Professional Documents

Culture Documents

Power Supply Input and Device Parameters

Uploaded by

Elias Moreira Campos0 ratings0% found this document useful (0 votes)

173 views7 pagesThis document provides design specifications for a power supply including parameters for the power supply input and output sections, device variables, transformer construction, board layout recommendations, bill of materials, electrical and mechanical diagrams, winding instructions, electrical test specifications, and comments. Key details include an input voltage range of 200-375V, an output of 12V at 0.8A, using a TNY266PN controller, and transformer specifications including 117 turns of 33AWG wire for the primary winding.

Original Description:

Original Title

TinySwitch II PIDesign1

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides design specifications for a power supply including parameters for the power supply input and output sections, device variables, transformer construction, board layout recommendations, bill of materials, electrical and mechanical diagrams, winding instructions, electrical test specifications, and comments. Key details include an input voltage range of 200-375V, an output of 12V at 0.8A, using a TNY266PN controller, and transformer specifications including 117 turns of 33AWG wire for the primary winding.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

173 views7 pagesPower Supply Input and Device Parameters

Uploaded by

Elias Moreira CamposThis document provides design specifications for a power supply including parameters for the power supply input and output sections, device variables, transformer construction, board layout recommendations, bill of materials, electrical and mechanical diagrams, winding instructions, electrical test specifications, and comments. Key details include an input voltage range of 200-375V, an output of 12V at 0.8A, using a TNY266PN controller, and transformer specifications including 117 turns of 33AWG wire for the primary winding.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

Power SuppIy Input

Var Value Units Description

VDCMÌN 200 V Minimum Ìnput DC Voltage

VDCMAX 375 V Maximum Ìnput DC Voltage

Z 0,70 Loss Allocation Factor

q 78,0 % Efficiency Estimate

ÌAVG 0,07 A Average Diode Bridge Current (DC Ìnput Current)

Input Section

Var Value Units Description

Fuse 1,25 A Ìnput Fuse Rated Current

MOV_VRATED 385 V MOV Rated Voltage

Device VariabIes

Var Value Units Description

Device TNY266PN PÌ Device Name

Device Mode Default Current Limit mode for device

PO 10,40 W Total Output Power

VDRAÌN Estimated 592,50 V Actual Estimated Drain Voltage

VDS 11,00 V On state Drain to Source Voltage

FSMÌN 120000 Hz Minimum Switching Frequency

KP 0,97 Continuous/Discontinuous Operating Ratio

ÌLÌMÌTMÌN 0,33 A Minimum Current Limit

ÌLÌMÌTMAX 0,38 A Maximum Current Limit

RLS 1,6 MD Line sense resistor

RLS2 1,6 MD Line sense resistor

ÌRMS 0,13 A Primary RMS Current (at VMÌN)

P_NO_LOAD 300 mW Estimated No Load Ìnput Power

DMAX 0,42 Maximum Duty Cycle

RTH_DEVÌCE 119,63 °C/W PÌ Device Maximum Thermal Resistance

2 Oz (70 µ)

Copper PCB

PÌ Device Heatsink Type

52 mm² PÌ Device Heatsink Area

CIamp Circuit

Var Value Units Description

Clamp Type Zener Clamp Clamp Circuit Type

VCLAMP 180 V Estimated average clamping voltage

Estimated Clamp

Loss

0,43 W Clamp Dissipation

Transformer Construction Parameters

Var Value Units Description

Core Type EE19 Core Type

Core Material NC-2H (Nicera)

or Equivalent

Core Material

Bobbin Reference Generic, 4 pri. +

5 sec.

Bobbin Reference

Bobbin Orientation Vertical Bobbin type

Primary Pins 4 Number of Primary pins used

Secondary Pins 2 Number of Secondary pins used

USE_SHÌELDS NO Use shield Windings

LP_nom 2185 µH Nominal Primary Ìnductance

LP_Tol 10,0 % Primary Ìnductance Tolerance

NP 116,9 Calculated Primary Winding Total Number of Turns

NSM 11 Secondary Main Number of Turns

CMA 394 Cmils/A Primary Winding Current Capacity

VOR 135,0 V Reflected Output Voltage

BW 9,00 mm Bobbin Winding Width

ML 0,00 mm Safety Margin on Left Width

MR 0,00 mm Safety Margin on Right Width

FF 46 % Actual Transformer Fit Factor. 100% signifies fully utilized winding window

AE 23,00 mm² Core Cross Sectional Area

ALG 144 nH/T² Gapped Core Effective Ìnductance

BM 2891 Gauss Maximum Flux Density

BAC 1206 Gauss AC Flux Density for Core Loss

LG 0,178 mm Estimated Gap Length

L_LKG 65,56 µH Estimated primary leakage inductance

LSEC 15 nH Secondary Trace Ìnductance

Primary Winding Section 1

Var Value Units Description

NP1 117 Rounded (Ìnteger) Number of Primary winding turns in the first section of primary

Wire Size 33 AWG Wire size of primary winding

Winding Type Single (x1) Primary winding number of parallel wire strands

L 2,81 Primary Number of Layers

DC Copper Loss 0,04 W Primary 1 DC Losses

Output 1

Var Value Units Description

VO 12,00 V Output Voltage

ÌO 0,80 A Output Current

VOUT_ACTUAL 12,00 V Actual Output Voltage

NS 11 Secondary Number of Turns

Wire Size 25 AWG Wire size of secondary winding

Winding Type Single (x1) Output winding number of parallel strands

L_S_OUT 0,79 Secondary Output Winding Layers

DC Copper Loss 0,11 W Secondary DC Losses

VD 0,70 V Output Winding Diode Forward Voltage Drop

PÌVS 47 V Output Rectifier Maximum Peak Ìnverse Voltage

ÌSP 3,19 A Peak Secondary Current

ÌSRMS 1,43 A Secondary RMS Current

RTH_DÌODE 89,83 °C/W Output Diode Maximum Thermal Resistance

OD_HSÌNK_TYPE 2 Oz (70 µ)

Copper PCB

Output Diode Heatsink Type

OD_HSÌNK_AREA 52 mm² Output Diode Heatsink Area

CO 470 x 1 µF Output Capacitor

ÌRÌPPLE 1,18 A Output Capacitor RMS Ripple Current

Expected Lifetime 25791 hr Expected Lifetime of Output Capacitor

Feedback Circuit

Var Value Units Description

NO Dual Output Feedback regulations use flag

SF_FLAG NO Soft Finish Circuits use flag

NO Phase Boost Network flag

The reguIation and toIerances do not account for thermaI drifting and component toIerance of the output diode forward voItage drop and voItage drops across the LC post fiIter. The actuaI

voItage vaIues are estimated at fuII Ioad onIy.

PIease verify cross reguIation performance on the bench.

Board Layout Recommendations

Click on the "Show me" icon to highlight relevant areas on the sample layout.

Description Show Me

1 Maximize source area for good heat-sinking

2 Keep drain trace short

3 The BYPASS pin capacitor should be located as close as possible to the BYPASS and SOURCE pins

4 Keep noisy traces away from EN/UV pin

5 Route bias winding currents back to the bulk cap

6 Keep clamp loop short

7 Connect Y capacitor to the B+ rail on the primary side for better surge immunity. Keep Y capacitor traces short

8 The area of the loop connecting the secondary winding, the output diode and the output filter capacitor should be minimized

BiII Of MateriaIs

Item # Quantity Part Ref Value Description Mfg Mfg Part Number

1 1 C1 2,2 µF 2,2 µF, 400 V, High Voltage Al Electrolytic, 180800 mD, (11 mm x 8

mm)

Nippon Chemi-Con ESMG400VB2R2M8X11LL

2 2 C2, C7 0,1 µF 0,1 µF, 16 V, Ceramic, X7R TDK C1005X7R1C104K

3 1 C3 2,2 nF 2,2 nF, 250 VAC, Ceramic, Y Class TDK CD12-E2GA222MYNS

4 1 C4 470 pF 470 pF, 100 V, Ceramic, C0G Epcos B37979G5471J000

5 1 C5 470 µF 470 µF, 25 V, Electrolytic, Super Low ESR, 41 mD, (20 mm x 8 mm) United Chemi-Con EKZE250ELL471MH20D

6 1 C6 100 µF 100 µF, 16 V, Electrolytic, Low ESR, 250 mD, (11,5 mm x 6,3 mm) United Chemi-Con ELXZ160ELL101MFB5D

7 1 D1 FR106 800 V, 1 A, Fast Recovery, 250 ns, DO-41 Diodes Ìnc. FR106

8 1 D2 SB160 60 V, 1 A, Schottky, DO-41 Vishay SB160

9 1 F1 1,25 A 600 VAC, 1,25 A, Glass Cartridge, Time Lag Fuse Littelfuse 04611.25ER

10 1 L1 3,3 µH 3,3 µH, 2,66 A Bourns Ìnc. RL822-3R3K-RC

11 2 R1, R2 1,6 MD 1,6 MD, 5 %, 0,25 W, Carbon Film Generic

12 1 R3 22 D 22 D, 5 %, 0,25 W, Carbon Film Generic

13 1 R4 210 D 210 D, 1 %, 0,125 W, Metal Film Generic

14 1 R5 1 kD 1 kD, 5 %, 0,125 W, Carbon Film Generic

15 1 R6 43,2 kD 43,2 kD, 1 %, 0,125 W, Metal Film Generic

16 1 R7 11,3 kD 11,3 kD, 1 %, 0,125 W, Metal Film Generic

17 1 RV1 VDRS10P385BSE 385 V, 67 J, 7,5 mm, RADÌAL, MOV Vishay VDRS10P385BSE

18 1 T1 EE19 NC-2H (Nicera) or Equivalent Core Material

See Transformer Construction's Materials List for complete information

TDK PC40EE19-Z

19 1 U1 TNY266PN TinySwitch-ÌÌ, TNY266PN, DÌP-8 Power Ìntegrations TNY266PN

20 1 U2 PS2501-1-K-A Optocoupler PS2501-1-K-A, 80 V, CTR 300 - 600 %, 4-DÌP CEL PS2501-1-K-A

21 1 U3 TL431CLPM 2,495 V, Shunt Regulator ÌC, 2 %, TO-92 Texas Ìnstruments TL431CLPM

22 1 VR1 P6KE180A 180 V, 5 W, 5 %, DO-204AC, TVS ON Semiconductor P6KE180A

23 1 52 mm² area on Copper PCB. 2 oz (70 µm) thickness. Heatsink for use

with Device U1.

Custom

24 1 52 mm² area on Copper PCB. 2 oz (70 µm) thickness. Heatsink for use

with Diode D2.

Custom

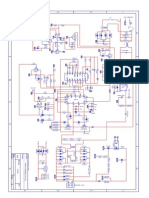

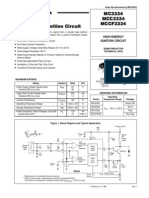

EIectricaI Diagram

MechanicaI Diagram

Winding Instruction

Primary Winding

Start on pin(s) 2 and wind 117 turns (x 1 filar) of item [5] in 3 layer(s) from left to right. At the end of 1st layer, continue to wind the next layer from right to left. At the end of 2nd layer, continue to wind the

next layer from left to right. On the final layer, spread the winding evenly across entire bobbin. Finish this winding on pin(s) 1.

Add 3 layers of tape, item [3], for insulation.

Secondary Winding

Start on pin(s) 6 and wind 11 turns (x 1 filar) of item [6]. Spread the winding evenly across entire bobbin. Wind in same rotational direction as primary winding. Finish this winding on pin(s) 5.

Add 2 layers of tape, item [3], for insulation.

Core AssembIy

Assemble and secure core halves. Ìtem [1].

Varnish

Dip varnish uniformly in item [4]. Do not vacuum impregnate.

Comments

1. For non margin wound transformers use tripIe insuIated wire for aII secondary windings.

MateriaIs

Item Description

[1] Core: EE19, NC-2H (Nicera) or EquivaIent, gapped for ALG of 144 nH/T²

[2] Bobbin: Generic, 4 pri. + 5 sec.

[3] Barrier Tape: PoIyester fiIm [1 miI (25 µm) base thickness], 9,00 mm wide

[4] Varnish

[5] Magnet Wire: 33 AWG, SoIderabIe DoubIe Coated

[6] TripIe InsuIated Wire: 25 AWG

EIectricaI Test Specifications

Parameter Condition Spec

Electrical Strength, VAC 60 Hz 1 second, from pins 1,2 to pins 5,6. 3000

Nominal Primary Ìnductance, µH Measured at 1 V pk-pk, typicaI switching frequency, between pin 1 to pin 2,

with aII other Windings open.

2185

Tolerance, ±% ToIerance of Primary Inductance 10,0

Maximum Primary Leakage, µH Measured between Pin 1 to Pin 2, with aII other Windings shorted. 65,56

AIthough the design of the software considered safety guideIines, it is the user's responsibiIity to ensure that the user's power suppIy design meets aII

appIicabIe safety requirements of user's product.

The products and appIications iIIustrated herein (incIuding circuits externaI to the products and transformer construction) may be covered by one or

more U.S. and foreign patents or potentiaIIy by pending U.S. and foreign patent appIications assigned to Power Integrations. A compIete Iist of Power

Integrations' patents may be found at www.powerint.com.

Design Passed (Optimization Done)

You might also like

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 13.8V 40A Power Supply Schematic PrintsDocument1 page13.8V 40A Power Supply Schematic PrintsRafael FersacaNo ratings yet

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- Taramps THV 10aDocument1 pageTaramps THV 10afabricio_marchi_3No ratings yet

- Basic Electrical & Electronics EngineeringDocument87 pagesBasic Electrical & Electronics EngineeringDr-Ahmed ElkoranyNo ratings yet

- MH 182 Multi-Purpose Hall Effect Latch Technical SpecificationDocument11 pagesMH 182 Multi-Purpose Hall Effect Latch Technical SpecificationharshalvikasNo ratings yet

- MK 2 PiDocument7 pagesMK 2 PiA Whick Bumbum TralalaNo ratings yet

- Datasheet MC3334Document6 pagesDatasheet MC3334odipasNo ratings yet

- 20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDocument9 pages20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquartersfernandes66No ratings yet

- Tda 1552 QDocument10 pagesTda 1552 QAnderson PotrikusNo ratings yet

- +/-18 V, Dual Output Power Supply: Design Note - DN06008/DDocument3 pages+/-18 V, Dual Output Power Supply: Design Note - DN06008/Dcornel_24No ratings yet

- TX Relays: Features Typical ApplicationsDocument7 pagesTX Relays: Features Typical ApplicationszakioNo ratings yet

- Panasonic Inverter ManualDocument8 pagesPanasonic Inverter Manualsamernet2100% (1)

- IR21571 Ballast Control IC Design Kit GuideDocument16 pagesIR21571 Ballast Control IC Design Kit Guide1cvbnmNo ratings yet

- LG Beko 28cz10rx Service ManualDocument32 pagesLG Beko 28cz10rx Service ManualAlan ScarfidiNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-X6729Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6729perro sNo ratings yet

- La 4278Document6 pagesLa 4278Carlos López Rivera0% (1)

- TDA2008Document10 pagesTDA2008miusayNo ratings yet

- Tda 2613 QDocument11 pagesTda 2613 Qpaulmx13No ratings yet

- Chapter 3Document3 pagesChapter 3Jun Mier SawitanNo ratings yet

- Ane Str3a100Document17 pagesAne Str3a100vietanh_askNo ratings yet

- RCB600 :: ROAL Living EnergyDocument10 pagesRCB600 :: ROAL Living EnergyroalscribdNo ratings yet

- Panasonic Sa-Ak270 (Eb, Eg)Document120 pagesPanasonic Sa-Ak270 (Eb, Eg)Rafael Hernandez100% (1)

- LA4278Document7 pagesLA4278aalex28No ratings yet

- An Analog Current Controller Design For Laser Diodes: Todd P. MeyrathDocument7 pagesAn Analog Current Controller Design For Laser Diodes: Todd P. MeyrathAfzal345No ratings yet

- Subminiature Dip Relay: ZettlerDocument2 pagesSubminiature Dip Relay: ZettlerSergiu BadalutaNo ratings yet

- STK400 040Document10 pagesSTK400 040Carlos Milton Martinez GaleanoNo ratings yet

- Ir 2153Document8 pagesIr 2153oasdopdasNo ratings yet

- TDA2050 - DatasheetDocument18 pagesTDA2050 - Datasheetnwo330No ratings yet

- TDA1557QDocument11 pagesTDA1557QLuiz FernandoNo ratings yet

- Two-Channel Class AB Audio Power Amplifier IC 40W + 40W: Package DimensionsDocument6 pagesTwo-Channel Class AB Audio Power Amplifier IC 40W + 40W: Package DimensionsYaquira Gonzales100% (1)

- Telemecanique ContactorDocument26 pagesTelemecanique ContactorgeoghoNo ratings yet

- Tda 1517Document14 pagesTda 1517Cris VMNo ratings yet

- TDA7262Document9 pagesTDA7262Nelson PereiraNo ratings yet

- DI-63 DatasheetDocument2 pagesDI-63 DatasheetJUANnn100No ratings yet

- Application Note 2034 LM3445 - 120VAC, 8W Isolated Flyback LED DriverDocument20 pagesApplication Note 2034 LM3445 - 120VAC, 8W Isolated Flyback LED DriverEduardoNo ratings yet

- BEKO 12.8 Service Manual PDFDocument20 pagesBEKO 12.8 Service Manual PDFkilol0No ratings yet

- ABB2CDS253001R0447Document3 pagesABB2CDS253001R0447Anonymous hXUhpe7SNo ratings yet

- BA5417Document11 pagesBA5417AntorimaNo ratings yet

- CCFL Inverter IC OZ960Document12 pagesCCFL Inverter IC OZ960davesworkshopNo ratings yet

- T Tda8563qDocument16 pagesT Tda8563qdanionescu2022No ratings yet

- Data Sheet: 1 W BTL Mono Audio AmplifierDocument9 pagesData Sheet: 1 W BTL Mono Audio AmplifierJuan Cruz PalmaNo ratings yet

- Current Sensor - LTSR 15-NPDocument3 pagesCurrent Sensor - LTSR 15-NPFadhil Tresna NugrahaNo ratings yet

- LM4863Document21 pagesLM4863Abdul NasirNo ratings yet

- 80W 3-Channel Audio Power ICDocument13 pages80W 3-Channel Audio Power ICsteffatoNo ratings yet

- Tda 2006Document12 pagesTda 2006Grand BrotherNo ratings yet

- Ca3kn22bd Telemecanique - Unit5.relayDocument8 pagesCa3kn22bd Telemecanique - Unit5.relaykapenziNo ratings yet

- Tda 1517Document11 pagesTda 1517minhchatnguyenNo ratings yet

- UCC381ADDocument33 pagesUCC381ADbenaya2012No ratings yet

- Switching IC for compact power supply STR-A6252Document9 pagesSwitching IC for compact power supply STR-A6252Fernando ChingaNo ratings yet

- FEP16DTDocument4 pagesFEP16DTElias Moreira CamposNo ratings yet

- dv7831 A1Document7 pagesdv7831 A1Elias Moreira CamposNo ratings yet

- dv7831 A1Document7 pagesdv7831 A1Elias Moreira CamposNo ratings yet

- RockfordFosgate-600a5 PwrampDocument7 pagesRockfordFosgate-600a5 PwrampElias Moreira CamposNo ratings yet

- 412 ENSC%2B320%2BElectric%2BCircuits%2BII Spring2015 v5Document22 pages412 ENSC%2B320%2BElectric%2BCircuits%2BII Spring2015 v5Robert HoNo ratings yet

- Weidmuller Technical Information of Energy ManagementDocument52 pagesWeidmuller Technical Information of Energy ManagementEuroJoseNo ratings yet

- On The Specification of Moving-Coil Drivers For Low Frequency Horn-Loaded Loudspeakers (W. Marshall Leach, JR) PDFDocument10 pagesOn The Specification of Moving-Coil Drivers For Low Frequency Horn-Loaded Loudspeakers (W. Marshall Leach, JR) PDFTrayNo ratings yet

- Load Test On High Current Low Voltage Inverters in Back-to-Back ConnectionDocument43 pagesLoad Test On High Current Low Voltage Inverters in Back-to-Back ConnectionSadie WilliamsonNo ratings yet

- DC Chopper FundamentalsDocument77 pagesDC Chopper FundamentalsyogitaNo ratings yet

- Alternating Current: Peak Value and R.M.S ValueDocument9 pagesAlternating Current: Peak Value and R.M.S ValueBinod KhatriNo ratings yet

- Panasonic 2013 Catalog - Chip InductorsDocument120 pagesPanasonic 2013 Catalog - Chip InductorsalltheloveintheworldNo ratings yet

- Electrical Engineering 2015 Set 2Document15 pagesElectrical Engineering 2015 Set 2Narendran KumaravelNo ratings yet

- Mitra Xu Benidris - InrushDocument8 pagesMitra Xu Benidris - InrushAlexis ibarraNo ratings yet

- PCB Ibm PDFDocument408 pagesPCB Ibm PDFFelipe AndinoNo ratings yet

- 12th Physics EM Important Questions With Solutions English MediuDocument16 pages12th Physics EM Important Questions With Solutions English MediuRagaviNo ratings yet

- Extended Essay Rough CompDocument19 pagesExtended Essay Rough CompBenjamin KnezNo ratings yet

- Measurement of Skin Effects Using The Bode 100: AbstractDocument8 pagesMeasurement of Skin Effects Using The Bode 100: AbstractSilvia De La CruzNo ratings yet

- TI Analog Applications Journal 4 2013Document41 pagesTI Analog Applications Journal 4 2013jupsilundNo ratings yet

- Analysis of Practical Result and MATLAB Simulation of Lightning Impulse Test On TransformerDocument5 pagesAnalysis of Practical Result and MATLAB Simulation of Lightning Impulse Test On TransformerMozar CostaNo ratings yet

- Nonlinear Discrete-Time Integral Sliding Mode Control of An Induction Motor: Real-Time ImplementationDocument10 pagesNonlinear Discrete-Time Integral Sliding Mode Control of An Induction Motor: Real-Time Implementationdamaya1701No ratings yet

- 31S11020518 Pdf-MergedDocument2 pages31S11020518 Pdf-MergedrameshNo ratings yet

- Model Exam - PSGDocument2 pagesModel Exam - PSGthangalakshmiprakashNo ratings yet

- Rollno. Anna University (University Departments) B.E. (Full Time) - End Semester Examinations, Nov/Dec 2021Document3 pagesRollno. Anna University (University Departments) B.E. (Full Time) - End Semester Examinations, Nov/Dec 2021hihelloNo ratings yet

- EMS Lab3 - 2 - 04Document15 pagesEMS Lab3 - 2 - 04Jegan PrasadNo ratings yet

- Induction Heating Coil Design and Basic DesignDocument12 pagesInduction Heating Coil Design and Basic DesignMF BarretoNo ratings yet

- Measurement and Transducers Unit 2Document76 pagesMeasurement and Transducers Unit 2Sagar VermaNo ratings yet

- Getting Started With Maxwell:: Designing A Rotational ActuatorDocument58 pagesGetting Started With Maxwell:: Designing A Rotational ActuatorAnel HrusticNo ratings yet

- Notes Ee 111 Fundamentals of Electrical EngineeringDocument73 pagesNotes Ee 111 Fundamentals of Electrical EngineeringadityaNo ratings yet

- Design of EMI Filters For DC-DC ConverterDocument6 pagesDesign of EMI Filters For DC-DC ConverterPABLO MAURONo ratings yet

- LAB EKT101 Ver018 PDFDocument46 pagesLAB EKT101 Ver018 PDFAin SolehahNo ratings yet

- ET4119 2007-12-07 Ten Met BundelDocument23 pagesET4119 2007-12-07 Ten Met BundelmeteNo ratings yet

- Transformers: N and Use It in CalculationsDocument25 pagesTransformers: N and Use It in CalculationsAnthony PadriqueNo ratings yet

- Elec - E8409 Hve Lecture 6Document56 pagesElec - E8409 Hve Lecture 6Syed Ahsan Ali SheraziNo ratings yet