Professional Documents

Culture Documents

RCM Implementation Profile

Uploaded by

Mohamed Altaf JafferCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCM Implementation Profile

Uploaded by

Mohamed Altaf JafferCopyright:

Available Formats

RCM Implementation Profile of ReliaSoft

Overview

ReliaSoft offers a comprehensive range of services dedicated to meeting the reliability engineering, quality and maintenance planning needs of product manufacturers and equipment operators worldwide. Our corporate capabilities encompass all aspects of reliability engineering through all stages of product development, deployment and operation. Our reliability consulting services team has combined expertise in almost all areas of reliability and quality engineering with experience that spans a broad spectrum of product types, from micro-electronics and appliances to advanced weapons systems.

RCM

Reliability centered maintenance is an engineering framework that enables the definition of a complete maintenance regime. It regards maintenance as the means to maintain the functions a user may require of machinery in a defined operating context. As a discipline it enables machinery stakeholders to monitor, assess, predict and generally understand the working of their physical assets. This is embodied in the initial part of the RCM process which is to identify the operating context of the machinery, and write a Failure Mode Effects and Analysis (FMEA). The second part of the analysis is to apply the "RCM logic", which helps to determine the appropriate maintenance tasks for the identified failure modes in the FMEA.

Our Customers

ReliaSoft has implemented RCM of its customers plant on several equipments whose list is given below Gujarat Narmada Valley Fertilizers Company Ltd.,- Ammonia Plant (Gujarat-India) Steam Turbine Air-Compressor Lubrication system of Turbine Liquid Oxygen pump Lubrication system of LO Pump Gassifier NH3 Synthesis Reactor High Voltage Switch Gear (11kv)

Indian Oil Company Ltd.,-Crude oil Refinery (Bongaigaon-Assam India)

Steam Turbo Generator Boiler Fuel oil Pump Boiler Feed Pump Air Pre Heater F D Fan Flushing Oil Pump Fractionator Bottom Pump OFF Gas Compressor De-Coking Sump Pump

Quench Column Pump LPG Pump Crude Charge Pump Fractionator Column Heat Exchanger Cooling Tower Aerator Coke Cutting System. 11 kv Switch Gear

UPS ECS Power Plant Transformer Recycle Gas Compressor ID Fan Fin Fan Cooler Escorts Faun Crane De-crystallization Furnace Coke Cutting Pump

Deepak Fertilizers & Petrochemicals Company Ltd.,- Ammonia Plant (Mumbai-India) Reciprocating Compressor Boiler FW Pump Ammonia Heat Exchangers Turbine Driven ID Fan DG Set AMF Panel HV Circuit Breaker HT & LT Motor

RCM implementation Process

RCM project is composed of four phases each of them has a definite objective to be accomplished and its outcome is an input to the subsequent phases. A brief outline of the four phases is given below PHASE I - Criticality Strategy To develop Criticality Analysis strategy for equipments based on selected criteria -Safety, Environment, Process, Maintenance etc. PHASE II - Criticality Analysis Ranking of the equipments (Compressor, Turbine etc.) based on the strategy developed during PHASE I. PHASE III FMEA, Failure Mode and Effect Analysis To perform FMEA on the selected equipments based on Criticality Analysis and to identify all potential failure modes and their corresponding control techniques.

PHASE IV RCM, Reliability Centered Maintenance Applying RCM techniques to selected equipments and decide on the appropriate maintenance activity for each cause identified in FMEA PHASE. During all the above phases of the project ReliaSofts RCM Experts will sit along with the operation and maintenance personnel of the equipment to facilitate & improvise the FMEA and the RCM analysis.

Benefits of RCM

The Benefits of RCM analysis is given below. Create a comprehensive Database containing all your significant assets information regarding its failure, effect and corrective/preventive actions. Develop a System driven maintenance strategy. Applying the failure history data to justify/optimize the maintenance interval. Apply simulation techniques to estimate the average availability and cost. Develop a scheduled maintenance plan for a physical asset that will provide an acceptable level of functionality, with an acceptable level of risk, in an efficient and cost-effective manner. Evaluate whether preventive maintenance is appropriate and determine optimum maintenance intervals. Promote analysis processes that are more efficient and more effective, utilizing lessons learned from past analyses when applicable.

Contact

Muthukumar. U Director-India Operations ReliaSoft India Private Ltd Old No.16, New No. 21 Cenotaph 1st Street, Alwarpet, Chennai-600018. kumar@ReliaSoft.com Phone: +91 44 4208 7785 Fax: +91 44 4208 7756 http://www.reliasoft.com/consulting/index.htm

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Design of Flyback Transformers and Filter Inductor by Lioyd H.dixon, Jr. Slup076Document11 pagesDesign of Flyback Transformers and Filter Inductor by Lioyd H.dixon, Jr. Slup076Burlacu AndreiNo ratings yet

- Go Ask Alice EssayDocument6 pagesGo Ask Alice Essayafhbexrci100% (2)

- Introduction To AirtelDocument6 pagesIntroduction To AirtelPriya Gupta100% (1)

- Hierarchy of The Inchoate Crimes: Conspiracy Substantive CrimeDocument18 pagesHierarchy of The Inchoate Crimes: Conspiracy Substantive CrimeEmely AlmonteNo ratings yet

- Certification and LettersDocument6 pagesCertification and LettersReimar FerrarenNo ratings yet

- Remuneration Is Defined As Payment or Compensation Received For Services or Employment andDocument3 pagesRemuneration Is Defined As Payment or Compensation Received For Services or Employment andWitty BlinkzNo ratings yet

- VoLTE KPI Performance - E2EDocument20 pagesVoLTE KPI Performance - E2EAnway Mohanty100% (1)

- Exercise 23 - Sulfur OintmentDocument4 pagesExercise 23 - Sulfur OintmentmaimaiNo ratings yet

- GATE General Aptitude GA Syllabus Common To AllDocument2 pagesGATE General Aptitude GA Syllabus Common To AllAbiramiAbiNo ratings yet

- Careem STRATEGIC MANAGEMENT FINAL TERM REPORTDocument40 pagesCareem STRATEGIC MANAGEMENT FINAL TERM REPORTFahim QaiserNo ratings yet

- Chapter 2 A Guide To Using UnixDocument53 pagesChapter 2 A Guide To Using UnixAntwon KellyNo ratings yet

- Power For All - Myth or RealityDocument11 pagesPower For All - Myth or RealityAshutosh BhaktaNo ratings yet

- Agreement Deed BangladeshDocument8 pagesAgreement Deed BangladeshVabna EnterpriseNo ratings yet

- IP Based Fingerprint Access Control & Time Attendance: FeatureDocument2 pagesIP Based Fingerprint Access Control & Time Attendance: FeaturenammarisNo ratings yet

- Ticket Udupi To MumbaiDocument2 pagesTicket Udupi To MumbaikittushuklaNo ratings yet

- Copeland PresentationDocument26 pagesCopeland Presentationjai soniNo ratings yet

- Chat Application (Collg Report)Document31 pagesChat Application (Collg Report)Kartik WadehraNo ratings yet

- Lemon AidDocument17 pagesLemon AidJade Anne Mercado BalmesNo ratings yet

- Curamik Design Rules DBC 20150901Document8 pagesCuramik Design Rules DBC 20150901Ale VuNo ratings yet

- KrauseDocument3 pagesKrauseVasile CuprianNo ratings yet

- Tenancy Law ReviewerDocument19 pagesTenancy Law ReviewerSef KimNo ratings yet

- Product Guide TrioDocument32 pagesProduct Guide Triomarcosandia1974No ratings yet

- Assessment 21GES1475Document4 pagesAssessment 21GES1475kavindupunsara02No ratings yet

- ABB Price Book 524Document1 pageABB Price Book 524EliasNo ratings yet

- Scope of Internet As A ICTDocument10 pagesScope of Internet As A ICTJohnNo ratings yet

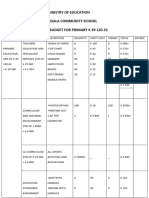

- Ministry of Education Musala SCHDocument5 pagesMinistry of Education Musala SCHlaonimosesNo ratings yet

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDocument2 pagesBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiNo ratings yet

- Chapter Two Complexity AnalysisDocument40 pagesChapter Two Complexity AnalysisSoressa HassenNo ratings yet

- Exoskeleton ArmDocument5 pagesExoskeleton Armc214ocNo ratings yet

- Canopy CountersuitDocument12 pagesCanopy CountersuitJohn ArchibaldNo ratings yet