Professional Documents

Culture Documents

Ucg

Uploaded by

Prem SagarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ucg

Uploaded by

Prem SagarCopyright:

Available Formats

Study on the model experiment and numerical simulation

for underground coal gasication

Lanhe Yang

*

College of Mineral Resources and Geosciences, China University of Mining and Technology, Xuzhou, Jiangsu Province 221008, China

Received 22 August 2002; accepted 4 August 2003; available online 21 September 2003

Abstract

The gas production process in underground coal gasication is closely linked to the temperature distribution and seepage conditions of the

gasier. In this paper, mathematical models on the underground coal gasication in steep coal seams are established according to their

storage conditions and features of gas production process. Additionally, the paper introduces ways to determine model parameters and the

control volume method to solve the model. On the basis of the model experiment, the calculation results are analyzed. From the distribution

of temperature eld, the calculation value is slightly higher than measurement one. The relative errors of all measuring points are virtually

within 10%. According to the simulated calculation results, with the increase of the length for the gasication channel, the heating value of

the gas improves. However, behind the reduction zone, it increases with a smaller margin. The inuence of the temperature eld on the

heating value for the gas is noticeable. Due to the effect of temperature, in high temperature zone, the change gradient of the measured value

of the concentration eld for the gas compositions is larger than that of calculated value. The simulated results of the pressure eld in the

gasication panel 22 and 75 h after the ignition indicate that the relative calculation errors are 5.0014.29 and 9.6817.24%, respectively,

with a corresponding pressure drop rate of 9.5 and 11.97%. On the whole, the simulation value conforms with the experiment value, which

supports the numerical simulation on the temperature eld, concentration eld and pressure eld of underground coal gasication in the steep

coal seams is correct. Thus, it lays a necessary and scientic theoretical foundation for further quantitatively studying the process of

underground coal gasication and forecasting the change patterns.

q 2004 Elsevier Ltd. All rights reserved.

Keywords: Underground coal gasication; Steep coal seam; Temperature eld; Concentration eld; Pressure eld; Mathematical model

1. Introduction

Thanks to the basic theoretical research on the technique

of underground coal gasication and its increasing appli-

cation and promotion as well as the joint efforts made by the

workmates home and abroad, great progress has been made

in the technique of this country and it is developing into a

new discipline. Because the gas production process

completely depends on the temperature conditions and

convection conditions of gasier, the research of tempera-

ture eld, concentration eld and pressure eld has always

been the focus of the researchers in the profession. As of the

beginning of 1980s, a large number of experimental and

theoretical studies on the technique of underground coal

gasication had been made in many countries such as the

Former Soviet Union, Belgium, France, Germany and

the United States, etc. [15], resulting in great progress in

this eld, which contributes a lot to the popularization and

application of the underground coal gasication. While, for

the last two decades, except China, all other countries in the

world has discontinued the research on this eld. Over the

past decades, research on the gasication of different coal

seams, ranging from model experiment, eld experiment to

numerical simulation [68], was made. Large number of

data and a lot of experiences are accumulated [912].

According to the data, the storage conditions of coal seams

in this country are diversied. Steep coal seams account for

8.3% [13]. In old and abandoned coalmines, high-angle coal

seams are becoming more and more [14,15]. In order to

further study the regularities of the gasication process in

the steep coal seams, the mathematical models on the

temperature eld, concentration eld and pressure eld of

the underground gasication, are established. The numerical

solution is found. Through the model experiment,

0016-2361/$ - see front matter q 2004 Elsevier Ltd. All rights reserved.

doi:10.1016/j.fuel.2003.08.011

Fuel 83 (2004) 573584

www.fuelrst.com

* Tel.: 86-516-3885-762; fax: 86-516-3888-682.

E-mail address: lhyang2053@sina.com (L. Yang).

the reasonability of the mathematical models is veried,

which provides an important theoretical basis for the

quantitative analysis and scientic guidance of the process

of underground coal gasication.

2. The features of the underground gasication

in the steep coal seams

The underground gasication in the steep coal seams

eminently features the following three aspects:

(1) The thickness of steep coal seams is much smaller

than its slant height and strike length; therefore, the

temperature conduction and retort gas movement in

the coal seams can be regarded as a matter of 2D

plane. Meanwhile, the heat absorption of aqueous

phase change and coal pyrolysis, together with the

heat losses in peripheral rocks, can be held up as

different minus source items in heat transfer

equations. Likewise, the height and width of the

gasication channel are far smaller than its

length, its eld model can be thought of as 1D

matter, as shown in Fig. 1. The contribution of the

output of retort gas in the coal seams to the gas

compositions in the channel can be thought of as

source items.

(2) With the consumption of coal, due to the dead weight

and the effect of protruding pressure of retort gases,

the unburned coal falls onto the gasication panel,

which leads to a percolation-patterned channel with

comparatively big porosity [16]. Assuming the

porosity is the same everywhere.

(3) Because the coal seams are thin, the downside

and upside of the reaction zone can be thought of

as oor and roof. There is lime-ash layer under the

reaction zone. Therefore, there is material ow only

at the upper boundary.

According to the features mentioned above, the simpli-

cation of the control equation set of the gasication

process in percolation-patterned channel and the model

equation set of dry and pyrolytic model gives the

mathematical models on the gasication process of steep

coal layers, where, only seven kinds of compositions are

taken into account in gas phases, i.e. O

2

, CO, H

2

, CH

4

, CO

2

,

N

2

, H

2

O

(g)

. Six kinds of compositions are taken into

consideration in solid phases. They are C, H, O, N, ash

matter, and water in coal. The corresponding relationship

between the compositions of gas phase, compositions

of solid phase, temperature and the order number is shown

in Table 1.

3. Mathematical models

3.1. Model of seepage gasication eld

of gasication channel

Theequationof theconservationof gasphasecomposition:

f

C

gi

t

x

fC

gi

U

g

C

g

D

y

gi

x

_ _

g

ji

R

j

b

p

i

r

p

i

i 17; j 914 1

where f is the porosity; C

gi

; the mole concentration of

composition i (mol/m

3

); U

g

; the velocity of gas phase (m/s);

C

g

; the overall concentration of gas phase (mol/m

3

); D; the

effective diffusion coefcient (m

2

/s); t; time (s); y

gi

; the mole

percent of the composition i; b

p

i

; r

p

i

; the weighing and

measures coefcient of pyrolysis reaction and reaction rate of

the composition i (mol/m

3

s); g

ji

; the weighing and measures

coefcient of chemical reaction; and R

j

is the reaction rate of

chemical reaction j (mol/m

3

s).

The equation of the conservation of overall gas phases

f

C

g

t

2f

C

g

U

g

g

ji

R

j

7

i1

b

p

i

r

p

i

2

The equation of the conservation of the compositions for

solid phase

12f

C

si

t

12f

C

si

U

s

x

2

g

ji

R

j

AM

i

i 914; j 17 3

Fig. 1. Physical model of the underground gasication in the steep coal

seam.

Table 1

The corresponding relationship between the compositions of gas phase,

compositions of solid phase, temperature and the order number

No. 1 2 3 4 5 6 7 8

The compositions of gas

phase and temperature

O

2

H

2

O

(g)

CO

2

CO H

2

CH

4

N

2

T

g

9 10 11 12 13 14 15

The compositions of solid

phase and temperature

C H O N Ash H

2

O T

s

L. Yang / Fuel 83 (2004) 573584 574

where C

si

is the concentration of the composition i for solid

phase (kg/m

3

) and AM

i

; the atomic (molecular) weight of

the composition i for solid phase (kg/mol).

The equation of the conservation of overall solid phases

1 2f

C

s

t

21 2f

C

s

x

2

g

ji

R

j

AM

i

4

where C

s

is the concentration of solid phase (kg/m

3

).

Assuming that the homogeneous reaction heat is exerted

on the gas phase, while nonhomogeneous reaction heat is

exerted upon the gas and solid phases, so the equation of

energy [17] is as follows.

Gas phase:

f

7

i1

C

gi

C

pgi

T

g

t

2f

7

i1

C

pgi

C

gi

U

g

T

g

x

_ _

C

g

DT

g

2

y

gi

x

2

f

g

4

i1

R

i

DH

i

_ _

R

5

DH

5

2a

1

A

1

T

g

2T

s

2Q

g

5

where T

g

is the temperature of gas phase (K); C

pgi

; the

specic heat of the composition i for gas phase

(kJ/mol K); f

g

; the distribution coefcient of nonhomo-

geneous reaction heat; DH

j

; the chemical reaction heat

(kJ/mol); R

5

; the rate of homogeneous reaction (5) (the

transformational reaction of CO) (mol/m

3

s); DH

5

;

the reaction heat of homogeneous phase reaction (5)

(the transformation reaction of CO) (kJ/mol); a

1

; the

overall heat exchange coefcient of solid and gas phases

(kJ/m

3

s K); A

1

; the contact area between solid phase and

gas phase (m

2

/m

3

); and Q

g

is the heat losses of gas

phase (kJ/m

3

s).

Solid phase:

12f

14

i9

C

si

C

ps

T

s

t

212f

14

i9

C

si

C

ps

U

s

T

s

x

K

s

T

s

x

_ _

12f

g

4

j1

R

j

DH

j

a

1

A

1

T

g

2T

s

2Q

s

6

where T

s

is the temperature of solid phase (K); C

ps

; the

specic heat of solid phase (kJ/kg K); and Q

s

is the heat

losses of solid phase (kJ/kg s).

The equation of gas phase ow

P

g

t

a

s

x

1

a

0

b

0

U

g

P

g

x

_ _

W

g

_ _

7

where P

g

is the gas pressure (Pa); a

s

; the coefcient of

conduction pressure (m

2

/s); a

0

; b

0

; the coefcients related to

the permeability and porosity of media; and W

g

is the

source-sink item.

The equation of gas state

P

g

C

g

RT

g

8

where R is the constant of gas (J/mol K).

The moving speed of ame working face is the amount of

coal consumed per unit area [18], i.e.

U

s

V

A

0

9

where V is the amount of coal consumed within a period of

time (m

3

/s) and A

0

is the cross section area of gasication

channel (m

2

).

Eqs. (1) (7) can be generalized into the following:

F

t

1

b

2

x

f

j

gj

s

2a

h

x

_ _

S

_ _

10

The initial condition

F

i

x; 0 F

i;0

11

The boundary condition

F

i

0; t F

i;0

12

F

i

L; t

x

0 13

3.2. The model on the temperature eld of coal seam

and the ow eld of the retort gas

The model on the temperature eld

rC

p

T

t

x

l

T

y

_ _

y

l

T

y

_ _

2ET 2

7

i1

b

p

i

r

p

i

C

pgi

T Tx; y; 0 T

0

14

2l

T0; y; t

x

a

1

T0; y; t 2T

in

15

2l

TL; y; t

x

a

1

TL; y; t 2T

out

16

2l

Tx; 0; t

y

a

2

Tx; 0; t 2T

g

17

2l

Tx; H; t

y

a

3

Tx; H; t 2T

0

18

where T is the temperature of coal seam (K); C

p

; the

specic heat of coal seam (kJ/kg K); r; the density of coal

seam (kg/m

3

); l; the coefcient of heat conductivity for

coal seam (kW/m K); E; heat losses coefcient

(kW/m

2

K); T

0

; the initial temperature of coal seam (K);

a

1

; the heat convection coefcient (kW/m

2

K); T

in

; the

temperature of the gasication agent at the inlet (K); T

out

;

the temperature of gas at the outlet (K); a

2

; the heat

convection coefcient, when the mass ow exists

L. Yang / Fuel 83 (2004) 573584 575

(kW/m

2

K); and a

3

is the heat losses coefcient

(kW/m

2

K).

The model on the ow eld (quasi-stable state)

0

x

KP

s

mRT

P

s

x

_ _

y

KP

s

mRT

P

s

y

_ _

7

i1

b

p

i

r

p

i

19

P

s

0; y P

in

20

P

s

L; y P

out

21

P

s

x; 0 P

N

22

P

s

x; H P

0

23

where P

s

is the pressure of coal seam (Pa); m; the dynamic

viscosity (Pa s); K; the permeability (D); P

in;

P

out;

P

N

; the

pressure at the inlet, outlet and gasication channel,

respectively (Pa); and P

0

is the pressure of natural coal

under the ground pressure (Pa).

4. The discretization and solution of the control equation

In view of the nonlinearity of the above control

equation set and the strong coupling between equations, it

is difcult to solve the model in analytical method. As a

result, numerical solution is adopted. In the paper, we use

control volume method [19], which belongs to nite

difference method in the form. In methodology, it is a

kind of discretization having no difference from nite

element method. This method is designed to keep the

balance of integral within control volume and uses nodes

to represent control volume. The discretization of the

domain to be solved normally consists of even network

and uneven network. According to the features of the

problem to be addressed in this paper, the spatial

distribution of each variant is the function of time.

Thus, when the solution is made, it will be divided in the

form of even network. Along the x-axis, the network

division of channel is identical with that of coal seam, as

shown in Fig. 2.

Eqs. (14) (19) have the same form. Selecting one of

them gives the general form. Take the discretization of the

equation of temperature eld as a proxy [20].

Taking the derivative of the internal control volume P

during the interval from t to t Dt in Eq. (14)

_n

s

_e

w

_tDt

t

rC

p

T

t

dt dx dy

_tDt

t

_n

s

_e

w

x

l

T

x

_ _

dx dy dt

_tDt

t

_e

w

_n

s

y

l

T

y

_ _

dy dx dt

2

_tDt

t

_n

s

_e

w

E

7

i1

b

p

i

g

p

i

C

pgi

_ _

T dx dy dt 24

Assuming the variants change in a stepped way

according to time and space in the unstable items; the

variants in the diffusion items change according to space in

a piecewise linear way, to time in a stepped way; in the

linear source items, the variants change according to time

and space in a stepped way, thus, the above integral of each

equation can be expressed as the following.

The left side is:

rC

p

T

P

2T

P

0 Dx Dy 25

The rst item on the right side is:

l

e

T

E

2T

P

d

x

2l

w

T

P

2T

W

d

x

_ _

Dy Dt 26

The second item on the right side is:

l

n

T

N

2T

P

d

y

2l

s

T

P

2T

S

d

y

_ _

Dx Dt 27

The third item on the right side is:

S

C

S

P

T

P

Dx Dy Dt 28

where

S

C

2 E

7

i1

b

p

i

r

p

i

C

pgi

_ _

T

P

0 29

S

P

2 E

7

i1

b

p

i

r

p

i

C

pgi

_ _

p

T

P

30

Substitute the above equations back into Eq. (24), and

simplify it into the commonly used form of discretization

equation:

a

P

T

P

a

E

T

E

a

W

T

W

a

N

T

N

a

S

T

S

b

T

31

where the specic expression of each coefcient is as

follows:

a

P

0

rC

P

0 Dx Dy

Dt

; b

T

S

C

Dx Dy a

P

0 T

P

0 32

a

E

l

e

Dy=d

x

; a

W

l

w

Dy=d

x

33

a

N

l

n

Dy=d

y

; a

S

l

s

Dy=d

y

34

Fig. 2. The network division of the domain to be solved.

L. Yang / Fuel 83 (2004) 573584 576

a

P

a

E

a

W

a

N

a

S

a

P

0 2S

P

Dx Dy 35

In the above equations, superscript 0 denoting the

feature of point P has the same feature with that of the

previous period; l

e

; l

w

; l

n

; and l

s

are heat conduction

coefcients in the interfaces of control volume, which are

the function of temperature. According to the temperature of

nodes, the heat conduction coefcients l

E

; l

W

; l

N

; and l

S

can be obtained. The heat conduction coefcients at the

boundary of control volume can be obtained through

compromise averaging method, thus

l

e

2l

E

l

P

l

E

l

P

; l

w

2l

W

l

P

l

W

l

P

;

l

n

2l

N

l

P

l

N

l

P

; l

s

2l

S

l

P

l

S

l

P

36

The establishment of the nodal equation at the boundary.

The four boundaries of the coal seams to be gasied are: the

left boundary x 0; the right boundary x L; the left and

right boundaries exchange heat through convection with

gasication agent and gas all the time. Thus, it belongs to

the third kind of boundary condition; the lower boundary

y 0; is mainly the heat convection between the air current

with high temperature in the gasication channel and wall

plane of the channel, belonging to the third kind of boundary

condition; the upper boundary y H; will be considered

under the following three circumstances: the rst, assuming

the temperature is xed. It is initial temperature and belongs

to the rst kind of boundary condition; the second, there is

heat radiation at a constant heat current, which belongs to

the second kind of boundary condition; the third, in the

model experiment, because the gasier is exposed to the air,

it is also regarded as the third kind of boundary condition.

As for the rst kind of boundary condition, because the

boundary node temperature T

B

is known, it is not necessary

to add the additional boundary nodal equation, but directly

substitute the boundary node temperature into the algebraic

equation of neighboring node.

As for the treatment of the second and the third kinds of

boundary conditions, the additional source item method is

adopted in this paper. Thus, we can substitute the boundary

conditions into the source items close to the boundary node

in the discretization equation. Remove the discretization

equation of the boundary node B; which can reduce the

dimension of the equation set and increase the solution

speed. According to the control body close to the boundary

(Fig. 3), the relational form between the close boundary

node P and the neighboring node can be obtained:

a

P

T

P

a

E

T

E

a

B

T

B

a

N

T

N

a

S

T

S

b 37

where B is boundary node, and

a

B

l

B

Dy

d

x

38

q

B

a

B

T

B

2T

f

39

Subtracting a

B

T

P

simultaneously from the two sides of

Eq. (37) gives

a

P

2a

B

T

P

a

E

T

E

a

N

T

N

a

S

T

S

a

B

T

B

2T

P

b

40

From the heat conduction formula, we know

a

B

T

B

2T

P

q

B

Dy 41

When the second kind of boundary condition is given, q

B

is a given value. Substituting Eq. (41) back into Eq. (37) and

simplifying it, we get

a

0

P

T

P

a

E

T

E

a

N

T

N

a

S

T

S

b

0

42

where

a

0

P

a

P

2a

B

a

E

a

N

a

S

a

P

0 2S

P

Dx Dy 43

b

0

q

B

Dy S

C

Dx Dy a

P

0 T

P

0 q

B

Dy b 44

When the third kind of boundary condition is given, i.e.

the heat convection coefcient a and the uid temperature

T

f

are given, from heat balance, we obtain

q

B

aT

f

2T

B

l

B

T

B

2T

P

d

x

45

Eliminating T

B

gives

q

B

T

f

2T

P

1

a

Dx

2l

B

46

Substitute Eqs. (46) and (47) back into Eq. (43), and

arrange it

a

0

P

a

P

2a

B

Dy

1

a

Dx

2l

B

b

0

b

T

f

Dy

1

a

Dx

2l

B

47

As for the turning node involving two boundaries, the

similar method mentioned above can be adopted to treat it.

Fig. 3. Boundary control volume.

L. Yang / Fuel 83 (2004) 573584 577

5. The determination of major model parameters

5.1. The heat exchange coefcient a

1

between gas

ow and solid particles

The reaction between gas and solid mainly occurs in the

gas holes of solid phase. The effect of nonhomogeneous

reaction heat is exerted on the solid phase. When the

oxidization reactions occur, the solid phase will transfer

heat to gas phase. While the reduction and drying occur, the

gas phase will transfer heat to solid phase.

The heat exchange between gas and solid consists of the

heat convection and radiation. Especially in the period of

high temperature, heat transfer in the form of radiation plays

a major role. Furthermore, when the diameter of the

particles is comparatively large, the heat conduction

among themselves should be taken into consideration.

According to Ref. [21], a

1

can be determined through the

following formula:

a

1

1

1

a

L

a

0

S

1

a

K

a

S

48

where, a

L

; and a

0

S

are the heat convection coefcient and

heat-exchange by radiation coefcient through the lime-ash

layer, respectively (kW/m

2

K), and a

K

; and a

S

are the heat

convection coefcient and heat-exchange coefcient by

radiation through the convert lm, respectively (kW/m

2

K).

5.2. The heat exchange coefcient a

2

of wall plane

The percolation-patterned gasication channel, the heat

exchange coefcient between gas ow and the wall plane of

channel can be obtained through the following formula [22]:

a

0

2

C

pg

u

g

Pr

2=3

0:6Re

1=2

Re , 40

0:2Re

20:2

Re . 40

_

49

where Pr is Prandtl number and Re is Reynolds number,

Re r

g

d

P

u

g

=m; r

g

is the density of gas phase (kg/m

3

).

Because Eq. (49) does not take into account the inuence

of mass ow opposite to the direction of heat transfer at the

wall plane on the heat exchange coefcient, the existence of

mass ow (the dry distillation gas) decreases the gradient of

temperature in the proximity of wall plane, which, as a

result, reduces the heat transfer coefcient. Therefore, on

the basis of the establishment of a simple membrane model,

Eq. (49) is revised in Ref. [23], which gives the following

expression:

a

0

2

a

2

ln1 V

V

50

where a

0

2

is the heat exchange coefcient without mass ow

(W/m

2

K); a

2

; the heat exchange coefcient with compara-

tively big mass ow (W/m

2

K); and Vis the ratio of the heat

in the channel brought by mass ow and the overall heat

transferred to wall plane through heat convection.

5.3. Heat conduction coefcient l

On the condition of the combustion and gasication of

coal seams, the overall heat conduction coefcient of media

consists of heat conduction and heat radiation, whose

expression is as follows:

l f

1

T f

2

T

where f

1

T is the function of heat conduction coefcient of

the coal body (kW/m K) and f

2

T is the function of

radiation and heat exchange coefcients between coal

chunks (kW/m K).

5.4. Permeability K

According to the seepage experiment, the permeability of

coal is the function of temperature [24] and increases with

the rise in temperature. The relationship between them can

be expressed as follows

K 0:2286 0:01041T 0:0001786T

2

51

5.5. The specic heat C

p

The specic heat of coal is related to its compositions and

temperature [25,26]. In this paper, the specic heat formula

of the gas-fat coal adopted can be expressed as follows

C

p

A

n

cosnpT=9 B

n

sinnpT=9 52

where the sampling of the coefcients A

n

and B

n

is as

follows:

A

0

1:69 A

1

20:60A

2

0:40 A

3

20:17 A

4

0:027

A

5

20:037A

6

0:046 A

7

20:05 A

8

0:04 A

9

20:012

B

0

0:00 B

1

0:333 B

2

0:017 B

3

20:131B

4

0:054

B

5

0:003 B

6

0:007 B

7

20:012B

8

0:026 B

9

0:00

The solution ow of numerical model on the computer is

shown in Fig. 4.

6. Model experiment

The model platform is 7.5 m long by 2 m high by 1 m

wide, consisting of base and lid, shown in Fig. 1. Under the

bottom of the gasier a line of hydraulic jacks was installed,

which makes the gasier rest in any angle. The hearth is so

spacious that it can be injected with other materials, which

are used to simulate coal seams with different thicknesses.

On the sides of the gasier there are a number of gas inlets,

outlets, and slip casting holes used to simulate various

L. Yang / Fuel 83 (2004) 573584 578

gasiers and study different modes of air pumping and

gasication channel with different lengths. A circular air

(steam) injection pipeline is equipped in the platform in

hope for supplying the air (steam) in a forward-inverse way

with moving pumping points. The gasier adopts hydraulic

insulation technology. Over the roof of the gasier is

installed a piece of pedal pushed by hydraulic push rod,

which imposes a certain pressure on the coal seam through

the pedal in the course of gasication, in order to simulate

the pressure on the coal seam.

The simulated coal seam in the gasier is 6.8 m long by

1.1 m high by 0.25 m wide, with the angle of 68 8C. The

properties of the coal sample used in the model experiment

are shown in Table 2.

Fig. 4. The box diagram of the numerical calculation program.

L. Yang / Fuel 83 (2004) 573584 579

The gasication panel is 6.0 m long by 1.0 m high by

0.25 m wide, and the initial equivalent diameter of

gasication channel is 70 mm.

The system of the model experiment is shown in Fig. 5.

The pipeline system is designed as armillary circuit.

Through the reversing valve, we can pump the air and

steam negatively and positively. Coal gas cleaner is mainly

to remove the tar from the gas and lower the temperature of

the resulting gas. In order to measure the temperature

distribution in the gasier accurately, we deploy the

temperature-measuring points in an intense way. In the

gasication panel, 22 rows of temperature-measuring points

are buried, with 7 each row. The number totals 154. The

temperature-measuring elements adopt the strictly standar-

dized NiCrNiSi thermal couples. The data are collected by

data acquisition system automatically and displayed on the

screen of the computer and recorded. The resulting gas will

be analyzed in gas phase chromatographer, which can tell

the contents of different compositions.

After the experimental system has been prepared, before

the formal ignition, the cold test should be carried out,

whose main purpose is to measure the leakage rate of the

gasier and check whether all the system is in a good

working state or not.

Suppose the owing capacity of the air supplied at the

inlet is Q

1

; the owing capacity of air discharged at the outlet

is Q

2

; the quantity of wind leaked in the gasier is

DQ Q

1

2Q

2

; thus the leakage rate of the gasier is

h DQ=Q

1

The experimental results of the cold test are shown

in Table 3.

From Table 3, we can see that the leakage rate generally

falls below 8.00%, with the maximum of only 10.16%. With

the increase in the air quantity blasted, leakage rate tends to

increase but still within the tolerance of losses, which is the

basic condition for the smooth run of the model experiment.

First of all, ignite the gasier by means of an electrically

red igniter, then, blast air with small quantity, sample the

gas from the outlet every 5 min, analyze its compositions

and heating value, half an hour later, the interval of

sampling is prolonged to 10 min, increase air blast quantity

gradually, the interval of sampling is so long as 1 h 15 min

later. When the heating value of the gas reaches 1300 kJ/m

3

,

the ignition process is considered successful. According to

the measurement results of the temperature, after the stable

temperature eld in the gasier is formed, the interval of

collecting temperature data at all the temperature-measuring

points is 1 min.

The model experiment lasts for 117 h, undergoing four

phases, namely, gasication preheating (24 h), stable gas

production (58 h), intermittent air pumping (18 h) and

inverse air pumping (17 h). The operating conditions are:

the gasication agent, air; the pressure at the inlet, 2400 Pa;

and the owing capacity at the inlet, 20 m

3

/h. The results of

the experiment are shown in Figs. 6(a) 9(a), 10 and 11.

7. The analysis of calculation results

The calculation results of numerical simulation are

shown in Figs. 6(b) 9(b), 10 and 11.

Comparing Figs. 6 and 8, we can nd that the calculation

results of temperature eld virtually conform with the

measurement results. Except the measuring points in the

combustion zone, where the relative errors between

calculated value and measured value of temperature are

comparatively high (certain points, over 20%), the relative

errors of other points are no more than 14%, majority of

which are within 10%, which completely meets the precision

Table 2

Properties of the coal sample studied

Proximate analysis (wt%) Ultimate analysis (daf, wt%) Heating value (MJ kg

21

)

Moisture Ash Volatile matter C H O N S

4.18 7.61 23.08 72.72 4.71 8.32 1.13 1.33 28.1429.31

Fig. 5. The system of the model experiment.

Table 3

The data of the cold test (m

3

h

21

)

Modes of air supply Forward air supply Inverse air supply

Q

1

36.4 32.1 27.3 21.5 40.0 33.8 24.7 19.5

Q

2

32.7 29.5 25.5 20.6 36.1 31.6 22.9 18.8

DQ 3.7 2.6 1.8 0.9 3.9 2.2 1.8 0.7

h (%) 10.2 8.1 6.6 4.2 9.7 6.5 7.3 3.6

Average (%) 7.3 6.8

L. Yang / Fuel 83 (2004) 573584 580

requirements [27] of numerical simulation on the tempera-

ture eld. From the distribution of temperature eld, the

calculation value is a bit bigger than measurement one. The

reasons are as follows: rst of all, heat losses coefcient E in

mathematical models is determined, on the basis of

composite structure calculation formula of heat transfer

coefcient for the xed conditions (temperature, wind

velocity). In the process of experiment, due to the natural

ventilation or forced ventilation, the heat losses coefcient

increases, which contributes to the slight drop of the

temperature. Then, during calculation, the heat conduction

coefcient of coal seams is not the one of body coal but

the equivalent heat conduction coefcient taking the

inuence of convection and heat radiation into consider-

ation. The coal seams in the model experiment are piled up

by various sizes of coal chunks. Though the interstices are

lled with coal powder, its holes are far bigger than the real

one. Therefore, heat exchange is not a single form of

heat conduction. With the effect of convection intensifying,

the surface heat conduction coefcient of the coal

seam improves, which inuences the precision of calcu-

lation results.

Because the reaction rate heightens rapidly with the

increase of temperature, as a result, due to the impact of

temperature, the change gradient of the compositions

concentration for measurement value in high temperature

zone is bigger than that of calculation value (Figs. 7 and 9).

According to Figs. 7 and 9, with the expansion of

gasication channel, the heating value of the gas increases

gradually. However, behind the reduction zone, the extent

of increase decreases. The inuence of the temperature eld

on the heating value of the gas is remarkable. In the rst

period, in spite of the comparatively long gasication

channel, due to the low temperature in the oven, the heating

value of the gas is relatively low; in the second period, the

temperature of the oven increases in the comparatively

shorter gasication channel, but the heating value of

resulting gas is higher than that in the rst period. Therefore,

maintaining a temperature eld with high temperature and

Fig. 6. The temperature eld in the gasication panel 22 h after the ignition.

Fig. 7. The concentration eld in the gasication channel 22 h after the ignition.

L. Yang / Fuel 83 (2004) 573584 581

comparatively longer gasication channel is conducive to

the stability and increase of the heating value for the gas.

Figs. 10 and 11 demonstrate that, the simulated

calculation value of the pressure for gas ow basically

conform with the measured value. The comparative error in

the rst period between calculation value and measurement

value is 5.0014.29%, with its average drop rate for the

pressure of uid 9.5% (15.2, 213.1%). From Fig. 11, we

know that, 75 h after the commencement of gasication, the

error of the simulated calculation for pressure is 9.68

17.24%, with its average drop rate of the pressure of gas

along gasication channel 11.97% (21.39, 217.33%). It

can be concluded that, with the prolonging of gasication

time, the extent of the pressure drop of uid increases and

the calculation error becomes bigger. The major reasons are

the following, at the very beginning of the experiment, the

gas moves along the free gasication channel with little

resistance on the uid and small uctuation of pressure.

Accordingly, the drop rate and calculation error are

comparatively low. With the development of gasication,

the top coal layer over the gasication channel, due to

the effect of high temperature, expands, inbreaks and

falls onto the gasication channel because of dead

weight, which lls the gasication channel with loose

coal chunks. Thus, the free gasication channel becomes

percolation-patterned. The resistance over the gas move-

ment increases dramatically, so does the extent of the drop

rate of pressure. The curve of the experiment takes on wild

uctuation. Considering the changes of movement con-

ditions and the determination of major model parameters,

such as conduction pressure coefcient, permeability as well

as the involvement of human factors and empirical factors in

the calculation results in a certain error in the parameters

calculation, which causes oscillation in the value of

numerical simulation.

In short, the simulated results support that the calculation

value conforms with the measurement value well, which

shows that the establishment of mathematical models on

Fig. 8. The temperature eld in the gasication panel 75 h after the ignition.

Fig. 9. The concentration eld in the gasication channel 75 h after the ignition.

L. Yang / Fuel 83 (2004) 573584 582

the temperature eld, concentration eld and pressure eld

in the gasier, the determination of parameters, the analysis

and treatment of boundary conditions and the solution

method are correct. This provides necessary theoretical

basis and scientic guidance for the comprehensive

quantitative study and production practice of underground

coal gasication.

8. Conclusions

(1) According to the storage conditions and the features of

gasication process for the steep coal seams, on the

basis of model experiment, the mathematical models

on the gasication process of steep coal seams are

established. The simulated results demonstrate that the

calculation value can virtually conform with the

measurement one, which supports that numerical

simulation on the temperature eld, concentration

eld and pressure eld is reasonable in the under-

ground gasication of steep coal seams on the

experimental condition.

(2) The numerical simulation shows that, in high tempera-

ture zone, the calculation value of the temperature eld

is a bit bigger than measurement value; the change

gradient of the measurement value of the concentration

of various compositions for the gas is bigger than that

of the calculation value; temperature eld has a great

inuence on the heating value of the gas. The

heating value of the gas increases with the rise in

the temperature of gasier. The ideal temperature

eld with high temperature is conducive to the

improvement of the gas and the stability of the

gasication process.

(3) According to the calculation results, the relative error

between the calculation value and measurement one of

the uid pressure and its drop rate increase gradually

with the gasication process. The change in the

seepage condition of gasication channel is mainly

responsible for the comparatively big calculation error.

(4) The numerical calculation results basically demon-

strate the real change patterns of the temperature eld,

concentration eld and pressure eld in the process of

underground gasication of steep coal layers. Though a

certain error exists between the calculation value and

experiment one, however, according to the specic

combustion and gasication conditions of coal seams,

choosing appropriate parameters or optimal parameters

with the help of inverse calculation, the above

mathematical models can be fully applied to pro-

duction practice and to predict the change patterns of

three elds of the process of underground coal

gasication.

Acknowledgements

This work was supported by the National Natural Science

Foundation of China (Ratication No. 59906014,

50276066). The technical contributions of professor Yu Li

and Dr Liang Jie are gratefully acknowledged by the author.

References

[1] Kpekmomo EB. Coal Chem Ind 1993;6:615.

[2] Chandelle V. Collect Transl Works Mining 1992;13:57.

[3] Beyer LG. Collect Transl Works Mining 1989;10:15.

[4] Guntermann K. Collect Transl Works Mining 1988;9:610.

[5] Liang J. PhD Thesis, China University of Mining and Technology;

1997.

[6] Yang LH. J China Univ Mining Technol 2000;29:142.

[7] Liu SQ. J China Univ Mining Technol 2000;29:606.

[8] Guntermann K, Gudenau HW, Franke FH. Proceedings of the 12th

Annual Underground, Coal Gasication Symposium, Washington,

DC, 2428 August. ; 1986. p. 20715.

[9] Mortazavi HR, Emery AF, Corlett RC. Proceedings of the 12th

Annual Underground Coal, Gasication Symposium, Washington,

DC, 2428 August. ; 1986. p. 25264.

[10] Francis TW, Mead SW, Daniel HS. Underground Coal Gasication:

The State of the Art 1983;79:1549.

[11] William BK, Robert DG. Underground Coal Gasication: The State

of the Art 1983;79:129.

[12] Guo CW. Mining World 1994;15:3.

[13] Sun JH. China Energy 2001;5:19.

[14] Yang LH. PhD Thesis, China University of Mining and Technology;

1996.

Fig. 10. The pressure eld in the gasication channel 22 h after the ignition.

Fig. 11. The pressure eld in the gasication channel 75 h after the ignition.

L. Yang / Fuel 83 (2004) 573584 583

[15] Liu SQ, Liang J, Yu L. Coal Conversion 1999;22:50.

[16] Yang LH. In: Song DY, editor. Study on the seepage combustion

methods in underground coal gasication. Xuzhou: China University

of Mining and Technology Press; 2001. p. 613.

[17] Fan WC, Wan YP. In: Hu SH, editor. The model on movement and

combustion and its calculation. Hefei: China University of Science

and Technology Press; 1992. p. 2017.

[18] Wu RY. In: Huang W, editor. Coal gasication. Xuzhou: China

University of Mining and Technology Press; 1988. p. 173.

[19] Guo KL, Kong XQ, Chen SN. In: Jiang YY, editor. Calculation heat

transfer. Hefei: China University of Science and Technology Press;

1988. p. 7591.

[20] Liu SQ. PhD Thesis, China University of Mining and Technology;

2000.

[21] Xiang YQ, Zhang LP, Xiang P, Wei JF. Coal Gas Heat 2001;21:24.

[22] Yagi S, Wakao N. AichE J 1959;5:805.

[23] Smith DM, Williams FL. Fuel 1984;63:259.

[24] Encinar JM, Beltran FJ, Ramiro A, Gonzalez JF. Fuel Process Technol

1988;55:2258.

[25] Qizhi N, Williams A. Fuel 1995;74:108.

[26] Xiang YQ. Coal Gas Heat 1995;15:10.

[27] Yang LH. In: Song DY, editor. Underground coal gasication

project. Xuzhou: China University of Mining and Technology

Press; 2001. p. 184.

L. Yang / Fuel 83 (2004) 573584 584

You might also like

- Coal GasificationDocument11 pagesCoal GasificationALIyilmazNo ratings yet

- PropertiesDocument143 pagesPropertiesPrem SagarNo ratings yet

- Design Slides FinalDocument231 pagesDesign Slides FinalPrem Sagar100% (1)

- Forchheimer Porous-Media Flow Models - Numerical Investigation and Comparison With Experimental DataDocument85 pagesForchheimer Porous-Media Flow Models - Numerical Investigation and Comparison With Experimental DataGrouchoMarx04No ratings yet

- Refinery Mass BalanceDocument221 pagesRefinery Mass BalancePrem Sagar91% (11)

- GasificationDocument11 pagesGasificationPrem SagarNo ratings yet

- UCG Presentation CorrectedDocument27 pagesUCG Presentation CorrectedPrem SagarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Solved Problems of Laser Chapter 4 KeiserDocument35 pagesSolved Problems of Laser Chapter 4 Keisersohaib50% (2)

- Swan UseDocument129 pagesSwan Use_cuackNo ratings yet

- Chem 542 Spring2010 Lecture 3 PDFDocument45 pagesChem 542 Spring2010 Lecture 3 PDFwuachinnNo ratings yet

- Homework 3 FebDocument42 pagesHomework 3 FebEmmanuel Olowosulu100% (3)

- Test AACEDocument5 pagesTest AACECrazy BrainNo ratings yet

- Links Eng Prod CederjDocument6 pagesLinks Eng Prod CederjHugo CostaNo ratings yet

- Problem 2.19 PDFDocument2 pagesProblem 2.19 PDFKauê BrittoNo ratings yet

- Grade 9 Lesson Plan 01Document2 pagesGrade 9 Lesson Plan 01RahmonGreenNo ratings yet

- Lab 6 - Transient Analysis (Transient Response) of Series RL Circuit Using OscilloscopeDocument3 pagesLab 6 - Transient Analysis (Transient Response) of Series RL Circuit Using OscilloscopehamzaNo ratings yet

- Energy - Wikipedia, The Free EncyclopediaDocument15 pagesEnergy - Wikipedia, The Free EncyclopediaJay SrivastavaNo ratings yet

- Konrad Wachsmann, The Turning Point of Building (Document14 pagesKonrad Wachsmann, The Turning Point of Building (Valentina De LeónNo ratings yet

- UNIT 1, Laser, Book NotesDocument12 pagesUNIT 1, Laser, Book NotesPranoy MukherjeeNo ratings yet

- Dynamic Stabilisation of Biped Lucy Powered by ActuatorsDocument340 pagesDynamic Stabilisation of Biped Lucy Powered by ActuatorstakinabreakNo ratings yet

- Basic Structure of Eddy Current Brakes: Found in Cars As WellDocument7 pagesBasic Structure of Eddy Current Brakes: Found in Cars As Wellpseudo networkNo ratings yet

- Closed Conduit Hydraulics DesignDocument44 pagesClosed Conduit Hydraulics DesignRaje kNo ratings yet

- Conductors and Electric Field in Static EquilibriumDocument1 pageConductors and Electric Field in Static Equilibriumfrance villNo ratings yet

- CEMDocument4 pagesCEMHaseeb Shafiq100% (1)

- EXPT 11 Intrinsic ViscosityDocument5 pagesEXPT 11 Intrinsic ViscosityBea A.100% (1)

- Asme Piping Vibration CriteriaDocument9 pagesAsme Piping Vibration CriteriaKonstantinos KamarasNo ratings yet

- DMSTDocument89 pagesDMSTCarlos Sánchez Coppel100% (1)

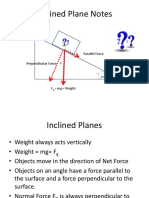

- Inclined Planes and Forces Notes PDFDocument19 pagesInclined Planes and Forces Notes PDFLeroy JenkinsNo ratings yet

- Autumn Break Home Work Class 9Document4 pagesAutumn Break Home Work Class 9nashjrodrigues709No ratings yet

- ElectricityDocument16 pagesElectricitypatrick omonyNo ratings yet

- MSL Technical Guide 18 Resistance Measurement For ThermometryDocument5 pagesMSL Technical Guide 18 Resistance Measurement For ThermometrydlonguinhoNo ratings yet

- Curve of A Baseball: Index Bernoulli ConceptsDocument1 pageCurve of A Baseball: Index Bernoulli Conceptspepe.booksNo ratings yet

- B Tech Mechatronic Syllanus Sem I-Vi PDFDocument60 pagesB Tech Mechatronic Syllanus Sem I-Vi PDFprNo ratings yet

- Materials Science HW ProblemsDocument8 pagesMaterials Science HW Problemsamitav_chak9523No ratings yet

- Axially Loaded Members PDFDocument50 pagesAxially Loaded Members PDFCharbel Saad SaadNo ratings yet

- Solidworks Flow Simulation Project Report: (Company Logo Here)Document9 pagesSolidworks Flow Simulation Project Report: (Company Logo Here)zarzosa rabanalNo ratings yet

- Four DimensionsDocument19 pagesFour DimensionsDeris NougadNo ratings yet