Professional Documents

Culture Documents

Effect of The Degree and Type of The Dealumination Method On The Structural, Compositional and Acidic Characteristics of H-ZSM5 Zeolites

Uploaded by

JOSEPH HERBERT MABELOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of The Degree and Type of The Dealumination Method On The Structural, Compositional and Acidic Characteristics of H-ZSM5 Zeolites

Uploaded by

JOSEPH HERBERT MABELCopyright:

Available Formats

Eect of the degree and type of the dealumination method

on the structural, compositional and acidic characteristics

of H-ZSM-5 zeolites

Costas S. Triantallidis

a

, Athanasios G. Vlessidis

a

, Lori Nalbandian

b

,

Nicholaos P. Evmiridis

a,

*

a

Laboratory of Inorganic and Analytical Chemistry, Department of Chemistry, University of Ioannina, Ioannina 45 110, Greece

b

Center for Research and Technology Hellas, Chemical Process Engineering Research Institute, P.O. Box 361, 570 01 Thermi,

Thessaloniki, Greece

Received 23 October 2000; received in revised form 12 June 2001; accepted 26 June 2001

Abstract

A series of H-ZSM-5 zeolites with dierent framework Si/Al ratios were prepared by hydrothermal synthesis and

post-synthesis dealumination by various methods, i.e., HCl, steaming, steaming/HCl and ammonium hexauorosilicate

(AHFS). The degree of framework dealumination and the amount/type of the extra-framework phases formed were

greatly dependent on the method of dealumination and the severity of the experimental conditions. The hydrothermal

treatment of a parent ZSM-5 sample with Si/Al ~ 27 was very eective and produced signicant amounts of SiAl

extra-framework phases, while the reaction with HCl in relatively strongly acidic environments resulted in very low

dealumination. Treatment with AHFS was proven to be an appropriate method for preparing moderately dealuminated

H-ZSM-5 samples which are free from extra-framework Al. The relative crystallinity and the microporosity of all

dealuminated H-ZSM-5 zeolites were retained to a high degree (>80%), even for the severely steamed samples (~96%

dealumination). The morphology of the crystals/particles was not changed signicantly; however, each dealumination

method had a dierent eect on the partial breakdown of the crystals and on the formation of extra-framework/

amorphous phases with a mesoporous character. The number of acid sites that corresponded to the high-temperature

desorption peak of the ammomia-temperature programmed desorption spectra was found to be equivalent to the

framework Al (FAl) content of all H-ZSM-5 samples, irrespective of the degree of dealumination and the amount of

extra-framework phases. Theses phases had a low capability of adsorbing ammonia compared to the FAl atoms and

were the main source of acidity for the severely steamed samples which had almost no FAl. 2001 Elsevier Science

B.V. All rights reserved.

Keywords: H-ZSM-5 zeolites; Dealumination; Extra-framework phases; Crystal morphology and porosity; Acidity

1. Introduction

H-ZSM-5 zeolite is a typical example of a shape-

selective acid catalyst [1,2]. Its unique catalytic

performance is attributed to the two-dimensional

Microporous and Mesoporous Materials 47 (2001) 369388

www.elsevier.com/locate/micromeso

*

Corresponding author. Tel.: +30-651-98-404; fax: +30-651-

44-831.

E-mail address: nevmirid@cc.uoi.gr (N.P. Evmiridis).

1387-1811/01/$ - see front matter 2001 Elsevier Science B.V. All rights reserved.

PII: S1387- 1811( 01) 00399- 7

system of intersecting channels and to the rela-

tively low number of strong acid sites due to the

high Si/Al ratio (>10) of the framework [3]. The

chemical uniformity of the Br onsted-type acid sites

(framework hydroxyl groups) in H-ZSM-5 zeolites

with dierent framework Al (FAl) contents has

been proven in the n-hexane cracking test reaction,

where the cracking activity is linearly related to

FAl content, even down to ~20 ppm of Al [4].

Furthermore, infrared (IR) studies of highly crys-

talline H-ZSM-5 zeolites revealed the existence of

one single type of bridging hydroxyl group related

to the FAl atoms [5,6]. However, (hydro)thermal

treatment of ZSM-5 produces extra-framework

Al (EFAl) species which aect the acid catalytic

activity of dealuminated H-ZSM-5 zeolites [710].

This behavior has also been recognized and is even

more pronounced in the case of Y-type dealumi-

nated zeolites [1113]. Furthermore, it has been

shown that both the amount and the type of extra-

framework/amorphous Al or SiAl species/phases

are important in dening the acidity and catalytic

activity of the catalysts. In general, it has been

shown that mild steaming conditions result in

catalysts with enhanced cracking activity either

due to increased acid strength of the remain-

ing framework OH or due to the interaction of

the reactant alkane molecule with both the FAl

hydroxyls and the EFAl species [710,14]. Addi-

tionally, FT-IR studies of hydrothermally dealu-

minated H-ZSM-5 zeolites revealed the formation

of weakly acidic hydroxyls on EFAl species at mild

steaming conditions, which progressively disap-

pear as the severity of the treatment increases [15

17].

In larger scale reactions/processes like the

cracking of gas-oil in uid catalytic cracking

(FCC) units for the production of gasoline and

gaseous products, the performance of ZSM-5 as

additive to the main (RE)USY cracking catalyst

changes gradually as it is being dealuminated/de-

activated between the successive reaction/regenera-

tion steps in the FCC riser and regenerator,

respectively [1,18,19]. The product distribution in

the FCC process shows that the ``fresh'' H-ZSM-5

additive is capable of catalyzing the cracking of

short chain alkanes which requires high acid

strength, but after deactivation it can mainly

contribute to alkene isomerization. In a previous

work, we have shown how the decrease of the

number of acid sites for a series of dealuminated

H-ZSM-5 additives of a commercial RE-USY

catalyst aect the product distribution and prop-

erties in the cracking of gas-oil [20]. The H-ZSM-5

samples used in the referenced work were dealu-

minated by dierent methods and to dierent ex-

tents in order to closely follow the changes induced

by variation in acidity.

A number of dealumination techniques have

been developed for zeolites, especially for the Al-

rich Y-type zeolites, i.e., treatment with steam or

SiCl

4

vapor at elevated temperatures or treatment

with ammonium hexauorosilicate (AHFS), acids

(i.e., HCl), chelating agents (i.e., EDTA), etc.

[1113,2123]. Zeolite ZSM-5 is more resistant to

dealumination and relatively severe process condi-

tions are necessary to obtain highly dealuminated

samples. The most commonly used methods are

the hydrothermal dealumination (sometimes com-

bined with HCl treatment) and the treatment with

SiCl

4

vapors at elevated temperatures [9,1416,24

30], while the use of mineral acids alone has also

been studied [31]. In order to simulate the dealu-

minated/deactivated state of the ZSM-5 additive

in the FCC catalyst, we applied in this work

relatively severe steaming conditions for the de-

alumination of the ZSM-5 samples, while mildly

steamed samples were also prepared to follow the

progressive changes in the acidic properties. Treat-

ment with HCl was also applied either for direct

dealumination or after steaming in order to re-

move the EFAl phases formed. In addition to

these methods, the dealumination of zeolite ZSM-5

with AHFS has also been tested. A limited num-

ber of studies have focused on the dealumination

of ZSM-5 with AHFS [20,32,33], since it is a rela-

tively mild dealumination agent. Its main advan-

tage, however, is that it produces samples almost

free of EFAl species, and this could be benecial

in avoiding the blockage of the acid sites from

EFAl species which can be located either on the

outer surface of the crystals or inside the narrow

channels of ZSM-5 zeolites.

The present study aims at a better understand-

ing of the unique eects that each dealumination

method induces on the compositional, structural

370 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

and acidic characteristics of dealuminated H-

ZSM-5 zeolites and rationalize their catalytic be-

havior in the FCC process as well as in other, acid

catalyzed reactions. The composition of the crys-

talline and extra-framework/amorphous phases of

the samples has been determined by the combina-

tion of chemical analysis and

29

Si

27

Al MAS-NMR

data, while structural and porosity characteristics

were studied by XRD, FT-IR, nitrogen adsorp-

tion/desorption, SEM and TEM experiments. The

acidic characteristics of the H-ZSM-5 samples were

tested by ammonia-temperature programmed de-

sorption (TPD) measurements and correlated

with the composition of the crystalline and amor-

phous phases present in the dealuminated sam-

ples.

2. Experimental section

2.1. Preparation of the samples

The ZSM-5 zeolite samples with dierent Si/Al

ratios were synthesized in this laboratory, based

on the method introduced by Argauer and Landolt

[34], and their crystallographic purity was deter-

mined by X-ray diraction. The as-synthesized

samples were calcined under a ow of dry air at

600C for 3 h in order to combust the organic

template. They were subsequently treated with a

0.25 N HCl acid solution at 80C for 24 h to ion-

exchange Na

by H

and produce the H-form

of the zeolites (samples ZM-1 to ZM-4, Table 1)

or they were ion-exchanged twice with a 1 M

NH

4

NO

3

solution at 80C for 24 h to produce

NH

4

ZSM-5 zeolites.

A calcined ZSM-5 sample (Si/Al = 27) was

treated with an excess of a 1.5 M HCl acid solution

at 90C for 24 h in order to induce framework

dealumination (sample DZM-5). The NH

4

ZSM-5

sample with an Si/Al ratio 27 was treated with

AHFS at 80C for 6 h. Two samples were prepared

by this method; the rst one was treated twice with

a 0.1 N AHFS solution using an amount of AHFS

that matches the FAl content of the zeolitic frame-

work (sample DZM-6); the second sample was

treated ve times with an excess of a 0.5 N AHFS

solution (sample DZM-7). These samples were

transformed to the H-forms by calcination at

530C for 2 h under a ow of dry nitrogen.

The NH

4

ZSM-5 samples were hydrothermally

treated at dierent temperatures (570C, 660C,

730C, 790C), for 6 h under a ow of a nitrogen

steam mixture at a ow rate of 30 ml min

1

and a

steam partial pressure of 90.4 kPa, in order to vary

the severity of steaming and the degree of dealu-

mination (samples DZM-8, DZM-9, DZM-10,

DZM-11). The steamed sample DZM-10 was fur-

ther treated with a 0.2 N HCl solution at 80C for

24 h in order to extract the EFAl species formed

(sample DZM-12).

All the parent and dealuminated samples were

dried at 120C in air for 6 h and were nally stored

over saturated MgCl

2

solution to equilibrate with

water vapor. The parent and dealuminated sam-

ples that were not hydrothermally treated are

usually designated in the text as ``fresh'' samples in

contrast to the steamed samples. All samples pre-

pared and the treatment methods applied are listed

in Table 1.

2.2. Composition and structure characterization

The chemical analysis procedure of the samples

involved a digestion step with 10% HCl, to extract

the Al

3

and Na

into the acid aqueous solution;

silica was then determined gravimetrically from

the solid residue; aluminum was determined in

solution titrimetrically by EDTA complexation;

the sodium content was measured by ame pho-

tometry, and the water content was estimated from

the weight loss after calcining the samples at

550C for 24 h.

The X-ray powder diraction patterns were

obtained on a Siemens D-500 automated dirac-

tometer (CuKa radiation, k = 1:5418

A), in the 2h

range of 535 and at a scanning rate of 2 min

1

.

The zeolites were checked for crystallinity by

comparing the intensity of the (0 5 1) peak of the

dealuminated samples with that of the parent

ZSM-5 zeolite which was considered to be 100%

crystalline. Mid-IR spectra were recorded at 2

cm

1

resolution on a Perkin Elmer 1650 FT-IR

spectrometer using the KBr-pellet technique (1

wt.% zeolite in a KBr matrix). High-resolution

solid state

29

Si MAS NMR spectra were recorded

C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388 371

using a Bruker MSL 400 spectrometer working at

79.49 MHz, with a pulse width of 12 ls, a pulse

delay of 100 s, a spinning rate of 4 kHz and 1000

scans. The

27

Al MAS NMR experiments were run

on a Varian Innity plus AS400 spectrometer

at 104.26 MHz, with a pulse width of 0.5 ls, a

radiofrequency eld strength of 50 G, a pulse delay

of 0.5 s, a spinning rate of 4 kHz and 85,000 scans.

29

Si shifts were referenced to TMS by using an

external sample of sodium 2,2-dimethyl-2-silapen-

tane-5-sulfate (SDS) which gave a single peak at

0 ppm as in the case of TMS, while a 1 M aqueous

Al(NO

3

)

3

solution was used as standard reference

for

27

Al. All samples were dried at 120C in air for

6 h and were nally stored over saturated MgCl

2

solution to equilibrate with water vapor before

testing.

Specic surface area (SSA) and porosity char-

acteristics of the samples were determined from

adsorption/desorption isotherms of nitrogen which

were obtained at 77K on an Automatic Volumet-

ric Sorption Analyzer (Autosorb-1, Quantachrome).

Prior to the determination of the adsorption iso-

therms the samples were evacuated overnight at

500C under 1:0 10

6

mbar vacuum.

Transmission electron microscopy (TEM) im-

ages were obtained on a JEOL JEM-100CX II

microscope with a CeB

6

lament and an acceler-

ating voltage of 120 kV. The TEM samples were

prepared by evaporating one drop of a powdered

zeoliteEtOH suspension (after sonication) onto

a carbon-coated, holey lm supported on a 3

mm, 300 mesh copper grid. The morphology of

the zeolitic particles was also examined by scan-

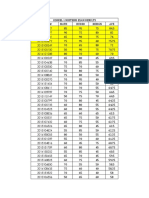

Table 1

Compositional and structural characteristics of the H-ZSM-5 samples (chemical analysis, XRD, FT-IR)

Sample Treatment Chemical analysis Si/Al XRD FT-IR Frequency

of bands

a

Composition (wt.%) Si and Al con-

tent (mg-

atoms g

1

)

(0 5 1)

peak

2h (de-

grees)

Rela-

tive

cryst.

(%)

b

SiO

2

(1)

Al

2

O

3

(0.2)

Na

2

O

(0.03)

H

2

O

(0.3)

Q

TSi

c

(0.01)

Q

TAl

(0.04)

m

1

(cm

1

)

(1)

m

2

(cm

1

)

(1)

ZM-1 Parent 84.77 5.75 0.20 9.16 14.11 1.13 12.5 23.11 ~97.5 1091.3 793.8

ZM-2 Parent 90.34 2.82 0.08 6.54 15.04 0.55 27.2 23.12 100 1099.9 797.2

ZM-3 Parent 92.22 2.13 0.15 5.30 15.35 0.42 36.7 23.16 100 1094.5 794.7

ZM-4 Parent 98.91 0.08 0.06 0.77 16.46 0.02 >10-

00

23.10 100 1104 799.4

DZM-5 HCl 90.41 2.62 0.13 6.68 15.05 0.51 29.3 23.13 94

d

1100.8 797.7

DZM-6 (NH

4

)

2

SiF

6

93.33 1.95 0.14 4.44 15.53 0.38 40.6 23.08 93 1103.6 799.1

DZM-7 (NH

4

)

2

SiF

6

95.24 1.63 0.10 2.94 15.86 0.32 49.6 23.10 92 1104.3 799.7

DZM-8 Steamed,

570C

94.40 2.95 0.08 2.46 15.71 0.58 27.2 23.08 89 1106 800.1

DZM-9 Steamed,

660C

94.98 3.01 0.07 1.82 15.81 0.59 26.8 23.08 84 1106.9 801.4

DZM-10 Steamed,

730C

96.00 3.05 0.07 0.73 15.98 0.60 26.7 23.08 80 1107.7 802

DZM-11 Steamed,

790C

96.35 3.08 0.07 0.42 16.04 0.60 26.5 23.10 82 1107.9 802.6

DZM-12 DZM-10/HCl 96.11 2.33 0.04 1.34 16.00 0.46 35.0 23.11 84 1107.3 802.5

a

Frequencies of the main asymmetric stretch (m

1

) and the main symmetric stretch (m

2

) vibrations.

b

Relative crystallinity of the samples using the (0 5 1) peak intensity from XRD patterns and considering the parent zeolite samples

100% crystalline except for sample ZM-1 which possesses some amorphous material as explained in the text.

c

Q

TSi

and Q

TAl

= total Si and Al contents per gram hydrated sample, where sample = crystalline zeolite plus amorphous material.

d

The parent zeolite for all dealuminated samples (DZM-5 to DZM-12) was sample ZM-2.

372 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

ning electron microscopy (SEM) images which

were taken on a JEOL JSM-6300 scanning mi-

croscope.

2.3. Acidity characterization

The number, strength and distribution of acid

sites were tested by TPD of ammonia experiments

which were performed on a conventional appara-

tus consisting of a cylindrical quartz micro-reac-

tor, a vertical furnace and a thermal conductivity

detector (TCD) of a Shimadzu GC-8A gas chro-

matograph. Typically, a 0.2 g zeolite sample (3 mm

thick bed) was placed in the reactor and was

heated up to 530C with a temperature program of

5Cmin

1

under He ow (5060 ml min

1

); at this

temperature the sample was further heated for 3 h.

Adsorption of dry ammonia (Merck, water free)

took place at 100C, in a static system for 1 h at

1.5 bar ammonia pressure. Prior to desorption the

samples were ushed with He for 1.5 h at 100C

to remove the physically adsorbed ammonia.

Desorption of ammonia was done at a rate of

10Cmin

1

from 100C up to 700C under a He

ow (50 ml min

1

). The desorbed ammonia was

detected on the TCD and then trapped in a 0.01 N

HCl aqueous standard solution. The trapped am-

monia was determined by titrating the excess of

HCl in a 0.01 N standard NaOH solution.

3. Results and discussion

3.1. Total Si and Al contents chemical analysis

The chemical composition of the parent and

dealuminated H-ZSM-5 samples is given in Table

1. The chemical analysis of the samples can pro-

vide the total Si and Al contents, including both

framework and extra-framework species, which

was used to calculated the bulk (total) Si/Al ratio.

The total Si/Al ratio for the parent zeolite samples

(ZM-1 up to ZM-4) ranges from 12.5 to >1000

(ZM-4 was synthesized without any Al source)

while for the samples dealuminated by HCl and

AHFS it ranges from 29 to 50. On the other hand,

the total Si/Al ratio for all the steamed samples is

almost constant and similar to that of the parent

zeolite (~27) since the extra-framework species

formed during the hydrothermal-treatment are not

leached out of the solid, except for the steamed/

HCl-treated sample (DZM-12) which has a bulk

Si/Al ratio of 35.

3.2. Structural properties and relative crystallinity

XRD and FT-IR spectroscopy

The structural and crystallinity characteristics

of the samples were studied by XRD (Fig. 1a) and

FT-IR spectroscopy (Fig. 1b). All the parent

samples are highly crystalline as it is revealed from

their XRD patterns, and they are almost free

from extra-framework/amorphous phases, except

Fig. 1. (a) XRD patterns and (b) IR spectra of the parent

sample ZM-2 and the steamed sample DZM-11.

C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388 373

for ZM-1; this sample possesses some amorphous

material as indicated by the octahedral Al ob-

served in the

27

Al MAS NMR spectra and from

the presence of irregularly shaped particles of ex-

tra-framework phases found in the SEM images,

as discussed below. All the dealuminated samples

(DZM-5 up to DZM-12) were prepared from the

parent sample ZM-2, and their relative crystallin-

ity (compared to ZM-2) was estimated on the ba-

sis of the intensity of the (0 5 1) peak in the XRD

pattern which is characteristic of the ZSM-5

structure. Relative crystallinity data and the posi-

tion of the (0 5 1) peak (at ~23 2h) for all the

samples are given in Table 1. It can be seen that all

the dealuminated samples retain a relative crys-

tallinity equal to or higher than 80%; furthermore,

the position of the (0 5 1) peak is slightly aected

by dealumination (framework dealumination in-

creases from DZM-5 to DZM-12 as shown below).

Consequently, the dimensions (a; b; c) and the

volume of the unit cell (not shown here) do not

change signicantly and systematically with de-

alumination of the parent ZSM-5 sample; this can

be attributed to the relatively small changes that

occur in the unit cell of a ZSM-5 zeolite, even

when all the Al is removed from its framework,

since the parent sample usually does not have

more than 34 Al atoms per unit cell (and 9293 Si

atoms). Similar results for the dealumination of

large ZSM-5 crystals have been previously re-

ported [27].

In contrast to the unit cell parameters, the IR

frequencies of the main asymmetric stretch vi-

bration (at ~10911108 cm

1

) and of the main

symmetric stretch vibration (at ~790802 cm

1

)

are systematically aected by dealumination.

Straightforward relationships between the fre-

quencies of the vibrations and the FAl content of

all the dealuminated samples were derived (as

shown below), irrespective of the method of de-

alumination and the extra-framework phases pre-

sent in the samples.

3.3. Framework Al content solid state MAS NMR

spectroscopy

29

Si and

27

Al solid state MAS NMR spectro-

scopy is usually applied for the determination of

the FAl and EFAl content of zeolites, as well as for

examining the coordination state of EFAl species

[10,15,16,23,24,3544]. In the present study, the

FAl content of the dealuminated ZSM-5 samples

was determined based on the integrated intensity

(area) of the peak at ~54 ppm (assigned to tetra-

hedrally coordinated Al) in the

27

Al MAS NMR

spectra by using an appropriate calibration line as

explained below.

27

Al MAS NMR spectra for the parent material

ZM-2 and samples dealuminated in dierent

manners are shown in Fig. 2. The parent ZM-2

sample (as well as the rest of parent samples)

shows a strong peak at ~54 ppm due to tetra-

hedrally coordinated FAl and a very weak peak at

~0 ppm due to octahedrally coordinated EFAl;

these few EFAl species in the parent samples were

formed during the calcination of the as-synthe-

sized zeolites for the combustion of the organic

template and the subsequent treatment with dilute

HCl solution to produce the H

-forms of the

samples. The eect of these treatments is stronger

on the Al-rich ZM-1 parent sample (stronger peak

due to EFAl species), although some amorphous

unreacted material was also observed in the as-

synthesized ZM-1 sample, indicating the diculty

of synthesizing Al-rich (Si/Al ~10) ZSM-5 zeolites.

The spectra of the AHFS-dealuminated sample

DZM-7 shows only the peak at ~54 ppm, sup-

porting the idea that AHFS-dealumination pro-

duces EFAl-free samples, as in the case of Y-type

zeolites [11,23,45].

The spectra of all the steamed samples show the

peak at ~54 ppm and a broad peak at ~0 ppm due

to octahedrally coordinated EFAl. The intensity of

the peak at ~54 ppm decreases progressively with

increasing severity of the hydrothermal treatment

(higher steaming temperature), while the peak at

~0 ppm decreases slightly instead of increasing

as a consequence of the formation of more EFAl

species. Furthermore, treatment of the steamed

sample DZM-10 with dilute HCl solution for the

extraction of the EFAl species leads to an increase

of the peak at ~0 ppm (although some EFAl

species were removed from the sample as shown

below), while the 54 ppm peak was not aected

signicantly. These results are in accord with pre-

viously reported data on the presence of ``NMR-

374 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

invisible'' EFAl in steamed ZSM-5 and Y zeolite

samples [10,15,16,38,43,44]. The chemical nature

of these EFAl species was assigned to oligomeric

alumina with a low degree of hydration/hydroxy-

lation which is dicult to be ion-exchanged, i.e. by

NH

4

ions. However, rehydration or complexa-

tion of these species with acetylacetone can make

them ``NMR-visible'' in the form of Al(H

2

O)

3

6

or

Al(acac)

3

complexes [10,43,44]. The broad peak/

shoulder at ~3040 ppm which was previously

observed in mildly steamed ZSM-5 [10,16] and

assigned to either tetrahedrally coordinated EFAl

species or 5-coordinated EFAl species, in analogy

to steamed Y-zeolite samples [11,22,38,4245], was

not clearly identied in the steamed samples of this

work; the very weak peak/shoulder observed at

~45 ppm could hardly be assigned to EFAl spe-

cies, and furthermore its intensity was very low

compared to the peaks of the tetrahedral FAl

atoms and the octahedral EFAl species. The rela-

tively harsh steaming conditions applied in this

work and the low FAl content of the parent

sample (Si/Al ~ 27) may account for the absence

of the peak at 3040 ppm which is related to Al

species in an intermediate, extra-framework envi-

ronment between the framework tetrahedral Al

and the extra-framework octahedral Al.

The intensities (areas) of the peak at 54 ppm

due to framework tetrahedral Al, estimated after

deconvolution of the experimentally determined

27

Al MAS NMR spectra of the samples using

mixtures of Gaussian and Lorentzian curves, are

given in Table 2. The calibration line for the

determination of the FAl content of the dealu-

minated samples was estimated based on the par-

ent sample ZM-1 and the dealuminated samples

DZM-6 and DZM-7. The FAl content of sample

ZM-1 was determined based on its

29

Si MAS

NMR spectra (shown in Fig. 3); ZM-1 is a ZSM-5

sample relatively rich in Al, and this enabled us to

estimate the framework Si/Al ratio by using the

equation Si=Al = I

(total)

=0:25 I

Si(1Al)

[16,35,37,39].

From the relative intensities of the deconvoluted

Gaussian peaks of the spectra in Fig. 3 and by

using the above equation, the framework Si/Al

ratio of ZM-1 was estimated to be 22.6. The

Fig. 2.

27

Al MAS NMR spectra of the parent sample ZM-2, the AHSF-dealuminated sample DZM-7 and the steamed samples

DZM-9 to DZM-12.

C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388 375

framework Si (FSi) and FAl contents of ZM-1

were then calculated based on the following

equations:

Q

FAl

= (N

FAl=u:c:

=MW) Y

Q

FSi

= (N

FSi=u:c:

=MW) Y

(1)

where Q

FAl

and Q

FSi

are the FAl and FSi contents,

respectively (in mg-atoms per gram hydrated solid

sample, where ``sample'' denotes the crystalline

zeolite plus amorphous material); N

FAl

/u.c. and

N

FSi

/u.c. are the number of FAl and FSi atoms per

dehydrated unit cell, respectively; N

FAl=u:c:

= 4:06,

N

FSi=u:c:

= 96 N

FAl=u:c:

= 91:94 (framework Si/

Al = 91:94/4:06 = 22:6, from

29

Si MAS NMR);

u.c.: unit cell; MW: weight of the dehydrated unit

cell; Y = (100 wt:% H

2

O of sample)=100 (Ta-

ble 1).

The FAl content of the AHFS-dealuminated

samples DZM-6 and DZM-7 can be considered to

be identical with the total Al (TAl) content (de-

termined by chemical analysis, Table 1) since the

27

Al MAS NMR spectra (Fig. 2) revealed the

absence of any EFAl in these samples. The FAl

contents determined (per g sample) for ZM-1,

DZM-6 and DZM-7 were then correlated to the

area of the peak at ~54 ppm of the

27

Al MAS

NMR spectra (Table 2), and a straight line with a

very good correlation coecient (r

2

= 0:9998) was

derived passing through the origin. From the in-

tercept and the slope of the above calibration line

the following equation was derived which was used

for the estimation of the FAl content per gram of

sample, from the area of the 54 ppm peak of the

27

Al MAS NMR spectra of the rest of the parent

and dealuminated samples:

Q

FAl

= (I 0:119)=46:94 (2)

where Q

FAl

is the FAl content (in mg-atoms per

gram hydrated solid sample), I is the intensity of

the 54 ppm peak of the

27

Al MAS NMR spectra

Fig. 3.

29

Si MAS NMR spectra of the parent sample ZM-1

(experimental spectra and deconvoluted peaks).

Table 2

FAl content of the H-ZSM-5 samples

Sample Framework Al content Degree of de-

alumination

a

(%)

Intensity of

27

Al-NMR peak at 54

ppm (arb. units 10

7

)

Q

FAl

(mg-atoms g

1

)

sample (0.04)

Q

FAl

b

(mg-atoms g

1

)

crystalline zeolite (0.04)

ZM-1 30.0 0.64 ~0.66

ZM-2 25.0 0.54 ~0.54

ZM-3 18.6 0.40 ~0.40

ZM-4 0.8 0.02 ~0.02

DZM-5 22.8 0.49 0.52 4

DZM-6 17.7 0.38 0.41 24

DZM-7 14.7 0.32 0.35 35

DZM-8 9.0 0.19 0.21 61

DZM-9 4.2 0.09 0.11 80

DZM-10 1.6 0.04 0.05 91

DZM-11 0.6 0.02 0.02 96

DZM-12 1.6 0.04 0.05 91

a

Based on the values of Q

FAl

per gram crystalline zeolite with reference to the parent sample ZM-2.

b

Q

FAl

per gram crystalline zeolite = (Q

FAl

per gram sample) (1=C), where C = (% relative crystallinity)=100 (Table 1).

376 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

(peak area in arb. units) and 0.119 and 46.94 are

the intercept and slope, respectively, of the cali-

bration line. The estimated FAl content per gram

sample, the estimated FAl content per gram of

crystalline zeolite and the degree of framework

dealumination for the dealuminated samples, are

given in Table 2. By considering a 10% error in the

determination of the intensity of the 54 ppm peak

of sample DZM-6, the error in the estimation of

the FAl content by Eq. (2) is 0.04 mg-atoms

per gram hydrated sample, which is similar to the

estimated error for the determination of the Al

content by chemical analysis (Table 1).

From the data in Table 2 it can be seen that

dealumination by HCl acid solution under the

relatively strongly acidic conditions applied for

sample DZM-5 is not an eective method for

ZSM-5 zeolites (4% framework dealumination

compared to the parent sample ZM-2), in accord

with previously reported data [31]. On the other

hand, the hydrothermal treatment is very eective;

dealumination increases rapidly with the steam-

ing temperature (when keeping all other condi-

tions constant) and reaches almost 96% at 790C

(DZM-11). In addition, mild treatment of the

steamed sample DZM-10 with HCl acid solution

does not aect the FAl content and removes a

small amount of EFAl species, as can be seen from

the data in Tables 1 and 3.

In the case of AHFS, a two-fold treatment of

ZM-2 with a total amount of AHFS which cor-

responds to 100% of its framework dealumination,

resulted in only 24% dealumination (DZM-6).

Extensive treatment with an excess of AHFS re-

sulted in 35% dealumination (DZM-7). However,

the advantage of this method is that no EFAl

phases are formed, as discussed below. In a recent

work, Han et al. [32], showed that dealumination

of ZSM-5 extrudates by AHFS under static di-

gestion conditions leads to selective removal of the

surface acidity, while the total number of acid sites

measured by NH

3

-TPD and hexane cracking was

reduced by approximately 30%. The authors sug-

gested that this limited dealumination was due to

the static system applied which could not favor the

diusion of the SiF

2

6

anion inside the ZSM-5

channels. The results of the present work, based on

27

Al MAS NMR and chemical analysis data, show

that the degree of ZSM-5 framework dealumi-

nation by AHFS does not increase signicantly

under stirring conditions, provided that the frame-

work Si/Al of the parent ZSM-5 samples in both

works was ~30. In a previous work on the de-

alumination of Y-zeolite by AHFS [23], we showed

that AHFS selectively removes the FAl atoms that

contribute to acid sites of weak or medium acid

strength, leaving the strong acid sites almost unaf-

fected up to ~50% dealumination of the Y-zeolite

framework. Furthermore, the dealumination ac-

tivity of AHFS was signicantly decreased after

50% dealumination, resulting in Y-zeolites with

very low crystallinity. Based on the results on both

Y and ZSM-5 type zeolites, it can be suggested

that the reaction of the SiF

2

6

anions and the FAl

atoms is mainly dependent on the number (den-

sity) of the FAl atoms and how this aects the

stability of the zeolite framework.

3.4. Formation of extra-framework phases in the

dealuminated H-ZSM-5 samples

The dierence between the values of Q

TAl

(mg-

atoms of total Al per gram sample, Table 1) and

Q

FAl

(mg-atoms of FAl per gram sample, Table 2)

gives the (EFAl) content of the samples. These

data are given in Table 3, together with compo-

sitional data of the extra-framework/amorphous

phases formed in each sample, i.e., the contents of

extra-framework Si and Al expressed as %SiO

2

and %Al

2

O

3

and the Si/Al ratio of the extra-

framework/amorphous phases. In addition, the

27

Al MAS NMR spectra provided with infor-

mation on the coordination of the Al atoms in

framework and extra-framework environments, as

discussed above. From the data in Table 3 it can

be seen that almost half of the TAl content of the

parent sample ZM-1 is on extra-framework sites.

The total Si content of this sample (determined

by chemical analysis) was found similar to the

framework Si content (determined by

29

Si MAS

NMR); thus the small amount of extra-frame-

work/amorphous material that exists in ZM-1

consists mainly of Al (~2.5% Al

2

O

3

). The EFAl

content of the other parent samples ZM-2, ZM-3

and ZM-4 and of the HCl-dealuminated sam-

ple DZM-5 is even lower than that of ZM-1, viz.

C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388 377

below the estimated experimental error. The

presence of EFAl species in the parent samples was

conrmed by the small peak at ~0 ppm in the

27

Al

MAS NMR spectra which corresponds to octa-

hedrally coordinated EFAl; the origin of these

EFAl species was discussed above.

By comparing the Q

TAl

and Q

FAl

values of

the AHFS-dealuminated samples DZM-6 and

DZM-7 it can be seen that they are the same and

practically no EFAl species were formed during

this treatment, as also conrmed by the

27

Al

MAS NMR spectra. However, a small amount

of amorphous material was present in these sam-

ples which mainly consisted of Si species. On the

other hand, the steamed samples possess signi-

cant amounts of EFAl species relative to their TAl

content; the amount of these species was found

to increase with increasing steaming temperature

(Table 3), although this was not shown in the

27

Al

MAS NMR spectra because of the ``NMR-invisi-

ble'' EFAl species, as discussed above. The ma-

jority of the EFAl species of the steamed samples

was found in octahedral coordination; however,

by applying relatively mild steaming conditions

(~350540C) the progressive transformation of

the EFAl from an extra-framework tetrahedral

environment to the octahedral coordination can

be monitored by

27

Al MAS NMR spectroscopy

[10,16,26]. Treatment of the steamed sample

DZM-10 with dilute HCl solution removed only

25% of the EFAl species, indicating that the

greater part exists as Al or SiAl oligomers which

are not easily ion-exchangeable, in accord with the

27

Al MAS NMR data regarding the presence of

``NMR-invisible'' EFAl species in the steamed

samples. The Si/Al ratio of the amorphous phases

of all the steamed samples is ~45 and 5.5 for the

HCl/-extracted steamed sample, indicating that

there is almost an equilibrium in the removal of Si

and Al atoms from the crystalline framework at

the dierent steaming conditions applied for these

samples.

3.5. Correlation of the framework Al content with

the infrared stretching vibrations

In addition to MAS NMR spectroscopy,

straightforward relationships between the unit cell

size (XRD) and the frequencies of certain stretch-

ing vibrations (IR) of Y-type zeolites have been

previously reported and can be used for the de-

termination of the FAl content of samples with

Table 3

Composition of extra-framework phases

Sample EFAl content Q

EFAl

a

(mg-atoms g

1

)

(0.04)

Si and Al content of extra-framework phases (%)

Amorphous material

b

Al

2

O

3

c

(0.2) SiO

2

d

(1) Si/Al

ZM-1 0.49 2.5 2.50

ZM-2 ~0(0.01) ~0(0.05)

ZM-3 ~0(0.02) ~0(0.10)

ZM-4

DZM-5 ~0(0.02) 6 ~0(0.10) 5.9

DZM-6 7 7.0

DZM-7 8 8.0

DZM-8 0.39 11 1.99 9.0 3.8

DZM-9 0.50 16 2.55 13.5 4.5

DZM-10 0.56 20 2.85 17.2 5.1

DZM-11 0.58 18 2.96 15.0 4.3

DZM-12 0.42 16 2.14 13.9 5.5

a

Estimated from the dierence Q

TAl

Q

FAl

(Tables 1 and 2, respectively).

b

Estimated from % relative crystallinity (XRD) of the dealuminated samples DZM-5 to DZM-12 (Table 1); for the parent sample

ZM-1 the amorphous phase consists mainly of Al which has been estimated as %Al

2

O

3

.

c

The extra-framework %Al

2

O

3

of the samples has been estimated from the values of Q

EFAl

.

d

The extra-framework %SiO

2

of the samples has been estimated from the dierence (% amorphous material extra-framework

%Al

2

O

3

).

378 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

framework and extra-framework phases [4648].

In order to test the application of similar rela-

tionships for the dealuminated ZSM-5 samples,

the determined FAl contents of the parent (ZM-2)

and all the dealuminated samples were correlated

to the main asymmetric stretching vibration at

~10911108 cm

1

(internal vibrations of the TO

4

tetrahedra-structure insensitive) and to the main

symmetric stretching vibration at ~790802 cm

1

(external linkages between the tetrahedra-structure

sensitive). The resulting curves were straight lines

with good correlation coecients (0.975), irre-

spective of the method of dealumination and the

amount/type of EFAl species present in the sam-

ples, as can be seen in Fig. 4a and b. From the

intercept and the slope of the straight lines in Fig.

4a and b the following equations were derived

which can be used for the estimation of the FAl

content per gram of samples:

Q

FAl

= (1108:3 m

1

)=14:48

Q

FAl

= (802:5 m

2

)=9:76

(3)

where Q

FAl

is the FAl content (in mg-atoms per

gram hydrated solid sample) and m

1

and m

2

are

the frequencies of the main asymmetric and main

symmetric stretching vibrations of IR spectra

(Table 1). The estimated error in the determination

of the IR frequencies was found to be 1 cm

1

,

which corresponds to ~0.06 (for m

1

) and 0.10

(for m

2

) mg-atoms FAl per gram hydrated sample.

3.6. Adsorption and porosity characteristics N

2

adsorption/desorption

Adsorption and porosity characteristics of the

parent and dealuminated samples derived from

nitrogen adsorption/desorption isotherms at 77 K

are given in Table 4. The relative isotherms for

the parent ZM-2 and ZM-4 samples, the AHFS-

dealuminated sample DZM-7 and the steamed sam-

ple DZM-11 are shown in Fig. 5. The adsorption

isotherm of ZM-2 is typical for an Al-rich crystal-

line/microporous H-ZSM-5 sample with relatively

small spheroid particles (~0.52 lm) which consist

of smaller individual crystallites, as it was revealed

by the SEM and TEM images (shown below). On

the other hand, ZM-4 is an Al-free highly crystal-

line sample with relatively large single crystals (~5

10 lm) of rectangular parallelepiped shape. The

type of isotherm that it exhibits is also well known

and has been a matter of detailed study in the past

leading to the conclusion that the two plateaus of

the isotherm (below 0.1 and above 0.2p=p

0

) cor-

respond to two dierent states of the adsorbed

nitrogen, a liquid-like and a solid-like phase, re-

spectively [4952]; the explanation of close packing

of the nitrogen molecules at the intersections of the

channels has also been suggested [53]. The shape

and position of the observed hysteresis loop were

found in previous work to be dependent on the

size of the ZSM-5 crystals and the content of FAl;

Fig. 4. Correlation of the frequencies of the main asymmetric

stretching vibration (a) and the main symmetric stretching vi-

bration (b) of the IR spectra with the FAl-content for the

parent sample ZM-2 and all the dealuminated samples.

C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388 379

larger crystals and a lower Al content resulted in a

steep increase of the adsorption isotherm and a well-

dened hysteresis loop at relative pressures lower

than 0.2p=p

0

.

Table 4

Surface area and porosity characteristics of the H-ZSM-5 samples

Samples SSA

a

(m

2

g

1

) Micro-area

b

(m

2

g

1

)

External area

b

(m

2

g

1

)

Micro-pore

volume

b

(cm

3

g

1

)

Total pore

volume

c

(cm

3

g

1

)

Meso- macro-

pore volume

(cm

3

g

1

)

ZM-1 387 347 40 0.142 0.194 0.052

ZM-2 416 331 85 0.136 0.231 0.095

ZM-3 429 331 98 0.141 0.232 0.091

ZM-4 386 349 37 0.167 0.209 0.042

DZM-5 404 319 85 0.131 0.227 0.096

DZM-6 397 323 74 0.140 0.228 0.088

DZM-7 378 303 75 0.142 0.255 0.113

DZM-8 371 315 56 0.148 0.223 0.075

DZM-9 367 308 59 0.148 0.227 0.079

DZM-10 374 285 89 0.135 0.240 0.105

DZM-11 364 281 83 0.129 0.222 0.093

DZM-12 385 303 82 0.141 0.238 0.097

a

Multipoint BET surface area.

b

t-plot method.

c

At P=P

0

~ 0:99.

Fig. 5. Nitrogen adsorption/desorption curves for the parent samples ZM-2 and ZM-4, the AHSF-dealuminated sample DZM-7 and

the steamed sample DZM-11.

380 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

Although the eect of the FAl content on the

shape of the nitrogen adsorpition/desorption iso-

therms can be recognized in both the dealuminated

samples DZM-7 and DZM-11 (Fig. 5), it is clear

that the isotherms of DZM-11 are dierent from

those of DZM-7 and ZM-4. In the mildly AHFS-

dealuminated sample DZM-7 the observed step in

the adsorption branch and the relative hysteresis

loop have developed to a small degree and are

located at a relative pressure below 0.2p=p

0

; how-

ever, a small increase of the total pore volume due

to a higher macropore volume can be observed in

this sample compared to the parent sample ZM-2

(Table 4). On the other hand, the severely dealu-

minated, steamed sample DZM-11, which has prac-

tically the same Al content as the sample ZM-4

(almost Al-free), exhibits a broader step in the

adsorption branch and a more pronounced hys-

teresis loop between 0.1 and 0.4p=p

0

. However, the

total pore volume of this sample, like the one of

the other steamed samples, is similar to that of the

parent zeolite (Table 4), indicating that this hys-

teresis loop could not be assigned to any sig-

nicant, ordered mesoporosity that might have

developed after steam dealumination of the parent

ZSM-5 sample (the absence of a Bragg peak due to

ordered mesoporosity in the low-angle region of

the XRD patterns of the steamed samples support

the above nitrogen adsorption results). In general,

from the data of Table 4 it can be seen that the

SSA of the parent sample ZM-2 does not decrease

by more than ~13% in the most strongly dealu-

minated samples (DZM-11), while the highest in-

crease in the total pore volume, which has been

observed in the AHFS-treated sample DZM-7,

does not exceed 20% of the total pore volume of

the parent sample ZM-2. These data are in accord

with the high relative crystallinity (XRD) of the

dealuminated samples and are further supported

by the TEM images of the crystals/particles, as

reported below.

3.7. Crystal/particle morphology and structural

characteristics transmission electron microscopy

The crystal/particle morphology and structural

characteristics regarding the pores and cages of

zeolites or other micro- and mesoporous materi-

als can be examined by the use of TEM [41,54,

55]. Furthermore, the changes induced to the

crystalline, microporous structure of zeolites after

post-synthesis dealumination by steaming or other

methods, can be visualized more easily by the use

of TEM; related data has been reported for de-

aluminated Y-type zeolites [56,57], ferrierites [58],

mordenites [59], and mazzites [60].

Fig. 6 shows the TEM images of the parent

sample ZM-2 (Fig. 6a and b). It can be seen that

the individual crystals have an almost rectangular

shape with dimensions of 100800 nm; appropriate

stacking or agglomeration of these crystals result

in the formation of bigger particles with spheroid

shape and dimensions of ~0.52 lm, as also found

by the SEM images (not shown here). The mor-

phology of the crystals/particles observed in the

TEM images of the dealuminated samples was

not changed signicantly compared to the parent

sample, in accord with the high degree of crystal-

linity and microporosity of all the samples. How-

ever, the dierent eect of the degree and the type

of dealumination method on the partial break-

down of the crystals and on the formation of ex-

tra-framework/amorphous phases could be easily

identied. The image shown in Fig. 6c is repre-

sentative of the morphology of the modied crys-

tals/particles observed in the AHFS-dealuminated

sample DZM-7; it can be seen that a small number

of relatively big voids (2050 nm) are formed on

the crystals while the edges of the crystals are not

sharp and well-dened as in the parent sample. In

addition, the phases shown in Fig. 6d have been

observed in DZM-7 and are agglomerates of very

small particles (2040 nm) with irregular shape;

the voids formed between these particles are in

the range of 510 nm. The images of the modied

crystals/particles of the more severely dealumi-

nated, steamed sample DZM-11, shown in Fig. 6

eg, are dierent from those of the AHFS-dealu-

minated sample. The particle shown in Fig. 6e is

more damaged (showing a sponge-like structure)

compared to the one of Fig. 6c, while numerous

holes of dierent sizes (520 nm) can be clearly

seen on the crystals of Fig. 6f. Furthermore, the

phases shown in Fig. 6g are nearly amorphous

(based on electron diraction data), and they

C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388 381

resemble a wormhole-like structure with pores in

the range of 25 nm; that pore size is in agree-

ment with the mean pore diameter (~2.7 nm) of

DZM-11 which was estimated by the Horvath

Kawazoe method based on the nitrogen adsorp-

tion data.

Fig. 6. Transmission electron micrographs of the parent sample ZM-2 (a,b), the AHSF-dealuminated sample DZM-7 (c,d), and the

steamed sample DZM-11 (eg).

382 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

3.8. Acidity characteristics of the H-ZSM-5 sam-

ples ammonia-temperature programmed desorp-

tion

The number and distribution of acid sites were

tested by ammonia-TPD experiments. By com-

paring the results of previous works regarding

Y-type [23,6163] or ZSM-5 type [6,26,27,6270]

zeolites, it was revealed that ammonia-TPD data

depend largely on the experimental conditions, i.e.

adsorption temperature, ``stripping'' temperature

and time, desorption heating rate, carrier gas ow

rate. In the present study, adsorption of ammonia

took place at 100C in a static system, followed by

stripping with dry pure helium for 1.5 h at the

same temperature. This time was sucient for the

TCD signal to be stabilized in all the tested sam-

ples. Desorbed ammonia was then monitored be-

tween 100C and 700C.

The TPD curves of selected samples are given in

Fig. 7. The TPD curves were deconvoluted into

individual desorption peaks of Gaussian shape, as

also shown in Fig 7. Before applying the decon-

volution procedure, the chromatographs were

baseline corrected by subtracting the ``blank'' TPD

experiments which were performed without the

adsorption of ammonia. The resulting peaks were

classied and grouped into two types of acid

sites with dierent acidity strength, i.e. weak and

strong, according to the temperature of the peak

maximum. The above characterization of the acid

sites is a qualitative indication of how strongly

the ammonia molecules are connected to the acid

sites. A quantitative determination of the acidity

strength of the acid sites from ammonia-TPD data

can be performed by applying appropriate calcu-

lation models [65,71,72]. The temperature range

for the peak maxima of the weak acid sites was set

between 150C and 220C and for the strong acid

sites above ~350C.

The total number of acid sites (mmoles NH

3

per gram hydrated sample), determined for each

sample from the total desorbed ammonia, and the

number of acid sites of weak and strong acidity,

estimated from the relative area of the deconvo-

luted peaks, are given in Table 5. The temperature

of the peak maximum of each individual desorp-

tion step and the ratio of the strong acid sites to

the weak acid sites are also given in Table 5. The

repeatability of the measurements was tested by

performing ve replicates of the TPD measure-

ments for the parent sample ZM-2 keeping all the

Fig. 7. Ammonia-TPD curves of the parent sample ZM-2, the AHSF-dealuminated sample DZM-7, and the steamed samples DZM-8

and DZM-11 (experimental spectra and deconvoluted peaks).

C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388 383

experimental conditions the same. The resulting

mean value (m) was found to be 1.05 mmoles NH

3

per gram hydrated sample, the standard deviation

(s) was 0.04, and for a condence level of 95%,

1:05 0:05 mmol NH

3

per gram hydrated sample

was calculated. The relative standard deviation

(RSD) was estimated to be 3.6%.

3.9. Eect of the degree and the type of dealumi-

nation method on acidity

In Fig. 8 the total number of acid sites is plotted

against the contents of TAl (Fig. 8a) and of FAl

(Fig. 8b). From Fig. 8a it becomes clear that the

total amount of desorbed ammonia (total number

of acid sites) is linearly correlated with the TAl-

content only for the parent and the dealuminated-

fresh (dealuminated by HCl and AHFS) H-ZSM-5

samples, with the exception of the parent sample

ZM-1. All the hydrothermally dealuminated sam-

ples as well as ZM-1 possess signicant amounts of

EFAl species which apparently have a lower ca-

pability of adsorbing ammonia compared to the

FAl atoms; as a result these samples are below the

line that connects the samples that possess mainly

FAl atoms. On the other hand, when the total

amount of desorbed ammonia is plotted against

Table 5

Acidic characteristics of the H-ZSM-5 samples

Samples Acidic FAl

a

(mmol g

1

)

Number of acid sites (desorbed ammonia) (mmol g

1

sample) Strong/weak

(mole ratio)

Total (0.05) Weak Strong

ZM-1 0.58 1.15 0.56 (218)

b

0.59 (330 436 608) 1.05

ZM-2 0.51 1.05 0.53 (218) 0.52 (342 435 610) 0.98

ZM-3 0.35 0.7 0.33 (208) 0.37 (338 426 593) 1.12

ZM-4 ~0 0.07 0.07 (~150)

DZM-5 0.45 0.89 0.45 (218) 0.44 (339 438 605) 0.98

DZM-6 0.34 0.68 0.35 (208) 0.33 (354 438) 0.94

DZM-7 0.29 0.52 0.25 (199) 0.27 (350 423) 1.08

DZM-8 0.16 0.45 0.27 (151 203) 0.18 (361 508) 0.67

DZM-9 0.07 0.21 0.13 (169 230) 0.08 (360 524) 0.62

DZM-10 0.02 0.11 0.07 (163 221) 0.04 (331 522) 0.57

DZM-11 ~0 0.09 0.09 (160 233)

DZM-12 0.03 0.14 0.10 (156 223) 0.04 (350 524) 0.40

a

Estimated from the FAl content in Table 2 after subtracting the Na

that has not been ion-exchanged by H

.

b

The numbers in parentheses represent the temperature peak maxima at degrees Celsius of the individual/deconvoluted desorption

peaks.

Fig. 8. Correlation of the amount of the total desorbed am-

monia (TPD) with the TAl content (a) and the FAl content (b),

for () parent samples, (_) AHFS dealuminated samples, (M)

HCl dealuminated sample, (j) steamed samples, ( ) steamed/

HCl sample (the dashed line corresponds to a 1:1 analogy).

384 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

the FAl content (Fig. 8b) all the samples fall on

a single line with a high correlation coecient

(0.990). However, the intercept value of this line is

little higher than zero, i.e. 0.08, and the slope value

is 1.82 which means that almost two ammonia

molecules correspond to each FAl atom. It has

been previously shown that the amount of am-

monia of the low-temperature peak is nearly the

same as that of the high-temperature peak in the

TPD spectra of fresh H-ZSM-5 zeolites [27,66,67];

this is now conrmed for hydrothermally dealu-

minated samples as well and is extended down to

very low FAl content values.

In order to examine the relation between the

desorbed ammonia that corresponds to the high-

temperature peaks (strong acid sites) and to the

low-temperature peaks (weak acid sites), the rela-

tive data from Table 5 were plotted against FAl

content, as shown in Fig. 9a and b respectively.

The slope of the mean line in Fig. 9a is 0.99 and

the intercept value is ~0. These results are in

accord with previous works [6,62,63,6669,73],

which suggest that the high-temperature peak of

the TPD spectra or the strong acid sites (and the

related amount of ammonia) correspond to the

FAl atoms of fresh H-ZSM-5 zeolites (OH of

the FAl atoms that give rise to the framework

Br onsted acidity). Based on the data of the present

work, the above suggestion can be extended also to

steam-dealuminated samples with low FAl con-

tent. In addition, the above suggestion of the 1:1

analogy between the ammonia desorbed from

strong acid sites and the FAl content is veried by

the thermal decomposition of the NH

4

ZSM-5

sample; the recorded spectra and the amount of

ammonia detected were similar to those that cor-

respond to the high-temperature peak of the TPD

spectra. Based on the above data and with regard

to the specic experimental conditions of the TPD-

tests, the intercept and the slope estimated from

the equation of the straight line in Fig. 9a can be

used for the determination of the FAl content per

gram sample of the H-ZSM-5 zeolites, irrespective

of the degree of dealumination and the amount of

extra-framework phases present in the samples.

The slope of the mean line for the fresh samples

in Fig. 9b (low-temperature peak) is 1.06 and the

intercept value is ~0; the corresponding values for

the mean line of the steamed samples in Fig. 9b are

1.22 and 0.06. It seems that when only the fresh

samples are considered, the amount of desorbed

ammonia of the low-temperature peak is in a 1:1

analogy with the FAl content, as in the case of the

strong acid sites. However, there is a small amount

of ammonia (~0.07 mmol g

1

sample) that has

been detected in the parent sample ZM-4, which

has practically no acidic FAl; if this small amount

of ammonia, which could be attributed to physical

adsorption and to weak chemisorption on the

terminal SiOH sites, is subtracted from the am-

monia of the low-temperature peak then the above

ratio for the sites that correspond to the low-

temperature peak is somewhat less than 1 (~0.8).

These weak sites become even less after hydro-

thermal treatment (when the sample ZM-4 was

Fig. 9. Correlation of the amount of ammonia desorbed (TPD)

from the (a) strong and the (b) weak acid sites, with the FAl

content, for () parent samples, (_) AHFS dealuminated

samples, (M) HCl dealuminated sample, (j) steamed samples,

( ) steamed/HCl sample (the dashed line corresponds to a 1:1

analogy).

C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388 385

steamed at 790C the amount of desorbed am-

monia dropped to 0.02 mmol g

1

sample); this can

be explained on the basis of

1

H MAS NMR results

where it has been shown that the SiOH defect

sites in the framework of fresh ZSM-5 zeolites are

``healed'' by the formation of SiOSi bonds after

steaming [74].

The amount of ammonia of the low-tempera-

ture peak is aected by the experimental conditions

of the TPD-tests. When the time of the stripping

step (at 100C) in the TPD-test of the sample ZM-

2 was increased from 1.5 to 24 h, the amount of

ammonia of the low-temperature peak gradually

decreased from 0.53 to ~0.10 mmol g

1

sample,

while the amount of the high-temperature peak

(strong acid sites) remained almost unchanged. It

is thus unclear whether the ammonia of the low-

temperature peak corresponds to actual weak

Br onsted acid sites or to physical adsorption, and

quantication of this peak should done by con-

sidering the experimental conditions of the TPD

experiment as well as the overall characterization

of the dierent types of hydroxyls of the crystalline

or extra-framework phases of the samples. De-

tailed

1

H MAS NMR studies of unsteamed H-

ZSM-5 zeolites with framework Si/Al ~ 1520 did

not reveal the existence of some type of SiOH

which are almost equal in amount with the OH

connected to the FAl atoms [10,7476]. However,

under the TPD-experimental conditions applied in

this study, the molecules of the desorbed ammonia

which are in excess to the FAl content, are shown

to be related to the presence of Al atoms in the

zeolitic framework.

The intercept value of the mean line of the

steamed samples which is little higher than zero

(~0.06 mmol g

1

sample) indicates that these sam-

ples possess some additional sites capable of ad-

sorbing ammonia; these sites can be related to the

Al or SiAl oligomers with low degree of hy-

droxylation, in accord with the

27

Al MAS NMR

data, which have a much lower capability of ad-

sorbing ammonia compared to the FAl atoms, as

discussed above (Fig. 8). Furthermore, this small

amount of ammonia does not increase with the

increase of the EFAl or amorphous phases of the

steamed samples (Table 3) and it is not systemati-

cally related to these species. Related FT-IR stud-

ies on the hydroxyl groups of mildly steamed H-

ZSM-5 zeolites have shown the formation of

weakly acidic hydroxylated EFAl species, which

are no more present under harder steaming con-

ditions [15,16,77]. Furthermore, FT-IR tests on

the adsorption of pyridine on steamed H-ZSM-5

samples have shown that the Lewis acid sites ini-

tially formed become less with increasing severity

of the hydrothermal treatment and they are al-

most eliminated in the most severely steamed sam-

ples [15,77,78]. From the data in Table 5, it can be

seen that the strong/weak acid sites ratio remains

practically unchanged for the parent samples and

those dealuminated by HCl and AHFS (fresh sam-

ples) while it decreases in the steamed samples;

the ratio gets very low in the severely steamed

sample DZM-11 since the amount of ammonia

detected in the TPD spectra of this sample over

350C was negligible. Based on these results, the

eect of steam deactivation of the H-ZSM-5 ad-

ditives in the FCC catalyst on product distribution

can be rationalized in terms of the number of sites

and their acidity strength [1,1820]. It is clear that

the severely steamed samples do not possess any

type of relatively strong acidity (neither Br onsted

nor Lewis) such as that it can be detected by

ammonia-TPD tests and further catalyze the high-

acidity-strength demanding reactions in the crack-

ing of gas-oil. However, the traces of FAl atoms

left in these samples, the SiAl oligomers and to a

lesser extent the terminal SiOH groups may

contribute to reactions like cracking and/or alkene

isomerization which have a signicant eect on

product distribution and properties.

4. Conclusions

The results of the present work showed that the

degree of framework dealumination of ZSM-5 and

the amount/type of the extra-framework phases

formed during dealumination were greatly de-

pended on the method of dealumination and the

severity of the treatment. Although steaming or

steaming/HCl are very eective methods, treatment

with AHFS can be applied for the preparation

of moderately dealuminated (~35%) H-ZSM-5

386 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

samples with the characteristic of being free of

EFAl.

The eect of the method and the degree of

dealumination on the structural characteristics of

the H-ZSM-5 samples with respect to their relative

crystallinity (XRD) and microporosity (SSA) was

relatively small; no more than 20% of structure

break-down was observed even for severely

steamed and highly dealuminated samples (96%

dealumination). The crystals/particles of the

AHFS dealuminated samples were damaged to

a much lesser degree compared to those of the

steamed samples, as shown by the TEM images,

mainly due to the dierence in the dealumination

process between the two methods. Dierent extra-

framework/amorphous phases with disordered

mesoporosity were observed in the dealuminated

samples; however, the majority of the crystals/

particles retained their integrity to a high degree

in accord with the high crystallinity and micro-

porosity of all the dealuminated samples.

When the ammonia-TPD tests were performed

under certain experimental conditions, the amount

of ammonia that corresponded to the high-tem-

perature peak of the TPD spectra was in a 1:1

analogy with the FAl content of the H-ZSM-5

zeolite samples for a wide range of the FAl content

and irrespective of the dealumination method that

was applied. The extra-framework phases formed

during dealumination of the H-ZSM-5 zeolites had

a very low capability of adsorbing ammonia. The

severely steamed samples showed no strong acid-

ity, rationalizing the performance of the steam-

deactivated H-ZSM-5 zeolites in processes like the

cracking of gas-oil.

References

[1] F.G. Dwyer, T.F. Degnan, in: J.S. Magee, M.M. Mitchell,

Jr. (Eds.), Fluid Catalytic Cracking: Science and Techno-

logy, Studies in Surface Science and Catalysis, vol. 76,

Elsevier, Amsterdam, 1993, p. 499.

[2] N.Y. Chen, W.E. Garwood, Catal. Rev.-Sci. Eng. 28

(1986) 185.

[3] A. Humphries, D.H. Harris, P. O'Connor, in: J.S. Magee,

M.M. Mitchell, Jr. (Eds.), Fluid Catalytic Cracking:

Science and Technology, Studies in Surface Science and

Catalysis, vol. 76, Elsevier, Amsterdam, 1993, p. 41.

[4] W.O. Haag, R.M. Lago, P.B. Weisz, Nature 309 (1984)

589.

[5] P.A. Jacobs, R. von Ballmoos, J. Phys. Chem. 86 (1982)

3050.

[6] N.-Y. Topsoe, K. Pedersen, E.G. Derouane, J. Catal. 70

(1981) 41.

[7] R.M. Lago, W.O. Haag, R.J. Mikovsky, D.H. Olson, S.D.

Hellring, K.D. Schmitt, G.T. Kerr, in: Y. Murakami et al.

(Eds.), New developments in Zeolite Science and Techno-

logy, Studies in Surface Science and Catalysis, vol. 28,

Elsevier, Amsterdam, 1986, p. 677.

[8] Y. Sendoda, Y. Ono, Zeolites 8 (1988) 101.

[9] V.L. Zholobenko, L.M. Kustov, V.B. Kazansky, E.

Loeer, U. Lohse, Ch. Peuker, G. Oehlmann, Zeolites

10 (1990) 304.

[10] E. Brunner, H. Ernst, D. Freude, T. Fr ohlich, M. Hunger,

H. Pfeifer, J. Catal. 127 (1991) 34.

[11] F. Lonyi, J.H. Lunsford, J. Catal. 136 (1992) 566.

[12] A.I. Biaglow, D.J. Parrillo, G.T. Kokotailo, R.J. Gorte,

J. Catal. 148 (1994) 213.

[13] C.S. Triantallidis, N.P. Evmiridis, Ind. Eng. Chem. Res.

39 (9) (2000) 3233.

[14] J. Dakta, S. Marschmeyer, T. Neubauer, J. Meusinger, H.

Papp, F.-W. Sch utze, I. Szpyt, J. Phys. Chem. 100 (1996)

14451.

[15] S.M. Campbell, D.M. Bibby, J.M. Coddington, R.F.

Howe, R.H. Meinhold, J. Catal. 161 (1996) 338.

[16] A. Maijanen, E.G. Derouane, J.B. Nagy, Appl. Surf. Sci.

75 (1994) 204.

[17] N.-Y. Topsoe, F. Joensen, E.G. Derouane, J. Catal. 110

(1988) 404.

[18] J. Scherzer, Catal. Rev.-Sci. Eng. 31 (3) (1989) 215.

[19] J. Biswas, I.E. Maxwell, Appl. Catal. 58 (1990) 1.

[20] C.S. Triantallidis, N.P. Evmiridis, L. Nalbandian, I.A.

Vasalos, Ind. Eng. Chem. Res. 38 (3) (1999) 916.

[21] L. Kubelkova, S. Beran, A. Malecka, V.M. Mastikhin,

Zeolites 9 (1989) 12.

[22] J. Sanz, V. Fornes, A. Corma, J. Chem. Soc., Faraday

Trans. 1 84 (1988) 3113.

[23] C.S. Triantallidis, A.G. Vlessidis, N.P. Evmiridis, Ind.

Eng. Chem. Res. 39 (2) (2000) 307.

[24] M. M uller, G. Harvey, R. Prins, Micropor. Mesopor.

Mater. 34 (2000) 135.

[25] A. De Lucas, P. Canizares, A. Duran, A. Carrero, Appl.

Catal. A: Gen. 154 (1997) 221.

[26] T. Masuda, Y. Fujikata, S.R. Mukai, K. Hashimoto, Appl.

Catal. A: Gen. 172 (1998) 73.

[27] J. Kornatowski, W.H. Baur, G. Pieper, M. Rozwadowski,

W. Schmitz, A. Cichowlas, J. Chem. Soc., Faraday Trans.

88 (1992) 1339.

[28] G. Debras, A. Gourgue, J.B. Nagy, G. De Clippeleir,

Zeolites 6 (1986) 241.

[29] M.W. Anderson, J. Klinowski, J. Chem. Soc., Faraday

Trans. 1 82 (1986) 1449.

[30] S. Namba, A. Inaka, T. Yashima, Chem. Lett. (1984) 817.

[31] P.J. Kooyman, P. van der Waal, H. van Bekkum, Zeolites

18 (1997) 50.

C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388 387

[32] S. Han, D.S. Shihabi, C.D. Chang, J. Catal. 196 (2000)

375.

[33] S. Kumar, A.K. Sinha, S.G. Hegde, S. Sivasanker, J. Mol.

Catal. A: Chem. 154 (2000) 115.

[34] R.J. Argauer, G.R. Landolt, US Patent, 1972, no.

3,702,886.

[35] G. Engelhardt, D. Michel, High-Resolution Solid-State

NMR of Silicates and Zeolites, Wiley, Chichester, 1987,

pp. 205318.

[36] M. St ocker, in: J.C. Jansen et al. (Eds.), Advanced Zeolite

Science and Applications, Studies in Surface Science and

Catalysis, vol. 85, Elsevier, Amsterdam, 1994, p. 429.

[37] C.A. Fyfe, G.C. Gobbi, G.J. Kennedy, J. Phys. Chem. 88

(1984) 3248.

[38] C.A. Fyfe, J.L. Bretherton, L.Y. Lam, J. Am. Chem. Soc.

123 (22) (2001) 5285.

[39] J.B. Nagy, Z. Gabelica, E.G. Derouane, P.A. Jacobs,

Chem. Lett. (1982) 2003.

[40] D. Coster, J.J. Fripiat, Chem. Mater. 5 (1993) 1204.

[41] W. Zhang, X. Bao, X. Guo, X. Wang, Catal. Lett. 60

(1999) 89.

[42] A. Samoson, E. Lippmaa, G. Engelhardt, U. Lohse, H.-G.

Jerschkewitz, Chem. Phys. Lett. 134 (1987) 589.

[43] J. Klinowski, C.A. Fyfe, G.C. Gobbi, J. Chem. Soc.,

Faraday Trans. 1 81 (1985) 3003.

[44] P.J. Grobet, H. Geerts, M. Tielen, J.A. Martens, P.A.

Jacobs, in: H.G. Karge, J. Weitkamp (Eds.), Zeolites as

Catalysts, Sorbents, and Detergent Builders: Applications

and Innovations, Studies in Surface Science and Catalysis,

vol. 46, Elsevier, Amsterdam, 1989, p. 721.

[45] J.M. Cruz, A. Corma, V. Fornes, Appl. Catal. 50 (1989)

287.

[46] L. Kubelkova, V. Seidl, G. Borbely, H.K. Beyer, J. Chem.

Soc., Faraday Trans. 1 84 (1988) 1447.

[47] J.R. Sohn, S.J. DeCanio, J.H. Lunsford, D.J. O'Donnell,

Zeolites 6 (1986) 225.

[48] H. Fichtner-Schmittler, U. Lohse, G. Engelhardt, V.

Patzelova, Cryst. Res. Technol. 19 (1984) K1.

[49] U. M uller, K.K. Unger, in: K.K. Unger et al. (Eds.),

Characterization of Porous Solids, Studies in Surface

Science and Catalysis, vol. 39, Elsevier, Amsterdam,

1988, p. 101.

[50] P. Voogd, J.J.F. Scholten, H. van Bekkum, Colloids Surf.

55 (1991) 163.

[51] B. Sulikowski, J. Klinowski, Appl. Catal. A: Gen. 84

(1992) 141.

[52] J. Kornatowski, M. Rozwadowski, W. Lutz, W.H. Baur,

in: L. Bonneviot, S. Kaliaguine (Eds.), Zeolites: A Rened

Tool for Designing Catalytic Sites, Studies in Surface

Science and Catalysis, vol. 97, Elsevier, Amsterdam, 1995,

p. 259.

[53] P.A. Jacobs, H.K. Beyer, J. Valyon, Zeolites 1 (1981) 161.

[54] O. Terasaki, Y. Sakamoto, J. Yu, Y. Nozue, T. Ohsuna, N.

Ohnishi, Y. Horikawa, K. Hiraga, G. Zhu, S. Qiu, R. Xu,

M. Anderson, Supramol. Sci. 5 (1998) 189.

[55] Y. Sakamoto, M. Kaneda, O. Terasaki, D.Y. Zhao, J.M.

Kim, G. Stucky, H.J. Shin, R. Ryoo, Nature 408 (2000)

449.

[56] A.H. Janssen, A.J. Koster, K.P. de Jong, Angew. Chem.

Int. Ed. 40 (6) (2001) 1102.

[57] C. Choi-Feng, J.B. Hall, B.J. Huggins, R.A. Beyerlein,

J. Catal. 140 (1993) 395.

[58] J. Pellet, D.G. Casey, H.-M. Huang, R.V. Kessler, E.J.

Kuhlman, C.-L. O'Young, R.A. Sawicki, J.R. Ugolini,

J. Catal. 157 (1995) 423.

[59] Z.M.M. Noronha, J.L.F. Monteiro, P. Gelin, Micropor.

Mesopor. Mater. 23 (1998) 331.

[60] R. Dutartre, L.C. de Menorval, F. Di Renzo, D.

McQueen, F. Fajula, P. Schulz, Micropor. Mater. 6

(1996) 311.

[61] L. Forni, E. Magni, E. Ortoleva, R. Monaci, V. Solinas,

J. Catal. 112 (1988) 444.

[62] C.V. Hidalgo, H. Itoh, T. Hattori, M. Niwa, Y. Mura-

kami, J. Catal. 85 (1984) 362.

[63] H.G. Karge, L.C. Jozefowicz, in: J. Weitkamp et al. (Eds.),

Zeolites and Related Microporous Materials: State of the

Art 1994, Studies in Surface Science and Catalysis, vol. 84,

Part A, Elsevier, Amsterdam, 1994, p. 685.

[64] C.J.H. Jacobsen, C. Madsen, T.V.W. Janssens, H.J.

Jakobsen, J. Skibsted, Micropor. Mesopor. Mater. 39

(2000) 393.

[65] L. Forni, F.P. Vatti, E. Ortoleva, Micropor. Mater. 3

(1995) 367.

[66] G.I. Kapustin, T.R. Brueva, A.L. Klyachko, S. Beran, B.

Wichterlova, Appl. Catal. 42 (1988) 239.

[67] W. Reschetilowski, B. Unger, K.-P. Wendlandt, J. Chem.

Soc., Faraday Trans. 1 85 (1989) 2941.

[68] S.B. Sharma, B.L. Meyers, D.T. Chen, J. Miller, J.A.

Dumesic, Appl. Catal. A: Gen. 102 (1993) 253.

[69] V.V. Yushchenko, A.N. Zakharov, B.V. Romanovskii,

Kinet. Catal. 27 (1986) 409.

[70] P.A. Jacobs, J.A. Martens, J. Weitkamp, H.K. Beyer,

Faraday Discuss. Chem. Soc. 72 (1981) 353.

[71] C. Costa, I.P. Dzikh, J.M. Lopes, F. Lemos, F.R. Ribeiro,

J. Mol. Catal. A: Chem. 154 (2000) 193.

[72] T. Masuda, Y. Fujikata, S.R. Mukai, K. Hashimoto, Appl.

Catal. A: Gen. 165 (1997) 57.

[73] R.W. Weber, J.C.Q. Fletcher, K.P. M oller, C.T. O'Con-

nor, Micropor. Mater. 7 (1996) 15.

[74] M. Hunger, Catal. Rev.-Sci. Eng. 39 (1997) 345.

[75] L. Heeribout, P. Batamack, C. Doremieux-Morin, R.

Vincent, J. Fraissard, Colloids Surf. A 115 (1996) 229.

[76] E. Brunner, K. Beck, M. Koch, L. Heeribout, H.G. Karge,

Micropor. Mater. 3 (1995) 395.

[77] J.C. Vedrine, A. Auroux, V. Bolis, P. Dejaifve, C.

Naccache, P. Wierzchowski, E.G. Derouane, J.B. Nagy,

J.-P. Gilson, J.H.C. van Hoo, J.P. van den Berg, J.

Wolthuizen, J. Catal. 59 (1979) 248.

[78] A. Martin, U. Wolf, S. Nowak, B. L ucke, Zeolites 11

(1991) 85.

388 C.S. Triantallidis et al. / Microporous and Mesoporous Materials 47 (2001) 369388

You might also like