Professional Documents

Culture Documents

TVS 80-DC Series Automatic Differential Condensate Controllers

Uploaded by

Jozsef MagyariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TVS 80-DC Series Automatic Differential Condensate Controllers

Uploaded by

Jozsef MagyariCopyright:

Available Formats

TVS 80-DC Series Automatic Differential Condensate Controllers

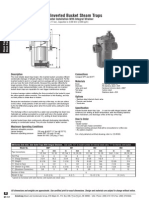

For Pressures to 250 psig (17 bar)Capacities to 4,400 lb/hr (2,000 kg/hr)

Steam Trapping and Steam Tracing Equipment

A 30 F F C E B L F

F B C E L

TVS 81-DC

TVS 82-DC & TVS 83-DC

Description

Armstrong automatic differential condensate controllers (DC) are designed tofunction on applications where condensate must be lifted from a drain point or in gravity drainage applications where increased velocity will aid in condensate drainage. When lifting from the drain point, often referred to as syphon drainage, the reduction in pressure that occurs when the condensate is elevated causes aportion of it to flash back into steam. Ordinary steam traps, unable to differentiate between flash steam and live steam, close and impede drainage. Increased velocity with gravity drainage will aid in drawing the condensate and air to the DC. This increased velocity is caused by an internal steam by-pass, controlled by a manual metering valve, so the condensate controller will automatically vent the by-pass or secondary steam. This is then directed to the condensate return line or collected for use in other heat exchangers.

Connections Materials

Screwed NPT and BSPT

Body: Internals: Valve and seat: Fittings metering valve: Handwheel: TVS 80 Series Piston valve internals:

ASTM A48 Class 30 All stainless steel304 Hardened chrome steel17-4PH Metering valveBronze with stainless steel trim. Fittings 250# malleable iron. Ductile iron Stainless steel and graphite

Specification

Automatic differential condensate controller, type TVS in cast iron complete with integral piston valves on the inlet, and outlet with strainer.

Maximum Operating Conditions

Maximum allowable pressure (vessel design): Maximum operating pressure: 250 psig @ 450F (17 bar @ 232C) 250 psig (17 bar)

How to Order

Specify Specify Specify Specify

model number size and type of pipe connection maximum working pressure that will be encountered or orifice size any options required

For a fully detailed certified drawing, refer to: TVS 81-DC CD #1088 TVS 82-DC and TVS 83-DC CD #1089

TVS 80-DC Series Model No. Inlet & Outlet Connections Secondary Steam Connections Test Plug A Width Across Handwheels B Outlet Valve Open C Face to Face E F L Number of Bolts Weight lb (kg) Maximum Allowable Pressure (Vessel Design) Maximum Operating Pressure psi (bar) TVS 81-DC in mm 1/2, 3/4 15, 20 3/8 9 1/4 6 8-1/4 210 11 279 5 127 7-5/8 194 3 76 16-3/4 425 6 6 13-1/2 6 TVS 82-DC in mm 1/2, 3/4 15, 20 1/2 15 1/2 15 13-3/4 349 12-5/8 320 6-1/2 165 13 330 4-1/2 114 18-3/8 467 6 6 27-1/2 12.5 250 psig @ 450F (17 bar @ 232C) 250 (17) TVS 83-DC in mm 3/4, 1 20, 25 1/2 15 3/4 20 15-1/8 384 15-1/8 384 7-3/4 197 14-3/8 365 4-7/8 124 20-3/4 527 6 6 50 23

114

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

TVS 80-DC Series Automatic Differential Condensate Controllers

212/812/882/22;82TVS-82

211/811/881/21-DC/81-DC/TVS-81DC

For Pressures to 250 psig (17 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr) Model TVS 81-DC Capacity

Steam Trapping and Steam Tracing Equipment

Model TVS 82-DC Capacity

Series 213/813/883/23;83;TVS-83DC

Model TVS 83-DC Capacity

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

115

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Next

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Armstrong International SA - Com 80-DC Series Automatic Differential Condensate ControllersDocument2 pagesArmstrong International SA - Com 80-DC Series Automatic Differential Condensate ControllersWalid SaifNo ratings yet

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- E4Document14 pagesE4juanca_eduNo ratings yet

- Series 826YD Specification SheetDocument2 pagesSeries 826YD Specification SheetFEBCONo ratings yet

- 30-DC Series Automatic Differential Condensate Controllers: DescriptionDocument2 pages30-DC Series Automatic Differential Condensate Controllers: DescriptionJozsef MagyariNo ratings yet

- Trampas de Vapor Armstrong, Series880 PDFDocument2 pagesTrampas de Vapor Armstrong, Series880 PDFLuis Guillermo Gallardo BoscanNo ratings yet

- Valvulas Diafragma InformacionDocument4 pagesValvulas Diafragma InformacionCHRISTIANCHIROQUENo ratings yet

- Vickers DG4V-3 DG4V-3S 6xDocument32 pagesVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroNo ratings yet

- Asco Series 223 CatalogDocument2 pagesAsco Series 223 CatalogEduard RamosNo ratings yet

- HR E576qDocument12 pagesHR E576qIsanka SathsaraneeNo ratings yet

- Medidor de Gas - Smith MeterTM Turbine Meters FMCDocument5 pagesMedidor de Gas - Smith MeterTM Turbine Meters FMCjplutodNo ratings yet

- DeaeratorDocument8 pagesDeaeratorfjoesandiNo ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- 100P Series: High Pressure FiltersDocument6 pages100P Series: High Pressure FiltersPartsGopher.comNo ratings yet

- Tappan Furnace FG6RK 096N 16BDocument4 pagesTappan Furnace FG6RK 096N 16BAnubis RahlNo ratings yet

- 2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StyleDocument2 pages2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StylemaarwaanNo ratings yet

- Catalog of WEIR-Steam Conditioning Control ValveDocument8 pagesCatalog of WEIR-Steam Conditioning Control ValveTim KuNo ratings yet

- Flowserve Lined Flush BottomDocument32 pagesFlowserve Lined Flush BottomDevdatt WaghuleNo ratings yet

- Series 825YD Specification SheetDocument2 pagesSeries 825YD Specification SheetFEBCONo ratings yet

- FlowCon EVS Tech 08.2013Document7 pagesFlowCon EVS Tech 08.2013Jeff Anderson CollinsNo ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- Planet Dewy 60 BFRDocument4 pagesPlanet Dewy 60 BFRRaja MatharuNo ratings yet

- TescomDocument16 pagesTescomrafaareNo ratings yet

- Gate Valve - SpecDocument8 pagesGate Valve - Specuvarajmecheri0% (1)

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123No ratings yet

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- Interruptor de Presion - AscoDocument9 pagesInterruptor de Presion - AscoJosephGutierrezNo ratings yet

- Blow Down Control ValveDocument2 pagesBlow Down Control ValveAmruth Babu V TNo ratings yet

- Catálogo Válvula DirecionalDocument20 pagesCatálogo Válvula DirecionalcristianoclemNo ratings yet

- WW Ordering Guide 700 SeriesDocument4 pagesWW Ordering Guide 700 SeriesEdwin BautistaNo ratings yet

- The Power of Blue .: Quick SpecsDocument4 pagesThe Power of Blue .: Quick SpecszulaikhaabdrahmanNo ratings yet

- Tac Erie Vt/Vs Poptop Series Two Position Spring Return ValvesDocument12 pagesTac Erie Vt/Vs Poptop Series Two Position Spring Return ValvesElmer Ramón Murillo MejiaNo ratings yet

- Aether DBS Natural Gas Line HeatersDocument4 pagesAether DBS Natural Gas Line Heatersmatteo20090% (1)

- 8356 - nsfr4 Asco Mini ValveDocument4 pages8356 - nsfr4 Asco Mini ValveNandor KermeciNo ratings yet

- Tescom RegulatorDocument4 pagesTescom RegulatormiaberyNo ratings yet

- Fluid Components Full CatalogDocument464 pagesFluid Components Full Catalognegg 348No ratings yet

- SPW Immersion Fired - Specification Data Sheet (7000)Document9 pagesSPW Immersion Fired - Specification Data Sheet (7000)daemonohNo ratings yet

- ElectrovalvulasDocument8 pagesElectrovalvulasRaul Guevara TorresNo ratings yet

- HR E577rDocument6 pagesHR E577rAnton RenaldoNo ratings yet

- Ra 92711Document39 pagesRa 92711Agus Yulfizar100% (3)

- CV300 2Document13 pagesCV300 2Achariya ParpromNo ratings yet

- Condenser Technical DataDocument3 pagesCondenser Technical DatakawkatrNo ratings yet

- Series LF25AUB-Z3 Specification SheetDocument2 pagesSeries LF25AUB-Z3 Specification SheetWattsNo ratings yet

- Valvula WW-820Document4 pagesValvula WW-820Anonymous Iic1fi49uENo ratings yet

- Valvula ASCO Falcon SB2500Document2 pagesValvula ASCO Falcon SB2500Elmer HuashuayoNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- SM TM 1.5-4 Guardsman (G) Series02002Document4 pagesSM TM 1.5-4 Guardsman (G) Series02002Paola Arevalo RinconNo ratings yet

- Desaireador GKMOSS - Tray - Deaerator - Brochure PDFDocument6 pagesDesaireador GKMOSS - Tray - Deaerator - Brochure PDFCdMoraSNo ratings yet

- Low Loss Header Tech Data ManualDocument8 pagesLow Loss Header Tech Data ManualBobbyB2No ratings yet

- Carrier38CKC 50HzDocument20 pagesCarrier38CKC 50HzAaron LeveyNo ratings yet

- DESUPERHEATERDocument4 pagesDESUPERHEATERghkashyap1No ratings yet

- Directional Control Valves: Catalog HY15-3502/USDocument21 pagesDirectional Control Valves: Catalog HY15-3502/USPartsGopher.comNo ratings yet

- Surface Pumps: Motor Power HP KWDocument24 pagesSurface Pumps: Motor Power HP KWAscenderBSPNo ratings yet

- Asco Dust Collector Main Pulse Valves DC CatalogDocument4 pagesAsco Dust Collector Main Pulse Valves DC CatalogFelipe SalvatierraNo ratings yet

- Carrrier Manual 38ckc-c5pdDocument20 pagesCarrrier Manual 38ckc-c5pdAaron LeveyNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Sample Calculations of Boiler Pumps and IDDocument5 pagesSample Calculations of Boiler Pumps and IDJozsef MagyariNo ratings yet

- Fall 2002 DuplexStainlessSteelsSeaWaterDocument3 pagesFall 2002 DuplexStainlessSteelsSeaWaterJozsef MagyariNo ratings yet

- About PumpsDocument8 pagesAbout PumpsJozsef MagyariNo ratings yet

- Foster Wheeler - Package BoilersdocxDocument3 pagesFoster Wheeler - Package BoilersdocxJozsef MagyariNo ratings yet

- Corrosion of DuplexDocument13 pagesCorrosion of DuplexgirishnitwNo ratings yet

- HRSG 2011 BrochureDocument12 pagesHRSG 2011 BrochureAndry SetiawanNo ratings yet

- International Metal Trading NetworkDocument26 pagesInternational Metal Trading NetworkJozsef MagyariNo ratings yet

- Multistage Horizontal Boiler Feed Pumps - Rotor Dynamic and Structural Advantages of The Opposite Versus Equidirectional Impellers ConfigurationDocument9 pagesMultistage Horizontal Boiler Feed Pumps - Rotor Dynamic and Structural Advantages of The Opposite Versus Equidirectional Impellers ConfigurationJozsef MagyariNo ratings yet

- Automated Cause & Effect Analysis For Process PlantsDocument6 pagesAutomated Cause & Effect Analysis For Process PlantsAprianto SasrNo ratings yet

- Pneumatic PlugsDocument35 pagesPneumatic PlugsJozsef MagyariNo ratings yet

- Digital Control Systems (DCS) : Ddcs in Thermal Power Plant OperationDocument2 pagesDigital Control Systems (DCS) : Ddcs in Thermal Power Plant OperationJozsef MagyariNo ratings yet

- Plugin CVsectionDocument40 pagesPlugin CVsectionJozsef MagyariNo ratings yet

- Boiler Condition AssessmentDocument4 pagesBoiler Condition AssessmentJozsef Magyari100% (1)

- Fire ProtectionDocument48 pagesFire ProtectionJozsef Magyari100% (1)

- Gta 15Document3 pagesGta 15Jozsef MagyariNo ratings yet

- Hydraulic Pressure Test PumpDocument1 pageHydraulic Pressure Test PumpJozsef MagyariNo ratings yet

- UniquePackageTestingCapability A10022Document1 pageUniquePackageTestingCapability A10022Jozsef MagyariNo ratings yet

- GasTurbineBroDocument12 pagesGasTurbineBroJozsef MagyariNo ratings yet

- P37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Document12 pagesP37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Jozsef MagyariNo ratings yet

- Brochure Compressors Screw Oil FreeDocument2 pagesBrochure Compressors Screw Oil FreeJozsef MagyariNo ratings yet

- Figure 1.1.5x - Impeller Between Bearings - Flexibly Coupled - Multistage - Radial Split-Double CasingDocument1 pageFigure 1.1.5x - Impeller Between Bearings - Flexibly Coupled - Multistage - Radial Split-Double CasingJozsef MagyariNo ratings yet

- The Sets Operate On Both Gaseous (Natural Gas, Associated Oil Gas) and Liquid Fuel (Kerosene, Diesel Fuel)Document5 pagesThe Sets Operate On Both Gaseous (Natural Gas, Associated Oil Gas) and Liquid Fuel (Kerosene, Diesel Fuel)Jozsef MagyariNo ratings yet

- Process Screw Compressor BrochureDocument16 pagesProcess Screw Compressor BrochureJozsef Magyari100% (1)

- Gta 6Document6 pagesGta 6Jozsef MagyariNo ratings yet

- 2935 0594 10 ZH350+ 12p Litho EN LR 20110919 - tcm795-1706670Document12 pages2935 0594 10 ZH350+ 12p Litho EN LR 20110919 - tcm795-1706670Jozsef MagyariNo ratings yet

- Productsheet 1519853Document3 pagesProductsheet 1519853Jozsef MagyariNo ratings yet

- IR C1000 20 Brochure LTR AMDocument12 pagesIR C1000 20 Brochure LTR AMRamil Serdan100% (2)

- Air & Industrial Gas Compressors - 2935 0598 11 - tcm795-2928482Document40 pagesAir & Industrial Gas Compressors - 2935 0598 11 - tcm795-2928482Jozsef MagyariNo ratings yet

- ZH Brochure 16p Full Update LR Single 20101027 Tcm795-1691248Document16 pagesZH Brochure 16p Full Update LR Single 20101027 Tcm795-1691248Jozsef MagyariNo ratings yet

- Elliot TurbineDocument2 pagesElliot TurbinefjafarvandNo ratings yet

- Topic No 2 Hydraulics UpdatedDocument21 pagesTopic No 2 Hydraulics UpdatedSamarth SNo ratings yet

- Swimming Pool Pump & Filter SystemDocument8 pagesSwimming Pool Pump & Filter SystemDedy KristiantoNo ratings yet

- Whirlpool Cabrio Washer Fault CodesDocument7 pagesWhirlpool Cabrio Washer Fault CodesqweezyNo ratings yet

- Cessna Citation - X Ice - and - Rain Protect PDFDocument10 pagesCessna Citation - X Ice - and - Rain Protect PDFjuan100% (1)

- De Nora Water Technologies Introduction. Presenter Name de Nora Water TechnologiesDocument114 pagesDe Nora Water Technologies Introduction. Presenter Name de Nora Water Technologieszhigang ding100% (2)

- PBV 3pc Trunnion 2015Document32 pagesPBV 3pc Trunnion 2015Uday GokhaleNo ratings yet

- Be Excavator 325H Parts PDFDocument432 pagesBe Excavator 325H Parts PDFFabian CurtoNo ratings yet

- BC NR1180 Rev05 SQX-STX-SWITDocument28 pagesBC NR1180 Rev05 SQX-STX-SWITTonyNo ratings yet

- 15 IRC Plumbing Final ChecklistDocument3 pages15 IRC Plumbing Final ChecklistImam Pujo SusenoNo ratings yet

- Iom Biffi Morin Series A B C S en en Us 6089118Document37 pagesIom Biffi Morin Series A B C S en en Us 6089118Anonymous Wu6FDjbNo ratings yet

- Manual Ingersoll RandDocument18 pagesManual Ingersoll RandJunior Francisco QuijanoNo ratings yet

- KSB Ball Valve 2 inDocument8 pagesKSB Ball Valve 2 inrusli bahtiarNo ratings yet

- Punching Machine REPORTDocument33 pagesPunching Machine REPORTJilly Arasu100% (2)

- 21 SOP For Vacuum PumpDocument6 pages21 SOP For Vacuum PumpAmit Biswas100% (1)

- INSTALLATION Training PresentationDocument36 pagesINSTALLATION Training PresentationamirNo ratings yet

- Lansas 2015 CatalogDocument40 pagesLansas 2015 CatalogCleaner MagazineNo ratings yet

- Lab Manual-H & P-1me2603Document40 pagesLab Manual-H & P-1me2603Hi helloNo ratings yet

- AGA Product List July '06Document178 pagesAGA Product List July '06Adin11100% (1)

- BALON Floating Valve - Installation and Repair Manual 2Document13 pagesBALON Floating Valve - Installation and Repair Manual 2Rudi Syarif Hidayat HarahapNo ratings yet

- Horseley Bridge Tanks BrochureDocument12 pagesHorseley Bridge Tanks BrochureObinna OkaforNo ratings yet

- Water Supply-Distribution in A BuildingDocument36 pagesWater Supply-Distribution in A BuildingDharmesh YadavNo ratings yet

- Valvula S Sarco Mod LEADocument10 pagesValvula S Sarco Mod LEAJunior OliveiraNo ratings yet

- Operation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreDocument17 pagesOperation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreSathishkumar DhamodaranNo ratings yet

- Logik15: Logika Control S.R.LDocument17 pagesLogik15: Logika Control S.R.LsebastianNo ratings yet

- Crosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsDocument17 pagesCrosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsTarek MohamedNo ratings yet

- Centrifugal Compresssor Pre-Commissioning ChecklistDocument3 pagesCentrifugal Compresssor Pre-Commissioning ChecklistNikhil JadhavNo ratings yet

- Lab No 6 - Coordinated Control - Signal OverlapDocument5 pagesLab No 6 - Coordinated Control - Signal OverlapMuhammad RafayNo ratings yet

- ACRD 502 Tech Manual 50-60 CycleDocument64 pagesACRD 502 Tech Manual 50-60 CycleMajid AkramNo ratings yet

- Manual de Serviço Compressor Denso 6p148 (Eng)Document17 pagesManual de Serviço Compressor Denso 6p148 (Eng)AssisNo ratings yet

- FWD Fire Pump - Main Ring Pressurizing Failure - Tag 5110-ZZZ-513001-FFDocument4 pagesFWD Fire Pump - Main Ring Pressurizing Failure - Tag 5110-ZZZ-513001-FFBruno Augusto ReisNo ratings yet