & ADDRESS

PREPARED BY : PSNR-QUALITY, NOIDA

PROJECT : DADRI 2 x 500 MW

BHEL, PS-NR,

Noida

PSNR - Quality

ITEM

: BOILER

SUB-SYSTEM : STRUCTURES

CHARACTERISTICS / ITEM TYPE OF CHECK INSTRUMENT

: SG QP NO. : PN-QPE-BR-100 PACKAGE REV. : R00 CONTRACT NO : CS-6130-108-2-FC-NOA-4722 DATE : 24-04-2007 CONTRACTOR : BHEL, PS-NR PAGE 8 OF 10

CLASS QUANTUM / FREQUENCY OF CHECK REFERENCE DOCUMENT/ ACCETANCE STANDARD FORMAT OF RECORD REMARKS

SL. NO.

b) Butt Welds : i. MPI / LPI on all back gouged / ground grooves prior to welding from second side. ii. RT for t 32 mm. iii. MPI / LPI on finished welds for t 25 mm < 32 mm. iv. MPI / LPI on finished welds for t < 25 mm. c) Groove Welds : i. MPI / LPI for back gouged / ground area before second side welding in case of double side welding in case of double side groove joint. ii. MPI / LPI on finished welds for t > 25 mm. iii. MPI / LPI on finished welds for 25 mm. V B 100% NDE Manual V B 100% NDE Manual

V V V

B B B

100% 100% 10% of weld length at random

- do - do - do -

V V

B B

100% 10% of weld length at random

DOC. NO.

- do - do -

FOR NTPC USE BHEL, PSNR-QUALITY BHEL, PS-NR MANUFACTURER / SUBCONTRACTOR CONTRACTOR SIGNATURE FMT-QP-015 REV.02

ERECTION

AREA REVIEWED BY NAME & SIGNATURE, OF APPROVING AUTHORITY & SEAL

FIELD QUALITY PLAN

MANUFACTURERS NAME & ADDRESS

PREPARED BY : PSNR-QUALITY, NOIDA

PROJECT : DADRI 2 x 500 MW

BHEL, PS-NR,

Noida

PSNR - Quality

ITEM

: BOILER

SUB-SYSTEM : STRUCTURES

CHARACTERISTICS / ITEM TYPE OF CHECK INSTRUMENT

: SG QP NO. : PN-QPE-BR-100 PACKAGE REV. : R00 CONTRACT NO : CS-6130-108-2-FC-NOA-4722 DATE : 24-04-2007 CONTRACTOR : BHEL, PS-NR PAGE 9 OF 10

CLASS QUANTUM / FREQUENCY OF CHECK REFERENCE DOCUMENT/ ACCETANCE STANDARD FORMAT OF RECORD REMARKS

SL. NO.

d) Fillet Welds : i. LPI / MPI for welds between flange and web. ii. LPI / MPI for other welds joining plate members in which both plate members are over 25 mm thick. iii. All other welds. 6. NDE FOR CEILING GIRDERS : a) Butt welds : i. MPI / LPI for back gouged / ground area before second side welding. ii. MPI on all butt welds for ceiling girders. iii. For flange - RT iv. For web spot RT of joints, including T / + joints. V B 100% - do V V B B 100% 10% of weld length 100% NDE Manual - do -

- do -

V V V

B B B

100% 100% 10% of weld length

DOC. NO.

- do - do - do -

FOR NTPC USE BHEL, PSNR-QUALITY BHEL, PS-NR MANUFACTURER / SUBCONTRACTOR CONTRACTOR SIGNATURE FMT-QP-015 REV.02

ERECTION

AREA REVIEWED BY NAME & SIGNATURE, OF APPROVING AUTHORITY & SEAL

FIELD QUALITY PLAN

MANUFACTURERS NAME & ADDRESS

PREPARED BY : PSNR-QUALITY, NOIDA

PROJECT : DADRI 2 x 500 MW

BHEL, PS-NR,

Noida

PSNR - Quality

ITEM

: BOILER

SUB-SYSTEM : STRUCTURES

CHARACTERISTICS / ITEM TYPE OF CHECK INSTRUMENT

: SG QP NO. : PN-QPE-BR-100 PACKAGE REV. : R00 CONTRACT NO : CS-6130-108-2-FC-NOA-4722 DATE : 24-04-2007 CONTRACTOR : BHEL, PS-NR PAGE 10 OF 10

CLASS QUANTUM / FREQUENCY OF CHECK REFERENCE DOCUMENT/ ACCETANCE STANDARD FORMAT OF RECORD REMARKS

SL. NO.

b) Fillet welds : MPI on fillet welds joining web tension flange. V B 100% NDE Manual

FOR NTPC USE BHEL, PSNR-QUALITY BHEL, PS-NR MANUFACTURER / SUBCONTRACTOR CONTRACTOR SIGNATURE FMT-QP-015 REV.02

DOC. NO.

ERECTION

AREA REVIEWED BY NAME & SIGNATURE, OF APPROVING AUTHORITY & SEAL

QP NO. : PN-QPE-BR-100 DOCUMENTS REFERRED IN QUALITY PLAN

PSNR Quality

REV.NO.: R00 PAGE 1 OF 1

SL.NO.

1.

Reference Document

Guidelines for the Erection of Boiler Supporting Structures Tightening Procedure for HSFG Bolts (Pub. No. 2302-82) Welding Manual (Doc. No. :PS:CMX:001 Rev.No.: 01/12-98) NDE Manual (Doc. No. :PS:CMX:002 Rev.No.: 01/12-98) Heat Treatment Manual (Doc. No. :PS:CMX:003 Rev.No.: 01/12-98) Storage & Preservation Instructions for Boiler & Auxiliaries (Doc. No. : PS:CMX:005 Rev. 00 / 93 )

Issuing Authority

BHEL, Trichy

2.

BHEL, Trichy

3.

BHEL, PS-NR, Noida

4.

BHEL, PS-NR, Noida

5.

BHEL, PS-NR, Noida

6.

BHEL, PS-NR, Noida

FMT-QP-017 REV.00

RECORD OF QUALITY CHECKS

PSNR - Quality

SHEET NO. OF QPI

CHECK NO.

RESULTS ACHIEVED OK / NOT OK

DRAWING / DOCUMENT REFERENCE

FORMAT OF RECORD

CHECKED BY SIGN. & DATE

ACCEPTED BY SIGN. & DATE

REMARKS

Note : Any protocol made is to be numbered & mentioned in Format of Record column. SYSTEM SUB-SYSTEM AREA QP NO. : PN-QPE-BR-100 REV. NO. : R00 LOG SHEET NO. : L-00 PAGE 1 OF 1

PROJECT UNIT NO. RATING

FMT-QP-007 REV. 00

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

BOILER FOUNDATIONS TOP OF PEDESTAL

Top elevation of pedestals as per drawing _______ mm Tolerance : + 30 mm - 20 mm Pedestal Sl, No. Designation

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29.

PROJECT UNIT NO. RATING FMT-QP-008 REV.00

Top Elevation

Sl. No.

30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 54. 55. 56.

All dimensions are in mm Pedestal Top Designation Elevation

S1R S2R S3R S4R S5R S6R S7R S8R S9R S10R S11R S12R S13R S14R S15R S16R S19R S20R S21R S22R S23R S24R S25R S26R S27R LC1R LC2R

S1L S2L S3L S4L S5L S6L S7L S8L S9L S10L S11L S12L S13L S14L S15L S16L S17 S18 S19L S20L S21L S22L S23L S24L S25L S26L S27L LC1L LC2L

NAME CHECKED BY ACCEPTED BY CUSTOMER

SIGNATURE & DATE

QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-01 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION DRAWING / DOCUMENT NO. Power Sector - Quality

BOILER COLUMN FOUNDATION PEDESTALS - SPACING

B 1

S22L

2

S23L

3

S1L S2L

4

S3L

5

S4L

6

S5L

7

S6L S21L

S28L

S27L S24L

8 49 50 A

61

44

S7L S8L

9 45 17

S14L

10 46

S9L

11 47

S10L

12 48

S11L

13

S12L

14

S20L

15 60 C

16 51

S13L

52

18

S15L S16L

53 22

S17

57

58

59 S18 S25R

S21L S25R

64 S19

62 LONGITUDINAL AXIS OF BOILER

19

S13R S14R

20

63

21

64 S15R S16R

65 72

26 66

S7R

67

S8R

27 68 74

69

S9R S3R

28 70 75

S4R

29 71

S10R

30

S11R

31 S21 R

S12R S20R

73

S1R S2R

76

S5R

77

S6R

78

S21R 42 S27R 43 S24R

32

33

34 D

35 38

79

S22R

80

S28R

81

S23R

39

40

41

NAME PROJECT UNIT NO. RATING FMT-QP-007 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

SIGNATURE / DATE

PN-QPE-BR-100 REV. NO.: R00 LOG SHEET NO.: L-02 PAGE 1 OF 3

QP NO.:

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

BOILER COLUMN FOUNDATION PEDESTALS - SPACING

Sl.No. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. Location 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 As per drawing Actual Sl.No. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. Location 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 1 mm / M, 5 mm max. 1 mm / M, 15 mm max.

SIGNATURE & DATE QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-02 PAGE

As per drawing

Actual

26. 26 53. 27. 27 54. Tolerances : 1. Between adjacent foundation pedestals centres : 2. Spacing between first and last row of foundation : All dimensions are in mm.

NAME PROJECT UNIT NO. RATING FMT-QP-008 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

BOILER COLUMN FOUNDATION PEDESTALS - SPACING

Sl.No.

55. 56. 57. 58. 59. 60. 61. 62. 63. 64. 65. 66. 67. 68. 69. 70. 71. 72. 73. 74. 75. 76. 77. 78. 79. 80. 81.

Location

55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81

As per drawing

Actual

Sl.No.

82. 83. 84. 85.

Location

A B C D

As per drawing

Actual

NAME PROJECT UNIT NO. RATING FMT-QP-008 REV.0 CHECKED BY ACCEPTED BY CUSTOMER

SIGNATURE & DATE

QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-02 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION DRAWING / DOCUMENT NO. Power Sector - Quality

BOILER COLUMN FOUNDATION PEDESTALS - SPACING

B

S22L S23L

S28L

S1L S2L S3L S4L S5L S6L S21L S27L S24L

S7L

S8L

S9L

S10L

S11L

S12L

S20L

S21L

S13L S14L LONGITUDINAL AXIS OF BOILER 63 S13R S14R 64 S15R S15L S16L

A

S17 S18 S25R S16R

S25R

S19

S21 R

S7R S1R S8R S2R S9R S3R S10R S4R S11R S5R S12R S6R S20R S21R S27R S24R

S22R

S28R

S23R

NAME PROJECT UNIT NO. RATING FMT-QP-007 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

SIGNATURE / DATE

PN-QPE-BR-100 REV. NO.: R00 LOG SHEET NO.: L-03 PAGE 1 OF 2

QP NO.:

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

DIAGONAL CHECK BETWEEN MAIN COLUMN FOUNDATION PEDESTALS

Diagonal between

S7L & S8R S7R & S8L S13L & S14R S13R & S14L S8L & S9R S8R & S9L S9L & S10R S9R & S10L S15L & S16R S15R & S16L S10L & S11R S10R & S11L S11L & S18 S17 & S12L S17 & S12R S11R & S18 S11L & S12R S11R & S12L

Sl.No.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Measurement

Difference

Sl.No.

Diagonal between

Measurement

Difference

Tolerances : 1. Foundation pedestals diagonal difference 2. Cumulative diagonal difference All dimensions are in mm.

NAME PROJECT UNIT NO. RATING FMT-QP-008 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

: :

1 mm / M, 10 mm max. 1 mm / M, 25 mm max.

SIGNATURE & DATE QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-03 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

PITCH DISTANCE OF FOUNDATION BOLTS AND DIAGONALS

b3 b4

a2 A a1 D1

D2

a4

a3

b1 B

AS PER DRAWING PEDESTAL DESIGNATION L R L R L R L R L R A B a1 a2 a3

b2

a4

b1

b2

b3

b4

D1

D2

Tolerances: 1. Pitch Distances 2. Diagonal Difference

PROJECT UNIT NO. RATING FMT-QP-008 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

: 3 mm All dimensions are in mm : 5 mm max.

NAME SIGNATURE & DATE QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-04 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

GROUTING OF COLUMN BASES

1.

Column Numbers

2.

Grout Material Specification

3.

Ratio of proportion of grout mix

4.

Whether any additives added

Yes / No

If yes, details

5.

Date of grouting

6.

Whether test cubes have been taken

Yes / No

If yes, test results

7.

Remarks

The following column bases________________________________________are cleared for further erection after ________ days of curing.

NAME PROJECT UNIT NO. RATING FMT-QP-008 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

SIGNATURE & DATE

QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-05 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

VERTICALITY OF COLUMNS

Tolerance: 1mm / M, 25 mm Max. Column Number All dimensions are in mm Inclined towards East West North South

Elevation

NAME PROJECT UNIT NO. RATING FMT-QP-008 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

SIGNATURE & DATE

QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-06 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

CEILING STRUCTURES ALIGNMENT

P S7L S8L Q S9L R S S10L T S11L S12L

GIRDER A GIRDER B GIRDER C GIRDER D GIRDER E C. L. of boiler axis marked on girders

GIRDER F

S7R P1

S8R Q1

S9R R1

S10R S1

S11R T1

S12R

SPACING BETWEEN CEILING GIRDERS: As per drawing

Tolerance :

5 mm Max.

Location P Q R S T

Actual

Location P1 Q1 R1 S1 T1

As per drawing

Actual

All dimensions are in mm

NAME PROJECT UNIT NO. RATING FMT-QP-008 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

SIGNATURE & DATE

QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-07 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

CEILING STRUCTURES ALIGNMENT

DIAGONAL DIFFERENCE BETWEEN ADJACENT CEILING GIRDERS Tolerance : 25 mm Max. Between Girders AB BC CD DE E-F D1 D2 D1~D2

CEILING GIRDER C. L. VARIATION W.R.T. BOILER AXIS : Tolerance : 12 mm Max. All dimensions are in mm

Girder Designation Girder - A Girder B Girder C Girder D Girder E Girder F

Variation w.r.t. boiler axis Towards Left Towards Right

NAME PROJECT UNIT NO. RATING FMT-QP-008 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

SIGNATURE & DATE

QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-07 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

JOINT INSPECTION PROTOCOL FOR COMPLETION OF STRUCTURE PRIOR TO DRUM ERECTION

Sl.No. 1 2 Activity Completion and verification of all log sheets / records of erection. Erection completion of : a) All columns b) Horizontal beams between columns c) Vertical bracings and tie members d) Horizontal bracing on all main brace levels (MBLs) e) Ceiling girders, welded beams (WBs) & ceiling bracings. 3. 4. 5. 6. 7. Welding completion Completion of HSFG bolts tightening. NDE completion Heat treatment completion Remarks : Observation

Note : Minimum structures required for drum erection are listed in sheets 2 / 3 and 3 / 3. Boiler supporting structure is cleared for drum erection.

NAME PROJECT UNIT NO. RATING FMT-QP-008 REV.00 CHECKED BY ACCEPTED BY CUSTOMER SIGNATURE & DATE QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-08 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

MINIMUM STRUCTURES REQUIREMENT FOR DRUMERECTION (LIST OF REVAMPED PG - MA UNDER PG - 35

Sl.No. 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

PROJECT UNIT NO. RATING FMT-QP-008 REV.00 ACCEPTED BY CUSTOMER

MA 4 146 4 196 24 335 010 111 112 121 122 130 140 150 190 211 212 213 214 221 222 231 232 311 312 321 322 331 332 341 342 351 352 361 362

Description Upper Drum Sspn Id 6 17300 DL Upper Drum trans Str 4483 DL Slncr & support starting 3320 DL Foundation Materials Main Columns Left Main Columns Left Main Columns Right Main Columns Right Main Columns Middle, except S14 L & S14 R and S17 Auxiliary Columns Left Auxiliary Columns Right Girder Pin Connection Ceiling Girder (fabricated) Ceiling Girder (fabricated) Cross Girder Cross Girder Ceiling Rolled shapes Ceiling Rolled shapes Ceiling Bracing Ceiling Bracing Floor Bracing I MBL Floor Bracing I MBL Floor Bracing II MBL Floor Bracing II MBL Floor Bracing III MBL Floor Bracing III MBL Floor Bracing IV MBL Floor Bracing IV MBL Floor Bracing V MBL Floor Bracing V MBL Floor Bracing VI MBL Floor Bracing VI MBL

1st Pass 2nd Pass 1st Pass 2nd Pass

1st Pass 2nd Pass 1st Pass 2nd Pass 1st Pass @ 2nd Pass @ 1st Pass 2nd Pass 1st Pass 2nd Pass 1st Pass 2nd Pass 1st Pass 2nd Pass 1st Pass 2nd Pass 1st Pass 2nd Pass 1st Pass 2nd Pass

QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-08 PAGE

OF

INSTRUMENT REGN.NO. DATE OF INSPECTION

PSNR - Quality

DRAWING / DOCUMENT REF.

MINIMUM STRUCTURES REQUIREMENT FOR DRUMERECTION (LIST OF REVAMPED PG - MA UNDER PG - 35

Sl.No. MA Description

33 381 Landing Platforms - 1st tier * 34 382 Landing Platforms - 2nd tier * 35 383 Landing Platforms - 3rd tier * 36 390 Drum Floor * 37 441 Main Beams - Lower - 1st Pass 38 442 Main Beams - Middle - 1st Pass 39 443 Main Beams - Upper - 1st Pass 40 451 Main Beams - Lower - 2nd Pass 41 452 Main Beams - Middle - 2nd Pass 42 453 Main Beam - Upper - 2nd Pass 43 511 Front Bracing - Lower 44 512 Front Bracing - Middle 45 513 Front Bracing - Upper 46 521 Side Bracing - Lower 47 522 Side Bracing - Middle 48 523 Side Bracing - Upper 50 531 Rear Bracing - Lower 51 532 Rear Bracing - Middle 52 533 Rear Bracing - Upper 53 700 Fasteners 54 811 Floor grills & Guard Plate * 55 821 Main Stairs - Lower 56 822 Main Stairs - Middle 57 823 Main Stairs - Upper 58 851 Handrails & Posts * @ - Rolled shapes which are required for drum lifting are to be erected and others as and when requirements arises. - These items are not mandatory for drum lift, but may be important from statutory regulation, operation / erection and health / safety point of views.

NOTE : For details refer applicable PGMA list.

NAME PROJECT UNIT NO. RATING FMT-QP-008 REV.00 CHECKED BY ACCEPTED BY CUSTOMER

SIGNATURE & DATE

QP NO.:PN-QPE-BR-100 REV.NO.: R00 LOG SHEET NO.: L-08 PAGE

OF

You might also like

- FGD Outlet Guillotine Gate Spec-BHELDocument80 pagesFGD Outlet Guillotine Gate Spec-BHELSRINIVASAN TNo ratings yet

- Inspection and Test Plan For Silos and HoppersDocument15 pagesInspection and Test Plan For Silos and HoppersHOMAYOUN KHADIVINo ratings yet

- Process Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003Document31 pagesProcess Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003m4metzNo ratings yet

- Financial Management 2E: Rajiv Srivastava - Dr. Anil Misra Solutions To Numerical ProblemsDocument5 pagesFinancial Management 2E: Rajiv Srivastava - Dr. Anil Misra Solutions To Numerical ProblemsParesh ShahNo ratings yet

- DFo 2 1Document15 pagesDFo 2 1Donna HernandezNo ratings yet

- FQP BAR 660MW BOWL MILL R00 - VoidDocument31 pagesFQP BAR 660MW BOWL MILL R00 - VoidMatthew JacobsNo ratings yet

- Inspection Report For Pipeline Route Survey Sign Copy and Blank FormatDocument1 pageInspection Report For Pipeline Route Survey Sign Copy and Blank FormatVishvjeet Prakash TiwariNo ratings yet

- Project Standard Specification: Fuel Oil Piping 15191 - Page 1/6Document6 pagesProject Standard Specification: Fuel Oil Piping 15191 - Page 1/6adel rihanaNo ratings yet

- FQP 16.11.18 Vol-I - BoilerDocument90 pagesFQP 16.11.18 Vol-I - Boilerashis chatterjeeNo ratings yet

- N1P 1.5 P1T2 BLK LDocument2 pagesN1P 1.5 P1T2 BLK LRijo RajanNo ratings yet

- BGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Document4 pagesBGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5Santoshkumar GuptaNo ratings yet

- 1 04 039 03 PDFDocument9 pages1 04 039 03 PDFanuragpugaliaNo ratings yet

- Practical Guidelines For CTG Power PlantsDocument11 pagesPractical Guidelines For CTG Power Plantsandrei12320003181No ratings yet

- Protocol Column AlignmentDocument9 pagesProtocol Column AlignmentManikandan elumalaiNo ratings yet

- Waste Heat Recovery Power Plant 2mw 100tpd OrissaDocument84 pagesWaste Heat Recovery Power Plant 2mw 100tpd OrissaEdgardo Chavez BelloNo ratings yet

- CR QapDocument2 pagesCR QapSimbu ArasanNo ratings yet

- Typical QAPDocument4 pagesTypical QAPhemantmech09No ratings yet

- "Waste Heat Recovery System ": Internship / Summer Vocational Training Project Report OnDocument17 pages"Waste Heat Recovery System ": Internship / Summer Vocational Training Project Report OnPiyush SinghNo ratings yet

- 100m3 Mkongoro Water TankDocument1 page100m3 Mkongoro Water TankamonNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Ruel fernandezNo ratings yet

- IRN-8108577716-432-01-RIL-Audco-17 Jan 2014Document1 pageIRN-8108577716-432-01-RIL-Audco-17 Jan 2014MuralitclNo ratings yet

- Technical Specifications - CompDocument57 pagesTechnical Specifications - CompAnonymous gr5Pr9AVNo ratings yet

- Compressor Air Piping Calculation PDFDocument1 pageCompressor Air Piping Calculation PDFThai VoNo ratings yet

- Inspection and Testing of Piping Systems ES-14-602-02Document44 pagesInspection and Testing of Piping Systems ES-14-602-02Edmund MoraldeNo ratings yet

- General Checklist For Procurement OF Material Handling System / EquipmentDocument8 pagesGeneral Checklist For Procurement OF Material Handling System / Equipmentjkhan_724384No ratings yet

- MD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationDocument30 pagesMD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationTran KhuynhNo ratings yet

- Final 26 - 53Document34 pagesFinal 26 - 53Bebe BucătaruNo ratings yet

- ITB-spc For Tape Coating For UG Piping PDFDocument15 pagesITB-spc For Tape Coating For UG Piping PDFShyam Sundar GayenNo ratings yet

- ACDBDocument88 pagesACDBuvilasNo ratings yet

- Procedure For DYE PENETRANT TestingDocument10 pagesProcedure For DYE PENETRANT TestingKarrar Talib100% (1)

- PUMP Testing SheetDocument3 pagesPUMP Testing SheetAlan Tan Y RNo ratings yet

- GTS 2Document730 pagesGTS 2Aveek SenguptaNo ratings yet

- Quality Assurance and QA PlansDocument13 pagesQuality Assurance and QA PlansAKHIL JOSEPH100% (1)

- Relief ValveDocument2 pagesRelief ValveAdil AzizNo ratings yet

- NTPC-GCC (Civil)Document122 pagesNTPC-GCC (Civil)Shyamal DuttaNo ratings yet

- McQuay MCC Data Sheet EngDocument1 pageMcQuay MCC Data Sheet EngSaeful Malik GintingNo ratings yet

- Note For Electrical & Civil WorkDocument5 pagesNote For Electrical & Civil WorkNitin SharmaNo ratings yet

- BFV Nom... H... en - Mot Valve v9 Nom - (Actuator Nom) - NewDocument6 pagesBFV Nom... H... en - Mot Valve v9 Nom - (Actuator Nom) - NewHans MuntheNo ratings yet

- 2 TS SS STR R8 030309 060213Document16 pages2 TS SS STR R8 030309 060213dkshtdkNo ratings yet

- 3p081-Itp ADocument17 pages3p081-Itp AMariah PearsonNo ratings yet

- RooftopDocument4 pagesRooftophjduarteNo ratings yet

- Section 2 QAP, Cable TrayDocument3 pagesSection 2 QAP, Cable TrayveerendraNo ratings yet

- Construction and Working of Thermal Power PlantDocument5 pagesConstruction and Working of Thermal Power Plantdibyenindus100% (1)

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Handover To QAQC-Anand KumarDocument6 pagesHandover To QAQC-Anand KumarAnonymous fBkcEze1No ratings yet

- Jacobs: Equipment Inspection Code: ADocument2 pagesJacobs: Equipment Inspection Code: ASigit BintanNo ratings yet

- Water Pump STN StandardDocument5 pagesWater Pump STN StandardTeguh SetionoNo ratings yet

- Field Quality Plan For LgfsDocument7 pagesField Quality Plan For LgfsUday PratapNo ratings yet

- Method of Statement Boiler Hous FoundationDocument16 pagesMethod of Statement Boiler Hous FoundationSetia EdiNo ratings yet

- Valve Inspection ChecklistDocument1 pageValve Inspection ChecklistTengku Mohd ImranNo ratings yet

- QAP of HT Breaker Panel SchneiderDocument1 pageQAP of HT Breaker Panel Schneidermadhu_bedi12No ratings yet

- Hy 19580Document6 pagesHy 19580kompany_dNo ratings yet

- Pump ChlorineDocument44 pagesPump ChlorineAlexandreCaironiNo ratings yet

- Excitation Systems: Raman JainDocument15 pagesExcitation Systems: Raman JainrohitctppNo ratings yet

- (How To) Calculate The Required Blower Capacity For FBD - Pharma EngineeringDocument11 pages(How To) Calculate The Required Blower Capacity For FBD - Pharma EngineeringTerrence Terry BhengoeNo ratings yet

- Minimum Distance Between Pipes With FlanchesDocument12 pagesMinimum Distance Between Pipes With FlanchesJMVNo ratings yet

- FQP - Civil NewDocument13 pagesFQP - Civil NewVenkatesh MudragadaNo ratings yet

- GVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantDocument15 pagesGVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantRohit100% (1)

- Field Quality Plan: 2 X 520Mw TPP at VizagDocument12 pagesField Quality Plan: 2 X 520Mw TPP at Vizagryan940No ratings yet

- DBB BNCPP B M v29 0015 Revb IfaDocument6 pagesDBB BNCPP B M v29 0015 Revb IfaIzzadAfif1990No ratings yet

- Endorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPCDocument1 pageEndorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPCSrinivasan RajuNo ratings yet

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Document4 pagesFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- Water TreatmentDocument27 pagesWater TreatmentEzhil Vendhan PalanisamyNo ratings yet

- Project Management in Thermal Power Plant-Ntpc'S ExperienceDocument58 pagesProject Management in Thermal Power Plant-Ntpc'S ExperienceEzhil Vendhan Palanisamy100% (1)

- AIM Training Report - ATANUDocument9 pagesAIM Training Report - ATANUEzhil Vendhan PalanisamyNo ratings yet

- Off - Site Facilities Coal Transportation Handling: 1 June 2010 PMI Revision 00 1Document40 pagesOff - Site Facilities Coal Transportation Handling: 1 June 2010 PMI Revision 00 1Ezhil Vendhan PalanisamyNo ratings yet

- Recapitulation of Concepts.: /var/www/apps/conversion/tmp/scratch - 1/209957082Document7 pagesRecapitulation of Concepts.: /var/www/apps/conversion/tmp/scratch - 1/209957082Ezhil Vendhan PalanisamyNo ratings yet

- Site Visit Report - GeneralDocument3 pagesSite Visit Report - GeneralEzhil Vendhan PalanisamyNo ratings yet

- Project Planning and Interface With Govt. Agencies: S.D.Mathur AGM (Systems)Document41 pagesProject Planning and Interface With Govt. Agencies: S.D.Mathur AGM (Systems)Ezhil Vendhan PalanisamyNo ratings yet

- Power Trading PptFinalDocument54 pagesPower Trading PptFinalEzhil Vendhan PalanisamyNo ratings yet

- Project Management in Thermal Power Plant-Ntpc'S ExperienceDocument58 pagesProject Management in Thermal Power Plant-Ntpc'S ExperienceEzhil Vendhan PalanisamyNo ratings yet

- FR Formulation&Infrastructure For EtsDocument27 pagesFR Formulation&Infrastructure For EtsEzhil Vendhan PalanisamyNo ratings yet

- Cost & Cost ConceptsDocument51 pagesCost & Cost ConceptsEzhil Vendhan PalanisamyNo ratings yet

- Burner Block AlignmentDocument12 pagesBurner Block AlignmentEzhil Vendhan PalanisamyNo ratings yet

- O&M BudgetDocument17 pagesO&M BudgetEzhil Vendhan PalanisamyNo ratings yet

- Raw WaterDocument41 pagesRaw WaterEzhil Vendhan PalanisamyNo ratings yet

- Gen ProtectionDocument78 pagesGen ProtectionEzhil Vendhan PalanisamyNo ratings yet

- Boiler EffyDocument32 pagesBoiler EffyEzhil Vendhan PalanisamyNo ratings yet

- Steam BlowingDocument28 pagesSteam BlowingEzhil Vendhan Palanisamy100% (1)

- Critical Chain Project Management N NotesDocument22 pagesCritical Chain Project Management N NotesEzhil Vendhan PalanisamyNo ratings yet

- O&M BudgetDocument17 pagesO&M BudgetEzhil Vendhan PalanisamyNo ratings yet

- PW SystemDocument12 pagesPW SystemEzhil Vendhan PalanisamyNo ratings yet

- Boiler EffyDocument32 pagesBoiler EffyEzhil Vendhan PalanisamyNo ratings yet

- Energy Audit and DSM: Ceetem-CosDocument38 pagesEnergy Audit and DSM: Ceetem-CosEzhil Vendhan PalanisamyNo ratings yet

- Raw WaterDocument41 pagesRaw WaterEzhil Vendhan PalanisamyNo ratings yet

- Feasibility Report Project Cost APPRAISALDocument30 pagesFeasibility Report Project Cost APPRAISALEzhil Vendhan PalanisamyNo ratings yet

- Burner Block AlignmentDocument12 pagesBurner Block AlignmentEzhil Vendhan PalanisamyNo ratings yet

- Power Factor & Its ImprovementDocument23 pagesPower Factor & Its ImprovementEzhil Vendhan PalanisamyNo ratings yet

- Gen ProtectionDocument78 pagesGen ProtectionEzhil Vendhan PalanisamyNo ratings yet

- Vemu Institute of Technology: Department of Computer Science & EngineeringDocument79 pagesVemu Institute of Technology: Department of Computer Science & EngineeringSiva SankarNo ratings yet

- Current Concepts in Elbow Fracture Dislocation: Adam C Watts, Jagwant Singh, Michael Elvey and Zaid HamoodiDocument8 pagesCurrent Concepts in Elbow Fracture Dislocation: Adam C Watts, Jagwant Singh, Michael Elvey and Zaid HamoodiJoão Artur BonadimanNo ratings yet

- 1Document3 pages1Stook01701No ratings yet

- P 348Document196 pagesP 348a123456978No ratings yet

- Famous Little Red Book SummaryDocument6 pagesFamous Little Red Book SummaryMatt MurdockNo ratings yet

- DMIT - Midbrain - DMIT SoftwareDocument16 pagesDMIT - Midbrain - DMIT SoftwarevinNo ratings yet

- Acc116 Dec 2022 - Q - Test 1Document6 pagesAcc116 Dec 2022 - Q - Test 12022825274100% (1)

- Battery Guide - 2021Document27 pagesBattery Guide - 2021Mario LaurieNo ratings yet

- Biological Assets Sample ProblemsDocument4 pagesBiological Assets Sample ProblemsKathleenNo ratings yet

- Roxas City For Revision Research 7 Q1 MELC 23 Week2Document10 pagesRoxas City For Revision Research 7 Q1 MELC 23 Week2Rachele DolleteNo ratings yet

- Internship Report Format For Associate Degree ProgramDocument5 pagesInternship Report Format For Associate Degree ProgramBisma AmjaidNo ratings yet

- Aliping PDFDocument54 pagesAliping PDFDirect LukeNo ratings yet

- Notes On Antibodies PropertiesDocument3 pagesNotes On Antibodies PropertiesBidur Acharya100% (1)

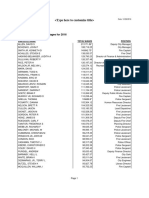

- 2016 W-2 Gross Wages CityDocument16 pages2016 W-2 Gross Wages CityportsmouthheraldNo ratings yet

- Derebe TekesteDocument75 pagesDerebe TekesteAbinet AdemaNo ratings yet

- BMGT 200 Assignment 2 Answer KeysDocument3 pagesBMGT 200 Assignment 2 Answer Keysharout keshishianNo ratings yet

- Introduction To Retail LoansDocument2 pagesIntroduction To Retail LoansSameer ShahNo ratings yet

- Smart Gas Leakage Detection With Monitoring and Automatic Safety SystemDocument4 pagesSmart Gas Leakage Detection With Monitoring and Automatic Safety SystemYeasin Arafat FahadNo ratings yet

- Measuring Temperature - Platinum Resistance ThermometersDocument3 pagesMeasuring Temperature - Platinum Resistance Thermometersdark*nightNo ratings yet

- Shelly e CommerceDocument13 pagesShelly e CommerceVarun_Arya_8382No ratings yet

- Editan - Living English (CD Book)Document92 pagesEditan - Living English (CD Book)M Luthfi Al QodryNo ratings yet

- FE CH 5 AnswerDocument12 pagesFE CH 5 AnswerAntony ChanNo ratings yet

- 24 DPC-422 Maintenance ManualDocument26 pages24 DPC-422 Maintenance ManualalternativblueNo ratings yet

- Decision Trees For Management of An Avulsed Permanent ToothDocument2 pagesDecision Trees For Management of An Avulsed Permanent ToothAbhi ThakkarNo ratings yet

- Student Management SystemDocument232 pagesStudent Management Systemslu_mangal73% (37)

- Chapter 1Document6 pagesChapter 1Grandmaster MeowNo ratings yet

- ETAP Power Station ErrorDocument5 pagesETAP Power Station ErroryogacruiseNo ratings yet

- Arduino Uno CNC ShieldDocument11 pagesArduino Uno CNC ShieldMărian IoanNo ratings yet