Professional Documents

Culture Documents

Heman Attachments

Uploaded by

Lalit KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heman Attachments

Uploaded by

Lalit KumarCopyright:

Available Formats

Skid Steer Loader Attachments

FOR: VECTRA HEMAN 175 SKID STEER LOADER

� � � � � � � � � � � � � � � � � � � �

� � � �

4 in 1-MULTI FUNCTION BUCKET BACKHOE BLADE ANGLE-Dozer Blade/Tilt-Dozer Blade CEMENT MIXER DEBRIS SCRAPER DOUBLE-HEAD SLASHER EARTH AUGER DRIVE GRADER INDUSTRIAL PLIERS (GRAPPLE) PALLET FORK RIPPERS (ESCAVATION) ROCK BREAKER (Hydraulic Hammer) RUBBER TRACKS-OTT (Over-the-tire) TRENCHER (Heavy Duty Side Shift) SNOW BLADE/SNOW BLADE (HIGH) SNOW BLOWER STEEL TRACKS STUMP GRINDER SWEEPER COLLECTOR (with Bucket) SWEEPER COLLECTOR (with Bucket and Water Pressure Kit/Container) VIBRATORY ROLLER FRONT SHREDDER PATCH PLANER TILLER

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments 4 IN 1-MULTI FUNCTION BUCKET

� � �

It is a versatile multiple-use tool for digging work, loading and discharging, for flatting, leveling etc Its heavy duty construction provides a long life for landscaping, municipal, construction or demolition jobs Teeth fixed with bolts are optional

SPECIFICATIONS-Model B4-1550 DESCRIPTION DATA Width 1550mm Approx Weight 350 kg Capacity 0.31m3

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments BACKHOE 3C0041

The backhoe is a working attachment for skid steer loaders intended for digging canals, trenches, ditches etc and for demolition and dozing work. It turns the carrier machine into a powerful excavator matching versatility of backhoe loaders. It has a maximum digging depth of close to 2.5m

SPECIFICATIONS BASIC BUCKET WIDTH (mm) BUCKET CAPACITY (m3) DIGGING DEPTH (mm) UNLOADING HEIGHT (mm) FORWARD HORIZONTAL COVERAGE (mm) SIDE HORIZONTAL COVERAGE (mm) ROTATION ANGLE () WEIGHT (kg) BUCKET CUTTING FORCE (KN) DISTANCE BETWEEN STABILIZORS (mm) SYSTEM PRESSURE (bar) FLOW RATE (lt/min) FRAME WIDTH FOR HEMAN 175 (mm) TEARING POWER TEETH (kg) 300 0.2 2,477 1,974 3,195 3,195 180 536 16.50 1,560 160 20 1600 1800

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments BLADE ANGLEDozer Blade/Tilt-Dozer Blade

Dozer Blade for dozer application works with left-right angulation +/- 30 coupled to mechanical or hydraulic support with an attachment kit plate for skid steer loader attachment.

Model LA 1800

Blade Width 1800mm

Weight 230kg

Tilt-Dozer Blade for dozer application works with left-right angulation +/- 30 coupled to mechanical or hydraulic support with an attachment kit plate for skid steer loader attachment.

Model LTD 1800

Blade Width 1800mm (1558mm-Blade Totally Angled)

Weight 330kg

Options: Quick Couplers Kit and Electrical Connectors with 8 or 14 poles

*Specifications and Model Numbers subject to change without prior notice December 2009

Skid Steer Loader Attachments CEMENT MIXER

Features-Model 62CM125 � � � � � � � � � � All operations are performed from within the cab Fully enclosed drive mechanism Working capacity: 125-150 litres (40 GPM) Operating flow rate: 30-90 l/min Loader only needs to be idling while mixing Maximum operating pressure 207 bar (3000 PSI) Bowl fitted with durable mixing paddles Bowl driven by heavy-duty drive chain Bowl opening is 500mm (20) and is reinforced Mass (unloaded) 316 kg (695 LBS)

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments DEBRIS-SCRAPER

Max. Flow: 100 lpm (26 gpm)

Max Pressure: 240 bar (3500 psi)

Mass: 380 kg (830 lbs)

Model: 81SC3000

The Pivoted Debris Scraper is used for cleaning under conveyor belts and hard to access areas. It is used to clean debris out from areas where a loader is unable to reach. The maximum reach from the tip of the chain to the frame base plate is 2800mm 110. The main frame can be side shifted to one side to increase the reach of the Scraper. With the Scraper's boom pivoted, the skid steer is reversed passed the area to be cleaned, to drag material out in front of the loader for collection with a bucket or bucket-broom. The chain is fitted with thirty-three (33), 350mm (14") paddle blades with closed in sides for dragging the material towards the loader. The chain has a pitch of 1.654", with a 33,000 lbs breaking strain. For best results when using the Scraper, the loader should be reversing. A robust gerotor hydraulic motor that directly drives the drive sprocket via a drive shaft drives the scraper chain. This type of set-up reduces wear parts (e.g. gearboxes), requires no on-going servicing, and achieves high start-up torque

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments DOUBLE HEAD SLASHER

Model: 76DH1800

The Double-Headed Slasher utilizes two cutting heads to successfully slash an area 1800mm wide (the deck is approximately 1800mm x 900mm). This set-up is able to cut through small saplings and lantana up to 50mm thick. The 8mm thick cutting blades and slasher deck combine to give a durable slasher attachment. The shorter depth of the slasher increases the stability of the loader when travelling on inclinations or loading/unloading the attachment off a truck etc. Slasher Attachment is provided with quick attach frame to suit the carrier machine. The quick attach frame pivots on two bosses, allowing you to crowd the quick hitch forward when slashing to let the slasher deck follow the contours of the ground. A hydraulic motor drives two right angle drive (high horsepower) gearboxes, there by eliminating cumbersome belts, which can jam with debris. Cross-port relief valve acts as a clutch should the cutter bars stop suddenly, protecting the hydraulic motor. The two jockey wheels supporting the slasher deck are puncture proof. The wheels keep the deck level with the ground and (via adjustable pins) are used to control the cutting height. Debris chains are fitted to the front and rear of the deck. Operating Pressure: 138 - 207 Bar (2000 - 3000 PSI) Operating Flow Rate: 60 - 75 L/Min (16 - 20 GPM) Mass approx.: 475kgs

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments EARTH AUGER DRIVE 3C0039

The earth auger drive is fitted with a fixed multi-fit frame to suit the carrier machine.

� � � � � � � � �

Carrying frame incorporates a cradle to prevent unwanted auger swing when traversing the job site. Standard 65mm round output shaft In standard configuration, maximum output torque is 4,496 nm. (3316 ft/lbs) Maximum output @114 lpm is 95rpm High torque quality gearbox fitted with Eaton motor. High torque, high efficiency Augers from 100mm-750mm (4-30) in diameter Standard digging length of the augers is 1500mm (60) Borer will go down a 250mm post-hole, increasing the digging depth by a further 700mm Can be fitted with earth teeth, tungsten carbide teeth or MFT (abrasive ) teeth Extensions from 500mm to 1000mm are available.

SPECIFICATIONS Motor: EATON 18.7CI Single speed bell motor Min. Hydraulic flow: 50 lpm (13 gpm) Max. Hydraulic flow:114 lpm (30 gpm) Max. Continuous pressure: 3500 psi (240 bar) Output shaft option: 65mm round Weight: 60 kg Hydraulic Flow Output speed Hydraulic pressure lpm (gpm) RPM Bar (PSI) 50 (13) 41 240 (3500) 76 (20) 65 220 (3200) 114 (30) 95 205 (3000)

Output torque NM (ft/lbs) 4496 (3316) 4110 (3032) 3853 (2842)

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments GRADER

� � �

It is ideal for ground preparation and landscaping It is also used to prepare grounds for asphalting or concreting The compact size of the unit is excellent for driveways, building sites and road maintenance

SPECIFICATIONS - Model 2100 STD DESCRIPTION Blade Width Working width (blade totally angled) Right angolation-Left angolation Side translation to right-left to centre Oscillation Approx Weight DATA 2100mm 1820mm +/- 35 degrees +/- 400 +/- 27 degrees 650 kg

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments INDUSTRIAL PLIERS (GRAPPLE)

� �

Useful for municipalities, green waste handling scrap dealership, handling applications with varied sizes or loose loads Can carry awkward or dangerous loads securely.

SPECIFICATIONS - Model FPRI-1550 DESCRIPTION Width Approx Weight DATA 1550mm 340 kg

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments PALLET FORK

� �

Moves bulky or palletized material with ease Ideal for construction sites, farm chores, fertilizer handling and industrial plants etc

SPECIFICATIONS - Model FP 14- STD DESCRIPTION A X B mm C mm D mm E mm Capacity Approx Weight DATA 80 x 30 1000 1400 510 1000 kg 140 kg

December 2009

*Specifications and Model Numbers subject to change without prior notice

Skid Steer Loader Attachments RIPPERS (EXCAVATION)

Model 7801

The Excavation Ripper fits easily to the front of the loader and has the strength to quickly break up hard ground. The loader is reversed whilst the points are lowered into the ground. The maximum possible ripping depth is 300 mm (12) and the maximum ripping width is 1500 mm (60). The shanks used are genuine ripper shank with removable points. Wedges lock in the shanks to prevent them from moving when in operation. There are a total of five tyne positions available with three tynes fitted as standard. This gives the operator the flexibility to control the specific area to be excavated. Mass 160 kg (352 lbs)

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments ROCK BREAKER (Hydraulic Hammer) 3C0048

One of the latest range of innovative hydraulic, vibrating rock breakers offering impeccable performance levels and are totally eco-friendly being silent and discreet. The rock breaker including the rubber parts are suitable to work under varying climatic conditions prevailing in high altitudes and deserts. Representing cutting edge technology in the demolition field, the breaker has a reduced maintenance frequency requirement. The high counter-pressure tolerance on the discharge circuit makes for easy application and high performance levels in terms of power levels per stroke.

Impact Frequency (Strokes/min) Impact Energy Weight in working position (with tool): Weight of bare hammer: Height without tool Width Depth Mass of cone shaped standard tool: Tool diameter Height with tool Oil Flow: Working pressure: Diameter fitting IN Diameter fitting OUT

TECHNICAL DATA

600 - 900 600 820 Joules 359 kg 166 kg 1201 mm 410 mm 410 mm 18.5 kg 77.5 mm 1721 mm 55 80 litres/min 80 120 bars (psi) 1/2 3/4

**Complete with backing plate/hydraulic hoses and quick couplers *Specifications and Model Numbers subject to change without prior notice December 2009

Skid Steer Loader Attachments RUBBER TRACKS-OTT (Over-the-tire) 3C0047

Description Over-the-Tire tracks are fitted over the tires of skid steer loaders, and provide all the features and benefits of a track loader at a fraction of the cost. They are ideal for muddy conditions, providing the machine with superior traction and reduced ground pressure.

� � � � � � �

Rubber tracks that convert an everyday skid steer into a more versatile track loader Easily installed in thirty minutes or less and removed in 10 minutes Better performance in sand and mud Float over soft, sandy, or muddy ground Better Traction on slippery surfaces with over tire metal tracks Provides tire protection Build in length adjustment

Note: Tracks are supplied complete with a set of 4 wheel rim spacers. *Specifications and Model Numbers subject to change without prior notice December 2009

Skid Steer Loader Attachments TRENCHER- HEAVY DUTY SIDE SHIFT

With Pitch Chain Assembly

Model: 8102L-03 and 8006HDL

� �

It can dig trenches for gas, electricity, telecom and other general purposes The auger coupled with the trencher disperses soil on both sides of the trench, making fill-back operation easy

Technical Information� � � Max. Flow 130 lpm (34 gpm) Max Press 250 bar (3650 psi) Mass Approx. 380 kg (837 lbs)-with 150mm chain

The Heavy Duty Side Shift Trencher is a sturdy trencher for the operator whose primary task is trenching. This unit utilizes the standard auxiliary hydraulic system of the host machine and has the added bonus of durable wear parts. The trencher has a 1200mm boom length and a 900mm recommended digging depth (up to 1200mm maximum digging depth #). Trenching widths range from 100mm up to 350mm . # Digging depths are calculated with the boom at a 50 degrees angle to the ground-it is not the boom length.

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments SNOW BLADE / SNOW BLADE (HIGH)

Snow Blade for snow clearing application works with horizontal self-leveling +/- 10, Antishock system and spring return, fixing rods for burying works, left-right hydraulic angulation +/- 30, rubber pipes for hydraulic circuit function with an attachment kit plate for skid steer loader. Blade Width (mm) 1800 Weight (kg) 280 Working width with blade totally angled (mm) 1558

Model LS 1800

High Snow Blade for snow clearing application works with horizontal self-leveling +/10, Antishock system and spring return, fixing rods for burying works, left-right hydraulic angulation +/- 30, rubber pipes for hydraulic circuit function with an attachment kit plate for skid steer loader. Blade Width (mm) 2100 Weight (kg) 380 Working width with blade totally angled (mm) 818 December 2009

Model LSA 2100

*Specifications and Model Numbers subject to change without prior notice

Skid Steer Loader Attachments SNOW BLOWER 3C0045

This hydraulic snow blower is specially designed for skid steer loaders. It is available in 66 (1676mm) width and 30 (762mm) high. The fan is 24 (610mm) diameter, 6 (152mm) deep and has six blades for smooth blowing. The fan paddles and the cutting edge are replaceable. The paddles on the two augers are very effective for breaking up hard snow. The augers are protected by shear pins. The blower mount is compact for increased stability. Standard equipment includes:

� � � �

Skid shoes for height control Replaceable cutting edges Power spout turning Non-skid access steps

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments STEEL TRACKS-3C0046

� � � �

Full floatation Maximum traction Tire protection Self cleaning

� � � � �

No tire to track slipping Less ground damage Fully rebuildable Interchangeable shoes Less skid steer bouncing

This state-of-the-art skid steer steel tracks system uses pins and links made of heat treated forged chromium-enriched steel alloy to protect the tires against punctures and provides maximum floatation to go over sand, deep mud and debris. This material ensures exceptional wear resistance and guarantees extensive track life and low cost maintenance. The system has more pushing and pulling power, especially in deep mud, and sand or during demolition and land clearing. Note: Tracks are supplied complete with a set of 4 wheel rim spacers. SPECIFICATIONS Size 10" Fits Tires 10x16.5 Steel Alloy Manganese BASE ASSEMBLY Count 50 units Steel Alloy Cast Manganese Process Heat Treated LINKS Count 100 pcs Steel Alloy Forged Steel Process Heat Treated PINS Count 200 pcs Steel Alloy Forged Steel Process Heat Treated *Specifications and Model Numbers subject to change without prior notice December 2009

Skid Steer Loader Attachments STUMP GRINDER 3C0035

The stump grinders can be used in landscaping, parks and municipality applications. The offset design of the stump grinder increases productivity by providing maximum visibility to the stump, allowing better control of the cutting head. The offset design also directs the chips and dust to the side and away from the operator, improving operator comfort. The grinder utilises high torque, direct-drive motors for maximum productivity. Depth and swing functions are easily and precisely controlled with the swing-in hydraulic controls. The direct acting hydraulic valve mounts on a swing-in arm, which swings into the operator compartment for fast, precise control of the cutting head. The hydraulic circuit gives metered flow to the control circuit without reducing the power to the cutting head. For ease of operation the stump grinders are mounted on stabiliser rollers, allowing the operator to position or reposition the grinder without operating individual stabilisers. The rollers allow movement of the unit on the ground without any damage to the surface. Specifications Minimum HYD. HP recommended Swing width (mm) Swing arc Below ground depth (mm) Above ground height (mm) Wheel diameter Teeth Approx. shipping weight (kg) STUMP GRINDER 3C0035 18 1700 90 190 610 530 16 320

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments SWEEPER COLLECTOR (with Bucket)

� �

Daily cleaning in an industrial environment is made easy Useful for side clearance, road clearance, housing development, municipalities and civic utilities

SPECIFICATIONS - Model 1550 STD DESCRIPTION Width Approx Weight Bucket Capacity Diameter and no. of brushes DATA 1550mm 350 kg 440 litres 560mm/34

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments SWEEPER COLLECTOR (with Bucket, Water Pressure kit and 100 litres Container)

� �

Daily cleaning in an industrial environment is made easy Useful for side clearance, road clearance, housing development, municipalities and civic utilities

SPECIFICATIONS - Model 1680 STD

DESCRIPTION Width Approx Weight Bucket Capacity Diameter and no. of brushes

DATA 1680mm 370 kg 475 litres 560mm/36

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments VIBRATORY ROLLER

Model: 87CD1200-1200mm-48 Drum Model: 87CD1600- 1600mm-63 Drum

The 2 models (1200 mm 48 drum) and (1600 mm 63 drum) Vibratory Rollers fit easily to the skid steer loaders quick hitch and only require standard oil flow to operate. It is an ideal attachment for flat-work, trenching and asphalt patch contractors. The drum is able to tilt either direction up to 15 to follow the contours of the ground. The smooth drum version is suitable for compacting asphalt, silt sand and gravel. The vibration frequency is achieved by precision machined elliptical masses secured onto the rollers main shaft. The shaft is supported on each end by barrel roller bearings that are designed to withstand the vibration generated by the revolving shaft. The bearings are sealed within an oil cavity for constant lubrication and heat diffusion. Eight special rubber mounts that isolate 97% of vibration from the drum support the entire drum assembly. Adjustable UHMW nylon strips are fitted to the smooth drum rollers, steel fingers are fitted for cleaning the drum surface. Vibration Force: 1200mm drum=2400kg 1600mm drum=3000kg Vibration Frequency: 2500 vpm @ 60 l/min Nominal Amplitude: 0.8 mm Operating Pressure:138 172 bar Operating Flow Rate: 50 70 lpm Mass of 1200mm-48roller: 780kg Mass of 1600mm-63roller: 930kg

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments FRONT SHREDDER

Model: SCORPION 1900 HD

The Front hammer shredder/grass cutter is with floating linkage plate for skid steer loaders, hydraulic drainage motor and quick coupler hoses.

Working Width: Total width: Weight:

1900 mm 2100mm 510kgs

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments PATCH PLANER -for Asphalt & Concrete

Model: CP41.13

� � � �

Operates on standard flow hydraulics (Does not require case drain line) Hydraulic side shift, manual tilt and depth control Low cost planer for road repair for use by contractors, municipalities and rental fleets Applications include for small pavement crust stripping jobs, crossings or planing small trenches

SPECIFICATIONS

MODEL: Cutting (Drum) Width Cutting Depth Tilt Lateral Sideshift No. of Asphalt Teeth Flow (lpm) Pressure (bar) Approx. Weight (kg)

CP41.13 406 mm 0 127 mm +/- 15 degrees 660 mm 38 57-95 138-242 650

*Specifications and Model Numbers subject to change without prior notice

December 2009

Skid Steer Loader Attachments TILLER

Model: RH1500

The Vectra TILLER is a great landscaping attachment designed for breaking up and pulverizing soil, mixing compost or other materials into existing soil, and stabilizing and levelling existing terrain in landscape finish applications. It is ideal for residential, commercial, agricultural, building construction, lawn care and golf course maintenance applications. SPECIFICATIONS

MODEL: Cutting Width Cutting Depth Tyne Speed No. of Tynes Flow (lpm) Pressure (bar) Approx. Weight (kg)

RH1500 1500 mm 0 150 mm 120-180 rpm 36 50-90 140-240 275

*Specifications and Model Numbers subject to change without prior notice

December 2009

You might also like

- SPC 450DX Oct 2013 PDFDocument155 pagesSPC 450DX Oct 2013 PDFPIJUSH NANDINo ratings yet

- Load Chart of TMS 475 PDFDocument10 pagesLoad Chart of TMS 475 PDFGaurav singh negiNo ratings yet

- Holdwell Inventory JCB Catalogue 2020Document16 pagesHoldwell Inventory JCB Catalogue 2020Epure GabrielNo ratings yet

- 4 2product List Tata Hitachi EX 60 EX 70Document4 pages4 2product List Tata Hitachi EX 60 EX 70Shree HydraulicsNo ratings yet

- 6 Product List Tata Hitachi EX 200Document4 pages6 Product List Tata Hitachi EX 200ER Sudhir MishraNo ratings yet

- HMT Tractor Oil SealsDocument17 pagesHMT Tractor Oil SealsAmit Chopra Amit100% (2)

- 10 Product List Tata JD 315Document2 pages10 Product List Tata JD 315KAIDEAR100% (4)

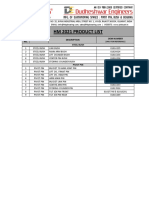

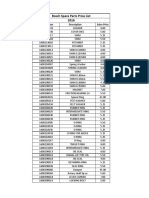

- HM 2021 Product List: SR. NO. Item Description Oem Number Steel BushDocument2 pagesHM 2021 Product List: SR. NO. Item Description Oem Number Steel BushMax Sashikhin100% (1)

- KOEL TC Eng Parts Catalogue-4D.Document58 pagesKOEL TC Eng Parts Catalogue-4D.Mohan CharanchathNo ratings yet

- Forklift and Lodar PDFDocument17 pagesForklift and Lodar PDFJe MotorNo ratings yet

- Tata Hitachi Construction Machinery Company Private Limited: E-Sale Catalogue FOR Spare Items, NagpurDocument59 pagesTata Hitachi Construction Machinery Company Private Limited: E-Sale Catalogue FOR Spare Items, NagpurShivam Kushwah0% (1)

- FT NEW PRICE LIST 4.10.2021-Converted-UnlockedDocument693 pagesFT NEW PRICE LIST 4.10.2021-Converted-UnlockedAmit Chopra AmitNo ratings yet

- Parts Manual: Model: DVX 5 Ton FC With Tsj436 Simpson EngineDocument147 pagesParts Manual: Model: DVX 5 Ton FC With Tsj436 Simpson EngineJohnson James80% (5)

- Catalog List APRIL'21Document6 pagesCatalog List APRIL'21Bhawani CopyNo ratings yet

- HEMAN Skid 175 Parts ManualDocument259 pagesHEMAN Skid 175 Parts ManualKARMA EQUIPMENTS50% (2)

- Escorts BHL Backhoe Loader JUNGLI Dated 12-10-2017Document391 pagesEscorts BHL Backhoe Loader JUNGLI Dated 12-10-2017ashish singh thakurNo ratings yet

- Tools Catalogue - BHL 3DX Xtra, 3DX Super, 4DXDocument28 pagesTools Catalogue - BHL 3DX Xtra, 3DX Super, 4DXmushfiq66No ratings yet

- Godrej Forklift New Part NumbersDocument3 pagesGodrej Forklift New Part Numbersboobalan_shriNo ratings yet

- Bosch Spare Parts Price List 2016Document113 pagesBosch Spare Parts Price List 2016David PomaNo ratings yet

- Jacktech Price ListDocument26 pagesJacktech Price ListANKURNo ratings yet

- 1 Product-List 4 PagesDocument4 pages1 Product-List 4 PagesKamal SabNo ratings yet

- 5product List Tata Hitachi EX 100 EX 110Document5 pages5product List Tata Hitachi EX 100 EX 110mmr constructionsNo ratings yet

- SD-13 Part ManualDocument240 pagesSD-13 Part Manualduongpn50% (2)

- 4WH Electrical - NPD Circular - Nov'20Document63 pages4WH Electrical - NPD Circular - Nov'20JB Thusthehir100% (1)

- Ex 110 PDFDocument145 pagesEx 110 PDFDharma ProductionNo ratings yet

- Escort Compactor Ec 5250Document2 pagesEscort Compactor Ec 5250Felix Sanders100% (3)

- R 45 F17 10 Introduction of New Mahindra YUVODocument13 pagesR 45 F17 10 Introduction of New Mahindra YUVODipen patraNo ratings yet

- Testing and Adjusting 12GDocument5 pagesTesting and Adjusting 12GJuan GonzalezNo ratings yet

- Part Manual PMDVX30FC 02 (OCT 2020) UpdatedDocument171 pagesPart Manual PMDVX30FC 02 (OCT 2020) UpdatedM. RameshNo ratings yet

- Bearing Application ListDocument86 pagesBearing Application Listmanojkhare7620No ratings yet

- HG Kawasaki K3VL Parts Catalog WebDocument17 pagesHG Kawasaki K3VL Parts Catalog WebPartagon PowNo ratings yet

- Ex110 5Document7 pagesEx110 5adi078No ratings yet

- 7575 DI Arjun International 4WD 2WD Parts Catalogue17 PDFDocument246 pages7575 DI Arjun International 4WD 2WD Parts Catalogue17 PDFSamsher AliNo ratings yet

- Mahindra Regular Parts CatalogueDocument283 pagesMahindra Regular Parts CatalogueWorkshop RSG100% (1)

- JCB Original Spare Parts ListDocument4 pagesJCB Original Spare Parts ListTarang agrawalNo ratings yet

- Hydraulics - MKM - DLX - Parts - Catalogue MAR 14 PDFDocument33 pagesHydraulics - MKM - DLX - Parts - Catalogue MAR 14 PDFRS Rajib sarkerNo ratings yet

- EX70 SuperDocument217 pagesEX70 SuperKudanthai Senthilkumar86% (7)

- Export Price Lists For All HTT Hydraulic Component RangeDocument68 pagesExport Price Lists For All HTT Hydraulic Component RangeHuseyin TASKIN100% (2)

- PDF Heman Skid 175 Parts ManualDocument259 pagesPDF Heman Skid 175 Parts Manualindrabhansingh22443No ratings yet

- Backhoe Loader Product ListDocument15 pagesBackhoe Loader Product ListMax Sashikhin100% (4)

- Catalogues$ci LPK 2518HD BS3 Cum PDFDocument322 pagesCatalogues$ci LPK 2518HD BS3 Cum PDFSajan AhmedNo ratings yet

- Da10 Air Cooled Engine (Appn Code D3.2007 & D3Document26 pagesDa10 Air Cooled Engine (Appn Code D3.2007 & D3Sandeep NikhilNo ratings yet

- Engine Developing 165 FHP (123 KW) Standard EquipmentDocument3 pagesEngine Developing 165 FHP (123 KW) Standard EquipmentDhirendraRavi100% (1)

- Gradall Parts List PriceDocument454 pagesGradall Parts List PriceZiggy Jirgens33% (3)

- Dealer Code Dealer Name Quo No Quo Date Cust Code Cust Name Mac No Item No Part NoDocument6 pagesDealer Code Dealer Name Quo No Quo Date Cust Code Cust Name Mac No Item No Part NoJonathan Kale100% (1)

- Ace 14XW Part BookDocument243 pagesAce 14XW Part Bookasim ghoshNo ratings yet

- Kat 8Document185 pagesKat 8RomanNo ratings yet

- Escorts EC2420 Parts CatalogDocument202 pagesEscorts EC2420 Parts CatalogPrakash Niroula0% (1)

- All Parts & Price ListDocument7 pagesAll Parts & Price ListSaswati KhatuaNo ratings yet

- JCB Spares ListDocument6 pagesJCB Spares ListROHIT AGGARWALNo ratings yet

- New Holland - Range List - NovemberDocument62 pagesNew Holland - Range List - NovemberMyo AungNo ratings yet

- Bevel Gear PDFDocument7 pagesBevel Gear PDFubaldo caraballoNo ratings yet

- JCB Drive Shaft and Pump ShaftDocument8 pagesJCB Drive Shaft and Pump ShaftHangzhou Dingshun Machanical CONo ratings yet

- Test Report: Brakes: Enquiries@vca - Gov.ukDocument103 pagesTest Report: Brakes: Enquiries@vca - Gov.ukMarsellusProbstNo ratings yet

- Voltas DVX 405 FC Parts ManualDocument97 pagesVoltas DVX 405 FC Parts ManualJohnson James100% (4)

- PHC Cylinder Seal KitDocument1 pagePHC Cylinder Seal KitJohnson JamesNo ratings yet

- Tata PricelistDocument4 pagesTata Pricelistbaritone18m100% (1)

- IR LM100A Crawlair Drill PDFDocument8 pagesIR LM100A Crawlair Drill PDFAnonymous 8yIptglHhNo ratings yet

- Catalogo - Generale - 2016 - ENG Escavatori SXNC093A16.compressed PDFDocument29 pagesCatalogo - Generale - 2016 - ENG Escavatori SXNC093A16.compressed PDFFlorin SpiridonNo ratings yet

- LT1213 Tech SpecDocument7 pagesLT1213 Tech SpecVijay BhureNo ratings yet

- Dainik Sadhna VidhiDocument30 pagesDainik Sadhna VidhiNikhil Prakash82% (11)

- Delhi Metro Route MapDocument1 pageDelhi Metro Route Mapnakulyadav7No ratings yet

- Sri Panchamukha Anjaneya Stotram KavachamDocument3 pagesSri Panchamukha Anjaneya Stotram KavachamLalit Kumar0% (1)

- Leaflet HemanDocument2 pagesLeaflet HemanLalit KumarNo ratings yet

- धनवर्षणी तारा साधनाDocument22 pagesधनवर्षणी तारा साधनाVikram Singh80% (10)

- निखिल सहस्त्रनाम -1Document56 pagesनिखिल सहस्त्रनाम -1Vikram Singh86% (7)

- PAN Correction FormDocument1 pagePAN Correction FormRAMESHBABUNo ratings yet

- Phase 1 Application Form KensitonDocument23 pagesPhase 1 Application Form KensitonLalit KumarNo ratings yet

- Sri Panchamukha Anjaneya Stotram KavachamDocument3 pagesSri Panchamukha Anjaneya Stotram KavachamLalit Kumar0% (1)

- Onyx PPT New 2Document36 pagesOnyx PPT New 2Lalit KumarNo ratings yet

- Applicationform Green Crest HomesDocument24 pagesApplicationform Green Crest HomesLalit KumarNo ratings yet

- Urbtech Trade Centre, Sector 132 Info PackDocument18 pagesUrbtech Trade Centre, Sector 132 Info PackLalit KumarNo ratings yet

- Phase 1 Application Form KensitonDocument23 pagesPhase 1 Application Form KensitonLalit KumarNo ratings yet

- H2ODocument9 pagesH2OLalit KumarNo ratings yet

- KassiaDocument13 pagesKassiaLalit KumarNo ratings yet

- Esfera 2 NewDocument32 pagesEsfera 2 NewLalit KumarNo ratings yet

- Investment PlanDocument2 pagesInvestment PlanLalit KumarNo ratings yet

- WTC Noida Furnished Application FormDocument12 pagesWTC Noida Furnished Application FormLalit KumarNo ratings yet

- Site Office: Jaypee Greens AMAN, Sector 151, Noida (U.P.), India. Mobile: +91 9999988901 / 02 / 03Document12 pagesSite Office: Jaypee Greens AMAN, Sector 151, Noida (U.P.), India. Mobile: +91 9999988901 / 02 / 03Lalit KumarNo ratings yet

- Onyx PPT New 2Document36 pagesOnyx PPT New 2Lalit KumarNo ratings yet

- Greencrest Homes InfopackDocument13 pagesGreencrest Homes InfopackLalit KumarNo ratings yet

- Sunworld Arista Info PackDocument16 pagesSunworld Arista Info PackLalit KumarNo ratings yet

- Boomerang Noida-App FormDocument14 pagesBoomerang Noida-App FormLalit Kumar100% (1)

- Dream Homes SpecificationDocument1 pageDream Homes SpecificationLalit KumarNo ratings yet

- Urbtech Trade Centre, Sector 132 Info PackDocument18 pagesUrbtech Trade Centre, Sector 132 Info PackLalit KumarNo ratings yet

- Imperia Mirage HomesDocument21 pagesImperia Mirage HomesLalit KumarNo ratings yet

- Appliation - Form For HQ11DEC12Document2 pagesAppliation - Form For HQ11DEC12Lalit KumarNo ratings yet

- Appliation - Form For RO-11DEC12Document2 pagesAppliation - Form For RO-11DEC12Lalit KumarNo ratings yet

- Sunworld Arista Info PackDocument16 pagesSunworld Arista Info PackLalit KumarNo ratings yet

- REHS0440-02-01-List of Schematics-Referenced in TextDocument56 pagesREHS0440-02-01-List of Schematics-Referenced in TextEder100% (1)

- Parts Reference GuideDocument170 pagesParts Reference GuideAndrey GyrychNo ratings yet

- Liebherr LTF 1035 3 1Document16 pagesLiebherr LTF 1035 3 1SzilágyiRóbert100% (1)

- Plant BiDocument44 pagesPlant BiRetro PunkNo ratings yet

- Lathe - LVDocument23 pagesLathe - LVakshaygiitmNo ratings yet

- TTT - D9R - General Literature ListDocument6 pagesTTT - D9R - General Literature ListStasNo ratings yet

- HE Transmissions PDFDocument13 pagesHE Transmissions PDFlahcen boudaoud0% (1)

- XCMG Catalogue 2017Document14 pagesXCMG Catalogue 2017Islam AttiaNo ratings yet

- Harga Satuan 2023Document12 pagesHarga Satuan 2023Ratih MelatiNo ratings yet

- Gloster Engineers Tool Catalogue PDFDocument110 pagesGloster Engineers Tool Catalogue PDFJ.NieuwenhuisNo ratings yet

- (45T Mobile Crane) - Kobelco RK450 Load ChartDocument8 pages(45T Mobile Crane) - Kobelco RK450 Load ChartadrianNo ratings yet

- Catalogo Trasteel 2018Document177 pagesCatalogo Trasteel 2018claygonNo ratings yet

- Caterpillar Performance Handbook 49 62020 Partie1Document4 pagesCaterpillar Performance Handbook 49 62020 Partie1ali alilouNo ratings yet

- Common Farm EquipmentDocument2 pagesCommon Farm Equipmentchasing catNo ratings yet

- Packing List CC2500 and CC2800-1Document15 pagesPacking List CC2500 and CC2800-1Duong Truong100% (1)

- Construction Products Catalog: Specifications For Direct Replacement ProductsDocument30 pagesConstruction Products Catalog: Specifications For Direct Replacement ProductsAndrey GyrychNo ratings yet

- Common G Codes and M Codes For CNC Machine ControlsDocument2 pagesCommon G Codes and M Codes For CNC Machine ControlsVidyut KumarNo ratings yet

- Critical Lift Plan For Forklifts: G. Pre-Lift Checklist (Yes) N/A (NO)Document15 pagesCritical Lift Plan For Forklifts: G. Pre-Lift Checklist (Yes) N/A (NO)Edward HutaurukNo ratings yet

- Učenje - Programiranje Industrijskega Robota Fanuc: Iztok MILOŠIČ, Univ. Dipl. Inž. ElDocument43 pagesUčenje - Programiranje Industrijskega Robota Fanuc: Iztok MILOŠIČ, Univ. Dipl. Inž. ElIztok MILOŠIČNo ratings yet

- The History of Combine HarvestersDocument16 pagesThe History of Combine Harvesterspop bogdanNo ratings yet

- Former Models CPH v1.1 03.13.14Document105 pagesFormer Models CPH v1.1 03.13.14sinho27100% (1)

- Laporan Tugas Khusus Nermass Kiln SystemDocument7 pagesLaporan Tugas Khusus Nermass Kiln SystemSuci SetianingsihNo ratings yet

- EX3003 Hose Anaconda Line KDocument10 pagesEX3003 Hose Anaconda Line KJelski Hizkia IlatNo ratings yet

- Cement Technology: ReclaimerDocument17 pagesCement Technology: ReclaimerYana Damayanti100% (1)

- A S T U D y o F F A I L U R e S I N E X C A V A T o R A R MDocument8 pagesA S T U D y o F F A I L U R e S I N E X C A V A T o R A R MSonyAcerNo ratings yet

- Cat Defense Product LineDocument24 pagesCat Defense Product Linelmn_grss100% (1)

- TrainingDocument66 pagesTrainingandiNo ratings yet

- Construction EquipmentsDocument119 pagesConstruction Equipmentstulsi pokhrelNo ratings yet

- Carraro 707 P1Document1 pageCarraro 707 P1davi henrique boaz100% (1)

- Equipment RentalDocument4 pagesEquipment Rentaljungzki jungzkiNo ratings yet