Professional Documents

Culture Documents

IoCT Part2 06PaperMachines LR

Uploaded by

BrYan Frias RuizOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IoCT Part2 06PaperMachines LR

Uploaded by

BrYan Frias RuizCopyright:

Available Formats

Success Stories

for Control

Cross-Direction Control of Paper Machines

A paper machine is a technological marvel! Think of it as a 100-meter-long, 10-meter-wide wire screen that can move at faster than 100 km/hour. At one end of the machine, pulp stock is extruded onto the wire screen; this stock is composed of about 99.5% water and 0.5% fibers. Over a 100-meter-long machine, the paper sheet travels a path that may cover more than 200 meters. Ultimately paper is produced; the moisture content at the dry end is about 5-8% water and 92-95% wood fibers. With new cross-direction control technology, the paper can be produced to a thickness (caliper) uniformity of within a few microns over entire production reels, each of which can contain a 40 km length of the paper sheet. Scanning sensors measure sheet properties such as weight, moisture, and caliper in a zig-zag path on the moving paper sheet, and up to 300 individually controlled actuators in each of up to seven actuator beams are used for pulp stock metering, steam heat drying, water shower re-wetting, and induction heating.

Cross-Direction versus Machine Direction Traditionally, paper machine control was limited to the machine directionreducing the variation in the paper linearly along the direction of travel, without coordinating control across the sheet. Cross-direction (CD) control is a considerably more challenging problemits solution revolutionized paper making!

Problem Characteristics

The response of the paper to the cross-directional actuators has both a dynamic component and a spatially distributed component. Analysis of the response in frequency domains reveals that the dynamic response is small at fast temporal frequencies and the spatial response is small at short spatial wavelengths (corresponding to the existence of small singular values). A common closed-loop instability occurs at slow temporal frequencies and short spatial wavelengthsa result of combining aggressive control action (an integrator!) with low plant gain.

Honeywells cross-direction paper machine control products, IntelliMap and PerformanceCD, are deployed on more than 300 paper machines. Benets include up to 50% higher performance and about 80% reduction in control tuning time.

A long-standing industrial control problem solved by robust control design.

Contributor: Gregory Stewart, Honeywell, Canada

From: The Impact of Control Technology, T. Samad and A.M. Annaswamy (eds.), 2011. Available at www.ieeecss.org.

Operators and engineers in paper manufacturing plants are not experts in control theory. Providing tools that can be used by paper industry personnel has been instrumental to the success of this CD control innovation.

Design and Tuning Tools

The tools provided for the success of this CD control innovation include: A test and identification tool that automatically makes changes to the actuators, collects the resulting sensor data, and analyzes the data to develop a large-scale, spatially distributed model. An automated controller tuning tool that takes the developed model and determines optimal tuning parameters for the cross-directional controller. The controller is designed using a technique called two-dimensional robust loop shaping.

The Previous State of the Art: Prior to the introduction of advanced control, these systems would often develop a slow closed-loop instability, sometimes taking as long as 24 to 48 hours to appear after controller tuning.

Elapsed time 24-48 hours

Awards

IEEE Control Systems Technology Award from the IEEE Control Systems Society for innovative application of modern identification and control methods to the papermaking process awarded to D. Gorinevsky and G. Stewart in 2001. IEEE Transactions on Control Systems Technology Outstanding Paper Award given to G. Stewart, D. Gorinevsky and G. Dumont, Feedback Controller Design for a Spatially Distributed System: The Paper Machine Problem, vol. 11, no. 5, September 2003.

For further information: Go to www.honeywell.com and search paper quality control system

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- FMEA Training v1.1Document78 pagesFMEA Training v1.1Charles Walton100% (1)

- Enterprise Resource Planning (ERP) - SEM-IV (GTU)Document139 pagesEnterprise Resource Planning (ERP) - SEM-IV (GTU)keyur100% (1)

- Typical Q&A - SOftware EngineeringDocument81 pagesTypical Q&A - SOftware EngineeringJafar Khan87% (38)

- Common SAP Testing Terminology Ensures Project UnderstandingDocument8 pagesCommon SAP Testing Terminology Ensures Project UnderstandingZelimir KovacevicNo ratings yet

- Fundamentals of Control Systems Fundamentals of Control SystemsDocument60 pagesFundamentals of Control Systems Fundamentals of Control SystemsĐỗ Ngọc CẩnNo ratings yet

- Ligjerata 9Document38 pagesLigjerata 9Buleza ShehuNo ratings yet

- The Future of Communication Through Technological AdvancementsDocument1 pageThe Future of Communication Through Technological Advancementsvkook luvNo ratings yet

- Business Driven Management Information Systems 3rd Edition Baltzan Test BankDocument65 pagesBusiness Driven Management Information Systems 3rd Edition Baltzan Test Bankcodykerrdiaqbnwyrp100% (30)

- 304-Article Text-615-2-10-20231030Document19 pages304-Article Text-615-2-10-20231030Fatma Al KhalifinNo ratings yet

- Z Language: Libyan International Medical University Faculty of Information TechnologyDocument10 pagesZ Language: Libyan International Medical University Faculty of Information TechnologyMaryam FarkashNo ratings yet

- 7th Semester AI Booklet 2023-24Document38 pages7th Semester AI Booklet 2023-24GEETHA KRISHNAMA NAIDU PALADUGUNo ratings yet

- Applications of AI in manufacturing, healthcare, and oil and gasDocument2 pagesApplications of AI in manufacturing, healthcare, and oil and gasJesse MacDonald PhiriNo ratings yet

- Software Cost Estimation With Use Case Points - Free Excel SpreadsheetDocument10 pagesSoftware Cost Estimation With Use Case Points - Free Excel Spreadsheethongnh-1No ratings yet

- Managing The Control ProcessDocument11 pagesManaging The Control ProcessAlifiarosa Astari RamadhentiNo ratings yet

- Bab 8 DataWareHouseDocument28 pagesBab 8 DataWareHousebangkit sitohangNo ratings yet

- Final Thesis Albert Juan MasoDocument130 pagesFinal Thesis Albert Juan MasoBhuvanesh RaamNo ratings yet

- Project Phase I ReportDocument4 pagesProject Phase I ReportMayankNo ratings yet

- WWW Softwaretestingclass Com PDFDocument4 pagesWWW Softwaretestingclass Com PDFavi1champNo ratings yet

- Classification Applications With Deep Learning and Machine Learning TechnologiesDocument287 pagesClassification Applications With Deep Learning and Machine Learning TechnologiesJose Angel Gonzalez OlmosNo ratings yet

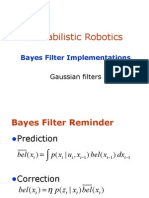

- Probabilistic Robotics: Bayes Filter ImplementationsDocument61 pagesProbabilistic Robotics: Bayes Filter ImplementationsMatt Brian CapangpanganNo ratings yet

- Part 3 - Short-Term Memory, Long-Term Memory and Retrospective and Prospective Memories - Centre of ExcellenceDocument6 pagesPart 3 - Short-Term Memory, Long-Term Memory and Retrospective and Prospective Memories - Centre of ExcellenceSajid AliNo ratings yet

- Lecture 2.1.3 2.1.4Document30 pagesLecture 2.1.3 2.1.4yuvrajaditya1306No ratings yet

- Deep Convolutional Neural Networks Architecture For An Efficient Emergency Vehicle Classification in Real-Time Traffic MonitoringDocument11 pagesDeep Convolutional Neural Networks Architecture For An Efficient Emergency Vehicle Classification in Real-Time Traffic MonitoringIAES IJAINo ratings yet

- Assignment No 4: Text Classification Using Naive BayesDocument6 pagesAssignment No 4: Text Classification Using Naive BayesHusnain IqbalNo ratings yet

- Agile ModelDocument5 pagesAgile ModelRaghavendra SinghNo ratings yet

- Partial Feedback LinearizationDocument11 pagesPartial Feedback Linearizationzamzuri_rashidNo ratings yet

- 25492-Article Text-41335-1-10-20221220 PDFDocument4 pages25492-Article Text-41335-1-10-20221220 PDFRezki AlhakimNo ratings yet

- Machine learning methods identify and classify toxic commentsDocument5 pagesMachine learning methods identify and classify toxic commentsAnh Đinh ViệtNo ratings yet

- 2.160 Identification, Estimation, and Learning: End-of-Term ExaminationDocument3 pages2.160 Identification, Estimation, and Learning: End-of-Term ExaminationRahul Raveendran PillaiNo ratings yet

- Outline: Software Engineering For Software-Intensive Systems: IV RequirementsDocument11 pagesOutline: Software Engineering For Software-Intensive Systems: IV Requirementsvar6212No ratings yet