Professional Documents

Culture Documents

Tray Dryer Experiment

Uploaded by

Sujan BasyalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tray Dryer Experiment

Uploaded by

Sujan BasyalCopyright:

Available Formats

ABSTRACT

In this experiment, we use tray dryers to dry the wet sample. We choose the tea herbs as our sample because we believe that tea herbs re uires short dryin! time, and the moisture content will decrease "aster with time. The measurement o" the moisture content is based on the wei!ht o" the sample which inversely proportional with the temperature # time. Thus, we can determine the dryin! rate o" the sample. Based on the data "rom the experiment, the mass and moisture content is decreasin! with time, whereas the dryin! rate is varyin! rapidly with time.

I$TR%&'CTI%$

&ryin! is the process o" thermally removin! volatile substances (e.!., moisture) to yield a solid product. *echanical methods "or separatin! a li uid "rom a solid are not considered in thermal dryin!. When a wet solid is sub+ected to thermal dryin!, two processes occur simultaneously, "irst is the trans"er o" ener!y, mostly as heat "rom the surroundin! environment to evaporate the sur"ace moisture, and second is the trans"er o" internal moisture to the sur"ace o" the solid and its subse uent evaporation due to the "irst process.

Several specialties.

types The

o"

dryers

are

used o"

in

di""erent in many

"ields

and

common

type

dryer

industrial

applications that involve dryin! operation is tray dryers (or cabinet dryers). The dryers are made o" trays held in a cabinet, which is

connected to a source o" heated air by !as, diesel or biomass. The "ood, which is to be dried, is spread out, !enerally uite thinly, on trays which the dryin! ta-es place. .eatin! may be by an air current sweepin! across the trays, by conduction "rom heated trays or heated shelves on which the trays lie, or by radiation "rom heated sur"aces. *ost tray dryers are heated by air, which also removes the moist vapours. The temperature o" ambient air is controlled by thermostat which is usually set in the ran!e o" /0 to 1002C. The air enters the bottom o" the chamber below the trays and then rises, throu!h the trays o" "ood bein! dried, and exits "rom an openin! in the top o" the chamber. 3resh air is allowed to enter the cabinet and moist air is exhausted by usin! a dehumidistat to control an exhaust "an and air inta-e shutters. The dryer trays are ti!ht4"ittin! in the cabinet to prevent air "rom bypassin! the material to be dried. &ependin! upon the "ood and the desired "inal moisture, dryin! time may be o" the order o" 50 or even 60 hours. Tray dryers re uire low capital and maintenance costs but have relatively poor control and produces more variable product uality.

.owever, in recirculation desi!ns, the moisture laden air, a"ter evaporatin! water "rom "ood, would have to be dried be"ore bein! under!o recirculation, or else it would soon become saturated and "urther dryin! o" the "ood would stop. In such a case passin! it throu!h a desiccant such as a bed o" silica !el, or condensin! moisture out by passin! the moist air over cold plates or coils could dry the air. $ote also that i" we are not !oin! to dry the exhaust air "or recirculation, then the exhaust vent should not be close to the "resh air inta-e area, otherwise the moist exhaust air will be drawn bacthrou!h the drier and dryin! e""iciency will be lost. Thermometers are installed with the sensitive elements directly in the main air current approachin! the dryin! trays, and o"ten also in the air current leavin! trays.

%ne o" the most important problems encountered is not to supply the same dryin! rate at the all position within the tray dryers. The other is the "ast dryin! o" "ood in the position where the air "irst enters to the system and the slow dryin! o" "ood in the other position. There"ore, additional heaters and "ans may be placed above or alon!side the trays to increase the rate o" dryin!. Tray dryers are used "or small4scale production or "or pilot4scale wor-.

%B78CTI98S

The purpose o" this experiment is to determine the dryin! rate o" the sample by dryin! method usin! tray dryer besides learn to use and operate the tray dryer.

T.8%R:

&ryin! occurs with the help o" evaporation by supplyin! heat to the wet "eedstoc-. There are two options "or medium o" heat trans"er that is throu!h convection by direct driers or conduction by contact or indirect driers. The removal o" water "rom dryin! is to inhibit the !rowth o" microor!anisms and there"ore the "ood is well preserved besides reducin! the wei!ht and bul- o" "ood "or cheaper transport and stora!e. When carried out correctly, any alteration o" nutritional uality, colour, "lavour and texture o" r ehydrated "oods will not be a""ected too much.

&ryin! methods and processes can be classi"ied as batch, where the material is inserted into the dryin! e uipment and dryin! proceeds "or a !iven period o" time, or as continuous, where the material is continuously added to the dryer and dried material continuously removed. &ryin! processes can also be cate!ori;ed

accordin! to the physical conditions used to add heat and remove water vapour. In the "irst cate!ory, heat is added by direct contact with heated air at atmospheric pressure, and the water vapour "ormed is removed by the air. In vacuum dryin!, the evaporation o" water proceeds more rapidly at low pressures, and the heat is added indirectly by contact with a metal wall or by radiation (low temperatures can also be used under vacuum "or certain materials that may decolouri;e or decompose at hi!her temperatures). In "ree;e dryin!, water is sublimed "rom the "ro;en material. The "irst consideration in selectin! a dryer is its operability, above all else, the e uipment must produce the desired product in the "orm at the desired rate. The uality re uired in a "inished product, and its necessary physical characteristics, are determined by its end use. The "inal choice is then made on the basis o" capital and operatin! costs. Attention must be paid, however, to the costs o" the entire isolation system, not +ust the dryin! unit alone. Thermally sensitive materials must be dried at low temperature under vacuum, with a low4temperature heatin! medium, or very rapidly. The dryer must also operate reliably, sa"ely, and economically. %peration and maintenance costs must be excessive, pollution must be controlled, ener!y consumption must be minimised. As "ar as the dryin! operation itsel" is concerned, adiabatic dryers are !enerally less expensive than non4adiabatic dryers, in spite o" the lower thermal e""iciency o" adiabatic units.

'n"ortunately there is usually a lot o" dust carry over "rom adiabatic dryers, and these entrained particles must be removed almost uantitatively "rom the dryin! !as. In herbs and medicinal industry, most medicinal and culinary herbs are sold dried. When dryin! lar!e uantities o" herbs "or commercial sale, !rowers should use a "orced4air dryer to preserve their color, "lavour, oil content, and medicinal properties. To achieve this, !ood air circulation within the dryer is important, as it reduces dryin! time and allows the use o" lower temperatures, both o" which can prevent the de!radation o" chemical constituents durin! the dryin! process. There4"ore, dependable temperature control and the ability to provide hi!h air "low throu!hout the plant material are important. &ryin! temperatures and times di""er by plants, and plant parts, thus most herbs should be dried at low temperatures, ideally around <0450023. When outside conditions are hot and humid, however, it may be necessary to raise temperatures to as hi!h as 5=023. The si;e o" the dryer should be based on the herb production area and how much will be harvested at one time. The dryer should have well4spaced rac-s to ensure that all sides o" the plant receive su""icient air "low and the plant material dries evenly. The shelves should be constructed o" "ood !rade The 8vidence o" screens or covered with an acceptable "ood !rade material. dryer should be "ree o" dust, dirt, insects, and rodents. unmar-etable. The dryer should be able to hold an entire harvest and dry it "ast enou!h that the crop does not spoil. concerns must be ta-en into 8""iciency and economic the cost4 consideration to ensure

any o" these in the "inal product can lower its value or render it

e""ectiveness o" its operation. >i-ewise, a dryer can be constructed

"rom

new

or

existin!

shed

out"itted

with

heater,

"an, and

dehumidi"ier. "rom scratch.

Additionally, a !rower may choose to construct one

In this experiment, tea leaves are chosen as herbs that under!o dryin! process by operatin! tray dryer. The best method to dry herb will depend lar!ely on the physical characteristics o" the material, the volume o" herb in the dryer, and the relative humidity o" the outside air. &i""erent herbs will re uire di""erent temperatures. Typically, the hi!her the ambient humidity, the hi!her the temperature that is re uired to dry the material thorou!hly. Introducin! drier air will reduce the amount o" time the material is in the dryer, thus reducin! the cost o" dryin! the material. The moisture content o" dried products is very important, and i" it is too hi!h, moulds and yeasts tend to !row. The moisture content may be chec-ed usin! scales and an oven. The "ollowin! is the expression that we may use in order to calculate the moisture content o" our dryin! tea leaves,

%ther important parameter "or dryin! process is the dryin! rates, v (min45), v ? @t5 A @t6 T6 A T5

8@B8RI*8$TA> BR%C8&'R8

5. 2. 3. C. 5. D. 1.

All

o"

the

e uipment

which

used

in

this

experiment

were

switched on. Rinse the empty tray usin! water be"ore start The mass o" the empty tray were measured and tared. The data was recorded. The dry tea herbs were sprin-led with enou!h o" water to ma-e it wet. The tea herbs were placed onto the empty tray and put into the tray dryers to be prepared to be dried. The initial mass o" the wet tea herbs were measured and recorded be"ore bein! dried. The initial temperature and humidity which shown on the tray dryers ta-en and recorded. The initial air "low inside the tray dryers were measured usin! the anemometer and the readin!s was recorded. E. <. The dryin! process is started by pressin! the F.8ATG button on the tray dryers. All o" the data readed and recorded every = minutes in one hour time o" the dryin! process o" the tea herbs. 50. The moisture content and the dryin! rate were calculated. 55. The !raph o" dryin! rate a!ainst moisture content was plotted.

ABBARAT'S

Tray dryers Analytical balance

Water Anemometer Stopwatch Dry tea herbs

R8S'>T

*ass o" tray

? 5=<5.= ! ? <<.C !

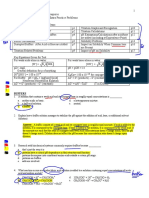

Mass of sample (g) Anenometer (m/s) Moisture Content Drying rate (min-1)

*ass o" dry tea leaves

Time (min) Humidity (%rF)

Temperatures (C)

0 / 50 5/ 60 6= 6D 6<

50.D E.C E.0 E.0 E.0 E.0 E.0 E.0

0./ 0./ 0./ 0./ 0./ 0./ 0./ 0./

C5.< C/.= C/.E C/.1 C/.D C/.D C/.1 C/.D

=<./ C=.0 CC.= CC.D CC.1 CC.E CC.1 CC.1

50<.C 50/.= 500.C <E.E <E.= <E.0 <1.< <1.1

5.C1 5.65 5./5 5.C< 5.C< 5./6 5./6 5./5

0.55<E 0.011E 0.061D 0.055= 0.00D5 0.00=5 0.006 0

0.00EC 0.0500C 0.00=6D 0.0050C 0.005 0.000=1 0.000D1 0

SA*B>8 CA>C'>ATI%$S

5. *oisture content,x calculated usin! the "ollowin! "ormulaH * o i s t u r e c o n t e n t , x ? mass1-massfinalmassfinal

8xampleH *oisture Content 5, x5

?

109.4-97.797.7

0.55<1/

*oisture Content 6, x6

105.3-97.797.7

0.0111<

6. A"ter calculated the moisture content, the dryin! rate calculated usin! the "ollowin! "ormula H & r y i n ! R a t e , v ? xt

8xample H 3or tea herbs sample H & r y i n ! R a t e , v ? x1- x2t ? 0.11975 - 0.077795 ? 0.00E=<6

&ISC'SSI%$

Based on !raph mass versus time, it shows that the mass o" the tea herbs are decreasin! with time. This is the same with !raph o" moisture content versus time, where the moisture content is decreasin! with time.

&ryin! occurs in three di""erent periods, or phases, which can be clearly de"ined. is The "irst phase, or to the initial period, is the where sensible heat trans"erred product and contained

moisture. 3rom both !raph, the "irst phase can be seen clearly at time between the "irst minute until minute <. The second phase, or constant rate period, is when the "ree moisture persists on the sur"aces and the rate o" evaporation alters very little as the moisture content reduces. This is seen "rom the !raph at minute < until minute 56. The third phase, or "allin! rate period, is the phase durin! which mi!ration o" moisture "rom the inner interstices o" each particle to the outer sur"ace becomes the limitin! "actor that reduces the dryin! rate. Brinciples o" tray dryer states that durin! the early sta!es o" dryin!, the conditions in the dryer, which is at hi!h humidity and moderate temperature, are ideal "or the !rowth o" microor!anisms. The uic-er the dryin! time the better the "inal microbial uality o" the product. 3rom the !raph o" drying rate versus time, we can see that the chan!in! pattern is not consistent or in mannered pattern. .ence, it is well said that the dryin! rates is not dependin! much upon time.

C%$C>'SI%$

Based on the data plotted on each !raph, we can conclude that the moisture content and mass o" the tea herbs are both decreasin! with time. $evertheless, the dryin! rates o" the herbs are varyin! with time.

R8C%**8$&ATI%$

In order to obtain better results, there are a "ew methods or recommendations that may be considered. 3irstly, the dryin! rates can be increased with two di""erent options, by increasin! the air "low or increasin! the air temperature. .owever, the temperature must not be set to too hi!h "or it may cause dama!e or chan!e to the products. This is true "or herbs and spices, as hi!h temperature will have the ris- o" losin! delicate "lavours or colours.

As a matter o" "act, "an driven dryers may suc- in "ine dust particles in dusty areas, causin! contamination o" the product. In very dusty areas, powered dryers may need a muslin "ilter over the air inlet. .erbs and spices must be dried to a moisture content that is low enou!h to prevent the !rowth o" micro4or!anisms such as moulds and bacteria.

*ost commercial dryers are insulated to reduce heat losses, and they recirculate hot air to save ener!y. *any desi!ns have ener!y4savin! devices, which recover heat "rom the exhaust air or automatically control the air humidity. Computer control o" dryers is increasin!ly sophisticated and also results in important savin!s in ener!y. I" the exhaust air is not dried "or recirculation, then the exhaust vent should not be close to the "resh air inta-e area, otherwise the moist exhaust air will be drawn bac- throu!h the drier and dryin! e""iciency will be lost. Iood air circulation within the dryer is important, as it reduces dryin! time and allows the use o" lower temperatures, both o" which can prevent the de!radation o" chemical constituents durin! the dryin! process. The dryer should have well4spaced rac-s to ensure that all sides o" the plant receive su""icient air "low and the plant material dries evenly. The dryer should be "ree o" dust, dirt, insects, and rodents. 8vidence o" any o" these in the "inal product can lower its value or render it unmar-etable.

R838R8$C8S

1. h t t p H J J w w w . " a o . o r ! J d o c r e p J 9 / = E 0 8 J 9 / = E 0 8 0 < . h t m 2. h t t p H J J w w w . e n o t e s . c o m J h o w 4 p r o d u c t s 4 e n c y c l o p e d i a J ! r e e n 4 t e a =. Bird,R.B,Steward.W8,and >i!ht"oot,8$, Transport Bhenomena, 7ohn Wiley and Sons, Inc,5<D0

ABB8$&IC8S

You might also like

- Tray Dryer ExperimentDocument13 pagesTray Dryer Experimentgeek311295% (37)

- KhanDocument4 pagesKhanirfan hilmanNo ratings yet

- Drying systems overviewDocument7 pagesDrying systems overviewtapanshahNo ratings yet

- SEO Tray Dryer Guide - Drying Methods & Mechanisms ExplainedDocument21 pagesSEO Tray Dryer Guide - Drying Methods & Mechanisms ExplainedConquer ConquerNo ratings yet

- Microwave Assisted Fluidized Bed Drying of BeetrootDocument21 pagesMicrowave Assisted Fluidized Bed Drying of BeetrootsreenuNo ratings yet

- Dryers and Drying ProcessesDocument24 pagesDryers and Drying ProcessesKristine Joy MataroNo ratings yet

- Tray DryerDocument22 pagesTray DryerjuaxxoNo ratings yet

- Drying EquipmentDocument9 pagesDrying EquipmentHIT- MANNo ratings yet

- Abstract, Intro, Objectives Tray DryerDocument3 pagesAbstract, Intro, Objectives Tray DryerNawal DaBombNo ratings yet

- 4_5992044737350079507Document4 pages4_5992044737350079507abdelrhman aboodaNo ratings yet

- Pharmaceutical DryersDocument2 pagesPharmaceutical Dryersf_azarNo ratings yet

- Drying2 and TutorialDocument9 pagesDrying2 and TutorialDr-Khalid Al-Shemmari100% (1)

- Sterilization Methods and PrinciplesDocument11 pagesSterilization Methods and PrinciplesChanthini VinayagamNo ratings yet

- Mass Transfer Lectures on Drying ProcessesDocument10 pagesMass Transfer Lectures on Drying ProcessesAndrea Louisse CorbillonNo ratings yet

- Drying PDFDocument48 pagesDrying PDFuzzal ahmedNo ratings yet

- Dryer and Drying SystemDocument53 pagesDryer and Drying Systemeric labordoNo ratings yet

- 34) Classification of DryersDocument27 pages34) Classification of Dryersalvin100% (1)

- Vacuum Dryer: Aim: To Find Time of Constant Rate Period and Constant Fall Period Using ADocument6 pagesVacuum Dryer: Aim: To Find Time of Constant Rate Period and Constant Fall Period Using Aanjan_srihari0% (1)

- DryingDocument19 pagesDryingEngr Muhammad Asif JavaidNo ratings yet

- Aspects of Lead Acid Battery Technology 5 Dry Charging of Formed Negative PlatesDocument12 pagesAspects of Lead Acid Battery Technology 5 Dry Charging of Formed Negative PlatestjkiddNo ratings yet

- Tray dryer: optimize pharmaceutical drying with 40-char titleDocument6 pagesTray dryer: optimize pharmaceutical drying with 40-char titleSara JuitaNo ratings yet

- Drying tea: the constant and falling rate periodsDocument9 pagesDrying tea: the constant and falling rate periodsSukumar RamasamyNo ratings yet

- DRYERS AND DRYING PROCESS Group 2Document9 pagesDRYERS AND DRYING PROCESS Group 2markdanielgolisaoNo ratings yet

- Materi-Minggu 12-TPP Ii-Kur 21Document12 pagesMateri-Minggu 12-TPP Ii-Kur 21toto nugrohoNo ratings yet

- Activity No. 8: DryersDocument19 pagesActivity No. 8: DryersCherry ObiasNo ratings yet

- Influence of Air Velocity on Drying Rate of Wet SandDocument3 pagesInfluence of Air Velocity on Drying Rate of Wet SandJohanNo ratings yet

- Lab 2 Full Report PDFDocument20 pagesLab 2 Full Report PDFmuhammad ilyas100% (1)

- GROUP 2 MIPPV Dryers and Drying ProcessDocument23 pagesGROUP 2 MIPPV Dryers and Drying ProcessmarkdanielgolisaoNo ratings yet

- Lesson 3 DryingDocument32 pagesLesson 3 DryingDhayalan RamachandranNo ratings yet

- Sterilization Process: Department of PharmaceuticsDocument32 pagesSterilization Process: Department of PharmaceuticsOmar PopocaNo ratings yet

- Producing drying curves using tray dryerDocument2 pagesProducing drying curves using tray dryerNur amirahNo ratings yet

- Heat and Mass TransferDocument90 pagesHeat and Mass TransferAnonymous 0zrCNQNo ratings yet

- Intro Exp 2Document2 pagesIntro Exp 2Nur amirahNo ratings yet

- 2017 CH 414Document38 pages2017 CH 414Mian GulshadNo ratings yet

- Refrigeration and Air ConditioningDocument7 pagesRefrigeration and Air ConditioningshreedharkolekarNo ratings yet

- SOP Freeze DryingDocument4 pagesSOP Freeze Dryingazura_zfNo ratings yet

- Autoclave Sterilization: A GuideDocument8 pagesAutoclave Sterilization: A GuideMohd Azzeeruff HafizNo ratings yet

- Tray Dryers: An IntroductionDocument10 pagesTray Dryers: An IntroductionSohan rautNo ratings yet

- Sterile Technique 2013Document11 pagesSterile Technique 2013KRP1212No ratings yet

- Appendix G - SteamSterilizers Instruction For Operation and Maintenance of SterilizaersDocument18 pagesAppendix G - SteamSterilizers Instruction For Operation and Maintenance of SterilizaersVishal SharmaNo ratings yet

- SterilizationDocument7 pagesSterilizationdereje_kebebeNo ratings yet

- Types of Industrial Dryers and Their Selection PDF (1) (1)Document20 pagesTypes of Industrial Dryers and Their Selection PDF (1) (1)Hari KishoreNo ratings yet

- DryerDocument5 pagesDryerLokraj PantNo ratings yet

- Bhutan Final BacteriologyDocument56 pagesBhutan Final Bacteriology99nonameNo ratings yet

- How Choose Vacuum DryerDocument4 pagesHow Choose Vacuum DryerGomatheeswariNo ratings yet

- Dryers and Drying Processes (Module 4)Document25 pagesDryers and Drying Processes (Module 4)Gold BlandoNo ratings yet

- Spray Drying Process Explained in 7 StepsDocument33 pagesSpray Drying Process Explained in 7 StepsAhosan Habib RakibNo ratings yet

- Tray Dryer Suitability Approach in IndustryDocument4 pagesTray Dryer Suitability Approach in IndustryhasnizaNo ratings yet

- A Presentaion On DryingDocument40 pagesA Presentaion On DryingMd. Abu Bakar Siddique TayefNo ratings yet

- Drying ExperimentDocument10 pagesDrying ExperimentKris Dominic RubillosNo ratings yet

- FT 409 - (19 Arid 4816)Document32 pagesFT 409 - (19 Arid 4816)Hani TatlaNo ratings yet

- Abstract 1Document2 pagesAbstract 1FatinnnnnnNo ratings yet

- Fundamentals of DryingDocument14 pagesFundamentals of DryingAlisha AnchearyNo ratings yet

- Drying-4-Document48 pagesDrying-4-『ABN』NARUTO أبن ناروتو (Gamer)No ratings yet

- Drying: Chemical Engineering SeriesDocument54 pagesDrying: Chemical Engineering Serieskmrosario67% (21)

- DRYINGDocument85 pagesDRYINGdivakarNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- A Guide to Perfume Production - A Selection of Vintage Articles on the Methods and Ingredients of PerfumeryFrom EverandA Guide to Perfume Production - A Selection of Vintage Articles on the Methods and Ingredients of PerfumeryRating: 5 out of 5 stars5/5 (2)

- 0.115 F Where,: Flood PDocument2 pages0.115 F Where,: Flood PSujan BasyalNo ratings yet

- Continuous LabDocument3 pagesContinuous LabSujan BasyalNo ratings yet

- Continuous LabDocument3 pagesContinuous LabSujan BasyalNo ratings yet

- JdsgsdfgdsgdsDocument10 pagesJdsgsdfgdsgdsSujan BasyalNo ratings yet

- Pizza Store PriceDocument8 pagesPizza Store PriceSujan BasyalNo ratings yet

- Optimization:: Sensitivity Analysis of Input Reactor Variables Among Itself and Rest of The SystemDocument7 pagesOptimization:: Sensitivity Analysis of Input Reactor Variables Among Itself and Rest of The SystemSujan BasyalNo ratings yet

- His and Her Weight Loss Tracker1Document1 pageHis and Her Weight Loss Tracker1Sujan BasyalNo ratings yet

- Us 3767726Document4 pagesUs 3767726Sujan BasyalNo ratings yet

- Project 200 CalcDocument4 pagesProject 200 CalcSujan BasyalNo ratings yet

- Us 3767726Document4 pagesUs 3767726Sujan BasyalNo ratings yet

- CMEN 332 - Chemical Engineering Thermodynamics II Winter Quarter 2013-2014Document4 pagesCMEN 332 - Chemical Engineering Thermodynamics II Winter Quarter 2013-2014Sujan BasyalNo ratings yet

- Inorganic and Physical Chemistry ConceptsDocument4 pagesInorganic and Physical Chemistry ConceptsAamerNo ratings yet

- ECE 3223 Separation Processes I: B. Eng (Hons.) Chemical EngineeringDocument19 pagesECE 3223 Separation Processes I: B. Eng (Hons.) Chemical EngineeringJosh VatomNo ratings yet

- Bio-Soft N-Series PDFDocument9 pagesBio-Soft N-Series PDFGina AriasNo ratings yet

- Measure Moisture Content Using Direct and Indirect MethodsDocument8 pagesMeasure Moisture Content Using Direct and Indirect MethodsJet Ronnie DacayaNo ratings yet

- Cabin Air Temperature of Parked Vehicles in Summer ConditionsDocument12 pagesCabin Air Temperature of Parked Vehicles in Summer ConditionsSWANAND KIRPEKARNo ratings yet

- Sublimation and Melting Point Determination (Repaired)Document3 pagesSublimation and Melting Point Determination (Repaired)MherizNo ratings yet

- EvaporatorsDocument37 pagesEvaporatorsGerald JobNo ratings yet

- Whole Life Assessment of Nitrocellulose in Double Base PropellantsDocument34 pagesWhole Life Assessment of Nitrocellulose in Double Base PropellantsAl VlaerNo ratings yet

- PEKA Experiment Chemistry Form 4 Chapter 2 To 5Document9 pagesPEKA Experiment Chemistry Form 4 Chapter 2 To 5James Chua Hong Kheng67% (6)

- PLT InterpretationDocument71 pagesPLT Interpretationdhiaa100% (2)

- Test3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Document18 pagesTest3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Anas SaadNo ratings yet

- Ferro Magnetism and Anti Ferro MagnetismDocument31 pagesFerro Magnetism and Anti Ferro MagnetismPrachiNo ratings yet

- LOTADER GMA & LOTRYL IMPACT MODIFICATION OF POLYESTERSDocument30 pagesLOTADER GMA & LOTRYL IMPACT MODIFICATION OF POLYESTERSRajiva Joshi100% (1)

- Techniques of Natural Gas Sampling and Composite Sampling SystemsDocument9 pagesTechniques of Natural Gas Sampling and Composite Sampling SystemsShubham CholeNo ratings yet

- Chul Park The Limits of Two-Temperature ModelDocument13 pagesChul Park The Limits of Two-Temperature ModellazharNo ratings yet

- Phosphate RockDocument3 pagesPhosphate RockManoj Kumar AcharyNo ratings yet

- Chroma Notes 2Document8 pagesChroma Notes 2Marielle GuevaraNo ratings yet

- Review Article: Chemical Recycling of PET Wastes With Different CatalystsDocument12 pagesReview Article: Chemical Recycling of PET Wastes With Different Catalystsdragonborn dragonbornNo ratings yet

- D and F Block Elements IIT JEE Notes PDFDocument15 pagesD and F Block Elements IIT JEE Notes PDFDILPREET SINGHNo ratings yet

- CHPT 12.1 PowerpointDocument31 pagesCHPT 12.1 PowerpointA ANo ratings yet

- FAT-values and surface roughness for steel batchesDocument1 pageFAT-values and surface roughness for steel batchesBergheisenNo ratings yet

- Darwish Et Al 2004Document9 pagesDarwish Et Al 2004Meruyert KarimNo ratings yet

- BibliographyDocument2 pagesBibliographyAdhi HutariNo ratings yet

- Chemistry Criterion B and C Lab ReportDocument7 pagesChemistry Criterion B and C Lab ReportBRIGHTON ONYANGONo ratings yet

- 3.SALT ANALYSIS Cobalt NitrateDocument4 pages3.SALT ANALYSIS Cobalt Nitratemohnish100% (1)

- Purification and Characterization of Resistant DextrinDocument17 pagesPurification and Characterization of Resistant DextrinNguyenvan TuonglamNo ratings yet

- An Overview of Methods To Mitigate Condensate Banking in Retrograde Gas ReservoirsDocument6 pagesAn Overview of Methods To Mitigate Condensate Banking in Retrograde Gas ReservoirsAdanenche Daniel EdohNo ratings yet

- Thermodynamic Class Note PDFDocument58 pagesThermodynamic Class Note PDFGBonga MossesNo ratings yet

- Pipe Terms With AnswerDocument23 pagesPipe Terms With AnswerTIKTOK COMPILATIONNo ratings yet

- Pr1 - Dr. Siti Nurul 'Ain Yusop - Norhafizah Binti Ismail NasiruddinDocument4 pagesPr1 - Dr. Siti Nurul 'Ain Yusop - Norhafizah Binti Ismail NasiruddinNafiz SyadhamierNo ratings yet