Professional Documents

Culture Documents

An Efficient Approach For Capacitor Sizing and Location On A Radial Distribution System Using Artificial Intelligence Technique

Uploaded by

sahastra244122Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Efficient Approach For Capacitor Sizing and Location On A Radial Distribution System Using Artificial Intelligence Technique

Uploaded by

sahastra244122Copyright:

Available Formats

Journal of Engineering Research and Studies

E-ISSN 0976-7916

Research Article

AN EFFICIENT APPROACH FOR CAPACITOR SIZING AND LOCATION ON A RADIAL DISTRIBUTION SYSTEM USING ARTIFICIAL INTELLIGENCE TECHNIQUE

Shikha Gupta1, Gursewak Singh Brar2

Address for Correspondence

Department of Electrical Engineering, Chitkara Institute of Engg. & Tech., Rajpura, District Patiala-147001 Department of Electrical Engineering, B.B.S.B.E.C., Fathegarh Sahib, Punjab E Mail shikhagupta157@gmail.com, brargs77@yahoo.com ABSTRACT

This paper undertakes the problem of optimal shunt capacitor placement for loss reduction in a radial distribution feeder. The objective is to determine the optimum size and location of the capacitors to be placed on a radial distribution system. The objective function is to have maximization of saving due to reduction of energy losses thereby taking into consideration cost of capacitor. The solution methodology used divides the problem into two parts. In first part, load flow solution for the radial feeder is obtained and followed by a loss sensitivity analysis to select the candidate capacitor installation locations. In second part, Genetic algorithm is used as an optimization tool, which obtains the optimal value of capacitors to be installed. The solution algorithms have been implemented into and tested on a 33-bus radial distribution system. Test results demonstrate the effectiveness of the developed algorithm. Computational results are calculated in MATLAB 7. KEYWORDS: Radial Distribution System (RDS), Capacitor placement, Loss reduction, Loss sensitivity factor (LSF), Genetic algorithm (GA).

I. INTRODUCTION The analysis of the customer failure statistics of most utilities indicates that the distribution system makes the greatest individual contribution to the unavailability of supply to a customer. Therefore, the analysis of a distribution system is an important area of activity. It is well known that losses in a distribution system are significantly high. The economic reduction of loss in power systems is considered one of the most important issues in the economy of all countries. Because of the growing effort to reduce system losses, many papers have been published in recent years referring to optimal distribution planning. Researches in this field show that loss reduction is more economical than increasing generation. Reduction of loss in the distribution systems with the maximum saving is achieved through various methods. One of the methods is the optimal selection of capacitors in such networks. The installation of shunt capacitors on radial distribution systems is essential for power flow control, improving system stability, power factor correction, voltage profile management and losses minimization. Therefore it is important to find the optimal size and location of capacitors required to minimize energy losses. A variety of methods have been devoted for load flow analysis and capacitor placement problems by many researchers. D. Shirmohammadi and A. Semlyen [3] presented a new compensation-based power flow method for the solution of weakly meshed distribution and transmission networks.S. Ghosh and D. Das [4] proposed a simple and efficient method for the load flow of radial distribution network using the evaluation based on algebraic expression of receiving

end. Goswami and Basu [5] have presented a direct method for solving radial and meshed distribution networks. Sundhararajan and Pahwa [7] have solved the general capacitor placement problem in a distribution system using a genetic algorithm. ChingTzong Su, Chu-S. Lee and Chin-S. Ho [8] has presented an optimal capacitor placement method which employs simplified power flow formulations, genetic algorithms and sensitivity factors for a given load pattern. Prakash and M. Sydulu[12] presented a novel Particle Swarm Optimization based approach for capacitor placement on Radial Distribution Systems. In this paper capacitor placement problem for loss minimization of distribution system is solved using GA. In order to demonstrate the effectiveness of GA an example from the literature is solved and the computational results are obtained. II. PROBLEM FORMULATION The problem of capacitor placement consists of determining the location, size and number of capacitors to be installed in a distribution system. III. OBJECTIVE FUNCTION The objective is to reduce the energy losses on the system while striving to minimize the cost of capacitor in the system. It thus consists of two terms. The first is the cost of capacitor placement and the second is the cost of the total energy losses. The cost associated with capacitor placement is composed of a fixed installation cost and a purchase cost. The total cost of the energy losses is obtained by summing up the real power losses for each load level multiplied by the corresponding duration.

JERS/Vol.II/ Issue II/April-June, 2011/50-54

Journal of Engineering Research and Studies

E-ISSN 0976-7916

Mathematical Representation: It is expressed mathematically by the equations below: 1. Capacitor Cost (KC): Capacitor cost is divided into two terms: constant installation cost and variable cost which is proportional to the rating of capacitors. Therefore capacitor cost is expressed as:

ncap

KC =

K

i =1

+ K Q c ci

(1) Where, Ki is the constant installation cost of capacitor. Kc is the purchase rate of capacitor per kVAR. Qci is the rating of capacitor on bus in kVAR. 2: Energy Loss Cost (ELC): The Energy loss cost (ELC) can be calculated by multiplying EL with the energy rate (Ke) ELC = EL x Ke (2) where ELi, is energy loss (kW) in sectioni in time duration T. Ke is the energy rate The cost function S [7] is expressed as: Minimize

n j =1 ncap

S = K e EL j + K i + K c Q ci

i =1

(3)

(4) Net saving = BEL KC (5) Where BEL is benefit due to energy loss reduction BEL = ELC(without capacitor) - ELC(with capacitor) ELC(without capacitor) is energy loss cost without capacitor. ELC(with capacitor) is energy loss cost with capacitor. KC is the total capacitors cost as expressed by equation. IV. METHODOLOGY USED The solution procedure solves the problem in two steps. Firstly load flow analysis of uncompensated system is carried out to calculate bus voltages and line losses followed by Loss Sensitivity Factor to identify the candidate buses for shunt capacitor placement. Then Capacitor allocation is done using Genetic Algorithm and finally load flow analysis of compensated system is carried out to obtain optimal solution.

F is the fitness function 1 F( f ) = 1+ S

V. CAPACITOR SIZING AND LOCATION USING GENETIC ALGORITHM The developed algorithm for identifying the sizing and location is based on Genetic Algorithm (GA). The various steps performed for Genetic Algorithm [12] are given as follow: The algorithm procedure can be summarized as: Step 1: Read the line and load data of distribution. Step 2: Run the Load Flow of Distribution System to find out voltage magnitudes at the buses and total power loss. Step 3: Select the candidate buses. Step 4: Set GEN = 0 Step 5: Form initial population of real numbers, which is randomly selected value of capacitors to be installed at the candidate buses for compensation. Step 6: Update the reactive power at candidate buses. Step 7: Run the Load Flow of Distribution System with updated reactive power at the candidate buses for each population. Also calculate total power loss for each population. Step 8: Calculate the total Energy Loss Cost (ELC) and Capacitor Cost (KC) for population. Step 9: For each population, evaluate the objective function and the fitness value. The objective function for each population is the total energy loss cost and the cost of capacitors given in eq. (3). Step 10: GEN = GEN + 1 Step 11: Select the solutions in pool from initial population by using Roulette Wheel Selection procedure. Step 12: Perform Crossover on the solutions selected randomly from the pool using procedure and generate two off springs. Step 13: Perform Mutation on the offspring generated by the crossover operation using the procedure and generate the offspring. Step 14: Calculate Energy Loss Cost (ELC) and capacitors cost (KC). Also evaluate objective function and Fitness Function of each off springs. Step 15: Combine the solutions of the pool and the off springs and refer them as new population. Step 16: Replace new population with initial population for next generation. Step 17: Go to step 10, till the solution converges. Step 18: STOP The above set of steps for the capacitor placement is depicted in flowchart as shown in Fig. 1 below.

JERS/Vol.II/ Issue II/April-June, 2011/50-54

Journal of Engineering Research and Studies

E-ISSN 0976-7916

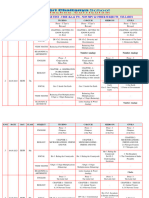

Table1. The proposed method and the algorithm are implemented by using MATLAB 7. Table 1: Comparison of the results obtained on 33 Bus RDS before and after placing the capacitors

Minimum System Voltage (p.u.) Power Loss (kW) Loss reduction (%) Buses Capacitor (kVAr) and size Uncompensated 0.9041 177KW ------Compensated 0.9304 104KW 41.24% (73kW) 7 250 12 350 16 250 27 200 1050 kVAr $54,662 =Rs.27,33,120 $7,150 = Rs. 3,57,500 $ 61,812 =Rs.30,90,620 $ 31,219 =Rs. 15,60,940

Total Compensation Total Energy Loss Cost Total capacitors cost Total Cost Total savings annual

-$93,031.2 = Rs. 46,51,560 --$93,031 = Rs. 46,51,560 --

Fig. 1 Flowchart for the capacitor placement on RDS VI. APPLICATION EXAMPLE AND RESULTS The single line diagram of compensated and uncompensated test system i.e. 33 bus system considered in this work is shown in fig. 2 & 3 resp. It has been found that by placing the capacitor at highly sensitive nodes (i.e. buses 7,12,16,27) maximum benefit can be obtained. Comparison of results of the compensated and uncompensated RDS is presented in Table 2: Comparison of the results obtained on 33-Bus RDS before and after placing the capacitors at four different buses on different locations in each case

Uncompensated Minimum system voltage (p.u.) Power Loss (kW) Loss reduction (%) Optimal location and Capacitor size (kVAr) 0.9041 177 KW -----Compensated Case I 0.9304 104 KW 41.2% 7 250 12 350 16 250 27 200 1050 kVAr $54,662 = Rs. 27,33,120 $7,150 =Rs. 3,57,500 $61,812 = Rs. 30,90,620 $31,219 = Rs. 15,60,940 Compensated Case II 0.9281 114 KW 35.5% 16 300 27 150 9 200 8 200 850 kVAr $59,918.4 = Rs. 29,95,920 $6,550 = Rs. 3,27,500 $66,468 = Rs. 33,23,420 $26,563 = Rs. 13,28,140 Compensated Case III 0.9209 126 KW 28.8% 27 200 9 250 8 100 30 350 900 kVAr $66,225.6 = Rs. 33,11,280 $6,700 = Rs. 3,35,000 $72,925 = Rs. 36,46,280 $20,106 = Rs.10,05,280 Compensated Case IV 0.9176 135 KW 23.7% 9 150 8 150 30 150 28 250 700 kVAr $70,956= Rs.35,47,800 $6,100 = Rs. 3,05,000 $77,056= Rs.38,52,800 $15,975= Rs.7,98,760

It has been found that if the capacitors are placed at locations other then the above (i.e. first four highly sensitive buses) but in the decreasing order of LSF, although losses are reduced but in each case losses are more than previous and total cost also increases thereby reducing overall annual benefit. Table 2 shown below gives the comparison of the results obtained by capacitor placement at four different buses on different locations in each case. Thus, it is shows that maximum loss reduction and savings are obtained when the capacitors are placed at first four highly sensitive buses are per LSF.

Total kVAr Total Energy Loss Cost Total capacitors cost Total cost Net annual savings

----$93,031= Rs. 46,51,560 ---$93,031= Rs. 46,51,560 ---

JERS/Vol.II/ Issue II/April-June, 2011/50-54

Journal of Engineering Research and Studies

E-ISSN 0976-7916

The 33-bus radial distribution system [6], as shown in Fig. 2, has following characteristics: Number of buses = 33 Number of lines = 32 Slack Bus No =1 Base Voltage=12.66 KV Base MVA=100

Fig 2 : Single line diagram of 33 bus system

Fig 3 : Single line diagram of 33 bus system after compensation In all the calculations following parameters are used [15]: 1. Population size = 100 2. Maximum Generation = 100 3. Crossover probability Pc=1 4. Mutation probability Pm= 0.006 5. Energy rate Ke = US $0.06/kWh (= Rs.3/kWh) 6. Installation cost of capacitor Ki = US $1000 (=Rs.50,000/each location) 7. Purchase rate of capacitor Kc = US $3.0/kVAR (=Rs.150/kVAR) JERS/Vol.II/ Issue II/April-June, 2011/50-54

Journal of Engineering Research and Studies

E-ISSN 0976-7916

VII. CONCLUSION In this paper the capacitor sizing and placement problem is discussed using an efficient GA algorithm. A test case of 33 bus system has been used and results demonstrate the improvement in voltage profile and reduction of the losses thereby maximizing net annual savings. This method places the capacitors at less number of locations with optimum size and offers much net annual savings. It has been found that maximum benefit can be obtained by placing the capacitors at highly sensitive nodes. ACKNOWLEDGEMENT This work is a part of M.Tech. Thesis work of Ms. Shikha Gupta conducted during the time period Jan to Dec, 2010 under the able guidance of Dr. Gursewak Singh Brar, HOD and Astt. Prof. at B.B.S.B.E.C. Fathegarh Sahib. REFERENCES

1. D. Rajicic and A. Bose, A modification to the fast decoupled power flow for networks with high R/X ratios, IEEE Transactions on Power Systems, vol. 3, no. 2, pp. 743-746, 1988. S. Iwamoto and Y. Tamura, A load flow calculation method for ill conditioned power systems, IEEE Transactions on Power Systems, vol. PAS-100, 1981. D. Shirmohammadi, H. W. Hong, A. Semlyen and G. X. Luo, A Compensation - Based Power Flow Method for Weakly Meshed Distribution and Transmission Networks, IEEE Transactions on Power Systems, vol. 3, no. 2, pp. 753-762, 1988. S. Ghosh and D. Das, Method for load-flow solution of radial distribution networks,IEEE Proceedings on Generation, Transmission & Distribution, vol. 146, no. 6, pp. 641-648, 1999. Goswami, S.K., and Basu, S.K., Direct solution of distribution systems,IEEE Proc. C. , 188, (I), pp. 78-88, 1991.D. Das,

6.

7.

8.

9.

10.

11.

12.

2.

13.

3.

14.

4.

15.

5.

D.Das,Optimal Placement of Capacitors in Radial Distribution System using a Fuzzy-GA method, Electrical Power and Energy System, vol. 30, pp. 361-367, 2008. S. Sundhararajan and A. Pahwa, Optimal Selection of Capacitors for Radial Distribution Systems using Genetic Algorithm, IEEE Transactions on Power Systems, vol. 9, no. 3, pp. 499-1507, 1994. Ching-Tzong Su, Chu-Sheng Lee and Chin-Shen Ho, Optimal selection of Capacitors in Distribution Systems IEEE Transactions on Power Systems. R. Ranjan and D. Das, Simple and Efficient Computer Algorithm to Solve Radial Distribution Networks, Electric Power Components and Systems, vol. 31, no. 1, pp. 95-107, 2003. T. Samimi Asl and S. Jamali, Optimal Capacitor Placement Size and Location of Shunt Capacitor for Reduction of Losses on Distribution Feeders, IEEE Transactions 2009. K. Prakash and M. Sydulu, Particle Swarm Optimization Based Capacitor Placement on Radial Distribution Systems IEEE Transactions on Power Systems 2007. Heranando Duran, Optimum Number, Location, and Size of Shunt Capacitor in Radial Distribution Feeders A Dynamic Programming Approach, IEEE Transactions on Power Apparatus and Systems, Vol. PAS-87,NO.9,Sept.1968. R.Srinivasa Rao and S.L.V. Narasiham, Optimal Capacitors placement in Radial Distribution System using Plant Growth Simulation Algorithm, Proceedings of world academy of science and tech., volume 35 Nov. 2008. S.M. Kannan,Fuzzy logic based Optimal Capacitors placement on Radial Distribution Feeders, IEEE Transactions 2008. Mesut E. Baran Felix F. Wu, Optimal Capacitors placement on Radial Distribution Systems, IEEE Transactions on Power Systems, Vol. 4, No. 1, January 1989.

JERS/Vol.II/ Issue II/April-June, 2011/50-54

You might also like

- Capacitor PlacementDocument5 pagesCapacitor PlacementmallagouthamNo ratings yet

- Optimal Capacitor Placement in A Radial Distribution System Using Dijkstra AlgorithmDocument9 pagesOptimal Capacitor Placement in A Radial Distribution System Using Dijkstra AlgorithmDizky Christian HadiNo ratings yet

- Abstract - : The Energy Usage IsDocument5 pagesAbstract - : The Energy Usage IsNunna BaskarNo ratings yet

- Optimal Capacitor Configuration For Enhancement of System Reliability Using Genetic Algorithm: A Case Study of IEEE 30 Bus SystemDocument5 pagesOptimal Capacitor Configuration For Enhancement of System Reliability Using Genetic Algorithm: A Case Study of IEEE 30 Bus SystemIDESNo ratings yet

- Page 8 Report7Document39 pagesPage 8 Report7Akshay NaikNo ratings yet

- 19 Avadhanam Kartikeya Sarma Final PaperDocument11 pages19 Avadhanam Kartikeya Sarma Final PaperiisteNo ratings yet

- Optimal Sizing of Capacitors Placed On A Radial Distribution SystemDocument9 pagesOptimal Sizing of Capacitors Placed On A Radial Distribution SystemghotourNo ratings yet

- Ijeet: International Journal of Electrical Engineering & Technology (Ijeet)Document9 pagesIjeet: International Journal of Electrical Engineering & Technology (Ijeet)IAEME PublicationNo ratings yet

- IET Template PDFDocument9 pagesIET Template PDFdebasishmee5808No ratings yet

- Sizing of Capacitors Placed Ieee 735 PDFDocument9 pagesSizing of Capacitors Placed Ieee 735 PDFEnrique Anchundia GuerreroNo ratings yet

- Optimal Capacitor Placement in Distribution Networks Regarding Uncertainty in Active Power Load and Distributed Generation Units ProductionDocument8 pagesOptimal Capacitor Placement in Distribution Networks Regarding Uncertainty in Active Power Load and Distributed Generation Units ProductionApikShafieeNo ratings yet

- Literature Survey For Compensating Capacitor PlacementDocument8 pagesLiterature Survey For Compensating Capacitor Placementhodeegits9526No ratings yet

- 2019 - Analytical Method For Optimal Reactive Power Support in Power NetworkDocument6 pages2019 - Analytical Method For Optimal Reactive Power Support in Power NetworkMohsin ShahzadNo ratings yet

- Optimal Capacitor Placement and Sizing in Unbalanced Distribution Systems With Harmonics Consideration Using Particle Swarm OptimizationDocument8 pagesOptimal Capacitor Placement and Sizing in Unbalanced Distribution Systems With Harmonics Consideration Using Particle Swarm OptimizationMohammad HosseiniNo ratings yet

- Optimal Placement of Capacitors in Radial Distribution System To Minimizes The Losses at Variable Load LevelsDocument4 pagesOptimal Placement of Capacitors in Radial Distribution System To Minimizes The Losses at Variable Load LevelsEditor IJRITCCNo ratings yet

- Capacitor Placement in Unbalanced Power SystemsDocument6 pagesCapacitor Placement in Unbalanced Power SystemsFabio NobNo ratings yet

- Mah Davian 2017Document4 pagesMah Davian 2017Pradeep PeriasamiNo ratings yet

- Optimal Placement of DG For Loss Reduction and Voltage Sag Mitigation in Radial Distribution Systems Using ABC AlgorithmDocument6 pagesOptimal Placement of DG For Loss Reduction and Voltage Sag Mitigation in Radial Distribution Systems Using ABC AlgorithmIDESNo ratings yet

- Loss ReductionDocument35 pagesLoss Reductionsolomon nchor akansakeNo ratings yet

- Habsi 19Vol58No2Document8 pagesHabsi 19Vol58No2NurAfandiAlhabsiNo ratings yet

- Dijkstra Algorithm For Feeder Routing of Radial Distribution SystemDocument6 pagesDijkstra Algorithm For Feeder Routing of Radial Distribution SystemIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Reconfiguration and Capacitor Placement For Loss Reduction of Distribution Systems by Ant Colony Search AlgorithmDocument9 pagesReconfiguration and Capacitor Placement For Loss Reduction of Distribution Systems by Ant Colony Search AlgorithmthanatitosNo ratings yet

- Capacitor, Bank, Statcom, PPDocument6 pagesCapacitor, Bank, Statcom, PPsirageldeenNo ratings yet

- Optimal Location and Sizing of Shunt Capacitors in Distribution Systems by Considering Different Load ScenariosDocument9 pagesOptimal Location and Sizing of Shunt Capacitors in Distribution Systems by Considering Different Load ScenariosSudheerKumarNo ratings yet

- Improvement by Voltage Profile by Static Var Compensators in Distribution SubstationDocument4 pagesImprovement by Voltage Profile by Static Var Compensators in Distribution SubstationJoe RanteNo ratings yet

- Optimal Placement of Dg-Voltage Stability and Losses-Our Project PaperDocument8 pagesOptimal Placement of Dg-Voltage Stability and Losses-Our Project PaperPavanhr4uNo ratings yet

- CIRED2009 0518 PaperDocument4 pagesCIRED2009 0518 PapersrivaishnaviNo ratings yet

- Optimal Allocation of Capacitor Bank For Loss Minimization and Voltage Improvement Using Analytical MethodDocument7 pagesOptimal Allocation of Capacitor Bank For Loss Minimization and Voltage Improvement Using Analytical MethodHamza AbdullahNo ratings yet

- ACO Based Algorithm For Distributed Generation Sources Allocation and Sizing in Distribution SystemsDocument6 pagesACO Based Algorithm For Distributed Generation Sources Allocation and Sizing in Distribution SystemsPervez AhmadNo ratings yet

- Iijee 2014 12 20 5Document6 pagesIijee 2014 12 20 5International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Dc-Opf UsmDocument28 pagesDc-Opf UsmIsrael Rom Olguín GuzmanNo ratings yet

- Project ProposalDocument4 pagesProject ProposalRajesh AwalNo ratings yet

- Low-And Ultra Low-Power Arithmetic Units: Design and ComparisonDocument4 pagesLow-And Ultra Low-Power Arithmetic Units: Design and ComparisonManoj SharmaNo ratings yet

- Maximizing Power System Loadability by Optimal Allocation of SVC Using Mixed Integer Linear ProgrammingDocument7 pagesMaximizing Power System Loadability by Optimal Allocation of SVC Using Mixed Integer Linear ProgrammingMohamed MansourNo ratings yet

- Optimal Selection of Capacitors For Radial Distribution Systems Using Plant Growth Simulation AlgoriDocument13 pagesOptimal Selection of Capacitors For Radial Distribution Systems Using Plant Growth Simulation AlgoriEverton Klinger Sousa SilvaNo ratings yet

- Optimal Capacitor Placement For Improving Voltage Profile and Loss Reduction of Distribution Systems by Genetic AlgorithmDocument1 pageOptimal Capacitor Placement For Improving Voltage Profile and Loss Reduction of Distribution Systems by Genetic AlgorithmIASCNo ratings yet

- Determination of Optimal Location and Sizing of Distributed Generator in Radial Distribution Systems For Different Types of LoadsDocument23 pagesDetermination of Optimal Location and Sizing of Distributed Generator in Radial Distribution Systems For Different Types of LoadsBatair BerkNo ratings yet

- Reconfiguration With Simultaneous DG Installation To Improve The Voltage Profile in Distribution Network Using Harmony Search AlgorithmDocument12 pagesReconfiguration With Simultaneous DG Installation To Improve The Voltage Profile in Distribution Network Using Harmony Search AlgorithmLava KumarNo ratings yet

- Capacitor Placement in Radial Distribution Systems For Loss ReductionDocument5 pagesCapacitor Placement in Radial Distribution Systems For Loss ReductionhmortNo ratings yet

- (IJETA-V8I5P8) :simiran Kuwera, Sunil Agarwal, Rajkumar KaushikDocument6 pages(IJETA-V8I5P8) :simiran Kuwera, Sunil Agarwal, Rajkumar KaushikIJETA - EighthSenseGroup100% (1)

- Optimal Location and Sizing of Shunt CapDocument9 pagesOptimal Location and Sizing of Shunt CapDa VidNo ratings yet

- Video PDFDocument9 pagesVideo PDFAlex ApazaNo ratings yet

- Voltage Profile Improvement by Capacitor Placement and Control in Unbalanced Distribution Systems Using Differential Evolution AlgorithmDocument8 pagesVoltage Profile Improvement by Capacitor Placement and Control in Unbalanced Distribution Systems Using Differential Evolution Algorithmswapna44No ratings yet

- Distribution System Nodal Pricing Analysis With Realistic ZIP Load and Variable Wind Power SourceDocument6 pagesDistribution System Nodal Pricing Analysis With Realistic ZIP Load and Variable Wind Power SourceSudheerKumarNo ratings yet

- DG Placement and Sizing in Radial Distribution Network Using PSO&HBMO AlgorithmsDocument6 pagesDG Placement and Sizing in Radial Distribution Network Using PSO&HBMO AlgorithmsDrVikas Singh BhadoriaNo ratings yet

- Optimal Placement of Capacitor For Voltage Support and Minimizing Overall Cost in Radial Distribution SystemDocument5 pagesOptimal Placement of Capacitor For Voltage Support and Minimizing Overall Cost in Radial Distribution SystemDavid Omar Torres GutierrezNo ratings yet

- Cat Swarm Optimization To Shunt Capacitor Allocation in Algerian Radial Distribution Power SystemDocument10 pagesCat Swarm Optimization To Shunt Capacitor Allocation in Algerian Radial Distribution Power SystemIAES IJAINo ratings yet

- Etap TutorialDocument6 pagesEtap TutorialMAGNETOxNo ratings yet

- A Method For Power Conditioning With Harmonic Reduction in MicrogridsDocument6 pagesA Method For Power Conditioning With Harmonic Reduction in MicrogridsINder DǝǝpNo ratings yet

- Optimal PlacementDocument21 pagesOptimal PlacementSunnyJoelNo ratings yet

- Newton-Raphson Method For Power Flow Equations in Matlab EnvironmentDocument5 pagesNewton-Raphson Method For Power Flow Equations in Matlab Environmentashikhmd4467No ratings yet

- IEEE Conf Feb2018Document5 pagesIEEE Conf Feb2018Abhishek GuptaNo ratings yet

- Modified Artificial Bee Colony Algorithm For Optimal Distributed Generation Sizing and Allocation in Distribution SystemsDocument9 pagesModified Artificial Bee Colony Algorithm For Optimal Distributed Generation Sizing and Allocation in Distribution SystemsKnyotNo ratings yet

- Installation of Capacitor Bank in 132 11 KV Substation For Paring Down of Load Current Ijariie7428Document9 pagesInstallation of Capacitor Bank in 132 11 KV Substation For Paring Down of Load Current Ijariie7428Prarthana AithalNo ratings yet

- Power Distribution Control Coordinating Ultracapacitors and Batteries Electric VehiclesDocument6 pagesPower Distribution Control Coordinating Ultracapacitors and Batteries Electric VehiclesrameshemandiNo ratings yet

- Reactive Power Control Using New Grey Wolf Optimizer Algorithm To Minimize Power System LossDocument9 pagesReactive Power Control Using New Grey Wolf Optimizer Algorithm To Minimize Power System LossZellagui EnergyNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Ibm Lombardi BPM 8.5 VDocument3 pagesIbm Lombardi BPM 8.5 VVirtualNuggets VNNo ratings yet

- Infinity Meta Weekly Ot - Ka & TN - Non MPC & Other Subjects - SyllabusDocument2 pagesInfinity Meta Weekly Ot - Ka & TN - Non MPC & Other Subjects - SyllabusR PranavNo ratings yet

- Darwin Geologist PDFDocument3 pagesDarwin Geologist PDFKendallhernandez100% (1)

- ODI Case Study Financial Data Model TransformationDocument40 pagesODI Case Study Financial Data Model TransformationAmit Sharma100% (1)

- Study Abroad at Drexel University, Admission Requirements, Courses, FeesDocument8 pagesStudy Abroad at Drexel University, Admission Requirements, Courses, FeesMy College SherpaNo ratings yet

- KitkatDocument11 pagesKitkatSugandha GuptaNo ratings yet

- Grammar: Present Simple and Present ContinuousDocument9 pagesGrammar: Present Simple and Present ContinuousMarialucia LugnaniNo ratings yet

- Anxiety in Practicing English Language As A Means of Communication in Esl ClassroomDocument40 pagesAnxiety in Practicing English Language As A Means of Communication in Esl Classroomkirovdust100% (1)

- STM ProcessDocument7 pagesSTM Processyadavpankaj1992No ratings yet

- Standards Booklet For Igsce Sociology (0495)Document64 pagesStandards Booklet For Igsce Sociology (0495)Ingrit AgustinNo ratings yet

- DesignationDocument21 pagesDesignationGayl Ignacio TolentinoNo ratings yet

- CCP303Document31 pagesCCP303api-3849444No ratings yet

- HRM BBA AssignmentsDocument2 pagesHRM BBA AssignmentsNitin GargNo ratings yet

- I S Eniso3834-5-2015Document24 pagesI S Eniso3834-5-2015Ngoc BangNo ratings yet

- Rhetoric AnalysisDocument3 pagesRhetoric AnalysisSam RussellNo ratings yet

- English: Quarter 3 - Module 5Document21 pagesEnglish: Quarter 3 - Module 5Maria Qibtiya100% (3)

- 2a Three Types of LightingDocument14 pages2a Three Types of LightingMarcus MasangkayNo ratings yet

- 2-General Physics 1-Uncertainties in MeasurementDocument22 pages2-General Physics 1-Uncertainties in MeasurementLiza Macalinao MangalimanNo ratings yet

- دور معايير التقارير المالية الدولية في الحد من ممارسات ادارة الارباح في القوائم المالية للمصارفDocument18 pagesدور معايير التقارير المالية الدولية في الحد من ممارسات ادارة الارباح في القوائم المالية للمصارفWshiar Omer100% (1)

- HL7 AdtDocument21 pagesHL7 AdtJerome B. AgliamNo ratings yet

- CoverPapers May-2016 1H QPDocument24 pagesCoverPapers May-2016 1H QPneNo ratings yet

- Data Migration To HadoopDocument26 pagesData Migration To Hadoopkrishna100% (2)

- NTCC FinalDocument43 pagesNTCC FinalNihar NanyamNo ratings yet

- Jurnal PEMELIHARAAN IKAN BAUNG (Hemibagrus Nemurus) DENGAN Padat Tebar Yang Berbeda Pada Sistem Budidaya BosterDocument14 pagesJurnal PEMELIHARAAN IKAN BAUNG (Hemibagrus Nemurus) DENGAN Padat Tebar Yang Berbeda Pada Sistem Budidaya Bosterdesi sukmawatiNo ratings yet

- Cot Angel Eng 3Document3 pagesCot Angel Eng 3Arjay GarboNo ratings yet

- Bei 076 III II AntenamarksDocument8 pagesBei 076 III II Antenamarksshankar bhandariNo ratings yet

- PFI ES-27-1994 - Visual Examination - The Purpose, Meaning and Limitation of The TermDocument4 pagesPFI ES-27-1994 - Visual Examination - The Purpose, Meaning and Limitation of The TermThao NguyenNo ratings yet

- The Eight Types of Interview QuestionsDocument2 pagesThe Eight Types of Interview QuestionsKayla Camille A. Miguel100% (1)

- Nhóm 1- Tấm CámDocument12 pagesNhóm 1- Tấm CámNguyễn NgọcNo ratings yet

- Lesson Plan in Story Time-C.o. 3Document9 pagesLesson Plan in Story Time-C.o. 3Girlie May MabasagNo ratings yet