Professional Documents

Culture Documents

Chemical Engg - Sciences

Uploaded by

Cesar Gutierrez0 ratings0% found this document useful (0 votes)

36 views1 pageThe Chemical Engineering Division at the Indian Institute of Chemical Technology in Hyderabad, India has expertise in various areas of chemical process engineering. It contributes to both basic and applied research as well as working with chemical process industries. Its specialists groups include process engineering, chemical plant design and modelling, and it has capabilities in areas like process engineering, plant design, simulation, and environmental engineering. It provides services to various clients in both the public and private sectors.

Original Description:

Original Title

Chemical Engg.sciences

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Chemical Engineering Division at the Indian Institute of Chemical Technology in Hyderabad, India has expertise in various areas of chemical process engineering. It contributes to both basic and applied research as well as working with chemical process industries. Its specialists groups include process engineering, chemical plant design and modelling, and it has capabilities in areas like process engineering, plant design, simulation, and environmental engineering. It provides services to various clients in both the public and private sectors.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views1 pageChemical Engg - Sciences

Uploaded by

Cesar GutierrezThe Chemical Engineering Division at the Indian Institute of Chemical Technology in Hyderabad, India has expertise in various areas of chemical process engineering. It contributes to both basic and applied research as well as working with chemical process industries. Its specialists groups include process engineering, chemical plant design and modelling, and it has capabilities in areas like process engineering, plant design, simulation, and environmental engineering. It provides services to various clients in both the public and private sectors.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

CHEMICAL ENGINEERING SCIENCES

Indian Institute of Chemical Technology

Tarnaka, Uppal Road, Hyderabad 500 007, INDIA

www.iictindia.org

VISION AND GOAL

The Chemical Engineering Division at IICT has made significant

contribution both to basic and applied research. The division,

catering to the needs of the chemical process industries, is

associated with activities ranging from experimental evaluation of

process routes to design & commissioning of commercial plants

for organic intermediates and specialty chemicals. All the activities

including scale-up studies, design data collection, process design,

preparation of engineering documents and interaction with project

implementation agencies are undertaken by the division for

successful transfer of technologies.

SPECIALIST GROUPS

Process Engineering and Novel Separations

Process Engineering

Process Dynamics and Control

Properties Evaluation

Membrane Separations

Chemical Plant Design and Modelling

Chemical Plant Design and Basic Engineering

Process Modelling and Simulation

Process Safety and Risk Analysis

Biochemical and Environmental Engineering

COMPETENCIES

Process Engineering and scale up of batch/continuous

chemical processes

Pilot plant design / operation

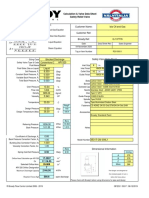

Melt Crystallization Unit Integrated Pesticide Plant

GAIL's Gas Cracker Pilot Plant

Chemical Plant Design and Basic Engineering

Consultancy services for revamp, debottlenecking of

commercial plants.

Techno economic evaluation

Startup assistance for commercial plants

Trouble shooting in commercial plants

Modelling, Simulation and optimization of Chemical / Petro

Chemical Plants

Process Safety and Risk Analysis

Advanced real time process control strategies for batch

reactors

Intelligent hybrid control systems for complex processes.

S&T SERVICES

Measurement and prediction of physico chemical and

thermodynamic properties

Industrial wastewater treatment

Performance evaluation of effluent treatment plants

Upgradation of effluent treatment plants

Analytical monitoring of air, water and soil.

Environmental audit

Process safety studies

www.iictindia.org

CHEMICAL ENGINEERING SCIENCES

CONTACT PERSONS (Technical)

Shri VEDANTA CHARY

Head, Chemical Engineering Sciences, IICT, Hyderabad.

Tel: +91 40 27193626 Fax: +91 40 27193626

e-mail: vchary@iict.res.in

or

Dr. M. RAMAKRISHNA

Area Leader, Chemical Engineering Sciences

IICT, Hyderabad.

Tel: +91 40 27193408 Fax: +91 40 27193626

e-mail: mrk@iict.res.in

FOR BUSINESS ENQUIRIES:

Dr. J. S. YADAV, FNA

Director, IICT, Hyderabad.

Phone: 91-40-27193030 Fax: 040-27160387

E-mail: yadav@iict.res.in

or

G. SAMPATH KUMAR

Head, Business Management

IICT, Hyderabad.

Phone/Fax: 91-40-27193943

E-mail: sampath@iict.res.in

Horton sphere for LPG storage

ACTIVITIES

Pilot Plant Studies for Mono Nitro Toluenes

Bench scale studies on Hydrazine Hydrate

Bench scale studies on continuous process for Sebacic Acid

Benzaldehyde Pilot plant Studies

CO

2

Removal from Natural Gas (Joint project with EIL/

ONGC)

Effluent treatment and chemical recovery for Consolidated

Fibres and Chemical Limited

Propane/Propylene Separation

Continuous alcohol fermentation using yeast crystals

Advanced Real-Time Process Control Technology for Batch

Reactors

Automation of Chemical Reactors in Pharmaceutical

Industries.

Artificial Intelligence Based Tools for Process Modeling,

Optimization and Control

Intelligent Hybrid Control System for Complex Processes

Plant Wide Control Design Procedure Based on Nonlinearity

and Interaction Measures.

INFRASTRUCTURE

The range of pilot plant equipment facilities cover wide range of

unit operations commonly encountered in chemical process

industries like distillation, absorption, filtration, evaporation, size

reduction, drying, liquid-liquid extraction and solid-liquid extraction

of various sizes capacities which are useful in up scaling the

chemical processes.

Software

Aspen Plus

BJAC

METANA

DISP

CONTOUR

PEEPI

SAFETI-Micro

PSM OFFICE, ver 1.0

WHAZAN EFFECTS

Facilities

Dust Explosion Test Apparatus

Reaction Calorimeter

Accelerating Rate Calorimeter

Bench Top Reactor System

Bench scale facilities for

* Reverse Osmosis

* Nano Filtration

* Ultra Filtration

* Pervaporation

* Electro Dialysis

CLIENTS

Gujarat State Fertilizer Corporation Limited, Baroda

Mangalore Chemicals& Fertilizers, Mangalore

Oil and Natural Gas Corporation, Uran

Hindustan Petroleum corporation, Visakhapatnam

Atic Industries, Valsad

Panyam cement & Mineral Industries Limited, Hyderabad

Gas Authority of India Ltd.

Deepak Nitrite Limited, Pune

Vasant Chemicals Ltd., Hyderabad

You might also like

- EV - Plantas Automatizadas-Manuales PDFDocument79 pagesEV - Plantas Automatizadas-Manuales PDFCesar Gutierrez0% (1)

- Chlorophyll Ethanol ExtractionDocument3 pagesChlorophyll Ethanol ExtractionCesar GutierrezNo ratings yet

- Clorofila Extraction PDFDocument20 pagesClorofila Extraction PDFCesar GutierrezNo ratings yet

- Statistica Release Notes - 125 PDFDocument12 pagesStatistica Release Notes - 125 PDFCesar GutierrezNo ratings yet

- DanielsEtAl ExperimentalPhysicalChemistry PDFDocument639 pagesDanielsEtAl ExperimentalPhysicalChemistry PDFCesar GutierrezNo ratings yet

- Wegstein Method Metodos NumericosDocument15 pagesWegstein Method Metodos NumericosCesar GutierrezNo ratings yet

- 2004 Chemical Engineering Syllabus: and Checklist For Self-EvaluationDocument10 pages2004 Chemical Engineering Syllabus: and Checklist For Self-EvaluationCesar GutierrezNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sheet (3) - PermeabilityDocument4 pagesSheet (3) - PermeabilityshereenNo ratings yet

- Empirical Relations of Convective Heat TansferDocument29 pagesEmpirical Relations of Convective Heat TansferArvin DalisayNo ratings yet

- ABET LAB Unitary OperationsDocument4 pagesABET LAB Unitary OperationsPaulina PerezNo ratings yet

- A8 GasLift SolutionsDocument13 pagesA8 GasLift SolutionsVatsal ShahNo ratings yet

- Bernoulli Equation Part 1Document34 pagesBernoulli Equation Part 1Ashish RanjanNo ratings yet

- Unit 330Document22 pagesUnit 330mohamed ghorabNo ratings yet

- DF7 - Vertical Lift PerformanceDocument2 pagesDF7 - Vertical Lift Performanceadnan0307100% (1)

- Refinery Amine, Sour Water & Sulphur Recovery Unit (SRU) HYSYS SimulationDocument58 pagesRefinery Amine, Sour Water & Sulphur Recovery Unit (SRU) HYSYS Simulationyou kackNo ratings yet

- Resin Transfer MouldingDocument11 pagesResin Transfer Mouldingyuvi yuviNo ratings yet

- Lecture 1 - Classification of Heat ExchangersDocument47 pagesLecture 1 - Classification of Heat ExchangersAhmed HelmiNo ratings yet

- Dust Reaction Model in Waste Heat Boiler of Copper Smelting: August 2019Document12 pagesDust Reaction Model in Waste Heat Boiler of Copper Smelting: August 2019vinayakbunNo ratings yet

- Processes 07 00615Document13 pagesProcesses 07 00615Adnan Ahmed ChahalNo ratings yet

- Physical Properties of Fire Hazards and The SpreadDocument6 pagesPhysical Properties of Fire Hazards and The SpreadBedrddine AggounNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- Blanking and PiercingDocument5 pagesBlanking and PiercingSatheesh Sekar100% (1)

- Advances in GranulationDocument14 pagesAdvances in GranulationRamesh DeodaNo ratings yet

- BASF R0-20 Data SheetDocument1 pageBASF R0-20 Data SheetAmir RahbariNo ratings yet

- Description Brand Supplier Thickness PriceDocument45 pagesDescription Brand Supplier Thickness PriceGlenn CalingasanNo ratings yet

- Technical Specification: Brazed Plate Heat ExchangerDocument1 pageTechnical Specification: Brazed Plate Heat ExchangerSergio Solar melendezNo ratings yet

- Sulfur Removal Methods: A. Hidalgo-Vivas and B. H. CooperDocument13 pagesSulfur Removal Methods: A. Hidalgo-Vivas and B. H. Coopergharibi.ali98486No ratings yet

- Proc Eng P&I DDocument60 pagesProc Eng P&I DGiang T LeNo ratings yet

- LNS Hydraulics Supplementary Information-V1Document16 pagesLNS Hydraulics Supplementary Information-V1cm21lpm1No ratings yet

- Reactor Separator Recycle NetworksDocument17 pagesReactor Separator Recycle Networkskiran367No ratings yet

- Paper 3 Section A 2nd Set MSDocument4 pagesPaper 3 Section A 2nd Set MSPrisha ShettyNo ratings yet

- CPP Lab Report 4Document11 pagesCPP Lab Report 4Muhammad Danial KhairuddinNo ratings yet

- Fluid Flow and Heat Transfer Over Staggered + ShapedDocument16 pagesFluid Flow and Heat Transfer Over Staggered + ShapedHawraa ImadNo ratings yet

- Ga Drawing Gas Scrubber Package 230822Document1 pageGa Drawing Gas Scrubber Package 230822CIRCLE CHANNELNo ratings yet

- ChE 122 LE1 NotesDocument4 pagesChE 122 LE1 Notesgoogley71No ratings yet

- AmmoniaDocument7 pagesAmmoniasaad ElsheikhNo ratings yet

- Filters For Compressed AirDocument11 pagesFilters For Compressed AirNiaz MalikNo ratings yet