Professional Documents

Culture Documents

Midterm - Exam CHEM4012 2010 2011

Uploaded by

Zezo AlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Midterm - Exam CHEM4012 2010 2011

Uploaded by

Zezo AlCopyright:

Available Formats

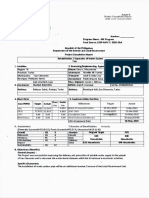

MID SEMESTER EXAMINATION Faculty of Engineering

COURSE CODE LEVEL / SEMESTER COURSE TITLE ACADEMIC YEAR DATE TIME DURATION MAXIMUM MARK : : : : : : : :

CHEM4012 4/2 Industrial Wastewater & Solid Waste Management 2010-2011 Wednesday 14th April 2011 09:00 2 Hours 100 Ahmed J. Ali Al-Dallal

COURSE COORDINATOR :

STUDENT NAME STUDENT ID GROUP NO

INSTRUCTIONS TO CANDIDATES This question paper consists of 7 pages only. Answer ALL questions. Write your ID, NAME and GROUP NUMBER clearly on all of your answer books. Follow all examination rules. Do not bring books or other related materials into the examination room.

Page |2

Question 1:

[30 marks]

Using the data plotted in Figure Q1 for the settling of activated sludge biomass, from a batch settling test for the Gravity solid flux (SFg) as a function of solid concentration. Assume that the mixed liquor flow rate to the clarifier is 20 MGD, the MLSS of the aeration tank is 2500 mg/L, and the underflow solids concentration of the secondary clarifier is 10,000 mg/L. i) Determine the total clarifying area required for secondary clarifier for this activated sludge process. ii) Determine the total thicknening area required for secondary clarifier iii) Which area you recommended for the design

7000 6000

Solid Flux (gm/m2.hr)

5000 4000 3000 2000 1000 0 0 2000 4000 6000 8000 10000 12000

Solid Concentration (gm/m3)

Figure Q1: Gravity solid flux (SFg) as a function of solid concentration . . . . . . . . . . . . .

Page |3 . . . . . . . . . . . . . . . . .

Question 2:

[10 marks]

The BOD5 of the raw Clarksville wastewater is 225 mg/L. A long term BOD test has revealed that this wastewater also has an ultimate carbonaceous BOD of 325 mg/L. Plant effluent testing has shown that the BOD5 drops by 92% across the plant. Long term tests on the effluent also show that the BOD decay coefficient is half the original value in the raw wastewater. i) What is the BOD decay coefficient of the raw wastewater? ii) What is the ultimate carbonaceous BOD of the effluent wastewater? . . . . . . . . . . . .

Page |4

Question 3:

[30 marks]

An in-line equalization basin is to be designed for a wastewater treatment plant. From plant records, a compilation has been made that gives the hourly flowrate versus hour of the day as follows: Hours 12:00-1:00 AM 1:00-2:00 2:00- 3:00 3:00- 4:00 4:00- 5:00 5:00- 6:00 6:00- 7:00 7:00- 8:00 8:00- 9:00 9:00- 10:00 10:00- 11:00 11:00- 12:00 12:00- 1:00 PM 1:00- 2:00 2:00- 3:00 3:00- 4:00 4:00- 5:00 5:00- 6:00 6:00- 7:00 7:00- 8:00 8:00- 9:00 9:00- 10:00 10:00- 11:00 11:00- 12:00 m3/d 11.4 8.3 7.9 7.6 9.1 10.6 13.6 20.8 25 28 28.8 26.9 25.7 25 25 26.9 28.8 32.9 37.5 37.5 31.8 32.1 15.9 13.2

Determine the fluctuating volume required for the basin in cubic meters.

. . . . . . . . . . . . .

Page |5

Question 4:

[30 marks]

Waste activated sludge is to be thickened using an air flotation system. Bench-scale batch flotation test was performed with different air to solids (A/S) ratio to determine air requirement as shown in Figure-Q4. The system treats 1500 m3/d of waste activated sludge and is to be operated to lower the sludge from 180 to 50 mg/L. The fraction of air dissolved in a retention tank having a 1-min detention time is 0.5. Other pertinent data are: average operating temperature = 200C, air solubility = 18.7 mg/L, recycle air pressure = 310 kPa absolute ( 3.0 atm), air introduced at 200C, overflow rate based on Q+R = 176 m3/m2/d, gas constant = 8.2057 x10-2 m3.atm/(kgmole. K). Determine: (a) The recycle flow R, m3/d, (b) The area of the floatation tank, (c) The kilograms of air required per day, (d) The cubic meters of air required per day.

0.06 0.05 0.04 0.03 0.02

A/S (mg/mg)

0.01 0 0 20 40 60 80 100 120 140 160 180

Concentration (mg/L) Figure Q-4: Bench-scale batch flotation test . . . . . . . . . . . .

Page |6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page |7

USEFUL INFORMATION

vscour

QR/A = SFL/XR or Qu/A = SFL/Xu

1 m = 3.28 ft 1 kg = 2.2046 lb 1 gal = 3.786 liter

You might also like

- Wwtbugs PDFDocument535 pagesWwtbugs PDFbudi budihardjoNo ratings yet

- 2011 Ifa FertigationDocument141 pages2011 Ifa Fertigationsarias355403100% (1)

- GATE SOLVED PAPER - CE ENVIRONMENTAL ENGINEERING YEAR 2013Document23 pagesGATE SOLVED PAPER - CE ENVIRONMENTAL ENGINEERING YEAR 2013shubhamNo ratings yet

- 2.2 Boilers - Revised (Table Format)Document11 pages2.2 Boilers - Revised (Table Format)Gajanan JagtapNo ratings yet

- Pipeline DesignDocument12 pagesPipeline Designjaffna0% (1)

- BLUE WATER Business & Operation Plan Financial Projections SummaryDocument67 pagesBLUE WATER Business & Operation Plan Financial Projections SummaryAly Khalaf80% (5)

- Waste Water Section Aug 2012Document176 pagesWaste Water Section Aug 2012VNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Steam CondenserDocument26 pagesSteam CondenserPushkar Pandit100% (1)

- COD Test Report Latest 2012Document10 pagesCOD Test Report Latest 2012emmafatimah0% (1)

- Comprehensive Quality by Design for Pharmaceutical Product Development and ManufactureFrom EverandComprehensive Quality by Design for Pharmaceutical Product Development and ManufactureGintaras V. ReklaitisNo ratings yet

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- DesalinationDocument6 pagesDesalinationNavneet SinghNo ratings yet

- Exam Examples Water TreatmentDocument38 pagesExam Examples Water TreatmentBinyam Kebede100% (1)

- Sample WW QuestionsDocument10 pagesSample WW QuestionsKrishna Kumar MeenaNo ratings yet

- Checklist ISO 22000 PDFDocument21 pagesChecklist ISO 22000 PDFkimkos2014No ratings yet

- Midterm - Exam CHEM4012 2011 2012Document5 pagesMidterm - Exam CHEM4012 2011 2012sahartalebiNo ratings yet

- Chemical Process Design 2009Document4 pagesChemical Process Design 2009Priyam RamsokulNo ratings yet

- Paper 4A SolutionDocument10 pagesPaper 4A SolutionSHAMSIK2002No ratings yet

- Physicochemical Treatment of Textile Industry Waste Water: Salman Mo Tabani, and Omprakash SahuDocument3 pagesPhysicochemical Treatment of Textile Industry Waste Water: Salman Mo Tabani, and Omprakash SahuCarlos Manuel RamosNo ratings yet

- Sem 1 2012-2013 (January) Ska 2922 Set ADocument7 pagesSem 1 2012-2013 (January) Ska 2922 Set AAfendi AriffNo ratings yet

- Cive3223 5 2014 2Document4 pagesCive3223 5 2014 2Yannick HowNo ratings yet

- Re-Final ExamDocument2 pagesRe-Final ExamArega GenetieNo ratings yet

- Monash Exam Paper CHE 2162Document11 pagesMonash Exam Paper CHE 2162venkieeNo ratings yet

- CE 4301-Wastewater and Industrial WastewaterDocument2 pagesCE 4301-Wastewater and Industrial WastewaterPranto KhanNo ratings yet

- Env. EM - Environmental Engineering and Management - 221TCH002Document7 pagesEnv. EM - Environmental Engineering and Management - 221TCH002Vis 22777No ratings yet

- University of Mauritius University of Mauritius University of Mauritius University of MauritiusDocument4 pagesUniversity of Mauritius University of Mauritius University of Mauritius University of MauritiusYannick HowNo ratings yet

- Final ExamDocument2 pagesFinal ExamArega GenetieNo ratings yet

- Environment Pollution Control ProblemsDocument3 pagesEnvironment Pollution Control ProblemsManish Kumar GhoraNo ratings yet

- Design and analysis of waste water treatment processesDocument53 pagesDesign and analysis of waste water treatment processesMuddasar ShaikhNo ratings yet

- Final Assessment (CCB31403)Document4 pagesFinal Assessment (CCB31403)Naz HelmiNo ratings yet

- Design Environmental Engineering AssignmentsDocument2 pagesDesign Environmental Engineering AssignmentsAnonymous Vx9KTkM8nNo ratings yet

- R09-Advanced Environmental EngineeringDocument1 pageR09-Advanced Environmental EngineeringRavi ThejaNo ratings yet

- CHE471Document7 pagesCHE471MaizatulAkmaNo ratings yet

- 3-COD LABSHEET WORD Tim & PikaDocument22 pages3-COD LABSHEET WORD Tim & PikadanielseleyNo ratings yet

- Hint: Assume Any Missing Data Name .. Number . Q1 (10 Points)Document5 pagesHint: Assume Any Missing Data Name .. Number . Q1 (10 Points)ReemALMousawiNo ratings yet

- ENE252 Environmental Engineering Class Test IDocument1 pageENE252 Environmental Engineering Class Test IHazel JamesNo ratings yet

- Caustic Recovery Tests ReportDocument17 pagesCaustic Recovery Tests ReportrashidafmNo ratings yet

- 2014 - Effluent CalcDocument66 pages2014 - Effluent CalcmaricorNo ratings yet

- 445046Document7 pages445046MD RashidNo ratings yet

- CG5082 Advanced Transport Processes - W.kwapinski Spring 2013Document11 pagesCG5082 Advanced Transport Processes - W.kwapinski Spring 2013WilliamLoobyNo ratings yet

- Reduction of Cod and Bod by Oxidation: A Cetp Case Study: Prashant K. Lalwani, Malu D. DevadasanDocument5 pagesReduction of Cod and Bod by Oxidation: A Cetp Case Study: Prashant K. Lalwani, Malu D. Devadasanjmrozo3No ratings yet

- Cive3223 5 2015 2Document4 pagesCive3223 5 2015 2Yannick HowNo ratings yet

- WorksheetDocument3 pagesWorksheetArega GenetieNo ratings yet

- Sem 2 2011-2012 (June) SAB 2912 SET ADocument6 pagesSem 2 2011-2012 (June) SAB 2912 SET AAfendi AriffNo ratings yet

- Bkc3683 - Wastewater Treatment (E) 21112Document6 pagesBkc3683 - Wastewater Treatment (E) 21112Berapi PanasNo ratings yet

- CE 341 Exam #2 Questions and SolutionsDocument1 pageCE 341 Exam #2 Questions and SolutionsJoshua chirchirNo ratings yet

- Environmental Engineering Lab COD TestDocument13 pagesEnvironmental Engineering Lab COD TestPink MerahJambuNo ratings yet

- Answer Questions Only: Chemical Engineering DeptDocument2 pagesAnswer Questions Only: Chemical Engineering DepthusseinNo ratings yet

- CHPR4405 Sample Exam2Document7 pagesCHPR4405 Sample Exam2Elena TodorovskaNo ratings yet

- City University of Hong Kong: Student IDDocument10 pagesCity University of Hong Kong: Student IDsui sui mangNo ratings yet

- UvarajDocument12 pagesUvarajsam regisNo ratings yet

- Che 501Document3 pagesChe 501Pronoy SinhaNo ratings yet

- Midterm 2020 Model AnswerDocument4 pagesMidterm 2020 Model AnswermidomoghaziNo ratings yet

- University of MauritiusDocument4 pagesUniversity of MauritiusYannick HowNo ratings yet

- Exam1 ACEE434Document7 pagesExam1 ACEE434s_murugan02No ratings yet

- A Paper4 QueDocument4 pagesA Paper4 Quezoom20No ratings yet

- Treatment of Sugar Industry Wastewater UsingDocument4 pagesTreatment of Sugar Industry Wastewater UsingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Lab 1: COD Test: University of Bahrain Department of Civil Engineering and Architecture Waste Water Treatment (CENG 426)Document11 pagesLab 1: COD Test: University of Bahrain Department of Civil Engineering and Architecture Waste Water Treatment (CENG 426)Anonymous uwajldLIONo ratings yet

- Exp 3 CO2 Absorption-Effect of Air Flow RateDocument5 pagesExp 3 CO2 Absorption-Effect of Air Flow RateLil Wayne JrNo ratings yet

- Caustic Soda Evaporator PDFDocument2 pagesCaustic Soda Evaporator PDFwitker2008No ratings yet

- Universiti Malaysia Pahang Environmental Engineering ExamDocument8 pagesUniversiti Malaysia Pahang Environmental Engineering ExamMohd AizadNo ratings yet

- SCH2208201105 Unit OperationsDocument4 pagesSCH2208201105 Unit Operationsziziphomkosana2003No ratings yet

- University of Mauritius Exam on Chemical Process DesignDocument5 pagesUniversity of Mauritius Exam on Chemical Process DesignPriyam RamsokulNo ratings yet

- University of MauritiusDocument4 pagesUniversity of MauritiusYannick HowNo ratings yet

- Constructed Wetlands for Industrial Wastewater TreatmentFrom EverandConstructed Wetlands for Industrial Wastewater TreatmentAlexandros I. StefanakisNo ratings yet

- Final - Exam CHEM4012 2009 2010Document6 pagesFinal - Exam CHEM4012 2009 2010Zezo AlNo ratings yet

- Energy Management For Houses and Building in OmanDocument35 pagesEnergy Management For Houses and Building in OmanZezo AlNo ratings yet

- Lecture Notes ENGG4000 Lecture 3 2013 2014Document10 pagesLecture Notes ENGG4000 Lecture 3 2013 2014Zezo AlNo ratings yet

- Lecture Notes CHEM4012 Lecture 3 2013 2014Document35 pagesLecture Notes CHEM4012 Lecture 3 2013 2014Zezo AlNo ratings yet

- 1Document11 pages1Zezo AlNo ratings yet

- Sohar University BUIS 2502 Assignment 1 - Analyzing a Business Information SystemDocument1 pageSohar University BUIS 2502 Assignment 1 - Analyzing a Business Information SystemZezo AlNo ratings yet

- Myanmar Climate Report Final 11 Oct 2017Document104 pagesMyanmar Climate Report Final 11 Oct 2017Moe yeik mayNo ratings yet

- CREW: U.S. Department of Homeland Security: U.S. Customs and Border Protection: Regarding Border Fence: 12/22/10 - FME001063-FME001240 SD ESP Appendices (Final)Document178 pagesCREW: U.S. Department of Homeland Security: U.S. Customs and Border Protection: Regarding Border Fence: 12/22/10 - FME001063-FME001240 SD ESP Appendices (Final)CREWNo ratings yet

- Air Pollution: Causes, Effects and PreventionDocument18 pagesAir Pollution: Causes, Effects and PreventionNicat RehimovNo ratings yet

- IELTS Speaking總整理Document13 pagesIELTS Speaking總整理Sarita Chuang SaraNo ratings yet

- Evs ProjectDocument11 pagesEvs ProjectUmesh TyagiNo ratings yet

- Ashirvad Only PVC Product MRP - 1st Dec 2020Document68 pagesAshirvad Only PVC Product MRP - 1st Dec 2020Ujwal Elijah GurramNo ratings yet

- Annex K - Project Completion ReportDocument2 pagesAnnex K - Project Completion Reportaeron antonioNo ratings yet

- Eor Potential For Dulang FieldDocument8 pagesEor Potential For Dulang FieldnikenanthaNo ratings yet

- Study Report On Implications of UnbondednessDocument19 pagesStudy Report On Implications of UnbondednessFatima tuz ZohraNo ratings yet

- Rapport Esi SuwaDocument233 pagesRapport Esi SuwaEzzadin BabanNo ratings yet

- Atlantic Coral Reefs: Flesh ApartDocument2 pagesAtlantic Coral Reefs: Flesh ApartIntan Gandhini 'Ige'No ratings yet

- The History of Philadelphia's Water Supply and Sanitation SystemDocument34 pagesThe History of Philadelphia's Water Supply and Sanitation SystemdaveaaaNo ratings yet

- Global Care Enviro System Tamil Nadu IndiaDocument10 pagesGlobal Care Enviro System Tamil Nadu IndiaGlobal Care Enviro SystemNo ratings yet

- Sodium Hydroxide (Cas 1310-73-2) MSDSDocument5 pagesSodium Hydroxide (Cas 1310-73-2) MSDSGao GraceNo ratings yet

- Echnology Rief: Autoclaved Aerated Concrete Masonry UnitsDocument4 pagesEchnology Rief: Autoclaved Aerated Concrete Masonry UnitsJayakumar AnanthaNo ratings yet

- Watershed Academy Web - Introduction To The Clean Water ActDocument15 pagesWatershed Academy Web - Introduction To The Clean Water ActChahak GuptaNo ratings yet

- Managing Alkalinity Levels in Shrimp PondsDocument3 pagesManaging Alkalinity Levels in Shrimp Pondsly minh quanNo ratings yet

- 2059 Pakistan Studies: MARK SCHEME For The May/June 2009 Question Paper For The Guidance of TeachersDocument10 pages2059 Pakistan Studies: MARK SCHEME For The May/June 2009 Question Paper For The Guidance of Teachersmstudy123456No ratings yet

- Self Healing ConcreteDocument21 pagesSelf Healing ConcretethirumalNo ratings yet

- Waste ManagementDocument37 pagesWaste ManagementMontzo Diana BaltonadoNo ratings yet

- Compilación de Investigaciones y Análisis de Coyuntura Ambiental en GuatemalaDocument194 pagesCompilación de Investigaciones y Análisis de Coyuntura Ambiental en GuatemalaPrograma Regional para el Manejo de Recursos Acuáticos y Alternativas EconómicasNo ratings yet

- Achieving MDGs Sanitation Target Through CLTS. PERCIK. Indonesia Water and Sanitation Magazine. December 2008Document53 pagesAchieving MDGs Sanitation Target Through CLTS. PERCIK. Indonesia Water and Sanitation Magazine. December 2008Oswar MungkasaNo ratings yet

- Hho 2Document5 pagesHho 2Prittam Kumar JenaNo ratings yet

- Tugas Alkohol 1 (3 Kelompok)Document39 pagesTugas Alkohol 1 (3 Kelompok)Galuh Eka WulandariNo ratings yet