Professional Documents

Culture Documents

Experiment 6 Effect of Tempering Temperature and Time On Properties of Quench Hardened Steel.

Uploaded by

Anisha ShafikhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment 6 Effect of Tempering Temperature and Time On Properties of Quench Hardened Steel.

Uploaded by

Anisha ShafikhaCopyright:

Available Formats

Experiment 6

EFFECT OF TEMPERING TEMPERATURE AND TIME ON PROPERTIES OF QUENCH HARDENED STEEL

Introduction Three types of steel will be used for this experiment that are low,medium and high carbon steels.All of these will be heated in a furnace at elevated temperature accordingly. Quenching treatment,sometimes called strengthening treatment makes the steel hard and brittle.Quenching refers to cooling from the temperature range of the solid solution at such a rate that transformations in the primary and bainite ranges are suppressed and martensite is formed. In this state, steels are characterized by the greatest hardness. In this experiment,it will use only normal quenching,which is used mainly for treatment of medium and high carbon steels.In this experiment as well,various quenching media will be used.Water,oil,brine and air will serve as cooling medium.Three types of steel are used, low,medium and high carbon steels.All of these will be heated in a furnace at elevated temperature.Tempering process will be use for quenched steel to remove residual stresses that iduced in the rapid cooling,steels later will becomes more softer,ductile and tougher than before the tempering process.

Procedures 1. Steel were selected and must containing more than 0.3% of carbon.Three types of steel were used,low ,mediu ,and high carbon steel. 2. The furnace temperature was set to 920C 3. The samples were placed in the furnace and heated up to 920 C.The heating process was continued at 920C to homogenize the composition. 1 hour usually is about 1 inch thickness. 4. Then,for each types of sample,one sample was left in the furnace to cool down slowly,called annealing process.Another one,was taken out from the furnace and place it on a refractory brick for normalizing process.The others samples then were removed one

by one and quenched in water for 4 samples,one sample were quenched into oil and brine respectively.Temperature was maintained along this process. 5. 1 mm from each surface of steels were removed in order to make sure that the oxidized and decaburized layer is removed.The samples than used standard techniques for microstructural investigation for metallograpic samples preparation 6. All samples then were measured their hardness using hardness machine 7. For part II,the furnace temperature was set to 600C for tempering process.This process only use specimens that were quenched in water. 8. The samples were placed in the furnace and heated up.The samples were only medium and high carbon steel. 9. Just after 1 hour,the samples were readily toremove from the furnace and were prepared for further microstructure examination as well as hardness. 10. The tempering process was repeated using different furnace temperature,500C,400C and 300C

Result

Discuusion

Suggestion/Recommendation

Conclusion.

You might also like

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Carburization of SteelDocument9 pagesCarburization of SteelRtr Ahmed Abidemi CertifiedNo ratings yet

- Wa0000.Document14 pagesWa0000.Shubham GhoshNo ratings yet

- Muhammad Afif Irfan Bin Zakaria 2018400006Document2 pagesMuhammad Afif Irfan Bin Zakaria 2018400006Kabuki MaskNo ratings yet

- Hardening Steel Using Different Quenching Media Fatema 8Document9 pagesHardening Steel Using Different Quenching Media Fatema 8fatema eyadNo ratings yet

- NED University Precipitation Hardening GuideDocument46 pagesNED University Precipitation Hardening GuideManish TiwariNo ratings yet

- Treatment Process For Making Material Softer But Does Not Produce The Uniform Material Properties of AnnealingDocument3 pagesTreatment Process For Making Material Softer But Does Not Produce The Uniform Material Properties of AnnealingSyahirzabidi100% (1)

- Lab Sheet 2Document4 pagesLab Sheet 2Christ LeeNo ratings yet

- Heat Treatment Part 2Document46 pagesHeat Treatment Part 2Naman DaveNo ratings yet

- 16MnCr5 PropertyDocument7 pages16MnCr5 PropertyGuru SamyNo ratings yet

- Heat Treatment of Steels in Different Mediums 2Document17 pagesHeat Treatment of Steels in Different Mediums 2haseebNo ratings yet

- Study and Analysis On Heat Treatment Process and Microstructure of Low Carbon SteelDocument6 pagesStudy and Analysis On Heat Treatment Process and Microstructure of Low Carbon SteelIJARTESNo ratings yet

- Types of Annealing Processes for SteelDocument6 pagesTypes of Annealing Processes for SteelSalim MullaNo ratings yet

- ExperimentsDocument2 pagesExperimentsafnene1No ratings yet

- Heat Treatment Effects on Material PropertiesDocument5 pagesHeat Treatment Effects on Material PropertiesArgha DasNo ratings yet

- Experiment 3:: Heat Treatment of SteelsDocument2 pagesExperiment 3:: Heat Treatment of Steelsafnene1No ratings yet

- Matreial Lab PDFDocument14 pagesMatreial Lab PDFNedaa AbboushiNo ratings yet

- Experiment 3Document2 pagesExperiment 3afnene1No ratings yet

- Experiment 3Document2 pagesExperiment 3afnene1No ratings yet

- Matreial Lab: Dr. Morad EtierDocument14 pagesMatreial Lab: Dr. Morad EtierNedaa AbboushiNo ratings yet

- Heat Treatment Lab ReportDocument12 pagesHeat Treatment Lab ReportCarl Behlmer100% (5)

- CHAPTER - Heat Treatment 3rd Sem ManufacturingDocument11 pagesCHAPTER - Heat Treatment 3rd Sem Manufacturingkaranragav12No ratings yet

- Experiment 2 (High Carbon Steel Heat Treatment)Document1 pageExperiment 2 (High Carbon Steel Heat Treatment)afnene1No ratings yet

- Kulliyyah of Engineering: Heat TreatmentDocument15 pagesKulliyyah of Engineering: Heat TreatmentWafa ZullfakherNo ratings yet

- Case Hardening Heat TreatmentDocument15 pagesCase Hardening Heat TreatmentHazrat BelalNo ratings yet

- Surface Hardening of SteelDocument50 pagesSurface Hardening of SteelTeptep GonzalesNo ratings yet

- Heat Treatment of Metals: Eng. Ahmed Afeefy Eng. Ibrahim AljaishDocument21 pagesHeat Treatment of Metals: Eng. Ahmed Afeefy Eng. Ibrahim AljaishAd Man GeTigNo ratings yet

- Heat Treatment Lab ReportDocument7 pagesHeat Treatment Lab Reportmuvhulawa bologo100% (1)

- Effect of heat treatment on spring steel microstructures and propertiesDocument7 pagesEffect of heat treatment on spring steel microstructures and propertiesMahmood KhanNo ratings yet

- Purpose of Heat TreatmentDocument4 pagesPurpose of Heat TreatmentVenkateshYadavCivarlaNo ratings yet

- Crucible FurnaceDocument27 pagesCrucible Furnaceadelina ednandaNo ratings yet

- Metallurgy Lab 3Document4 pagesMetallurgy Lab 3api-280725686No ratings yet

- What Is Heat TreatmentDocument5 pagesWhat Is Heat TreatmentAbdulbar kelilNo ratings yet

- Ferrous Alloys Microstructure AnalysisDocument12 pagesFerrous Alloys Microstructure AnalysisFadhil AimanNo ratings yet

- Practical 18,19,20Document9 pagesPractical 18,19,20Muhammad AwaisNo ratings yet

- Heat Treatment ProcessDocument31 pagesHeat Treatment ProcessAbhishek IndalkarNo ratings yet

- Report Heat Treatment Eng Lab 3Document7 pagesReport Heat Treatment Eng Lab 3khalifawhan43% (7)

- Heat Treatment ServisDocument10 pagesHeat Treatment ServisMuhammad SyameerNo ratings yet

- Heat Treatment of Medium Carbon SteelDocument29 pagesHeat Treatment of Medium Carbon SteelTejas T S TejasNo ratings yet

- Effect of Carburizing Time and Wear PropDocument6 pagesEffect of Carburizing Time and Wear PropSinan YıldızNo ratings yet

- Effect of Cryogenic Heat Treatment on Metallic MaterialsDocument6 pagesEffect of Cryogenic Heat Treatment on Metallic MaterialsSahil NegiNo ratings yet

- Lesson 6 HeatTreatmentDocument7 pagesLesson 6 HeatTreatmentupenderNo ratings yet

- Induction Furnace Testing of The Durability of Prototype Crucibles in A MoltenDocument7 pagesInduction Furnace Testing of The Durability of Prototype Crucibles in A MoltenOmar TahaNo ratings yet

- Report On Heat Treatment of Plain Carbon Steel Kuet MeDocument11 pagesReport On Heat Treatment of Plain Carbon Steel Kuet MeAhmed JishanNo ratings yet

- Course No: Experiment No:: Structural Study of Mild Steel After Heat TreatmentDocument13 pagesCourse No: Experiment No:: Structural Study of Mild Steel After Heat TreatmentRifat KhanNo ratings yet

- Lab Material 3Document11 pagesLab Material 3Faiz AmeeriNo ratings yet

- Effect of Solution Annealing Heat Treatm PDFDocument3 pagesEffect of Solution Annealing Heat Treatm PDFaltieri1No ratings yet

- JURNALDocument6 pagesJURNALEmka A. Ulil AbsharNo ratings yet

- Effect of Solution Heat Treatment on Ni-Based Superalloy CMSX-4Document6 pagesEffect of Solution Heat Treatment on Ni-Based Superalloy CMSX-4Harish KPNo ratings yet

- Heat Treatment Lab Report ResultsDocument13 pagesHeat Treatment Lab Report ResultsEslam MohamedNo ratings yet

- Effect of Various Heat Treatment Process On Tensile Strength and Elongation of Stainless SteelDocument5 pagesEffect of Various Heat Treatment Process On Tensile Strength and Elongation of Stainless SteelehsanNo ratings yet

- Lecture-6: Heat Treatment of Metals and Alloys - Importance Heat Treatment Processes NormalisingDocument47 pagesLecture-6: Heat Treatment of Metals and Alloys - Importance Heat Treatment Processes NormalisingSarojKumarSinghNo ratings yet

- Thermal Lab 1Document6 pagesThermal Lab 1Muhammad ZulhilmiNo ratings yet

- Effects of Bath Temperature On Cooling Rate, Mechanical Properties and Microstructure of Medium Carbon Steel During Quenching OperationsDocument10 pagesEffects of Bath Temperature On Cooling Rate, Mechanical Properties and Microstructure of Medium Carbon Steel During Quenching OperationsInaamNo ratings yet

- 3.MEET 315LA MatScie Engineering ME Lab Module 3Document52 pages3.MEET 315LA MatScie Engineering ME Lab Module 3Cj TilamNo ratings yet

- Mechanical Properties of Medium Carbon Steel After Heat TreatmentDocument9 pagesMechanical Properties of Medium Carbon Steel After Heat TreatmentKavin PrakashNo ratings yet

- Sponge Iron Production Using Tunnel Kiln ReportDocument20 pagesSponge Iron Production Using Tunnel Kiln Reportzmahfudz100% (1)

- Metallurgical Changes in Steels Due To Cryogenic Processing Its Applications Full ReportDocument15 pagesMetallurgical Changes in Steels Due To Cryogenic Processing Its Applications Full ReportABHI THAKKAR100% (1)

- SURFACE HEAT TREATMENT PROCESSESDocument48 pagesSURFACE HEAT TREATMENT PROCESSESnaseema shaikNo ratings yet

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceDocument12 pages1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- Thermal Physics & Circular MotionDocument2 pagesThermal Physics & Circular MotionMohammad TomaraeiNo ratings yet

- Materials and Design: Khairul Amilin Ibrahim, Billy Wu, Nigel P. BrandonDocument9 pagesMaterials and Design: Khairul Amilin Ibrahim, Billy Wu, Nigel P. BrandonjohnNo ratings yet

- Thermal Conductivity For Solid PDFDocument7 pagesThermal Conductivity For Solid PDFAhmed AlbayatiNo ratings yet

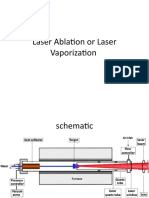

- Laser Ablation or Laser VaporizationDocument4 pagesLaser Ablation or Laser VaporizationJOEL STEPHEN 19BEE0262No ratings yet

- Luban HP2106N (Moplen HP500N) : Polypropylene HomopolymerDocument2 pagesLuban HP2106N (Moplen HP500N) : Polypropylene HomopolymerNazmul - Polymet SA100% (2)

- Fluidization 180402101141Document13 pagesFluidization 180402101141suraj nakumNo ratings yet

- ANALYTICAL METHODS Geochemical Analysis Including X RayDocument23 pagesANALYTICAL METHODS Geochemical Analysis Including X RayDanilo Luiz Donola LoretoNo ratings yet

- Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsDocument4 pagesCopper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsGreg YeeNo ratings yet

- Viscoelastic Bulk ModuliDocument19 pagesViscoelastic Bulk ModulikevinlimyuanlinNo ratings yet

- Light Gage Steel Design ManualDocument85 pagesLight Gage Steel Design ManualD SRINIVAS100% (1)

- 14 Draw Off Nozzle Hydraulics PDFDocument12 pages14 Draw Off Nozzle Hydraulics PDFMohsin EhsanNo ratings yet

- Lecture 26.20081029.49084b9fe41bc1.76327325.20081029.4908941e13c981.68685807Document9 pagesLecture 26.20081029.49084b9fe41bc1.76327325.20081029.4908941e13c981.68685807Aditya CandratamaNo ratings yet

- 2021 Q3 NCFET Dhaka 2Document117 pages2021 Q3 NCFET Dhaka 2Joy ChowdhuryNo ratings yet

- Physics SS2 Term 2 Dec 2022Document71 pagesPhysics SS2 Term 2 Dec 2022TahmidNo ratings yet

- Normalizing - Heat TreatmentDocument3 pagesNormalizing - Heat TreatmentferozNo ratings yet

- รายการคำนวณวิศวกรรมโครงส้ราง แบบที่ 4Document21 pagesรายการคำนวณวิศวกรรมโครงส้ราง แบบที่ 4jackcoolsNo ratings yet

- Material Selection Guide - Endura PlasticsDocument29 pagesMaterial Selection Guide - Endura PlasticsvadiNo ratings yet

- 15-Frictional Properties of Fibers.Document21 pages15-Frictional Properties of Fibers.Fahad HussainNo ratings yet

- M-120 Material Data Sheets For Structural Steel Edition 5Document47 pagesM-120 Material Data Sheets For Structural Steel Edition 5vlong3003100% (3)

- Shell Clavus G68 Properties: Density, Vapour Pressure & Viscosity vs. Concentration & TemperatureDocument5 pagesShell Clavus G68 Properties: Density, Vapour Pressure & Viscosity vs. Concentration & TemperatureJavier AffifNo ratings yet

- Characteristics of Polyglycerol Ester and Its Different FractionsDocument10 pagesCharacteristics of Polyglycerol Ester and Its Different FractionsliliNo ratings yet

- High-performance mortar for concrete fixingsDocument3 pagesHigh-performance mortar for concrete fixingsAndreja GjureskiNo ratings yet

- RocLab Users Guide PDFDocument25 pagesRocLab Users Guide PDFarslanpasaNo ratings yet

- Production of Foam Using Plastic Support: Submitted By: Hritik Lal ID:2018A1PS0281GDocument10 pagesProduction of Foam Using Plastic Support: Submitted By: Hritik Lal ID:2018A1PS0281GHritik Lal100% (1)

- Steam Tables DLL Developer's GuideDocument17 pagesSteam Tables DLL Developer's GuidepetritaNo ratings yet

- CE 322 Mechanics of Deformable BodiesDocument41 pagesCE 322 Mechanics of Deformable BodiesKristine May MaturanNo ratings yet

- Sandvik SteelDocument16 pagesSandvik Steeljohn9999_502754No ratings yet

- Rr320306 Heat TransferDocument8 pagesRr320306 Heat TransferandhracollegesNo ratings yet

- CV BUET (NadimChowdhury) Electrical & Electronic Engineering PDFDocument3 pagesCV BUET (NadimChowdhury) Electrical & Electronic Engineering PDFSujan DebnathNo ratings yet

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (33)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- The Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanFrom EverandThe Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanNo ratings yet

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (811)

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (11)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (221)

- Eels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishFrom EverandEels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishRating: 4 out of 5 stars4/5 (30)

- The Hidden Life of Trees: What They Feel, How They CommunicateFrom EverandThe Hidden Life of Trees: What They Feel, How They CommunicateRating: 4 out of 5 stars4/5 (1002)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (699)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderFrom EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderRating: 4 out of 5 stars4/5 (283)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- Gathering Moss: A Natural and Cultural History of MossesFrom EverandGathering Moss: A Natural and Cultural History of MossesRating: 4.5 out of 5 stars4.5/5 (347)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (63)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraFrom EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraRating: 3 out of 5 stars3/5 (10)

- The Optimist: A Case for the Fly Fishing LifeFrom EverandThe Optimist: A Case for the Fly Fishing LifeRating: 4.5 out of 5 stars4.5/5 (17)

- The Hummingbirds' Gift: Wonder, Beauty, and Renewal on WingsFrom EverandThe Hummingbirds' Gift: Wonder, Beauty, and Renewal on WingsRating: 4.5 out of 5 stars4.5/5 (60)