Professional Documents

Culture Documents

Air Conditioning Group 4

Uploaded by

Kline MicahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Conditioning Group 4

Uploaded by

Kline MicahCopyright:

Available Formats

Air conditioning often referred to as aircon, AC or A/C) Is the process of altering the properties of air (primarily temperature and

nd humidity) to more favorable conditions. Can refer to any form of technological cooling, heating, ventilation, or disinfection that modifies the condition of air. An air conditioner a major or home appliance, system, or mechanism designed to change the air temperature and humidity within an area (used for cooling and sometimes heating depending on the air properties at a given time). The cooling is typically done using a simple refrigeration cycle, but sometimes evaporation is used, Commonly for comfort cooling in buildings and motor vehicles. Free cooling Uses pumps to circulate a coolant (typically water or a glycol mix) from a cold source, which in turn acts as a heat sink for the energy that is removed from the cooled space.

An air conditioning unit: 1. The coils and pipes in an air conditioning unit contain refrigerant gas. The refrigerant gas enters the compressor as warm, lowpressure gas and leaves it as hot, high-pressure gas. 2. In the condenser coils, hot, compressed refrigerant gas loses heat to the outdoor air and becomes liquid while it is still warm. 3. The warm, liquid refrigerant passes through the tiny opening of the expansion valve, expands, and partly turns to gas at a low temperature. 4. In the cooling coils, the refrigerant takes up heat from the indoor air and leaves the coils as warm, low-pressure gas. 5. The indoor air gives up heat to the refrigerant in the cooling coils and also loses moisture as it is chilled. The moisture condenses on the coils and trickles down to outside drain holes. Cooled air is blown back into the room.

HISTORY

Ancient cooling

In ancient Egypt, reeds were hung in windows and were moistened with trickling water. The evaporation of water cooled the air blowing through the window, though this process also made the air more humid (also beneficial in a dry desert climate) In Ancient Rome, water from aqueducts was circulated through the walls of certain houses to cool them. In medieval Persia, it involved the use of cisterns and wind towers to cool buildings during the hot season.

Mechanical cooling

The 2nd-century Chinese inventor Ding Huan (fl 180) of the Han Dynasty invented a rotary fan. In the 17th century, Cornelis Drebbel demonstrated "Turning Summer into Winter" for James I of England by adding salt to water. In 1758, Benjamin Franklin and John Hadley, conducted an experiment to explore the principle of evaporation as a means to rapidly cool an object. They confirmed that evaporation of highly volatile liquids such as alcohol and ether could be used to drive down the temperature of an object past the freezing point of water. In 1820, English scientist and inventor Michael Faraday discovered that compressing and liquefying ammonia could chill air when the liquefied ammonia was allowed to evaporate. 1842, Florida physician John Gorrie used compressor technology to create ice, which he used to cool air for his patients in his hospital. James Harrison's first mechanical ice-making machine began operation in 1851.

Electromechanical cooling

In 1902, the first modern electrical air conditioning unit was invented by Willis Carrier. Designed to improve manufacturing process control in a printing plant, Carrier's invention controlled not only temperature but also humidity. Carrier used his knowledge of the heating of objects with steam and reversed the process. In 1906, Stuart W. Cramer of Charlotte, North Carolina was exploring ways to add moisture to the air in his textile mill. Cramer coined the term "air conditioning", using it in a patent claim he filed that year as an analogue to "water

conditioning", then a well-known process for making textiles easier to process. He combined moisture with ventilation to "condition" and change the air in the factories, controlling the humidity so necessary in textile plants. In 1945, Robert Sherman of Lynn, MA, invented the portable, in-window air conditioner that cooled and heated, humidified and dehumidified, and filtered the air.

Refrigerant development

The first air conditioners and refrigerators employed toxic or flammable gases, such as ammonia, methyl chloride, or propane, that could result in fatal accidents when they leaked.Thomas Midgley, Jr created the first non-flammable, non-toxic chlorofluorocarbon gas, Freon, in 1928.

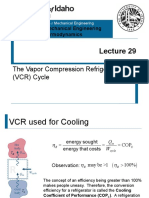

Refrigeration cycle

Condenser coil (hot side heat exchanger, gas cools and liquifies) Metering Device (liquid expands and cools) Evaporator coil (cold side heat exchanger, liquid vaporizes and heats up) Compressor (gas is compressed and heats up) Red = Gas at high pressure and very high temperature Pink = Liquid at high pressure and high temperature Blue = Liquid at low pressure and very low temperature Light Blue = Gas at low pressure and low temperature In the refrigeration cycle, a heat pump transfers heat from a lower-temperature heat source into a higher-temperature heat sink. Heat would naturally flow in the opposite direction. This is the most common type of air conditioning. A refrigerator works in much the same way, as it pumps the heat out of the interior and into the room in which it stands. This cycle takes advantage of the way phase changes work, where latent heat is released at a constant temperature during a liquid/gas phase change, and where varying the pressure of a pure substance also varies its condensation/boiling point.

1. 2. 3. 4.

Humidity control

The comfort air conditioner is designed to create a 40% to 60% relative humidity in the occupied space. A specific type of air conditioner that is used only for dehumidifying is called a dehumidifier. Dehumidifier

Evaporator and condenser coils are placed in the same air path. heat a room just as an electric heater

Having the condenser coil in the same air path as the evaporator coil produces warm, dehumidified air.

Design

1. Window and through-wall a. Unitary systems - the common one room air conditioners, sit in a window or wall opening, with interior controls

b. Packaged terminal (PTAC) systems - have two separate units (terminal packages), the evaporative unit on the interior and the condensing unit on the exterior, with tubing passing through the wall and connecting them 2. Split systems a. Central - inside heat-exchanger is typically placed inside the central furnace/AC unit of forced air heating system b. Mini-split - supplied chilled air to only a single space 3. Ductless (split-system) air conditioning - similar to PTAC air conditioners - allows design and installation flexibility because the inside wall space required is significantly reduced and the compressor and heat exchanger can be located further away from the inside space 4. Central Air Conditioning - Offers whole-house or large-commercial-space cooling, and often offers moderate multi-zone temperature control capability by the addition of air-louver-control boxes. 5. Evaporative coolers - device that draws outside air through a wet pad, such as a large sponge soaked with water. 6. Portable units a. Refrigerative - air-cooled, meaning they use air to exchange heat i. Split - has an indoor unit on wheels connected to an outdoor unit via flexible pipes ii. Hose - vented to the outside via air ducts - Monoblock - collects the water in a bucket or tray and stops when full - Air-to-air - re-evaporates the water and discharges it through the ducted hose and can run continuously. b. Evaporative - sometimes called "swamp coolers - do not have a compressor or condenser - Liquid water is evaporated on the cooling fins, releasing the vapor into the cooled area. - Evaporating water absorbs a significant amount of heat, the latent heat of vaporization, cooling the air: humans and animals use the same mechanism to cool themselves by sweating. 7. Heat pumps - air conditioner in which the refrigeration cycle can be reversed, producing heating instead of cooling in the indoor environment. 8. Refrigerants - substance used in a heat cycle usually including, for enhanced efficiency, a reversible phase transition from a liquid to a gas.

Uses

Comfort applications Makes deep plan buildings feasible, for otherwise they would have to be built narrower or with light wells so that inner spaces received sufficient outdoor air via natural ventilation. Allows buildings to be taller Can be used for many types of transportation Process applications Domestic use The objective may be to not only control temperature, but also humidity, air quality, and air movement from space to space. can promote the growth and spread of microorganisms can be used to provide a clean, safe, hypoallergenic atmosphere in hospital operating rooms and other environments can have a negative effect on skin, drying it out and also dehydration may have a positive effect on sufferers of allergies and asthma

Health issues

You might also like

- AirconDocument142 pagesAirconJervin Ocampo0% (2)

- Lecture 3Document27 pagesLecture 3Shubham SinghNo ratings yet

- Split Type AcuDocument40 pagesSplit Type AcuKristine Ann ReclosadoNo ratings yet

- Air - ConditioningDocument4 pagesAir - ConditioningDinesh ChahalNo ratings yet

- Airconditioning ProcessDocument5 pagesAirconditioning ProcessMark Anthony SibayanNo ratings yet

- Chapter 1-3Document8 pagesChapter 1-3Paul MendozaNo ratings yet

- Air ConditionerDocument14 pagesAir ConditionerZulhairie ZubaidiNo ratings yet

- On Air ConditioningDocument26 pagesOn Air ConditioningTej KalyanNo ratings yet

- RefrigerationDocument52 pagesRefrigerationSreejith VaneryNo ratings yet

- UntitledDocument103 pagesUntitledaNo ratings yet

- Air ConditioningDocument5 pagesAir ConditioningDC1234No ratings yet

- Air Conditioning Basics: Air-Source, Split SystemsDocument4 pagesAir Conditioning Basics: Air-Source, Split SystemsAhmad MujahidNo ratings yet

- Heat Ventilation Heat Pump Cooling Cycle Hvac Home Temperature ControlDocument3 pagesHeat Ventilation Heat Pump Cooling Cycle Hvac Home Temperature ControlGio LagadiaNo ratings yet

- Heating, Ventilating and Air Conditioning: Presented By: AnonymousDocument15 pagesHeating, Ventilating and Air Conditioning: Presented By: AnonymousramnikaNo ratings yet

- Lecture Week 4Document20 pagesLecture Week 4Saad SohailNo ratings yet

- Investigatory ProjectDocument17 pagesInvestigatory ProjectIan Villavicencio83% (6)

- Study On Air-Conditioning and Its ProcessDocument5 pagesStudy On Air-Conditioning and Its Processsdeep1990No ratings yet

- Building Services: Assignment 2Document40 pagesBuilding Services: Assignment 2Vivek SinghNo ratings yet

- RefrigerationDocument29 pagesRefrigerationaaisha pariNo ratings yet

- Group 4 IADocument11 pagesGroup 4 IAcervanamonica13No ratings yet

- Mahika Saxena Refrigeartion.Document9 pagesMahika Saxena Refrigeartion.Warrior InsideNo ratings yet

- HVAC PrinciplesDocument60 pagesHVAC PrinciplesshreyashNo ratings yet

- Auto Air Conditioning Servicing and Maintenance ModuleDocument5 pagesAuto Air Conditioning Servicing and Maintenance ModuleJelly Mae LongalongNo ratings yet

- Refrigeration and Air Conditioning 2Document11 pagesRefrigeration and Air Conditioning 2Varad KhedkarNo ratings yet

- Air ConditionerDocument14 pagesAir ConditionerAakash Soni AAstar0% (1)

- How Do Chillers Work by Nathan SchumacherDocument5 pagesHow Do Chillers Work by Nathan SchumacherNathan SchumacherNo ratings yet

- Air ConditioningDocument11 pagesAir ConditioningBrilliantJohnMalandacRubiaNo ratings yet

- Building Utilities 2 Air ConditioningDocument4 pagesBuilding Utilities 2 Air ConditioningianyanNo ratings yet

- Heat Ventilation and Air Conditioning (HVAC)Document46 pagesHeat Ventilation and Air Conditioning (HVAC)Sagar GoyalNo ratings yet

- Heating, Ventilation, and Air Conditioning (HVAC)Document24 pagesHeating, Ventilation, and Air Conditioning (HVAC)Khalid AshrafNo ratings yet

- Types of Air Conditioning UnitsDocument10 pagesTypes of Air Conditioning Unitssnowgalvez44No ratings yet

- Refrigeration and Air Conditioning 2Document33 pagesRefrigeration and Air Conditioning 2Christina OhNo ratings yet

- Aircon System and Fire Protection SystemDocument31 pagesAircon System and Fire Protection SystemReijen Canary S TierraNo ratings yet

- Air Conditioning Plant (BSME 5B)Document128 pagesAir Conditioning Plant (BSME 5B)Marvin ArnaizNo ratings yet

- Hvac Notes: Vapor-Compression Absorption Refrigeration Cycle Heat ExchangerDocument36 pagesHvac Notes: Vapor-Compression Absorption Refrigeration Cycle Heat ExchangerMohd Tarique AnwarNo ratings yet

- Script:-.Air Condition ScriptDocument11 pagesScript:-.Air Condition Scriptaimri_cochinNo ratings yet

- Hvac EquipmentsDocument16 pagesHvac EquipmentsRahul Prajapati100% (1)

- Air Conditioning System: Comfort ConditionsDocument55 pagesAir Conditioning System: Comfort ConditionsTunaNo ratings yet

- Oel HvacDocument21 pagesOel HvacFurqan AhmadNo ratings yet

- Architectural Science (HVAC) Lecture 6 & 7Document32 pagesArchitectural Science (HVAC) Lecture 6 & 7ezakbelachewNo ratings yet

- (CH 1) IntroductionDocument10 pages(CH 1) Introductionmahmoud shabanaNo ratings yet

- Refrigeration and Air ConditioningDocument7 pagesRefrigeration and Air ConditioningManjunatha EikilaNo ratings yet

- Dehumidifier - WikipediaDocument15 pagesDehumidifier - Wikipediauchechukwu AmanekweNo ratings yet

- 101Document59 pages101Vj AdityaNo ratings yet

- Design and Fabrication of Direct Evaporative Modified CoolerDocument14 pagesDesign and Fabrication of Direct Evaporative Modified CoolerPraful RajputNo ratings yet

- REFRIGERATORDocument11 pagesREFRIGERATORHacker ManNo ratings yet

- 16 - Air Conditionng Systems - Vaishnavi C. KambleDocument13 pages16 - Air Conditionng Systems - Vaishnavi C. KambleVaishnavi KambleNo ratings yet

- Ass 4Document6 pagesAss 4Nick's CreationNo ratings yet

- RAC Lab AssignmentDocument6 pagesRAC Lab AssignmentAhmed AliNo ratings yet

- Cooling TowerDocument6 pagesCooling TowerSubyyalNo ratings yet

- Assignment Refrigeration ComponentDocument4 pagesAssignment Refrigeration ComponentVishal DulangeNo ratings yet

- Air Conditioning SystemDocument15 pagesAir Conditioning SystemSamer Zebare100% (1)

- Hvac Def of TermsDocument3 pagesHvac Def of Terms88ncd4y4r7No ratings yet

- Building Services - Iii: 3 Year BS - Semester 1Document32 pagesBuilding Services - Iii: 3 Year BS - Semester 1TaanayaNo ratings yet

- Type of EvaporatorsDocument6 pagesType of EvaporatorsEVANGELISTA REYMUND V.No ratings yet

- Airconditioning UnitsDocument20 pagesAirconditioning Unitsatif jamalNo ratings yet

- Difference Between Air Conditioning and Refrigeration SystemsDocument2 pagesDifference Between Air Conditioning and Refrigeration SystemsGnana Subramanian Arumugam100% (3)

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Pritzker Architecture Prize Recipients: JohnsonDocument1 pagePritzker Architecture Prize Recipients: JohnsonKline MicahNo ratings yet

- The Pineapple Is A Traditional American Symbol of HospitalityDocument17 pagesThe Pineapple Is A Traditional American Symbol of HospitalityKline MicahNo ratings yet

- Lexber Incorporated Subdivision: From Triangulation Station, Bakakeng, Baguio City at A Point Marked "1" On Plan, BeingDocument1 pageLexber Incorporated Subdivision: From Triangulation Station, Bakakeng, Baguio City at A Point Marked "1" On Plan, BeingKline MicahNo ratings yet

- Land Use Map PDFDocument1 pageLand Use Map PDFKline MicahNo ratings yet

- Topographic Survey of LOT 1-C-11, (LRC) PSD-71303 Based On The Map Information As Of1977 SCALE 1:800MDocument1 pageTopographic Survey of LOT 1-C-11, (LRC) PSD-71303 Based On The Map Information As Of1977 SCALE 1:800MKline MicahNo ratings yet

- Parish Priest Barangay Captain School: Specific RequirementsDocument1 pageParish Priest Barangay Captain School: Specific RequirementsKline MicahNo ratings yet

- Deviant BehaviorDocument1 pageDeviant BehaviorKline MicahNo ratings yet

- Introduction To Korean Architecture: July 4, 2006 1:30-3:30 Pm. Instructor: Heekyung LeeDocument11 pagesIntroduction To Korean Architecture: July 4, 2006 1:30-3:30 Pm. Instructor: Heekyung LeeKline MicahNo ratings yet

- Facility Chutes - 02.06.12Document4 pagesFacility Chutes - 02.06.12Kline MicahNo ratings yet

- 2000 Performance PDFDocument12 pages2000 Performance PDFMehdi HasanNo ratings yet

- Refrigerant PropertiesDocument10 pagesRefrigerant PropertiesGaurav NimNo ratings yet

- Heat Pump and Refrigeration Cycle - Wikipedia, The Free EncyclopediaDocument5 pagesHeat Pump and Refrigeration Cycle - Wikipedia, The Free EncyclopediaPaplu PaulNo ratings yet

- Manual de Instruções Samsung RL39WBMS (10 Páginas)Document5 pagesManual de Instruções Samsung RL39WBMS (10 Páginas)Marcos Antonio Muniz LoboNo ratings yet

- Maintenance & Service CV Yobelindo Ok CompressDocument10 pagesMaintenance & Service CV Yobelindo Ok CompressfrediNo ratings yet

- Lab 2 ThermalDocument18 pagesLab 2 ThermalMuhamad Arif100% (1)

- Air Conditioner Presentation A1Document29 pagesAir Conditioner Presentation A1NovakurniawanNo ratings yet

- Danfoss Turbocor Compressors Retrofit Performance Data Worksheet 2005-08Document9 pagesDanfoss Turbocor Compressors Retrofit Performance Data Worksheet 2005-08echc5599No ratings yet

- LG Ac Dealers Price List AugDocument5 pagesLG Ac Dealers Price List AugShubham ChouhanNo ratings yet

- The Big Thaw - Safe Defrosting Methods For ConsumersDocument2 pagesThe Big Thaw - Safe Defrosting Methods For Consumersch_yepNo ratings yet

- Unit 2 HVACDocument66 pagesUnit 2 HVACJaya SubhaNo ratings yet

- Actual Vapor Compression Refrigeration Cycle Part 1Document12 pagesActual Vapor Compression Refrigeration Cycle Part 1jjNo ratings yet

- Sharp SJ-P58M-GY Fridge Service ManualDocument44 pagesSharp SJ-P58M-GY Fridge Service ManualAnonymous 2iQ1B59No ratings yet

- Toate SolutiileDocument10 pagesToate SolutiileDanijelNo ratings yet

- Ice Plant DesignDocument5 pagesIce Plant Designwaar lockNo ratings yet

- Ice Plant FrickDocument16 pagesIce Plant FrickDharani PathyNo ratings yet

- Refrigerador: Guia Del Controles & CircuitosDocument44 pagesRefrigerador: Guia Del Controles & CircuitosChristian LaytonNo ratings yet

- M14Document28 pagesM14Vijay RajaindranNo ratings yet

- Heat ExchangerDocument34 pagesHeat ExchangerducanhbkNo ratings yet

- FridgeDocument6 pagesFridgeshashlearnNo ratings yet

- Refri Samsung Da68-02659a Rev 00 Quick Guide Ibaci enDocument2 pagesRefri Samsung Da68-02659a Rev 00 Quick Guide Ibaci enComodin ServiciosNo ratings yet

- Denso15 125 A4 Uk Ac Installationsheet Webdl v13Document56 pagesDenso15 125 A4 Uk Ac Installationsheet Webdl v13RajuNo ratings yet

- CO2 Systems - Trends Benefits and ROIDocument33 pagesCO2 Systems - Trends Benefits and ROIOnofreNo ratings yet

- Air Conditioner Presentation A1Document29 pagesAir Conditioner Presentation A1Nova KurniawanNo ratings yet

- Reflection Paper in DressmakingDocument8 pagesReflection Paper in DressmakingMaria CeciliaNo ratings yet

- 5Document2 pages5Prsna PatilNo ratings yet

- L29 - Vapor Compression RefrigerationDocument14 pagesL29 - Vapor Compression RefrigerationAnonymous 5HYsyrddpNo ratings yet

- Pengaruh Penambahan Cooling Tower Terhadap Penurunan Suhu Air Bak Penampung Pada Proses Destilasi Uap Daun Sereh Dapur (Cymbopogoncitratus)Document9 pagesPengaruh Penambahan Cooling Tower Terhadap Penurunan Suhu Air Bak Penampung Pada Proses Destilasi Uap Daun Sereh Dapur (Cymbopogoncitratus)septa fernandoNo ratings yet

- light commercial compressor技术交流资料20170702Document29 pageslight commercial compressor技术交流资料20170702Ali MoazzamNo ratings yet

- Depliant 4ante Eu 2 2018 LowDocument2 pagesDepliant 4ante Eu 2 2018 LowManoj ManivasagamNo ratings yet