Professional Documents

Culture Documents

Liu 2014 Ocean-Engineering

Uploaded by

Jhy MhaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liu 2014 Ocean-Engineering

Uploaded by

Jhy MhaCopyright:

Available Formats

Ocean Engineering 78 (2014) 62 72

Contents lists available at ScienceDirect

Ocean Engineering

journal homepage: www.elsevier.com/locate/oceaneng

Numerical studies on global buckling of subsea pipelines

Run Liu a,n, Hao Xiong a, Xinli Wu b, Shuwang Yan a

a b

State Key Laboratory of Hydraulic Engineering Simulation and Safety, Tianjin University, Tianjin 300072, China School of Engineering Design, Technology, and Professional Programs, Pennsylvania State University, University Park, PA 16802, USA

art ic l e i nf o

Article history: Received 4 June 2013 Accepted 29 December 2013 Available online 23 January 2014 Keywords: Subsea pipeline Pipeline lateral buckling FEM Initial imperfection

a b s t r a c t

Subsea pipelines buckle globally because of their movement relative to surrounding soil. Global buckling is often triggered by high operational temperature of the oil in pipelines, initial imperfections in the pipeline, and/or a combination of both. Pipeline global buckling is a failure mode that must be considered in the design and in-service assessment of submarine pipelines because it can jeopardize the structural integrity of the pipelines. Global buckling is increasingly difcult to control as temperature and pressure increase. Therefore, location prediction and buckling control are critical to pipeline design. Finite element analysis (FEA) is often used to analyze the behavior of pipelines subject to extreme pressures and temperatures. Four numerical simulation methods based on the nite element method (FEM) program ABAQUS, i.e., the 2D implicit, 2D explicit, 3D implicit, and 3D explicit methods, are used to simulate pipeline global buckling under different temperatures. The analysis results of the four typical methods were then compared with classical analytical solutions. The comparison indicates that the results obtained using the 2D implicit and 2D explicit methods are similar and the results obtained using the 2D implicit method are closer to those obtained using traditional analytical solutions. The analysis shows that the results of the 3D implicit and 3D explicit methods are similar, but the results obtained using the 3D methods are signicantly different from those obtained using the analytical solution. A novel method to introduce initial pipeline imperfections into the FEA model in global buckling analysis is also presented in this paper. & 2014 Elsevier Ltd. All rights reserved.

1. Introduction Pipeline design faces numerous engineering challenges as oil and gas resources are being obtained from deep waters. One of these challenges is pipeline global buckling. Pipelines are being required to operate at increasing temperatures and pressures in deep water. Thermal lateral buckling is a typical global buckling mode of deep-water pipelines because pipelines are typically laid directly on the seabed rather than being trenched and buried. In-service hydrocarbons must be transported at a high temperature and pressure to ease the ow. Thus, the thermal stress induced by the difference between the operational and ambient temperatures coupled with the Poisson effect causes a pipeline to expand longitudinally. However, the pipeline cannot expand freely because the surrounding soil restricts it. Axial compressive stress builds up on the wall of a pipeline approximately one kilometer long, and sudden deformation occurs when the compressive load reaches or exceeds the soil foundation constraint to release the internal stress accumulated on the pipe wall. Uncontrolled buckling can have serious effects on pipeline integrity.

Corresponding author. E-mail address: liurun@tju.edu.cn (R. Liu).

Studies on thermal buckling in pipelines can be traced back to the early 1970s. Hobbs (1981, 1984) derived analytical solutions to the buckling and post-buckling behavior of a heated pipeline by assuming a pipeline buckling curve. He established the relationship between buckling temperature and buckling length in consideration of axial pipesoil interaction. Taylor and Gan (1986) derived an analytical solution to the global buckling of an initially imperfect pipeline based on the analytical solution obtained by Hobbs (1984) to lateral buckling in an ideal pipeline. They assumed that the shape of a deformed pipeline is symmetrical and similar to that of an initially imperfect. The seabed trench bottom deformation are neglected and the soil resistance force is fully mobilized per unit length acting against the lateral buckling mechanism. Solving the total potential energy equation with special boundary conditions, Taylor and Gan (1986) obtained the analytical solution of buckling force, buckling amplitude, and maximum compressive stress. A sophisticated nite element method (FEM) that considers all of the pertinent pipeline operation data has been applied to pipeline buckling analysis with the development of modern computers. FEM studies on subseapipeline global buckling can be classied into two categories. One focuses on the interaction between a pipeline and its subsoil because a reliable pipesoil resistance assessment plays a signicant role in pipeline global buckling analysis. Several researchers

0029-8018/$ - see front matter & 2014 Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.oceaneng.2013.12.018

R. Liu et al. / Ocean Engineering 78 (2014) 62 72

63

over the past 30 years have paid particular attention to pipesoil interaction in the analysis of on-bottom pipeline strength and stability behavior. Numerous excellent research studies have been conducted, and several useful achievements have been adopted for practical use, such as those of Lyons (1973), Friedmann (1986), Schaminee et al. (1990), Palmer et al. (1990), Hesar (2004), Merield, White, and Randolph (2007, 2009), Bruton et al. (2008), Wang et al. (2013) and Bruton et al. (2011). The other category simulates pipeline global buckling under high-pressure and high-temperature conditions. Numerical pipeline global buckling analysis tools, such as PIPLIN-III (Structural Software Development Inc., 1981), PlusOne (Palmer and Associates, 1995), PIPSOL (Nixon, 1994), ABP, and UPBUCK (Klever et al., 1990) have been used in different situations over the past 30 years. Shaw and Bomba (1994) have developed a nite element (FE) analysis method that considers both nonlinear geometry and material effects to examine pipeline response to upheaval buckling. Case studies show that the temperature difference corresponding to pipeline buckling with nonlinear material behavior is smaller than that in the elastic model. Andreuzzi and Perrone (2001) present a mathematical model that considers soil resistance to beam lateral deections by introducing linear spring resistance to beam lateral displacement, and report that FE and nite differences may generate errors in the results because of the discretization related to the modeling of the various axial compressive forces in the elements. A formula to analyze initially imperfect underground pipelines has been developed, and an issue regarding a 2D, initially imperfect, buried pipeline has been analyzed by Villarraga et al. (2004). All of these programs are based on pipe beam elements and elasticplastic soil springs. Using simplied analytical models has been a standard approach to analyze upheaval buckling of high-temperature and high-pressure pipelines. However, simplied approaches may be excessively conservative because they may fail to identify vulnerable features and underlying upheaval buckling risks that can result in severe economic consequences (Zhang and Tuohy, 2002). Therefore, understanding pipeline response to various loading conditions is critical in increasing pipeline design efciency. Zhang and Tuohy (2002) conduct a global-buckling analysis case study on a trenched but unburied 6.0-inch production owline using the commercial FEM program ANSYS (Kohnke and Peter, 1999). The results show that FE technology can be adopted as an effective tool to evaluate potential offshore owline buckling behavior. ABAQUS (Hibbitt et al., 2000) also incorporates pipeline beam elements, soilpipe interaction, and large displacements to model considerable pipeline length and predict overall structural behavior under different load conditions. Jukes et al. (2009) report the advantage of the FE analysis tools, which can be used in the design and simulation of subsea pipelines and their components. SIMULATOR, a highly nonlinear FE program, has been developed using ABAQUS as the FE engine. Case studies show that the developed program can be applied to complex pipeline design cases, such as global analysis, local modeling, and pipeline route selection. The case study results also imply that the advanced numerical tools are suitable for pipeline design and simulation, particularly of deep-water pipelines. These tools are also suited to extreme conditions because they can simulate highly non-linear cases quickly and efciently. Wang et al. (2009) and Jukes et al. (2009) developed the FE tool as a SIMULATOR component. The in-house pipeline analysis package designed by Kenny, which has been developed using the ABAQUS platform, can simulate global buckling with different pipeline congurations under various conditions. Global pipeline FE analyses have been widely used to investigate complex practical problems associated with lateral pipeline buckling and the walking pipeline phenomenon (Jukes et al., 2008; Jukes et al., 2009; Sinclair et al., 2009; Cumming et al., 2009; Cumming and

Rathbone, 2010; Jin et al., 2010; Bruton et al., 2011; Sun et al., 2011). Literature reviews have shown that the existing 3D, thermal-pipeline-buckling nite element analysis (FEA) method, which collectively considers temperature eld and stress elds, initial imperfections in a pipe, and soil/pipe interaction, is inefcient, although the FEA of offshore pipeline upheaval buckling has progressed rapidly in recent years. In this study, four typical FEA methods, namely, the 2D implicit, 2D explicit, 3D implicit, and 3D explicit methods, are used to analyze subsea-pipeline global buckling under high temperature and high pressure conditions. Initial pipeline imperfection as a result of fabrication or installation and seabed undulation is also considered in the FE analyses using a novel method. The analysis results obtained using the four typical FEA methods are then compared with analytical solutions derived by Taylor and Gan (1986).

2. Global buckling analysis methods 2.1. Establishment of 2D and 3D FEA models A global buckling analysis model is characterized by the long axial direction of the pipeline and the relatively small pipeline cross-section. Therefore, the beam element is highly suitable for pipeline structure simulation. The moment distribution along the pipeline can be obtained easily. The 2D FEA model can be adopted to simplify the study on one-direction global buckling under thermal stress conditions. The 2D FEA model offers a trustworthy solution to exposed pipelines on an even seabed, and it allows the pipeline to move both axially and laterally. The 2D FEA model not only can assess thermal expansion and longitudinal thermal loading, but also can investigate lateral and upheaval buckling. The horizontal 2D FEA model can be built as shown in Fig. 1. The 2D FEA model employed in this study uses ABAQUS as the underlying FE engine. PIPE32H beam elements and dimensions represent the pipeline in this model. The expansion coefcient of the pipeline material is also dened to determine the role of thermal stress induced by temperature. The pipeline is modeled using linear elastic material, and the seabed is assumed to be a rigid foundation. Contact elements are created between the pipeline and the rigid foundation, and these contact elements are positioned in two areas: one is perpendicular to the plane of the foundation soil, which displays normal contact behavior and has a hard contact parameter, and the other is parallel to the foundation soil surface/plane, which displays tangential contact behavior and has a penalty function parameter. This form of contact cannot determine pipeline settlement deformation as a result of selfweight, but it can simulate the increasing resistance of the foundation soil to the increasing weight of the submerged pipeline. The friction length effect cannot be extended to both ends of the pipeline because the pipeline is long ( Z 500 m). Both ends of the pipeline are completely xed, and the boundary conditions of the soil resist both laterally and axially. The bottom boundary of the soil is completely xed as well. The following three steps have been adapted in the simulation: (1) introduction of the initial curved pipeline section to simulate the initial imperfection generated in the manufacturing process and placement of the pipeline

Fig. 1. 2D FEA model.

64

R. Liu et al. / Ocean Engineering 78 (2014) 62 72

Table 1 Physical and mechanical parameters of pipeline. Wall thickness T (mm) 0.0127 External diameter D (mm) 0.3239 Young0 s modulus E (N/mm2) 206000 Poisson ratio 0.3 Bulk density s (kg/m3) 7850 Oil density o (kg/m3) 800 seawater density (kg/m3) 1120 Thermal coefcient (1C) 0.000011 yield stress sy (MPa) 448

Table 2 Physical and mechanical parameters of subsoil (from Bohai Gulf). Soil layer Thickness Moisture of soil (m) content (w%) 38.8 45.8 Effective bulk density Void (kN/m3) ratio e 7.8 9.4 1.05 1.27 Plasticity index IP 14.3 21.5 Cohesion (kPa) 18 10 Internal friction angle (1) 18.6 15.9 Compression modulus Es12 (MPa) 3.26 2.58 Shear strength (kPa) 4.07.5 7.516.0

Mucky silty clay 02 Silt clay 23

on the seabed, (2) application of a gravitational eld to model contact behavior between the pipeline and the rigid foundation soil, and (3) increase in pipeline temperature to simulate the hightemperature loading process until global buckling occurs. A 3D model is considered to simulate the pipeline global buckling process, pipeline self-penetration procedure, and seabed behavior. C3D8R solid elements are used to model the pipeline and foundation soil in the 3D FE model. Pipeline mechanical behavior is assumed to be linear-elastic. The MohrCoulomb model is used as the soil foundation constitutive model to simulate the stress strain relationship with respect to soil properties. Tables 1 and 2 provide additional details on these parameters. Soil dilatancy is not considered, and the contact between pipeline and soil occurs in three directions. The rst direction runs along the deadweight direction of the pipeline that displays normal contact behavior and has a contact parameter set to hard contact. The second direction runs along the longitudinal direction of the pipeline that exhibits tangential contact behavior and with contact parameter set to penalty function. The third direction runs along the radial direction of the pipeline with tangential contact behavior and with contact parameter set to penalty function. The 3D model boundary is similar to that of the 2D model and the specic simulation process involves three steps. First, the initial curved section of the pipeline is introduced to simulate the initial imperfection generated in the manufacturing process and the placement of the pipeline on the seabed. Second, a gravitational eld is applied to model the contact behavior between the pipeline and the rigid foundation soil. The pipeline sinks into the soil because of its own weight. Subsequent computation iteration begins when the deformation between the pipeline and soil is stabilized. Third, pipeline temperature is increased to simulate the high-temperature loading process until global buckling occurs. A signicant difference between the 3D and 2D models is that aside from the lateral and axial friction effects along the pipeline, strong lateral earth pressure from the deformed soil affects the pipeline during buckling because the pipeline partially sinks into the foundation soil. This sinking results in foundation soil deformation. The 3D analysis model is presented in Fig. 2. 2.2. Analysis type denition The non-linear static buckling problem is a part of pipeline global buckling under thermal stress conditions. The structure must release strain energy to maintain equilibrium when negative stiffness occurs in response to load displacement. Two current FEA methods simulate this behavior. One is the displacement control method in which a dampler controls the stable structure displacement and addresses

Fig. 2. 3D FEA model.

Fig. 3. Loaddisplacement response curve of the unstable equilibrium problem.

the static equilibrium of the unstable response segment in implicit analysis. This method is known as the modied Riks method (Hibbitt et al., 2000). The other method is the acceleration control method in which inertia controls acceleration and addresses the steady structure displacement in explicit analysis, thereby simulating the snapping of the pipeline. This method is known as the explicit dynamic method (Hibbitt et al., 2000).

2.2.1. Implicit arc-length iterative method (modied Riks method) The Riks method, originally proposed by Riks (1972, 1979) and Wempner (1971), tracks the nonlinear structural equilibrium path. This method has been modied and developed further by Criseld (1981) and Ramm (1981) and has become the main method used in

R. Liu et al. / Ocean Engineering 78 (2014) 62 72

65

the analysis of non-linear structure stability problems. The relationship between load and displacement in the unstable equilibrium problem corresponding to the load-displacement response curve is not monotonic. The stress or strain release phenomenon occurs during the response, as shown in Fig. 3. The modied Riks method is an effective solution algorithm in such cases. The Riks algorithm assumes that the loading process is applied in proportion to the overall response of the structure and that the process is smooth. All of the equilibrium solutions are viewed as nodal displacement variables during the development of instability, and a single equilibrium path in space is dened by the loading proportion coefcient. All size increments must be articially restricted when Newton0 s method is used in the iterative solution to ensure convergence. The size increment of this equilibrium path is the moving distance from the equilibrium point along its tangential direction to the next solving point in the modied Riks algorithm. Distance is determined by the automatic increase in convergence speed in this algorithm and does not have to be articially restricted in the computation process. The computation principle is described as follows. (1) A reference load is dened, and the proportionality factor of this load to the ultimate load corresponding to pipeline failure is calculated. ABAQUS/Standard uses the arc length (l) along the static equilibrium path in the loaddisplacement space to measure the progress of the solution and determines the relationships among load, arc length, and displacement. (2) The load is proportionally applied. The load magnitude (Ptotal) is dened as P total P 0 P ref P 0 1 where P0 is the initial load; Pref is the reference load vector; and is the load proportionality factor, which is considered as a part of the solution. ABAQUS/Standard determines the current value of the load proportionality factor at each increment. (3) Newton0 s method is used to obtain the nonlinear equilibrium equations. The modied Riks procedure extrapolates only a 1% strain increment. The ABAQUS program provides an initial arclength increment lin along the static equilibrium path in the Riks step denition. The initial load proportionality factor in is computed as in lin lperiod 2

Fig. 4. Modied Riks method.

N vN 0 are the displacements; 0 is the normalized tangential displaceN ment vector at the initial iterative step, where N 0 is v0 scaled by u; and u is the maximum absolute value of all displacement variables. The value lin is initially suggested by the user and is adjusted using the ABAQUS/Standard load increment method in static problems based on the convergence rate.

2.2.2. Explicit dynamic method The explicit integration algorithm in the ABAQUS/explicit model adopts the central interpolation method, i.e., the nodal force (external force P minus internal force I) can be calculated in the following manner by multiplying the mass matrix M with the acceleration matrix at time t if the dynamic equilibrium conditions are satised: P I Mu jt M 1 P I jt u 5

The acceleration at initial time increment t can be calculated as 6

where lperiod is a user-specied total arc-length scale factor (typically equal to 1). This t stable value is used during the rst iteration of a Riks step. The value is computed automatically according to Eq. (2) in subsequent iterations and increments. (4) Compared with the Riks method, the modied Riks method addresses the unstable collapse and conducts post-buckling analysis more effectively (see Fig. 4). The initial load proportionality factor can be determined using this method as shown in the following paragraphs. The solution is assumed to have developed to point A0 uN 0 ; 0 .

NM M N has The tangent stiffness K NM 0 has been formed and K 0 v0 P

The acceleration can be obtained directly and the entire system of equations in the explicit integration algorithm need not be used because the lumped mass matrix is typically adopted. Acceleration at a certain node can be determined simply through node mass and nodal force, thereby signicantly reducing calculation time. The velocity increment can be calculated using the central interpolation method based on the assumption that the acceleration remains constant at a certain time increment. The velocity at the midpoint of the current time increment can be obtained by adding the velocity increment to the velocity at the midpoint of the previous time increment. _ jt 1=2t u _ jt 1=2t u t jt 1=2t t jt jt u 2 7

Deformation at the end of the time increment can be calculated by integrating velocity as follows: ujt t ujt tujt 1=2t 8

been determined. The increment size (A0 to A1 in Fig. 4) is selected based on a specied path length lin in the solution space. Therefore,

N N 2 0 0 ; 1 : 0 ; 1 lin 2

Explicit procedure stability is conditional, i.e., the time increment cannot exceed the limitationt stable . This limitation can be estimated by q 2 9 1 2 t stable max where max is the supreme natural frequency and is the corresponding critical damping. As shown in preceding paragraphs, initial acceleration can be determined if the dynamic equilibrium conditions are satised at the initial time increment. Then, velocity and deformation can be calculated using the explicit procedure. The selected time increment must be adequately small to obtain precise solutions; thus, the assumption that acceleration remains constant through the time increment is reasonable. The explicit procedure therefore

Thus, 0 7 lin

1=2 N N 0 0 1

where 0 is the initial load magnitude parameter in the modied Riks method; N and M denote the degrees of freedom of the model; uN and

66

R. Liu et al. / Ocean Engineering 78 (2014) 62 72

typically requires numerous time increments. The computation time required for each time increment solution is quite small because the entire system of equations does not have to be solved. However, internal element computation is time consuming and includes calculating strain with deformation, computing stress according to constitutive relations, and nally determining the internal force at the nodes. 2.3. Introduction of initial imperfection into the FEA model Initial imperfection is considered in FEA because of pipeline out-of-straightness as a result of fabrication or installation and seabed undulation. An approach to introduce initial pipeline imperfection based on modal analysis results is presented in this paper. Modal analysis is often used to study the probability of different structure-buckling shapes under unit load. Buckling load decreases if structural deformation results in the generation of positive work by external loads because this deformation cannot resist external loads, according to the workenergy principle. Conversely, buckling load increases if structural deformation causes external loads to produce negative work because energy is absorbed. Thus, the deformation is advantageous to the structural ability to resist external forces. The proposed method is based on the workenergy principle and focuses on the rst-order buckling mode of the pipeline structure. Pipeline deformation is recorded to update the pipeline geometry when external loads

generate positive work. The implementation method used in the numerical analysis is described as follows. First, pipeline buckling modes are calculated and a geometric model identical to the global buckling analysis model is generated. Both models must have identical node numbers. The calculation subspace of the pipeline modal analysis is set to 2 and the nNODEFILE keywords are inputted into the INP le. The pipeline displacement modal le is outputted as FIL, which is used as the basis for the buckling analysis model. The model adds an nIMPERFECTION scale factor statement to introduce pipeline imperfection, as shown in Fig. 5. In this study, investigations and analyses of an in-service operational pipeline subject to high temperature are conducted using the aforementioned numerical analysis methods, i.e., the 2D implicit, 2D explicit, 3D implicit, and 3D explicit methods.

3. Analysis results using different FEA methods 3.1. A subsea pipeline case A pipeline engineering project is constructed in Bohai Gulf. The unburied subsea pipeline has an outside diameter of 323.9 mm and wall thickness of 12.7 mm. The designated temperature difference is 60 1C. The designed pipeline and foundation soil parameters are reported in Table 1 and 2, respectively. The four numerical analysis methods mentioned are used in this study to analyze pipeline global

Fig. 5. Introduction of initial imperfection into the pipeline model. (a) Straight pipeline and (b) pipeline with initial imperfection.

Table 3 Characteristics of different FEA models. FEA Model Load step 2D-implicit Riks Rigid Elastic PIPE32H 7850 206000 0.000011 Node to surface 0.4 2D-explicit Dynamic explicit Rigid Elastic PIPE32H 7850 206000 0.000011 Node to surface 0.4 3D-implicit Riks MC C3D8R 7.8 3.26 18 18.6 Elastic C3D8R 7850 206000 0.000011 Surface to surface 0.4 3D-explicit Dynamic explicit MC C3D8R 7.8 3.26 18 18.6 Elastic C3D8R 7850 206000 0.000011 Surface to surface 0.4

Subsoil

Material behavior Element type Property 0 (kN/m3) E (MPa) c (kPa) (1) Material behavior Element type Property (kg/m3) E (MPa) (1C) type Coefcient

Pipeline

Contact type between pipeline and seabed

R. Liu et al. / Ocean Engineering 78 (2014) 62 72

67

buckling under thermal stress. The results are computed using the various computational methods and subsequently compared. 3.2. Parameters of different FEA models The 2D implicit, 2D explicit, 3D implicit, and 3D explicit methods are employed in this study to examine the differences in the results obtained using the various numerical analysis/ simulation methods in terms of pipeline global buckling and establish the FEA model. The computation parameters of the different analysis models are shown in Table 3. Initial imperfections are introduced using the modal analysis method in this study. The initial imperfection amplitude is 150 mm and the wavelength is 23 m. The 2D and 3D computation models are presented in Fig. 4 and Fig. 5, respectively. 3.3. Analysis results 3.3.1. Comparison of pipeline global buckling shapes The aforementioned four types of numerical analysis/simulation methods can simulate the lateral pipeline global buckling process that occurs at the initially imperfect area under temperature loads. The lateral pipeline global buckling shape developments with the increase in temperature obtained using the four simulation methods are shown in Fig. 6. This gure presents only the local variation in the pipeline deformation segments. The deformation segment length is shown along the x-axis, and the lateral deformation amplitude is shown along the y-axis. Deformation rst occurs at the initially imperfect area of the pipeline with the increase in temperature and its amplitude gradually increases from 150 mm. A reverse bending deformation occurs on both sides of the initially imperfect pipeline wavelength

when this amplitude increases to a certain extent. Buckling amplitude and wavelength increase gradually in both positive and reverse directions in the pipeline, and the global buckling scope is enlarged. The pipeline global buckling deformation process in the 2D model is signicantly different from that in the 3D model. The maximum pipeline buckling amplitudes differ under similar temperature variations. Buckling amplitude in the 2D model is greater than 1.3 m when the temperature difference is 60 1C, whereas the maximum buckling amplitude in the 3D model is less than 1.2 m. The mutational temperatures in pipeline global buckling also differ with the increase in temperature variation. Pipeline buckling amplitude increases by over three times when the temperature difference is increased from 20 1C to 30 1C, as shown in the 2D model. However, mutational increase in the buckling amplitude in the 3D model occurs when the temperature difference is increased from 40 1C to 60 1C. The pipeline buckling shapes are different as well. Reverse pipeline buckling amplitude and wavelength in the 2D model undergo signicant changes as observed in the development of reverse pipeline buckling amplitude. However, the increase in the reverse pipeline amplitude is signicant and the wavelength change in the 3D model is substantial only if the temperature is higher than 40 1C. Buckling amplitude development in the 2D model under 40 1C is greater than 50% of the amplitude under 60 1C. This nding indicates that the development speed of buckling amplitude in the 2D model is faster than that in the 3D model. The differences mentioned are mainly caused by the partial embedding of the pipeline in the 3D model in the foundation soil; thus, soil resistance to lateral pipeline deformation increases signicantly. Maximum pipeline buckling amplitude in the 2D model reaches 1.49 m when the temperature difference is 60 1C and the

Fig. 6. Thermal buckling modes of different FEA models. (a) 2D-Implicit FEA model, (b) 2D-Explicit FEA model, (c) 3D-Implicit FEA model and (d) 3D-Explicit FEA model.

68

R. Liu et al. / Ocean Engineering 78 (2014) 62 72

implicit method is used. This amplitude is greater than the 1.35 m obtained using the explicit dynamic method, as shown in the comparison of the results obtained using both implicit and explicit methods. Maximum reverse-pipeline buckling amplitude reaches 0.52 m, which is less than the 0.57 m obtained via the explicit dynamic method. A similar trend appears in the results obtained in the 3D model, as shown in Fig. 6(c) and (d). The deformation regularities obtained using both the implicit and dynamic explicit methods are highly similar in the 2D model, whereas a signicant difference between the 3D model results obtained using the implicit and dynamic explicit methods is observed when the calculation results of both the 2D and 3D models are compared. The results of the two 3D models differ because the pipeline deformation rates are different.

3.3.2. Comparison of maximum stresses along the pipeline The maximum axial stress on the compressed side along the pipeline longitudinal direction changes with the increase in temperature when different simulation methods are used, as shown in Fig. 7. The gure shows only one side of the axial stress within the deformed segment experienced by the symmetrical pipeline axis in consideration of the symmetrical pipeline deformation. The horizontal axis is notably distant from the deformed symmetrical pipeline axis, whereas the stress on the compressed side of the pipeline is located on the vertical axis. Compressive stress is denoted as negative in the gure. Internal pipeline stress continues to accumulate under temperature variation, and the entire pipeline is compressed by the foundation soil constraints, as shown in Fig. 7. The compressive stress in the pipeline continuously increases with the increase in temperature difference, and the maximum compressive stress

occurs in the horizontal pipeline area with maximum deformation. Maximum stress gradually decreases with the increase in distance from the deformed symmetrical pipeline axis. The minimum stress value is reached when the distance reaches 20 m to 30 m, which is in accordance with the reverse displacement position depicted in Fig. 6. The stress at the compressed side of the pipeline begins to decrease and even tensile stress occurs when reverse pipeline displacement takes place. The difference in the deformation results computed using both the 2D and 3D models directly lead to a difference in pipeline stress. The stress value obtained in the 2D model is signicantly higher than that obtained in the 3D model. The increase in stress with the increase in temperature variation in the 2D model also varies signicantly from that in the 3D model. This nding is mainly attributed to the difference in temperature variation, which corresponds to the stress mutation. The temperature difference corresponding to the stress mutation is approximately 30 1C in the 2D model and 60 1C in the 3D model. The absolute maximum stress value in the pipeline can be shown as |sd| 195.608 MPa 4 |sb| 280.73 MPa 4 |sa| 201.95 MPa 4 |sc| 166.70 MPa when the temperature difference of 60 1C is used as an example in the comparison of the results obtained using the implicit Riks and the explicit dynamic methods. The absolute maximum stress value obtained using the explicit method is higher than the result obtained using the implicit method.

3.3.3. Relationship between maximum pipeline buckling amplitude and temperature difference Fig. 8 shows the relationship between maximum lateral deformation amplitude and temperature difference as determined using the four computation methods. Maximum lateral displacement at the symmetrical axis is positioned along the horizontal

Fig. 7. Axial stress variation in different FEA models at different operational temperatures. (a) 2D-Implicit FEA model, (b) 2D-Explicit FEA model, (c) 3D-Implicit FEA model and (d) 3D-Explicit FEA model.

R. Liu et al. / Ocean Engineering 78 (2014) 62 72

69

axis, and the temperature load is applied along the vertical axis of the pipeline. The lateral deformation amplitudes obtained using the four computation methods all increase with the increase in temperature difference, as shown in Fig. 8. However, differences in the deformation development processes exist. The pipeline buckling deformation amplitudes obtained using the four different methods are signicantly different when modeling analysis is conducted under similar temperature variation. The 3D model results are apparently different from those of the 2D model, and this nding is reected in the temperature variation differences corresponding to the occurrence of global buckling. The initial buckling temperature difference in the 2D model is approximately 20 1C, whereas the temperature difference in the 3D model is greater than 30 1C. The initial buckling temperature difference reaches 60 1C based on the 3D explicit method. This nding indicates that a low initial buckling temperature is obtained when the 2D model is used because this model does not consider the situation in which the pipeline is partially embedded in the foundation soil. By contrast, the 3D model considers such a situation. Also, higher soil resistance is used in the 3D simulation; thus, the initial buckling temperature difference is greater than that shown by the 2D simulation. Computation results obtained in the 2D models are consistent when the temperature difference is less than 30 1C; however, a relatively large pipeline deformation occurs when the temperature difference is between 20 1C and 30 1C. Maximum pipeline buckling amplitude increases rapidly with the use of the 2D explicit method compared with the use of the 2D implicit method when the temperature difference is greater than 30 1C. The calculation results in the two 3D models are consistent when temperature difference is less than 30 1C, but a large pipeline deformation occurs with the use of the 3D implicit method when the temperature difference is between 30 1C and 50 1C. When the temperature difference is greater than 60 1C, the maximum pipeline buckling amplitude increases linearly with the temperature increase, according to the 3D implicit method. The pipeline deformation increases more rapidly when the 3D explicit method is used.

Fig. 9. Pipeline buckling amplitude versus maximum axial stress.

3.3.4. Relationship between maximum bucking amplitude and axial pipeline stress Fig. 9 shows the relationship between maximum axial pipeline stress and the temperature differences obtained using the four computation methods. Maximum horizontal displacement at the symmetrical axis occurs along the horizontal axis, and maximum compressive stress on the symmetrical axis occurs along the vertical axis.

Fig. 10. Horizontal midpoint pipeline speed at different operational temperatures.

Fig. 8. Midpoint pipeline buckling amplitude versus operational temperature difference.

The lateral deformation amplitude values obtained using the four methods increase with the increase in axial-pipeline compressive stress, as shown in Fig. 9. The deformation development trends are similar. However, the pipeline deformation amplitudes are different under similar axial stress. This difference appears to increase with the increase in the axial load on the pipeline. Internal pipeline axial load obtained in the 3D model is greater than that obtained in the corresponding 2D model under similar deformation amplitudes as a result of the soil resistance effect. Internal pipeline axial force computed using the Riks implicit method is signicantly smaller than that obtained using the explicit dynamic method under similar horizontal deformation amplitudes because dynamic analysis considers the inuence of speed on the pipeline deformation process. Part of the work generated by internal force is converted into kinetic energy; thus, signicant axial stress in the dynamic algorithm is required to attain the same deformation amplitude as that of the static Riks algorithm. Fig. 10 shows the relationship between deformation rate in the horizontal symmetrical pipeline axis and the temperature loads applied to the pipeline in both 2D and 3D explicit dynamic models. Peak velocity v2d 0.23 m/s when the temperature difference is 25 1C in the 2D explicit model, whereas the peak velocity v3d 0.14 m/s when the temperature difference is 50 1C in the 3D explicit

70

R. Liu et al. / Ocean Engineering 78 (2014) 62 72

model as shown in Fig. 10. Buckling development reaches a turning point in the 2D explicit model when temperature variation is 25 1C, as shown in Figs. 8 and 10. Buckling deformation enters an unstable development stage with the increase in temperature difference. The 3D explicit model results are similar to those of the 2D explicit model. However, the temperature difference corresponding to this deformation turning point is 50 1C, which indicates that peak deformation rate is attained when the pipeline enters an unstable deformation stage. The deformation rate obtained via dynamic analysis can be used as a reference to determine when the entrance of a pipeline enters into unstable buckling stage.

4. Verication The computation results obtained using the numerical simulation methods in this study are compared with classic analytical solutions (Talor and Gan, 1986) to lateral pipeline global buckling to verify the accuracy of the proposed methods. Fig. 11 illustrates the relationship between pipeline deformation and the change in pipeline axial stress under temperature stress, as well as the relationships among horizontal pipeline buckling deformation amplitude, temperature difference, and axial compressive stress. The gure shows the comparison of the results obtained using the 2D implicit method and those calculated using the analytical solutions because the 2D implicit model meets the basic assumptions of analytical solutions. The pipeline deformation obtained using the 2D implicit method has a clear inection point according to the deformation distribution along the pipeline shown in Fig. 11(a). The maximum buckling amplitude of the forward/positive bending is 1.2 m and

the maximum buckling amplitude of the reverse curvature is 0.56 m. Reverse curvature/bending does not exist in the rst buckling mode in analytical solutions. The maximum buckling amplitude of the forward/positive bending is 2.74 m. The difference in deformed pipeline shapes is attributed to the assumption held by analytical solutions that deformed pipeline shapes are similar to initially imperfect pipelines. Fig. 11(b) shows that the internal stress distribution along the pipeline is related to deformed pipeline shapes. Internal compressive stress as determined using the FEA method is 25.5 MPa in the initial deformation segment, i.e., in the vicinity of the horizontal axis x 25 m. The result calculated using the analytical solution is 30 MPa. Internal compressive stress as determined using the FEA method is 196 MPa in the area with maximum pipeline deformation, i.e., at horizontal axis x 125 m. The result obtained using the analytical solution is 286 MPa, which is 1.45 times the result of the FEA method. This difference is directly related to the variations in the deformation analysis results. Fig. 11(c) illustrates the changes in maximum lateral pipeline deformation amplitude with the variation of the temperature difference. The initial temperature difference in pipeline buckling deformation calculated using the 2D implicit method is signicantly less than that determined using the analytical solution, as shown in the gure. The pipeline enters an unstable deformation stage when the temperature difference is greater than 20 1C, and deformation develops rapidly with the increase in temperature difference, as the FEA method results prove. However, the results of the analytical solution show that initial temperature difference is no less than 30 1C when pipeline deformation enters an unstable stage. Fig. 11(d) illustrates the variation trend of maximum lateraldeformation amplitude versus internal axial pipeline stress.

Fig. 11. Comparison of FEA model and analytical solution. (a) lateral deformation, (b) axial stress, (c) vm vs. T (d) vm vs. s.

R. Liu et al. / Ocean Engineering 78 (2014) 62 72

71

Internal axial pipeline stress as determined using the analytical solution is more signicant than that determined using the 2D implicit method when the buckling amplitudes are similar, as shown in the gure. The axial stress development trend as determined using the 2D implicit method is less signicant than that calculated using the analytical solution when buckling amplitude increases. Differences between the computation results determined using the 2D implicit method and those obtained using the analytical solution exist because the calculations of the analytic solution are limited by the assumption it holds, as summarized in the preceding paragraphs. However, the results of both methods can be effectively compared, thereby indicating that the numerical methods are reliable from the perspectives of globally deformed pipeline-shape development and internal pipeline stress.

Differences are observed between the results obtained using the classic method and those using the FEA method because the analytical solution is derived from simplied assumptions. However, the results obtained using the 2D implicit method and the analytical solution are comparable with respect to pipeline global buckling deformation development, buckling amplitude changes, and internal pipeline stress development because these two methods have consistent assumptions.

Acknowledgment The authors are grateful for the support provided by the Innovative Research Groups of the National Natural Science Foundation of China (51021004), the China National Natural Science Foundation (51322904, 40776055), and the Program for New Century Excellent Talents in University (HCET-110370). References

Andreuzzi, F., Perrone, A., 2001. Analytical solution for upheaval buckling in buried pipeline. Comput. Methods Appl. Mech. Eng. 190 (39), 50815087. Andrew Palmer, Associates, 1995, PlusOne Version 4.1 Modelling of Upheavel Buckling of Buried/Trenched Pipelines Theoretical Manual, SAIC Ltd., Artillery House, Artillery Row, London, England. Bruton, D.A.S., Carr, M., Sinclair, F. (2011). Geotechnical challenges for deepwater pipeline design SAFEBUCK JIP. Frontiers in Offshore Geotechnics II Gourvenec & White (Eds.), London. Bruton, D.A.S., White, D.J., Carr, M.C., Cheuk, C.Y. (2008). Pipe-soil interaction during lateral buckling and pipeline walking: the SAFEBUCK JIP. In: Proceedings of the Offshore Technology Conference, Houston, OTC19589. Criseld, M.A., 1981. A fast incremental/iteration solution procedure that handles snap-through. Comput. Struct. vol. 13, 5562. Cumming, G., Druzynski, A., Rathbone, A. (2009). Lateral walking and feed-in of buckled pipelines due to interactions of seabed features. In: Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering, OMAE, Honolulu, Hawaii, USA. Cumming, G., Rathbone, A. (2010). Euler buckling of idealized horizontal pipeline imperfections. In: Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, OMAE, Shanghai, China. Friedmann, Y. (1986). Some Aspects of the Design of Hot Buried Pipelines. Offshore oil and Gas Line Technology Conference, Paris, France, pp. 134. Hesar M. (2004). Pipeline-seabed interaction in soft clay. Proceedings of the 23rd International Conference on Offshore Mechanics and Arctic Engineering, OMAE2004-51425. Vancouver, Canada, pp. 19. Hibbitt, H.D., Karlsson, B.I., Sorensen, P., 2000, ABAQUS Theoretical Manual, Version 4.5, March 1984. Hobbs, R.E., 1981. Pipeline buckling caused by axial loads. J. Constr. Steel Res. 1 (2), 210. Hobbs, R.E., 1984. In-service buckling of heated pipelines. J. Transp. Eng., ASCE, 110; , pp. 175189. Jin, J., Audibert, J.M., and Kan, W.C. (2010). Practical design process for owlines with lateral buckling. In: Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, OMAE, Shanghai, China. Jukes, P., Eltaher, A., Sun, J. (2009). The latest developments in the design and simulation of deepwater subsea oil and gas pipelines using FEA. In: The Proceedings of The 3rd (2009) ISOPE International Deep-Ocean Technology Symposium: Deepwater Challenge, IDOT-2009, International Society of Offshore and Polar Engineers, United States, pp. 7082. Jukes, P., Wang, S., Wang, J. (2008). The sequential reeling and lateral buckling simulation of pipe-in-pipe owlines using nite element analysis for deepwater applications. The 18th International Offshore (Ocean) and Polar Engineering Conference, Paper, ISOPE, 2008-291. Kohnke, Peter. (1999). ANSYS theory reference. Ansys. Lyons, C.G. (1973). Soil resistance to lateral sliding of marine pipelines. In: Proceedings of the 5th Offshore Technology Conference, OTC 1876, pp. 479 484. Klever, F.J., Van Helvoirt, L.C., Sluyterman, A.C. (1990). A dedicated nite-element model for analyzing upheaval bucking response of submarine pipelines. In: Proceedings of the 22nd Annual Offshore Technology Conference, Houston, pp. 529538. Merield, R.S., White, D.J., Randolph, M.F., 2009. Effect of surface heave on response of partially embedded pipelines on clay. J. Geotech. Geoenviron. Eng., ASCE, 135; , pp. 819829. Nixon, J.F., 1994. PIPSOL, Stress Analysis Program for Pipes Subjected to Ground Displacements. Nixon Geotech Limited, Calgary, Alberta, Canada. Palmer, A.C., Ellinas, C.P., Richards, D.M., Guijt, J. (1990). Design of submarine pipelines against upheaval buckling. In: Proceedings 22nd OTC, Houston, Texas, pp. 540550.

5. Conclusions This study describes in detail the 2D implicit, 2D explicit, 3D implicit, and 3D explicit methods to simulate global buckling deformation in pipelines under temperature stress. These four methods have been utilized in systematic analysis and comparison of certain practical engineering projects. The following conclusions can be drawn based on the comparison of the results computed using the proposed methods and those obtained using classic analytical solutions to the lateral buckling of initially imperfect pipelines. Lateral global buckling in pipelines under temperature stress can be simulated by either the 2D or 3D model and either the implicit Riks or explicit dynamic method depending on the structural characteristics and deformation process of the pipeline. The 2D analysis model is simple and is evidently advantageous in the simulation of structures such as slender rods. The sinking of a pipeline into soil and the foundation soil loading and deformation processes can be simulated in the 3D analysis model. The implicit Riks method can monitor the unstable deformation process of the structure. The explicit dynamic method can capture the snapping phenomenon during pipeline global buckling. The results of an analysis of a practical engineering project demonstrate signicant differences among the pipeline global buckling results obtained using the four analysis methods, as reected in the various mutational temperature differences in pipeline deformation and stress development obtained via the 2D and 3D models. The pipeline buckling amplitude, internal pipeline stress, and initial buckling axial force computed using the implicit Riks method are also different from those determined using the explicit dynamic method. The differences in the analysis results are mainly caused by the following: the 3D model considers the sinking of the pipeline into the foundation soil because of selfweight, that is, the pipeline is partially embedded in the foundation soil. Therefore, additional soil resistance to the pipeline is generated in the pipeline deformation process. The dynamic analysis considers the inuence of speed on the deformation process, that is, the partial work generated by internal forces is converted into kinetic energy, which cannot be simulated by a static method. An analysis method based on modal analysis that introduces initial pipeline imperfection is presented in this paper. This method can be used to analyze thermal buckling in an initially imperfect pipeline. The temperature difference that corresponds to a high pipeline buckling deformation rate can be obtained using the explicit dynamic method. Thus, the deformation rate determined in the dynamic analysis can be used as a basis to determine when a pipeline enters into an unstable buckling stage.

72

R. Liu et al. / Ocean Engineering 78 (2014) 62 72 Sun, J., Jukes, P., Wang, J., Kenny, W.G. (2011). The advancements of FEA in confronting the deepwater pipelines under high pressure and high temperature. Offshore Technology Conference, Brazil, OTC22306. Taylor, N., Gan, A.B., 1986. Submarine pipeline buckling-imperfection studies. ThinWalled Struct. 4 (4), 295323. Villarraga, J.A., Rodrguez, J.F., Martnez, C., 2004. Buried pipe modeling with initial imperfections. J. Press. Vessel Technol. 126 (5), 250257. Wang, D., Gaudin, C., Randolph, M.F., 2013. Large deformation nite element analysis investigating the performance of anchor keying ap. Ocean Eng. 59, 107116. Wang, J., Eltaher, A., Jukes, P., Sun, J., Wang, F.S. (2009). Latest developments in upheaval buckling analysis for buried pipelines, Proceedings of the International Offshore and Polar Engineering Conference, ISOPE, Osaka, Japan, pp. 594602. Wempner, G.A., 1971. Discrete approximation related to nonlinear theories of solids. Int. J. Solids Struct. 7, 15811599. Zhang, W., Tuohy, J. (2002). A three-dimensional nite element analysis of unburied exible owline-A case study. In: Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, OMAE2002-28568, Newcastle Upon Tyne, Great Britain, pp. 435442.

Ramm, E., 1981. Strategies for tracing the nonlinear response near limit points, nonlinear nite element analysis in structural mechanics. Springer-Verlag, Berlin. Riks, E., 1972. The application of Newton0 s method to the problem of elastic stability. J. Appl. Mech. 39, 10601065. Riks, E., 1979. An incremental approach to the solution of snapping and buckling problems. Int. J. Solids Struct. 15, 529551. Schaminee, P.E.L., Zorn, N.F., Schotman, G.J.M. (1990). Soil response for pipeline upheaval buckling analyses: Full-scale laboratory tests and modeling. OTC 6486, 22nd annual otc, Houston, Texas, pp. 563572. Shaw, P.K., Bomba J.G. (1994). Finite-element analysis of pipeline upheaval buckling. In: Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, OMAE, Houston, TX, USA., pp. 291296. Sinclair, F., Carr, M., Bruton, D., Farrant, T. (2009). Design Challenges and Experience With Controlled Lateral Buckle Initiation Methods. International Conference on Ocean, Offshore and Arctic Engineering. OMAE-79434. Structural Software Development Inc., 1981. PIPLIN-III Computer Program for Stress and Deformation Analysis of Pipelines. Structural Software Development Inc., Berkeley, California.

You might also like

- 3D Nonlinear Modeling of Buried Continuous Pipeline Subjected To Ground CompressionDocument11 pages3D Nonlinear Modeling of Buried Continuous Pipeline Subjected To Ground CompressionmapasabcNo ratings yet

- Buckling Analysis of TubeDocument18 pagesBuckling Analysis of TubeBean-Jon LiNo ratings yet

- 1-S2.0-S1674237019300754-Main 1Document13 pages1-S2.0-S1674237019300754-Main 1Nelson VieiraNo ratings yet

- 1 s2.0 S0267726119314666 MainDocument13 pages1 s2.0 S0267726119314666 MainahmadNo ratings yet

- Behaviour of Buried Pipelines Subjected To External Loading PDFDocument339 pagesBehaviour of Buried Pipelines Subjected To External Loading PDFktsnl100% (2)

- Optimization in OBSDocument16 pagesOptimization in OBSGodwinNo ratings yet

- Elasto-Plastic Collapse Analysis of Pipe Bends Using Finite Element AnalysisDocument4 pagesElasto-Plastic Collapse Analysis of Pipe Bends Using Finite Element AnalysisMarcos VillavicencioNo ratings yet

- Pipe Stress Buriedrajeev - Pathmanathan - 3Document9 pagesPipe Stress Buriedrajeev - Pathmanathan - 3Erz ERNo ratings yet

- Buried Pipeline AnalysisDocument9 pagesBuried Pipeline Analysisim4uim4uim4uim4u100% (1)

- Engineering Science and Technology, An International JournalDocument7 pagesEngineering Science and Technology, An International JournalSamir GhoualiNo ratings yet

- A Study On Seismic Behavior of Buried Steel Pipelines Crossing Active FaultsDocument12 pagesA Study On Seismic Behavior of Buried Steel Pipelines Crossing Active FaultsabbassNo ratings yet

- Articulo CientificoDocument14 pagesArticulo CientificoJULIO ENRIQUE GUERRERO ROJASNo ratings yet

- Finite Element Model for Subsea Pipeline StabilityDocument9 pagesFinite Element Model for Subsea Pipeline StabilityJhy MhaNo ratings yet

- Study on leakage flow through clearancesDocument10 pagesStudy on leakage flow through clearancesShannon HutchinsonNo ratings yet

- Dinamic Force On An Elbow Caused by A Traveling Liquid SlugDocument11 pagesDinamic Force On An Elbow Caused by A Traveling Liquid SlugshaffetiNo ratings yet

- Ski Jump Hydraulics of Leak-Floor Flip BucketDocument10 pagesSki Jump Hydraulics of Leak-Floor Flip BucketPrameela GurungNo ratings yet

- Thermal Buckling Comparative Analysis Using Different FE Tools 01Document4 pagesThermal Buckling Comparative Analysis Using Different FE Tools 01Waldek BanasiakNo ratings yet

- Finite Element Analysis of Marine Buried Pipeline Upheaval Buckling in Clayey Backfill With Cover MaterialDocument7 pagesFinite Element Analysis of Marine Buried Pipeline Upheaval Buckling in Clayey Backfill With Cover MaterialZhiqiang GuNo ratings yet

- FE Simulation of PIP Systems With SAGE ProfileDocument8 pagesFE Simulation of PIP Systems With SAGE ProfileGodwinNo ratings yet

- Department of Civil Engineering Sydney NSW 2006 AustraliaDocument51 pagesDepartment of Civil Engineering Sydney NSW 2006 AustraliaalexrodriguezabcNo ratings yet

- Predict undrained uplift capacity of buried offshore pipelinesDocument49 pagesPredict undrained uplift capacity of buried offshore pipelinesaaaNo ratings yet

- Consideration For On-Bottom Stability of Unburied Pipelines Using A Dynamic Fluid-Structure-Soil Simulation ProgramDocument8 pagesConsideration For On-Bottom Stability of Unburied Pipelines Using A Dynamic Fluid-Structure-Soil Simulation ProgramOlusola OguntuberuNo ratings yet

- Please Do Not Remove This Page: Thank You For Do Wnloading This Docum Ment From The Rmit R Research R RepositoryDocument9 pagesPlease Do Not Remove This Page: Thank You For Do Wnloading This Docum Ment From The Rmit R Research R RepositoryFreddie KooNo ratings yet

- Modelling and Analysing Failure Modes of Buried Pipelines Perpendicularly Crossing Landslide BoundariesDocument12 pagesModelling and Analysing Failure Modes of Buried Pipelines Perpendicularly Crossing Landslide BoundariesJaime SeguraNo ratings yet

- Prediction of Corrosive Fatigue Life of Submarine Pipelines of API 5L X56 Steel Materials PDFDocument19 pagesPrediction of Corrosive Fatigue Life of Submarine Pipelines of API 5L X56 Steel Materials PDFJohan Esteban Garcia PuentesNo ratings yet

- Kerbala Journal Three JunctionsDocument13 pagesKerbala Journal Three JunctionsLaith ShammariNo ratings yet

- Fluid Induced Vibration of Composite Natural Gas PipelinesDocument16 pagesFluid Induced Vibration of Composite Natural Gas PipelinesSimon Achink LubisNo ratings yet

- 2009 TPC 406Document1 page2009 TPC 406monyetgilasekaliNo ratings yet

- Introduction, Abstract, Conclusion, ReferenceDocument4 pagesIntroduction, Abstract, Conclusion, ReferenceChiu Fong50% (2)

- CFD Modelling of Subsea Pipeline StabilityDocument5 pagesCFD Modelling of Subsea Pipeline StabilityGuomin JiNo ratings yet

- 2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLDocument11 pages2015-TPC-0930 Reel-Lay Method To Allow For Direct Tie-In of Pipelines - DRAFTLnicholas_j_vaughanNo ratings yet

- Author's Accepted Manuscript: Ijmecsci.2014.12.011Document25 pagesAuthor's Accepted Manuscript: Ijmecsci.2014.12.011Abdul Haris SiregarNo ratings yet

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- Spe 209716 MsDocument20 pagesSpe 209716 MsDiego PalaciosNo ratings yet

- Root Locus Theory in Active Vibration Co PDFDocument18 pagesRoot Locus Theory in Active Vibration Co PDFV.v. TaguisNo ratings yet

- UHB With MobiliationDocument2 pagesUHB With MobiliationkeplieNo ratings yet

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Document18 pagesIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationNo ratings yet

- Earth Pressure Development in Integral Abutment Bridge Subjected To Thermal LoadingsDocument8 pagesEarth Pressure Development in Integral Abutment Bridge Subjected To Thermal LoadingsSyed Abdul Wahab MuddasirNo ratings yet

- Materials and Design: P.F. Liu, J.Y. Zheng, B.J. Zhang, P. ShiDocument8 pagesMaterials and Design: P.F. Liu, J.Y. Zheng, B.J. Zhang, P. Shi123habib123fikriNo ratings yet

- FEM Analysis of Offshore Pipelines During Pressure Test - Multi-Objective OptimizationDocument13 pagesFEM Analysis of Offshore Pipelines During Pressure Test - Multi-Objective OptimizationLava SatNo ratings yet

- Review of Pipeline Span Analyis-2019Document78 pagesReview of Pipeline Span Analyis-2019Anjani PrabhakarNo ratings yet

- Configuration Analysis of Deepwater S La PDFDocument12 pagesConfiguration Analysis of Deepwater S La PDFAshish GuptaNo ratings yet

- Obtaining Optimal Performance With Ring Stiffeners On Strength For Submarine PipelineDocument9 pagesObtaining Optimal Performance With Ring Stiffeners On Strength For Submarine PipelineElendu Emmanuel ChigozieNo ratings yet

- A G Chehab PHD Thesis (Civil Engineering)Document265 pagesA G Chehab PHD Thesis (Civil Engineering)Obumse Chukwuebuka MichaelNo ratings yet

- Dokumen - Tips Seismic Design of Deep Bridge Pier Foundations in Seismic Design of DeepDocument324 pagesDokumen - Tips Seismic Design of Deep Bridge Pier Foundations in Seismic Design of DeepMiguel Angel Contreras OrtizNo ratings yet

- Water: Real Values of Local Resistance Coefficients During Water Flow Through Welded Polypropylene T-JunctionsDocument16 pagesWater: Real Values of Local Resistance Coefficients During Water Flow Through Welded Polypropylene T-JunctionsMUBASHIRNo ratings yet

- V3i9 Ijertv3is090001 PDFDocument3 pagesV3i9 Ijertv3is090001 PDFbarukomkssNo ratings yet

- A 3D Numerical Modeling of Polyethylene Buried Pipes Affected by FaultDocument7 pagesA 3D Numerical Modeling of Polyethylene Buried Pipes Affected by Faultmanu ioana danielaNo ratings yet

- VIV Analysis of PipelineDocument5 pagesVIV Analysis of Pipelineศุภกฤต รักในหลวงNo ratings yet

- Hydraulic: Official FileDocument44 pagesHydraulic: Official Filechu42No ratings yet

- Numerical Analysis For Pipeline Installation by S-Lay MethodDocument9 pagesNumerical Analysis For Pipeline Installation by S-Lay MethodGiuseppe PasqualeNo ratings yet

- OTC-27623-MS The State of Knowledge of Pipe-Soil Interaction For On-Bottom Pipeline DesignDocument27 pagesOTC-27623-MS The State of Knowledge of Pipe-Soil Interaction For On-Bottom Pipeline DesignReginaldo JesusNo ratings yet

- Beggs and Brill MethodDocument25 pagesBeggs and Brill MethodHuy Lâm100% (2)

- Jpe Sage ProfileDocument17 pagesJpe Sage ProfilefrvdabeeNo ratings yet

- Numerical Analysis of Rapid Drawdown: Applications in Real CasesDocument8 pagesNumerical Analysis of Rapid Drawdown: Applications in Real CasesAnonymous D5s00DdUNo ratings yet

- Radial Consolidation TheoriesDocument13 pagesRadial Consolidation TheoriesSidi Yéhia SounfountéraNo ratings yet

- Ground Improvement Case Histories: Chemical, Electrokinetic, Thermal and BioengineeringFrom EverandGround Improvement Case Histories: Chemical, Electrokinetic, Thermal and BioengineeringRating: 3 out of 5 stars3/5 (1)

- Analysis of Buckle Propagation in Marine PipelinesDocument20 pagesAnalysis of Buckle Propagation in Marine PipelinesJhy MhaNo ratings yet

- Tunnel Forced-Air Coolers For Fresh Fruits & VegetablesDocument14 pagesTunnel Forced-Air Coolers For Fresh Fruits & VegetablesJhy Mha100% (1)

- Pipeline Design Calculations PDFDocument21 pagesPipeline Design Calculations PDFjimallen21281% (21)

- Geometric ModellingDocument52 pagesGeometric ModellingJhy MhaNo ratings yet

- Xue 2006 Finite Elements in Analysis and DesignDocument9 pagesXue 2006 Finite Elements in Analysis and DesignJhy MhaNo ratings yet

- Karampour 2013 Thin Walled StructuresDocument8 pagesKarampour 2013 Thin Walled StructuresJhy MhaNo ratings yet

- LUN 2013 Petroleum Exploration and DevelopmentDocument7 pagesLUN 2013 Petroleum Exploration and DevelopmentJhy MhaNo ratings yet

- CAAM82N6 Finite Elements in The Analysis of Pressure Vessels and PipingDocument22 pagesCAAM82N6 Finite Elements in The Analysis of Pressure Vessels and PipingPeerasak ArunNo ratings yet

- Karampour 2013 Engineering-StructuresDocument14 pagesKarampour 2013 Engineering-StructuresJhy MhaNo ratings yet

- Xue 2012 Thin Walled StructuresDocument6 pagesXue 2012 Thin Walled StructuresJhy MhaNo ratings yet

- Liu 2009 Journal of Loss Prevention in The Process IndustriesDocument5 pagesLiu 2009 Journal of Loss Prevention in The Process IndustriesJhy MhaNo ratings yet

- LUN 2013 Petroleum Exploration and DevelopmentDocument7 pagesLUN 2013 Petroleum Exploration and DevelopmentJhy MhaNo ratings yet

- Guarracino 2008 Applied Ocean ResearchDocument8 pagesGuarracino 2008 Applied Ocean ResearchJhy MhaNo ratings yet

- Abela 2011 Engineering-StructuresDocument10 pagesAbela 2011 Engineering-StructuresJhy MhaNo ratings yet

- Albermani 2011 Engineering-StructuresDocument7 pagesAlbermani 2011 Engineering-StructuresJhy MhaNo ratings yet

- Book Dynamics of Offshore Structures by JF WilsonDocument344 pagesBook Dynamics of Offshore Structures by JF WilsonJhy MhaNo ratings yet

- Operations - Assignment 1Document3 pagesOperations - Assignment 1Jhy Mha0% (1)

- Gong 2012 Marine-StructuresDocument16 pagesGong 2012 Marine-StructuresJhy MhaNo ratings yet

- FeaDocument34 pagesFeaJhy MhaNo ratings yet

- Economic Analysis TechniqueDocument9 pagesEconomic Analysis TechniqueJhy MhaNo ratings yet

- Finite Element Model for Subsea Pipeline StabilityDocument9 pagesFinite Element Model for Subsea Pipeline StabilityJhy MhaNo ratings yet

- Tutorial 2 - March 7, 2012Document2 pagesTutorial 2 - March 7, 2012Jhy MhaNo ratings yet

- Economic Analysis TechniqueDocument9 pagesEconomic Analysis TechniqueJhy MhaNo ratings yet

- Economic Analysis TechniqueDocument9 pagesEconomic Analysis TechniqueJhy MhaNo ratings yet

- Assignment CAD CAM 1 2012Document1 pageAssignment CAD CAM 1 2012Jhy MhaNo ratings yet

- Topic 4 Introduction To Abaqus - ExplicitDocument9 pagesTopic 4 Introduction To Abaqus - ExplicitJhy MhaNo ratings yet

- Economic Analysis TechniqueDocument9 pagesEconomic Analysis TechniqueJhy MhaNo ratings yet

- Economic Analysis TechniqueDocument9 pagesEconomic Analysis TechniqueJhy MhaNo ratings yet

- Mcmaster MECH ENG 3O04 - Fluid Mechanics Notes by Dr. Mohamed S. HamedDocument394 pagesMcmaster MECH ENG 3O04 - Fluid Mechanics Notes by Dr. Mohamed S. Hamedcttiger7135100% (15)

- The Dedication of the Broken Hearted SailorDocument492 pagesThe Dedication of the Broken Hearted SailorGabriele TorresNo ratings yet

- Mycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Document10 pagesMycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Abdul MuqsitNo ratings yet

- RADIATION SAFETY FUNDAMENTALSDocument69 pagesRADIATION SAFETY FUNDAMENTALSJay Lawson100% (1)

- Abiotic and Biotic Factors DFDocument2 pagesAbiotic and Biotic Factors DFgiselleNo ratings yet

- 4 Ideal Models of Engine CyclesDocument23 pages4 Ideal Models of Engine CyclesSyedNo ratings yet

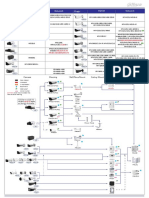

- YOKOGAWADocument16 pagesYOKOGAWADavide ContiNo ratings yet

- Schroedindiger Eqn and Applications3Document4 pagesSchroedindiger Eqn and Applications3kanchankonwarNo ratings yet

- 19 - Speed, Velocity and Acceleration (Answers)Document4 pages19 - Speed, Velocity and Acceleration (Answers)keyur.gala100% (1)

- Poultry DiseasesDocument5 pagesPoultry DiseasesAnjum IslamNo ratings yet

- Desiderata: by Max EhrmannDocument6 pagesDesiderata: by Max EhrmannTanay AshwathNo ratings yet

- Chemistry 12: Provincial ExaminationDocument25 pagesChemistry 12: Provincial ExaminationCát TriệuNo ratings yet

- Function and Euqations - Quantitative Aptitude Questions MCQDocument4 pagesFunction and Euqations - Quantitative Aptitude Questions MCQAnonymous v5QjDW2eHxNo ratings yet

- Company Profile 2Document7 pagesCompany Profile 2R Saravana KumarNo ratings yet

- LOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorDocument1 pageLOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorHorizon 99No ratings yet

- Ca2Document8 pagesCa2ChandraNo ratings yet

- Spin - 2021Document60 pagesSpin - 2021Tanel LaanemägiNo ratings yet

- Plow Moldboard or Disc PlowDocument7 pagesPlow Moldboard or Disc PlowAdewaleNo ratings yet

- Kundalini Meditation & The Vagus Nerve - Eleven Minute MedsDocument5 pagesKundalini Meditation & The Vagus Nerve - Eleven Minute Medstimsmith1081574100% (5)

- Com Statement (HT APFC22 - 02)Document2 pagesCom Statement (HT APFC22 - 02)SOUMENNo ratings yet

- 10risk Assessment and ComahDocument25 pages10risk Assessment and ComahHansraj RahulNo ratings yet

- Tennis BiomechanicsDocument14 pagesTennis BiomechanicsΒασίλης Παπατσάς100% (1)

- المحاضرة الرابعة المقرر انظمة اتصالات 2Document31 pagesالمحاضرة الرابعة المقرر انظمة اتصالات 2ibrahimNo ratings yet

- Cooling System Exhaust System: RadiatorDocument2 pagesCooling System Exhaust System: RadiatorMd ShNo ratings yet

- Ford 1982 3.8L V6Document22 pagesFord 1982 3.8L V6sc100% (1)

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- كونكت بلس - 2 ابتدائي - ترم 1 - مذكرة 2Document86 pagesكونكت بلس - 2 ابتدائي - ترم 1 - مذكرة 2cafubodoNo ratings yet

- Chapter 1Document33 pagesChapter 1Salihah AbdullahNo ratings yet

- Business PlanDocument63 pagesBusiness PlanKristine BalanayNo ratings yet

- Qualtrics Ebook Employee Lifecycle Feedback Apj - q8uL5iqE4wt2ReEuvbnIwfG4f5XuMyLtWvNFYuM5Document18 pagesQualtrics Ebook Employee Lifecycle Feedback Apj - q8uL5iqE4wt2ReEuvbnIwfG4f5XuMyLtWvNFYuM5RajNo ratings yet

- Tap Yourself FreeDocument134 pagesTap Yourself Freenguyenhavn100% (2)